DCPPTSS CDR

advertisement

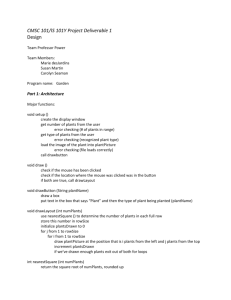

DCPPTSS CDR Group 6 Christian "The Muscle" Braun (CpE) Rashon "The Wildcard" Hogan (EE) Jelani "The Brains" Jackson (CpE) Donald "The Looks" Thomson (CpE) The DCPPTSS The Digital Competitive Precision Projectile Table Support Structure is an embedded system designed to function as an aid for the widely popular recreational beer drinking activity known as BEER PONG Motivation Beer pong is like bowling, a precision game which incorporates alcohol. If bowling can be automated, why not beer pong? ● Game rules vary from location to location ● Keeping track of who plays next always causes problems ● Most inebriated people stop caring about hygiene ● Have fun during senior design ● Gain experience with embedded systems and peripheral communication. Project Goals ● Demonstrate concepts needed for an electronic beer pong table ● User friendly ● Simple design ● Keep game score ● Detect presence of cups ● Detect made from missed shots ● Provide a reliable beer pong table ● Provide a ball sanitation system ● Use only generic equipment ○ i.e. special balls/cups Specifications ● Table Dimensions: 8'L x 2'W x 36"H ● Run on mains power (120v @ 60Hz) ● Be able to play 10+ consecutive games ● Distinguish between 12 different cups ● Display at least 6 different colors ● Creates 4+ distinguishable animations ● Demonstrate Communication between 2 different transmitting modules Block Diagram Table Layout Table Structure Cup Sensors ● Two cup sensor arrays ○ One for each side of the table ● Each array consists of 6 sensors ○ One sensor for each cup ● Each sensor consists of: ○ 1 TI Capacitive Touch Unit ○ 5 RGB LEDs ● Each array controlled via a MSP430G2553 MCU MSP430G2553 Originally, was using MSP430G2452 ● MCU came stock with TI Cap Touch Booster Pack ● Only a single Timer_A module ● PITA with so much IO ○ TAR Chose the MSP430G2553 ● Needed at least two Timer_A modules ● Needed Capacitive Touch capability ● TI E2E community ● Giant crap shoot choosing between parts matching the specs Presence of Liquid Basic Idea ● Capacitive Touch Sensor ● Presence of liquid displaces air ○ Changes the permitivity of space above sensor ○ Changes RC time constant Material Dielectric Constant Vacuum 1 Air 1.00059 Plexiglas 3.40 Water 80.4 Presence of Liquid Methods of Detection ● Relaxed Oscillator (RO) ○ Counts charge/discharge cycles ● RC Time Constant (RC) ○ Measures rise/fall time Driving the LEDs Multiple Options 1. Drive each LED with a single pin of a MCU 2. Multiplex/Charlieplex the LEDs 3. Drive each LED with a proprietary LED Driver Driving with MCU ● Would require MCU with > 90 pins (3pins x 5LEDs x 6units) for each side ● Would require a transistor as pin Imax = +/- 2mA Multi/Charlieplexing ● To drive all LEDs, must refresh faster than the "flicker threshold" ● Average current can reach above LED specifications Driving the LEDs Chose to use the TI TLC5940NT LED driver ● Dot Correction ○ Current control ○ Imax set by single external resistor for all 16 channels ○ 64 divisions 0 to Imax ● Grayscale ○ On/off control ● Serial communication ○ 2 pins from MSP for data for 30 RGB LEDs ● Total of 7 pins used from MSP for LEDs Light Barriers Problem ● Ping Pong balls are not detected by capacitive sensors ● Wanted to use standard beer pong equipment Multiple Designs ● Single Sided ○ Detects reflection ● Dual Sided ○ Detects beam break ● Discretizing ○ Laser Array above cups ○ Detect beam break Single Sided ● Detect reflection ● Emitters and Detectors in same plane ● AC vs DC source ● Problems ○ Balls diffuse light ○ Light reflected at angle different from angle of incidence ○ Ceiling height Dual Sided ● Detect beam break ● Emitters and detectors opposite Problems ● Rails create obstructions to game play Discretizing Laser Array ● 650nm wavelength ● 5mW @ 3.3V ● Adjustable columnating lens. ● Detect beam break ● Discretize the area above the cups ● Creates coordinate grid LED Table Animation ● Consist of 1 micro-controller communicating using I2C to MSP430G2553 main processor ● 5 output pins will control diodes through decoders ● Decoders will output to base nodes of BJTs driving LEDs. LED Table Animation Sanitation Implemented for eradicating pathogens, germs, viruses in water circulation system