Flow control of separating boundary layer on the

advertisement

4TH EUROPEAN CONFERENCE FOR AEROSPACE SCIENCES (EUCASS)

Flow control of separating boundary layer on the Coanda

surface

Florin Frunzulică*,**, Alexandru Dumitrache**, Horia Dumitrescu** and Octavian Preotu***

*“POLITEHNICA” University of Bucharest, Faculty of Aerospace Engineering, Polizu 1-7, 011611 Bucharest,

ROMANIA, e-mail: ffrunzi@yahoo.com

** “Gheorghe Mihoc-Caius Iacob” Institute of Statistics and Applied Mathematics, Calea 13 Septembrie no. 13,

050711 Bucharest, ROMANIA, e-mail: alex_dumitrache@yahoo.com

***University of Craiova, st. A. I. Cuza no.13, 200585, Craiova, Romania

Abstract

Flow control refers to the ability to alter flows with the aim to achieve a desired effect: examples

include delay of boundary layer separation and drag reduction, noise attenuation, improved mixing or

increased combustion efficiency among many other industrial applications. The main objective of this

paper is to investigate ways of keeping the flow attached to a larger length of a Coanda surface, with

application in aerospace and wind energy. The effect of surface curvature (Coanda effect) on the

development of a two-dimensional wall jet was investigated numerically using Reynolds averaged

Navier-Stokes model (RANS) with different turbulence models. For flow control on the Coanda

surface we investigated two possibilities: one passive, which uses a slot, and an active one, based on

the principle of synthetic jet. Reynolds averaged Navier-Stokes simulations (RANS) with shear stress

transport k-ω (SST model) of Menter have been used to compute the two-dimensional turbulent flow.

The numerical results are presented for the two flow control methods considered.

1. Introduction

In the field of aerospace engineering, the aerodynamic design of future civilian and military aerospace vehicles will

be greatly influenced by flow control technologies available for high-lift devices, flight at high angle of attack, jet

engine inlet and exhaustive systems, thrust vectoring, jet noise reduction, etc. The flow control devices will be used

in a variety of flow situations: to energize the boundary layer and to control the boundary layer transition in low and

high speed regimes, to modify the shear layers, to produce jet deflections and to control oscillations of different

structural parts of the aircraft.

In the field of wind energy, as the desire to capture more energy from the wind increases, industrial manufacturers

seek to implement techniques that improve wind turbine efficiency or reduce load fluctuations. The use of variablespeed rotors (used in most modern large-scale turbines) offers an efficiency increase by allowing the turbine to

operate closer to its maximum aerodynamic performance at a wider range of wind speeds, thus extracting more

energy from the wind. Aerodynamic control is achieved by variable pitch blades and in present by stall control;

however, other control concepts for efficiency improvement become a substantial source of study.

The approaches for separation control can be broken in: (1) passive control (vortex generators, flaps/slats, slots,

absorbant surfaces and riblets) and (2) active control (mobile surface, planform control, jets, advanced controls magnetodynamics).

Currently, the active control with jets is an effective technique that can be done with additional flow mass (blowing,

suction or blowing-suction forced jets) or without additional net mass flow (named dynamic forcing). The forced jets

are extremely effective, essentially for eliminating the separation of the boundary layer.

The circulation control as active control technique is know as improving the bound circulation and hence the lift

coefficient of airfoil. This technology has been investigated both experimentally and numerically in the last decade

[1]. Circulation control is implemented, usually, by tangential blowing a small high-velocity jet over a highly curved

surface, such as a rounded trailing edge. This causes the boundary layer and the jet to remain attached along the

curved surface due to the Coanda effect (the tendency of a moving fluid to attach itself to a surface and flow along it)

and causing the jet to turn without separation as in figure 1. The rear stagnation point moves toward the lower

surface, producing additional increase in circulation around the airfoil, leading to high value of lift coefficient

comparable to that achievable from conventional high lift devices. The airfoil with this device has a large-radius

rounded trailing edge (to maximize the lift), and the drag increase substantially when the jet is turned off.

Copyright 2011 by First Author and Second Author. Published by the EUCASS association with permission.

FP FLOW CONTROL 1

Figure 1: Circulation control at trailing edge

Forced jets have a few disadvantages: complexity of internal piping from a source of pressure or vacuum, and the

parasitic cost to produce this pressure. A currently challenge is to reduce the power consumption to produce the jet

and to use efficiently the jet to control flow separation.

