OBMI

Borehole imaging

in oil-base mud

Applications

A tradition of electrical coring

I

Before it was called logging, the downhole measurement of formation properties was called “electrical coring.”

Inspired by this ideal, Schlumberger

developed formation imaging to

advance log structural and stratigraphic

analysis to new levels of insight. The

OBMI* Oil-Base MicroImager tool is

the latest Schlumberger imaging solution and another industry first, extending microresistivity imaging into the

environment of nonconductive invertemulsion mud systems.

I

I

Structural analysis

G

Structural dip determination

G

Fracture and fault detection

Stratigraphic analysis

G

Characterization of

sedimentary deposits

G

Stratigraphic dip

determination

G

Thin-bed detection

Core analysis

G

Depth matching

G

Orientation

G

Missed interval coverage

I

Compartmentalization and

permeability analyses

I

High-resolution net pay count

I

Sample and formation test

positioning

I

Detection of drilling-induced

features

Benefits

I

Detection and measurement

of features too small for

conventional logs

I

Detection of anisotropic

features

I

Differentiation of structural

and stratigraphic features

I

Flexibility retained in

choosing mud systems

The measurement challenge

The increasing use of oil- and syntheticbase mud systems to limit drilling risks

and improve efficiency poses many

challenges for formation imaging.

Even a thin film of nonconductive mud

is essentially an opaque curtain, preventing conventional microresistivity

imagers from measuring the formation.

The presence of nonconductive mudcake or mud filtrate further complicates the situation. Oil-base mud can

be displaced with water-base mud at

considerable expense, but there is no

(a)

Operates in any oil-, dieselor synthetic-base mud

I

High-resolution, oriented

formation image

I

0.4-in. button size, 1.2-in.

resolution

I

Five measurements per pad

I

Quantitative Rxo measurement

I

Compact, integrated design

I

Combinable top and bottom

I

3600 ft/hr maximum logging

speed

I

Two-axis caliper

Uniquely engineered for oil-base mud

The solution for imaging in nonconductive muds pairs cutting-edge technology with a simple, time-honored

principle of resistivity logging. While

logging, the pads of the OBMI tool

are applied against the borehole wall,

where a thin layer of nonconductive

mud is between the pad face and the

formation. In accordance with the

four-terminal or short-normal method

of measuring resistivity, an alternating

current is injected into the formation

between the two electrodes at opposite ends of each pad. The unique

electronics inside the OBMI pad and

cartridge measure the potential difference between paired button electrodes

at the center of the pad. From this

value, the resistivity of the invaded

zone Rxo in the small interval of the

formation opposite the sensors is accurately and quantitatively calculated

using Ohm’s law.

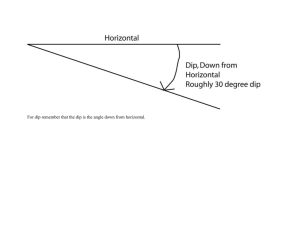

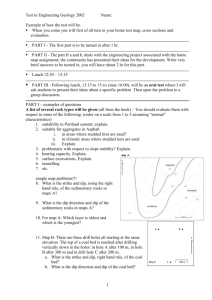

Innovative OBMI technology extends microresistivity image logging to the nonconductive mud environment.

(a) Profile of an OBMI pad applied to the borehole wall, with current I passing between the current electrodes

A and B and measurement of the potential difference between the voltage electrodes C and D. (b) Five pairs

of voltage electrodes on the OBMI pad face.

(b)

Features

I

guarantee that measurement will

be possible. Addressing the need for

images in this difficult environment

clearly demanded a novel approach.

A

I

C

Rxo

D

B

δV

Each of the four pads acquires

five measurements, and the data are

displayed as a color image, oriented

with respect to the geometry of the

tool and borehole. Structural and

stratigraphic features as small as 0.4 in.

[1 cm] can be seen, yielding a wealth of

high-resolution, azimuthal information

unobtainable through conventional

logging techniques. The resemblance

of the OBMI image to whole-round

core enables virtual visualization of the

reservoir—a first for the nonconductive mud environment.

The OBMI tool has been validated

in the field with more than 20 brands

of diesel-, oil- and synthetic-base muds.

In a shale formation that has little

resistivity contrast, automatically computed dips are often in error, and it is

necessary to resort to manual methods.

Using dipmeter data, it is a challenge

to determine the dip in this manner.

