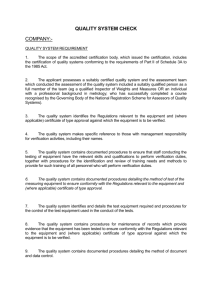

audit criteria evidence guide - Office of the Federal Safety

advertisement