The active control without additional net mass flow can be achieved by the small vibrating flap or small surface, and

synthetic jets.

Periodically exciting a leading-edge separation (using a small vibrating flap) the vorticity shear layer rolls up and

implies creating large scale phase – locked coherent vortex structure over downstream surface.

A synthetic jet is a concept that consists of an orifice or neck driven by an acoustic source in a cavity. At high level

of excitation by the acoustic source, a mean flow stream of flow is generate in vicinity of the orifice with no net mass

flux added to main flow. At sufficiently high levels of excitation by the acoustic source, a mean stream of flow has

been observed to emanate from the neck. Because there is no mass added to the system, the mean streamlines must

form a closed recirculation [2]. The excitation cycle increase the ability of the boundary layer to resist separation.

Another technique of increasing the lift of airfoils is the use of passive devices, one of these being known as Gurney

flap [3]. The Gurney flap is a small tab perpendicularly attached to the lower surface of the airfoil in the vicinity of

the trailing edge, with a height that can vary from 1% to 5%. The results showed a significant increment in lift

compared to the baseline airfoil.

Another passive device uses a slot between lower-pressure and high-pressure points (near the separation point) on the

upper surface of the thick airfoil (at positive angle of attack). The tendency of redistribution of the pressure on the

surface will maintain the boundary layer attached to the upper surface. Thus the form drag is reduced and the lift

changes the orientation. The advantage of this method is that is not implying additional source of power and can be

used as a passive/active control of flow [4].

In this paper we investigate three issues related to flow control applicable in aerospace and wind energy: appropriate

turbulence model for the study of jets on convex surfaces, passive control using a slot and active control using

synthetic jet at medium frequencies on Coanda surfaces.

2. Coanda effect. Computational analysis

In this part the effect of surface curvature (Coanda effect) on the development of a two-dimensional wall jet was

investigated numerically. The main goal is to provide a systematic survey of the performance of selected eddyviscosity models in a range of curved flows and to establish more clearly their potential and limitations.

Reynolds averaged Navier-Stokes simulations (RANS) with different turbulence models have been employed to

compute the two-dimensional turbulent wall jet flowing around a circular cylinder: (1) Spalart and Allmaras (SA one turbulence model equation)[5], (2) Launder and Spalding k-ε model [6], (3) Wilcox k-ω model [7] and (4)

Menter k-ω SST model [8]. The predictions of the simulations were compared to available experimental

measurements in the literature. The surface curvature enhances the near-wall shear production of turbulent stresses

and is responsible for the entrainment of ambient fluid which causes the jet to adhere to the curved surface.

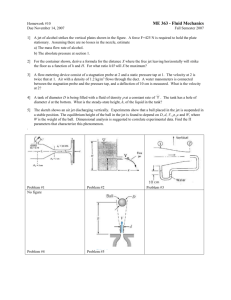

The particular configuration shown in figure 2 is considered cylindrical and wall jet properties have been reported by

Neuendor and Wygnanski [9] and provide a means for evaluation of simulation results (diameter d=0.2032 m, nozzle

height b=2.34 mm and jet-exit velocity Vjet=48 m/s).

The computational grid used for these investigations is shown in figure 3 and consists of 900 x 220 nodes. For the

turbulence models used in these calculations the laminar sublayer needed to be resolved. The y + values of the wallnext grid points were between 0.4 and 1, and the ∆x + values were between 50 and 300. The grid resolution in the jet

was between 40 and 180 times the local Kolmogorov length scale. A fully developed channel velocity profile was

prescribed at the nozzle inflow (no near field), with a medium turbulence. The ambient was quiescent.

For some of these turbulence models the jet-velocity decay and jet-half-thickness are plotted in figure 4 against

streamwise angle. When the k − ω model was used in combination with the k − ω SST model, a close match of the

2

F.Frunzulică, et al. FLOW CONTROL OF SEPARATING BOUNDARY LAYER ON THE COANDA SURFACE

jet-velocity decay with the measured data was achieved. However, even with this model, the downstream

development of the jet-half-thickness was poorly predicted.

