Lab Exercise #3: Torsion

advertisement

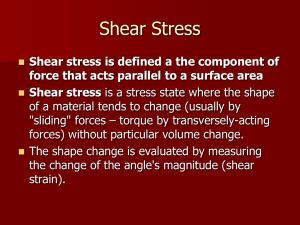

ENGR 151 – Strength of Materials Torsion Lab Exercise #3: Torsion Pre-lab assignment: Yes No Goals: 1. To evaluate the equations of angular displacement, shear stress, and shear strain for a shaft undergoing torsional stress. Principles: Torsion testing of round circular samples is another method of determining a basic engineering relationship in structural materials. Unlike tensile testing, torsion tests are not complicated by the phenomenon of necking and reduction in areas. A simple torsion test is relatively easy to perform. The angle of twist is measured on a specimen (with a circular cross-section) as an applied torque is increased at a constant rate. This is analogous to plotting the load and extension in a simple tensile test. The data can then be modified using appropriate equations to develop a curve where torsional stress and strain are plotted. As in a tensile test, there will be an elastic or linear portion of the curve where a proportional relationship can be used to determine engineering values. In a torsional stress versus strain graph, the value that will be determined by measuring the slope of the linear region is the modulus of rigidity, also known as the shear modulus and often given the symbol, G. It is analogous to Young’s Modulus in tensile testing. Before further discussing the modulus of rigidity, it should be noted that experimental values of angle of twist can be compared with expected calculations based on the applied torque and certain material properties and geometry. The relationship below describes the expected angle of twist given an applied torque, T. φ = TL/JG where: T is the applied torque L is the length of the sample being tested J is the polar moment of inertia G is the shear modulus φ is the angle of rotation (twist) within the tested length. Units are radians. Note the relationship between the modulus of elasticity, E, and G the modulus of rigidity within the linear elastic range of the material is described by Hooke’s law, which relates E, G, and Poisson’s ration, ν. The knowledge of any two can be used to find the third using the relationship: E= 2G / (1 + ν) As previously mentioned, data collected from a torque vs. angle of twist experiment can be used to develop a graph of torsional stress vs. strain. The following formulas can be used: τ = Tc/J γ = φc/L Shear stress Shear strain where: T is the applied torque L is the length of the sample being tested ENGR 151 – Strength of Materials Torsion J is the polar moment of inertia φ is the angle of rotation (twist) within the tested length c is the radius of the solid circular rod It should be noted that the value of c is used in these equations giving the stress and strain values at the outside surface of the rod. The value c can be replaced with a variable to determine the stress and strain values at any radial distance away from the center of the rod, if so desired. With values of stress and strain (based on experimental data), it is possible to calculate the shear modulus, G. The following formula is based on Hooke’s Law, as it applies to torsion: G = τ/γ It should be recognized that the torsion test determines shear stress vs. shear strain to find the shear modulus whereas in a tensile test, axial stress and axial strain are used to determine Young’s modulus. Engineering values or material properties that can be found from torsion testing include the shear modulus as well as proportional limit shear stress, and the proportional modulus of rupture. The shear stress is at a maximum at the outside surface of the material and can be calculated using τ = Tc/J. The highest shear stress that the material can withstand and still return to its original geometry is at the limit of the proportional area of the graph and is known as the proportional limit shear stress. The torsion modulus of rupture is the stress calculated at rupture. Materials: 3/16” diameter 1018 steel rod 3/16” diameter 6061-T6 aluminum rod 3/16” diameter 360 brass rod Safety Issues: Weights will be applied to hangers to develop an external torque on the rods. The weights will hang over the end of a table. Use caution when loading the weights. Always be aware that the weights may fall due to unbalanced loading, a broken string, or other unforeseen cause. Keep feet and hands away from the area under the weights. Pre-lab: NOTE: Unlike previous labs, the lab exercise will be done entirely in SI units. For consistency, use the following: Length – mm Force – N Stress – N/mm2 Modulus – N/ mm2 Both radians and degrees will be used. Radians must be used in equations 1. Calculate J for 3/16” diameter cylinders. Convert the diameter to mm and calculate J in mm4. 