The OBMI image (far right track) is developed from five resistivity measurements per pad. OBDT data

(center track) are displayed as a pseudoimage consisting of one data point per pad. OBDT-computed

dips are plotted in red and OBMI dips in black for a sand/shale sequence (top) and low-contrast shale

sequence (bottom).

OBDT

(Sinusoid)

Orientation North

Caliper 1

6

( in.)

6

( in.)

OBMI

True Dip

6

OBMI Resistivity

Gamma Ray

( gAPI )

0.2

120

Engineered for efficiency

( ohm-m )

0

( Deg )

10

MD

1 : 20

( ft )

XXX70

XXX75

Clear dip and structure resolution

XXX50

XXX55

0.2

( ohm-m )

0.2

( ohm-m )

0

20

0

AO10

Borehole Drift

Comparison of OBMI images with an

OBDT* Oil-Base Dipmeter Tool log

acquired in the same well demonstrates

the quantum leap in information for

formation evaluation. In the example

to the right, the value of the highresolution OBMI image is readily

apparent in resolving otherwise ambiguous dip and structural features.

In an interbedded, contrasting

sequence of sand and shale, an automatic algorithm can accurately identify

and compute the formation dip from

both data sets. However, the OBDT

tool measures one curve per pad at a

resolution of about 2 in. The array of

high-resolution sensors on each OBMI

pad provides an image, and bedding

and structure that are unresolved by

the OBDT data are clearly visible.

OBMI

(Sinusoid)

Orientation North

Caliper 2

6

20

Making breakthrough measurements

is but one benefit of the OBMI tool.

The compact, integrated design and

maximum logging speed of 3600 ft/hr

ensure efficient wellsite rig-up and

operation. The through-wired sonde

enables running other services such as

the UBI* Ultrasonic Borehole Imager

below the OBMI tool on the same

descent. To ensure high reliability, the

OBMI tool is built to the same mechanical shock standards as the proven

Platform Express* tools.

The sensitive response of the OBMI

measurement and the image it provides

enable manually picking dips with

confidence. The OBMI data yield accurate dip in this formation even when

processed by the automatic algorithm.

360

Resistive

20

OBDT

90

0

OBDT

True Dip

20

AO90

Deg

Conductive

Conductive

0

( Deg )

90

360

OBMI

Resistive

OBMI images and quantitative Rxo measurement from a deepwater well in the Gulf of Mexico show

an excellent match to the ultraviolet-light core photograph and conventional logs. Thresholds are

applied to the OBMI Rxo data to calculate the net pay thickness in the far-right track.

Deepwater answers in focus

A Gulf of Mexico deepwater operator

ran the OBMI tool in a partially cored

appraisal well to more fully characterize the thinly bedded reservoir sediments and refine the net pay count.

The OBMI image accurately reproduced the cored interval. An abrupt

change in the core dip, previously

thought to be coring induced, was

demonstrated to be natural in origin

by the image.

Stratigraphic analysis was successfully extended beyond the cored interval using the OBMI image. The OBMI

Rxo data correlated well with grain-size

information from sidewall cores. The

resulting net pay count was increased

by more than 50 ft from that determined by conventional log analysis.

Caliper 1

6

Sand

16

( in.)

OBMI Resistivity

Caliper 2

6

16

( in.)

0

20

( gAPI )

120

0.2

( ohm-m )

0.2

( ohm-m )

Shale / Wet Sand

20

Neutron Porosity

AO90

Borehole Drift

0

( Deg )

3

( ohm-m )

AO10

Gamma Ray

10

MD

1:7

( ft )

20

60

0.2

( p.u.)

0

20

( ohm-m )

60

( p.u.)

0

Conductive

Density Porosity

OBMI Resistivity

Cumulative Sand

( ft )

360

OBMI Image

Resistive

Core Image

0

Cumulative Silt

( ft )

Silt

265.04

49.58

XXX82

264.30

49.47

XXX83

264.10

49.34

XXX84

263.70

49.18

XXX85

263.24

48.87

The OBMI image proved that the reversal in dip direction at XXX36.5 ft is a natural feature,

not induced by twisting during the coring process.

OBMI

(Sinusoid)

Orientation North

Caliper 1

6

( in.)

16

Caliper 2

6

( in.)