to minimize transfer of sickness. Means Chosen: Ultra Violet - destroys Nucleic Acids; extremely effective, minimal maintenance required. Sterilization ● 120VAC 60Hz Power Input ● Pump rated for 180 Gallons per hour ● Connected via Vinyl Tubing for flexible routing ● 245nm UV Sterilizer rated for 180 gallon total volume & 1800Gph ● 99% Effective ● Better performance versus pasteurization or chemical dosing. ● Pasteurization has dangerous amounts of heat. ● Chemical Dosing presents a potential health hazards as well as added weight for chemicals and high maintenance. User Interface ● Handle up to 4 different functions that the table is unable to handle automatically ○ MISS ○ FORFEIT ○ SKIP TURN ○ RERACK ● Display 3 pieces of information for the current game ○ Team Number ○ Cups Left (on current side) ○ Reracks Left ● Handle queue tracking of 10+ different teams User Interface - Components ● Information Display ○ One module for both teams ● User Input ○ Buttons ■ Arcade-style - big, easy to use ○ 1 Button per Function vs. Menu Navigation ■ Menu navigation - cheap, more coding ■ 1 button per function - easier to implement in code, requires more table space, pricier ● Team Tracking ○ Winning team stays on to play ○ Losing team number incremented to next-up team User Interface - Components ● NHD-0216K3Z-FL-GBW - 16x2 Character LCD ○ Backlit - usable in low-light environments ○ Support for RS232, SPI, I2C ○ 64.5mm x 16.4mm - unobtrusive ● OBSF-30 ○ Chosen using different criteria ○ Price and availability most important User Interface - Layout ● Constructed as a single module ○ Mounted to side of the table ■ One MSP430G2553 ■ Three Arcade-style buttons ■ One 16x2 character LCD User Interface - Block Diagram User Interface - Schematic User Interface - Menu Flow Central Control Options Central Control Options Stellaris EKSLM3S8962 Communication UART, SSI, I2C Options ATMEL AT91SAM OKI ML674000 UART, SSC, SPI UART Programming Language C C C Price FREE $79.00 $89.00 Central Control - Choice MSP430G2553 microcontroller ● Uses I2C - which is used to communicate with external systems ● Complications with the Stellaris EKS-LM3S8962 ● The complication of programming the Stellaris ● Inexpensive Central Control - Requirements ● Communicate with external systems ○ Descretized laser subsystem ■ determines if ball was thrown ■ determines if ball was made/missed ○ Capacitive touch system ■ determines which cup the ball was thrown in ○ User Interface ○ LED pattern ● Maintain score count, player turn, cups remaining, and throws per turn Central Control - Functions ● void LEDpattern(char) - Starts LED pattern about player areas ● void playerInitialization() - Initializes player members ● void selectedPlayer(int) - Selects which player goes first ● int isBallDetected() - Was the ball detected ● int isBallMade() - Was the ball made ● struct Player currentTurn() - Returns whose turn it is Central Control - Functions ● void decrementThrows() - Decrement throws for turn ● void decrementCups() - Decrement cups remaining ● void cupsPerPlayer() - Shows cups per player ● void changeTurn() - Change turn of player ● void isWinner() - Check to see if there's a winner User Interface - Functions ● void initUI(int playerNum, int teamNum) - initializes UI to default state ● int getTeamNum(int playerNum) - gets team number from team queue ● void setNextTeam() - set next team number in queue ● void miss(int playerNum) - set last throw as MISS ● void rerack(int playerNum) - perform RERACK ● void skipTurn(int playerNum) - SKIP TURN/MULLIGAN User Interface - Functions ● void forfeit(int playerNum) - end game with loss ● struct Button buttonPressed() - returns which button is pressed for navigation Power ● Antec Basic Series ATX Computer Supply ● 350 Watt ● Reliable, Clean electricity, Multiple levels of power. ● 12, -12, 3.3, 5v available. ● No testing required ● Equipped with over current protection. Work Distribution Budget and Financing Total Budget: $800 Self-funded: $200 per person Challenges Overcome ● Procuring TI Cap Touch Units (Classmates) ● IR Barrier (Laser Grid) ● Laser Alignment (SteelStik & Cottonballs) ● I2C Communication (self condemnation) ● Brown Out from TLC surge (capacitor) ● User Error (testing) ● Equipment Failure (revise code) Thank You! Questions?