2. Calculate the expected value of twist angle (in degrees) per Newton·mm of torque for aluminum, brass and steel. Find SI values of G in order to perform the calculations. Either find or convert G to units of N/mm2. Assume a length of 200 mm and 400 mm for each type of material. ENGR 151 – Strength of Materials Torsion Procedure: See the Pre-lab note about units. 1. There are two profiled ends to each specimen, i.e. a semi-circular end and a triangular end. The triangular end is to be clamped in the jaws of the chuck, while the semi-circular end is to be clamped in the fixed clamp at the other end of the base plate. 2. Clamp the aluminum alloy specimen in position and put the load hanger on the cord. Set the pointer to be 400 mm from the fixed end and bring the rotation scale close to the pointer. Zero the pointer. 3. Add a load from 5 N to 60 N in 5 N increments, recording the twist of the specimen for each increment on your data sheet. Remove the load, move the rotation scale and pointer to 200 mm from the clamp, and repeat the above procedure. Measure and record the diameter of the rod. (The weight of the hanger can be neglected.) 4. Now change the specimen for the steel and brass rod and repeat the procedure with the pointer at 400 mm only. Discussion Items for report 1. For each case (aluminum, brass, and steel), plot a (single) graph of torque versus angle of twist (degrees) and draw best-fit straight lines through the points. Aluminum will have two lines since two tests were run. Since twist is proportional to length, the slopes of the two lines for aluminum should be in the ratio of 1:2. Important: This task asks for a graph of torque vs. angle of twist, which means torque is on the yaxis. In Excel, this is more difficult than using your data to create a graph of angle of twist vs. torque for several curves. However, such a graph would not be as useful when it comes time to create a stress vs. strain curve. Consult with your Teaching Assistant with any difficulties. 2. In Excel, calculate the values of shear stress (at the surface of the rods) and shear strain for each material at each torque value. Remember, φ must be in radians. Shear stress should be in N/mm2 and shear strain should be unitless. 3. Using the values determined in the previous step, create a single graph of shear stress vs. strain for all of the materials and lengths. 4. Determine the modulus of rigidity (G) for each specimen by measuring the slope of the curves. This may be done by either picking points or calculating the slopes, or by using the “Add Trendline” feature in Excel. 5. Research the values of G for aluminum (6061), steel (1018) and brass (360) and compare to your values. Calculate the percent difference. 6. For the 400 mm aluminum rod, calculate the expected angle of twist for each value of torque. The appropriate equation is shown on page one of this lab. After making the calculations in Excel, create a graph that shows the angle of twist (both measured and calculated) versus torque. Notice the x and y axes have been switched compared to the first graph made. Angle of twist will now be on the y-axis. Discuss any differences in the curves. ENGR 151 – Strength of Materials Torsion Pre-Lab Worksheet ENGR 151 – Strength of Materials Lab Exercise #3: Torsion Name: _____________________________________ Lab Day - M T W R F Lab Start Time: ________ Calculate J for 3/16” diameter rods J = ____________________________ mm4 Find a source that lists the values of G for the metals used in this lab G (1018 steel) = ________________________ N/mm2 G (6061 aluminum) = ________________________ N/mm2 G (360 brass) = ________________________ N/mm2 Calculate the expected angle of twist (in degrees) per N·mm of torque for each metal Angle of twist (1018 steel) = _______________________ degrees/(N·mm) Angle of twist (6061 aluminum) = _______________________ degrees/(N·mm) Angle of twist (360 brass) = _______________________ degrees/(N·mm) ENGR 151 – Strength of Materials Torsion Data Sheet ENGR 151 – Strength of Materials Lab Exercise #3: Torsion Name: _____________________________________ Lab Day - M T W R F Pulley radius ______________________ Aluminum (L = 400 mm) Weight Angle of Twist (N) (Deg) Aluminum (L = 200 mm) Weight Angle of Twist (N) (Deg) Brass (L = 400 mm) Weight Angle of Twist (N) (Deg) Steel (L = 400 mm) Weight Angle of Twist (N) (Deg) Lab Start Time: ________