16

AO10

Gamma Ray

20

( gAPI )

120

0.2

( ohm-m )

20

AO90

0.2

Borehole Drift

0

( Deg )

10

MD

1 : 10

( ft )

XXX35

XXX40

( ohm-m )

20

0

OBMI

True Dip

Conductive

OBMI Resistivity

0.2

( ohm-m )

20 0

( Deg )

90

360

OBMI

Resistive

Core Image

The OBMI image provides a structural overview of the bottom of a pilot hole for a horizontal well in the

Alberta Foothills, confirming the target between XX52 and XX60 m. The accuracy of the OBMI Rxo measurement is verified by excellent correlation with the shallow AIT* Array Induction Imager Tool log.

Insight to structurally complex settings

An operator in the Alberta Foothills,

Canada, drilled a pilot hole for a horizontal well in a poorly bedded reef

buildup. The lateral borehole was

planned to follow the long axis of the

reservoir to maximize the productive

interval. The structural dip—too subtle

for a dipmeter to determine—was

clearly revealed in the OBMI image,

confirming that the reservoir had been

penetrated in the planned location.

The image also confirmed the existence of fractures perpendicular to the

planned lateral, a critical factor for

maximizing productivity.

360

0

Borehole drift

Conductive

0

( Deg )

OBMI Image

Resistive

90

Caliper 1

5

Resistive Fracture

True Dip

15

( in.)

Caliper 2

5

Gamma Ray

0

0

15

( in.)

( gAPI )

150

MD

1 : 200

Bed Boundary

(Sinusoid)

Orientation Top of Hole

AHO10

2

( ohm-m )

(Deg)

Bed Boundary

True Dip

20000

OBMI Resistivity

2

(m)

( ohm-m )

20000 0

(Deg)

XX55

XX60

XX65

XX70

Determining structural dip is challenging in reservoirs such as this massive reef because of the lack of clear

bedding. The OBMI image enables handpicking the dip. A set of fractures (purple) could also be identified.

0

360

Borehole drift

Conductive

0

( Deg )

( in.)

Resistive

90

Caliper 1

5

OBMI Image

15

Bed Boundary

(Sinusoid)

Orientation Top of Hole

Bed Boundary

True Dip

Caliper 2

5

0

Conductive

360

OBMI Image

Resistive

( in.)

Gamma Ray

0

( gAPI ) 150

MD

1 : 20

(m)

XX54

XX55

XX56

0

15

Resistive Fracture

(Sinusoid)

Orientation Top of Hole

( Deg )

90

Resistive Fracture

True Dip

0

( Deg )

90

Customized image visualization

OMBI image logs are not static paper

prints but an interactive, versatile data

set for analysis with OBMI-Viewer

software. The OBMI images are placed

on a PC-compatible CD-ROM with the

OBMI-Viewer set of stand-alone tools

for image display and interpretation.

The application is intuitively easy to

use, with a Web-browser-styled interface and on-line help system. Changing

the depth or color scale, manually

picking dip and compiling a sand count

are just some of the analyses quickly

executed with a few clicks of the

mouse. The interpreted images can

also be printed.

You choose the mud—Schlumberger

delivers the images

Whatever your choice of mud system,

Schlumberger has a formation-imaging

solution for your well.

In challenging environments, drill

with the oil- or synthetic-base mud that

provides the best drilling performance.

Logging with the OBMI tool in nonconductive mud systems provides you

with the insight that only a microresistivity imaging tool can deliver.

High-resolution OBMI images help you

limit risks without limiting your operational flexibility or the information

needed for optimized decision making.

Tool Specifications

Length

Weight

Max OD

Max caliper

Recommended hole size

Max temperature

Max pressure

Conveyance

Effective button size

Effective resolution

Depth of investigation

Coverage in 8-in. hole

Max logging speed

Combinability

17 ft

310 lbm

5.75 in.

17.5 in.

7–16 in.

320°F [160°C]

20,000 psi

Wireline or TLC* Tough Logging Conditions system

0.4 in.

1.2 in.

3.5 in.

32%

3600 ft/hr

Top and bottom

OBMI Oil-Base MicroImager tool

www.slb.com/oilfield

06-FE-146

©2006 Schlumberger. All rights reserved

July 2006

*Mark of Schlumberger

![[#FWDIP-74] PVSS invalid Bits (including range) are not all reflected](http://s3.studylib.net/store/data/007282728_1-8b675e5d894a5a262868061bfab38865-300x300.png)