Figure 2: Configuration used in analysis

Figure 3: Computational grid

The shape of the normalized velocity profiles is predicted best by the k − ε model (figure 5). Because the predicted

half-thickness was small for all models, the normalized velocity profiles do not match the experimental velocity

profiles neither in the mild pressure region nor in the adverse pressure region.

Figure 4: Jet velocity decay and jet-halfthickness (exp.-Ref.[9])

Figure 5: The shape of normalized velocity

profiles at 900 and 1800 [ y/y2=f(u/Umax) ]

3

FP FLOW CONTROL 1

For the k − ω SST model the separation location was slightly closer to the experiment. When the k − ε and

Spalart-Allmaras models were used, the jet remained attached to the cylinder for more than 260 deg (figure 6).

a.

b.

c.

d.

Figure 6: Streamline function: (a) Spalart-Allmaras turbulence model, (b) k- ε

model (enhanced wall option), (c) k-ω SST model and (c) k-ω SST c.c. model

One weakness of the eddy-viscosity models is that these models are insensitive to streamline curvature and system

rotation. Based on the work of Spalart and Shur [10] a modification of the production term has been derived which

allows to sensitize k − ω SST to curvature effect. The empirical function suggested by Spalart and Shur to account

for these effects is defined by

2 r*

1 − cr 3 tan −1 (cr 2 rˆ) − cr1

(1)

f r1 = (1 + cr1 )

1+ r*

and it is used as a multiplier of the production term.

The terms in eq. (1) are computing using relationships:

r* = S / ω

2ωik S jk DSij

rˆ =

Dt

D4

1 ∂u ∂u j

Sij = i +

2 ∂x j ∂xi

1 ∂ui ∂u j

−

, ωij =

2 ∂x j ∂xi

1

S 2 = 2 Sij Sij , ω 2 = 2ωij ωij D 2 = ( S 2 + ω 2 )

2

cr1 = 1.0 , cr 2 = 12 , cr 3 = 1.0

(2)

(3)

(4)

(5)

(6)

The term DSij / Dt represents the components of the Lagrangian derivative of the strain rate tensor.

The results obtained with the corrected (curvature correction – c.c.) k − ω SST turbulence model were presented in

figures 4, 5 and 6. The results are close to the experimental data up to about 120 degrees; after this value the

development of the jet was poorly predicted.

3. Passive control using a slot

The first case study uses a simple convex surface and the second computational case uses the same convex surface

with a slot between over-pressure point and under-pressure point on the surface (placed in separation boundary layer

region) (figure 7). The tendency of equalizing the pressures leads to blow in the first orifice of slot, while in the

second one the suction appears. The jet (Vjet=25 m/s) is developed in a rectangular channel with 75 mm height and

pass over a convex surface (25 cm length).

4

F.Frunzulică, et al. FLOW CONTROL OF SEPARATING BOUNDARY LAYER ON THE COANDA SURFACE

Figure 7: The scale model of the surface and experimental device

Figure 8: Computational grid

For computation we use steady RANS with k-ω SST c.c. turbulence model and the computational grid has 219,300

nodes (the detail of the grid was showed in the figure 8). The suction-blowing phenomenon has a beneficial effect on

keeping boundary layer attached on 82% of the surface compared to the case without the slot when boundary layer is

attached to the 58% of the surface. Figure 9 shows the velocity field in the computational domain and pressure

distribution on the surface for the two mentioned situations. The jet is deflected by 20 degrees from the original

direction. Using a hydraulic resistance on the slot we can control the separation point of the jet and the jet orientation

(the problem will be investigated in a future work).

a.

c.

d.

b.

Figure 9: Velocity vectors without (a) and with (b) slot and pressure distribution ( ∆p = p − pref ) on the surface

without (c) and with (d) slot

Figure 10 shows the sections normal to surface where are evaluated the velocity profiles. We can notice the

thickening of the velocity profile due to blowing in section S2, while in sections S4 and S5 the suction effect of the

boundary layer effect is observed.

a.

b.

Figure 10: Velocity profile at different sections

5

FP FLOW CONTROL 1

4. Active control using synthetic jet (SJ) concept

Because investigation of flow control using synthetic jets is in progress, in this section we present only preliminary

results. The synthetic jet is created by the oscillation of a membrane attached to the cavity and the diaphragm

deflection is characterized by the deflection amplitude (A) and angular frequency (ω). The rectangular cavity is

defined by the cavity width (W) and the cavity height (H). A slot is characterized by a height (h) and width (d).

The synthetic jet behavior can be described by the nth moment of the jet:

Cn =

1 1

t2 − t1 d

t2

d/2

t1

−d / 2

∫ ∫

(V ( x, t ) )

j

n

(7)

dx dt

where n=1, n=2 and n=3 correspond to the jet mass flux (which is identically zero for a synthetic jet over a period),

normalized momentum and kinetic energy fluxes of the jet, respectively. If Cn ,in is the mean momentum during

ingestion phase and Cn ,ex similarly for the expulsion phase, then these quantities can be written in term of nondimensional parameters:

(

{Cn ,in , Cn , ex } = function W , A, d , h, 2π f d 2 /ν or St , Reδ = U ∞δ /ν , δ

)

(8)

where St = f d / U is Strouhal number, f is the frequency, U velocity of the fluid, d slot diameter, δ boundary

layer thickness. Clearly, the space of parameters is large for studied configurations and is difficult to cover in a single

investigation.

4.1. SJ (laminar flow) in quiescent air

The case corresponds to a quiescent external flow which has been studied extensively in the past by other researcher

groups [11].

One parameter found useful in the normalization of the jet velocity is the maximum inviscid jet velocity which, for

inv

the prescribed membrane motion (sinusoidal oscillation), is given by Vmax = AW ω / (2d ) . For our application

inv

Vmax

=5.4 m/s. At the maximum expulsion stage (when the membrane is moving up with the maximum velocity), a

pair of counter rotating vortices appears at the orifice (figure 11.c). This vortex pair is removed from the surface by

its own induced velocity. However, since the vortices have already travelled away from the orifice, they are not

affected by the motion of the entrained fluid. As the membrane moves down, external fluid entrains through the slot

(figure 11.a). Because there is no mass added to the system, the mean streamlines must form a closed recirculation.

Remark: the simulation include the dynamic mesh model in cavity using a spring network near the membrane for

interacting between membrane and adjacent fluid.

Figure 11: SJ in quiescent air: maximum ingestion (a-velocity vectors and b-velocity profile in slot) and maximum

expulsion (c-velocity vectors and d-velocity profile in slot). The parameters of simulation are H= 9 mm, A= 0.8 mm,

W= 40 mm, d= 1 mm, f= 50 Hz

6

F.Frunzulică, et al. FLOW CONTROL OF SEPARATING BOUNDARY LAYER ON THE COANDA SURFACE

4.2. Laminar boundary layer interacting with SJ on flat plate

The concept is shown in figure 12, where the synthetic jet is embedded in the wall of a boundary layer for which

separation control is desired. The cavity is provided at the bottom with a mobile surface that oscillates sinusoidally

with 1 mm amplitude and 50 Hz frequency. The flow (15 m/s) over plate is laminar with Blasius velocity profile. The

maximum inviscid jet velocity is

inv

Vmax

= AW ω / (2d ) =6.3 m/s.

Figure 12: Boundary layer interacting with SJ

The figure 13 shows the velocity vectors at time t=0.024 sec –maximum expulsion and t=0.033 sec – maximum

ingestion. At the maximum expulsion stage (when the membrane is moving up with the maximum velocity), a pair of

counter rotating vortices forms at the orifice and carried with locally flow speed.

a.

b.

Figure 13: Laminar boundary layer interacting with SJ: a-maximum expulsion and b-maximum ingestion

In figure 14.a the instantaneous profiles downstream of the slot (40 mm) at the peak of the in-stroke and peak of the

out-stroke are shown versus the baseline. The in-stroke profile illustrates the wall removal of the low-momentum

fluid at the same time with a freestream velocity decrease, and the out-stroke profile illustrates the high-momentum

injection at the same time with a freestream velocity increase. The time-averaged controlled boundary versus the

baseline profile is given in figure 14.b which shows the energization effect of the synthetic jet with a net diffusion of

the freestream.

a.

b.

Figure 14: The velocity profile: Instantaneous velocity profiles on flat plate with and without control (a) and timeaveraged velocity profiles on flat plate with and without control (b).

7

FP FLOW CONTROL 1

4.3. Turbulent boundary layer interacting with SJ over Coanda surface

The configuration is the same as in section 3 but it has an actuator with lateral slot placed at the point of the detached

boundary layer. The diaphragm oscillates sinusoidally with 100 Hz and 1 mm amplitude ( F + = f L / V jet = 1 ). For

simulation an unsteady RANS, k-ω SST turbulence model with curvature correction is used. The computational grid

has 160,000 nodes and the y+ values of the wall-next grid points are between 0.05 and 1, and the ∆x+ values between

10 and 100. In this investigation the separation did not completely suppress and the boundary layer was not enough

energized by the vortical structures generated (figure 15). A small unsteady deviation on the jet, about 3 degrees was

noticed (figure 16).

Figure 15: Contours of vorticity magnitudes (maximum expulsion).

Figure 16: Velocity vectors at maximum ingestion (a), and maximum expulsion (b)

5. Conclusions

The Coanda wall jet developing on a circular cylinder was investigated numerically. This configuration was used to

evaluate turbulence models for steady RANS of flows over curved surfaces. The main conclusion was that none of

the models tested correctly predicted all relevant aspects of the flow. Relatively speaking, the k-ω SST model with

curvature correction performed best.

Two methods for flow control were presented:

- One passive, which uses a slot that connects the low pressure and high pressure points on the Coanda surface.

Adding a controlled resistive device on the slot we can change the jet orientation and the system becomes an active

control device.

- An active one, based on the principle of synthetic jet, created through an orifice located near the point of the

detachment of the jet.

The synthetic jet concept and a numerically investigation of interacting jet with boundary layer were investigated.

Numerically investigation of medium frequencies of synthetic jets hasn’t led to expected results on the Coanda

surface.

Future work: we will introduce the active control on the slot and we will investigate experimentally the interaction

between SJ (generated using piezo-actuators) and turbulent boundary layer on the Coanda surface.

8

F.Frunzulică, et al. FLOW CONTROL OF SEPARATING BOUNDARY LAYER ON THE COANDA SURFACE

References

[1] Slomski, J.F., and P.A. Chang. 2006. Large Eddy Simulation of a Circulation Control Airfoil. AIAA Paper

2006-3011, 3rd AIAA Flow Control Conference, 5 - 8 June 2006, San Francisco, California.

[2] Glezer, A., and M. Amitay. 2002. Synthetic Jets. Annu. Rev. Fluid Mech., 34: 503-529.

[3] Van Dam, C.P., Yen, D.T., and P. Vijgen. 1999. Gurney flap experiments on airfoil and wings. Journal of

Aircraft (0021-8669), 36 (2): 484–486.

[4] Frunzulica, F., Dumitrache, A., and O. Preotu. 2011. Control of two-dimensional turbulent wall jet on a Coanda

surface. 82nd Annual Scientific Conference of the International Association of Applied Mathematics and

Mechanics (GAMM), Graz, Austria, April 18 - 21, 2011.

[5] Spalart, P.R., and S.R. Allmaras. 1992. A one-equation turbulence model for aerodynamic flows. AIAA Paper

92-0439.

[6] Launder, B.E., and D.B. Spalding. 1974. The numerical computation of turbulent flows. International Journal

for Numerical Methods in Fluids, 15, 127.

[7] D. Wilcox. 1994. Simulation of transition with a two-equation turbulence model. AIAA Journal, 32, 1192.

[8] F.R. Menter. 1997. Eddy viscosity transport equations and their relation to the k-ω model. ASME Journal of

Fluids Engineering, 119, 876.

[9] Neuendorf, R., and I. Wygnanski. 1999. On a turbulent wall jet flowing over a circular cylinder. Journal of

Fluid Mechanics, 381, 1.

[10] Shur, M. L., Strelets, M. K., Travin, A. K., and P.R. Spalart. 2000. Turbulence Modeling in Rotating and

Curved Channels: Assessing the Spalart-Shur Correction. AIAA Journal, 38, no.5: 784-792.

[11] Rizzetta, D.P., Visbal, M.R., and M.J. Stanek. 1998. Numerical investigation of synthetic jet flowfields. AIAA

Paper 98-2910.

[12] Fluent ANSYS 12. User Guide.

Acknowledgement: This paper was supported by National Research Program – 543 – IDEI/2008.

9