Density of Solids and Liquids - Plattsburgh State Faculty and

advertisement

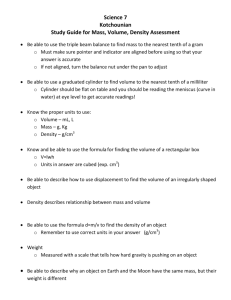

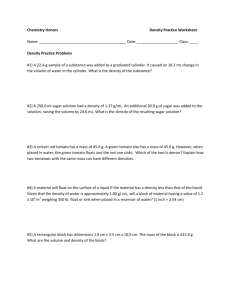

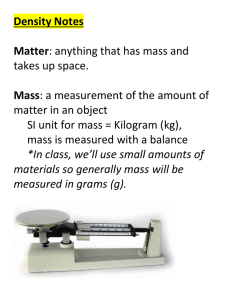

Density of Solids and Liquids Thomas M. Moffett Jr. September 20, 2009 CHE 111 Lab Section X September 21, 2009, CHE 111 Students, Notes on this sample: The purpose of writing lab reports is to help you develop the ability to communicate, it is not intended to torture you (that’s a side benefit). No matter what your field of study happens to be, even if it is outside of the sciences, you will be required to be able to communicate effectively with others in your field, and perhaps even to those outside of your chosen field (this is remarkably more difficult to do). No one works in a vacuum, the form of communication (lab notebooks, papers, posters, oral presentations, etc.) may vary but you will eventually have to tell someone what you have accomplished. Scientific writing (what a lab report is supposed to be) is more structured than the writing that you are probably accustomed to. The components of your report should be clearly defined and it should be easy for the audience to find the information they are looking for. When you read this sample report notice how I have broken down the methods and discussion into sub sections, each dealing with a different component of the lab. I have organized this draft more in line with how a scientific journal article would be written (the tables and figures are incorporated into the discussion). For a lab report it would also be acceptable to put all of the tables and figures in a separate section. Throughout the report I will interject comment in red italics to clarify different parts of the report. I have attempted to write this at a level that an outstanding first year student would be able to write at. -Tom Abstract An abstract should be short and summarize the results of your experiment. When people read journals they will read abstracts before deciding what articles to read, for this reason the abstract may be the most important part of the paper. In the first part of the experiment, solid sample A119 was determined to be iron, by comparison of measured densities to the accepted densities of several different metals. The volume of A119 was obtained by measuring the dimensions of the cylinder with a ruler (d = 8.3 g/cm3) and by displacement (d = 7.83 g/cm3). The displacement method proved to be much more accurate as the accepted density of iron is 7.87 g/cm3. In the second part of the lab, the concentration of sugar in unknown F was determined to be 15.76 % by comparing the measured density to a standard curve created from a serial dilution of a stock sugar solution. 1. Introduction Density is the ratio of an object’s mass to its volume. d= m v (1) Density is an example of an intensive property, a property in which the value is solely dependant upon the identity of the material, and not the amount present. Since intensive properties are an inherent characteristic of the material they can be used to identify the material. On the other hand mass and volume are extensive properties, these properties depend on the sample size, the bigger the sample the bigger the value. The ratio of two related extensive properties will always result in an intensive property. In this experiment, the identity of a metal cylinder was determined by measuring its density and comparing to the densities of several metals. The mass was measured with a balance. The volume was determined in two different ways, by measuring the dimensions and the displacement method. Since the metal was in the shape of a cylinder the volume could be determined by measuring radius and height. V = r2h (2) In the displacement method the metal cylinder is submerged in a graduated cylinder with water. The volume change in the water corresponds to the volume of the cylinder. Figure 1 – Dimensions of a cylinder Accuracy and precision are indications of the quality of a set of measurements. Accuracy is indicated by %-error and shows how close the measured values are to the accepted value. All tables and figures must be titled and numbered % error = (measured value - accepted value) X 100 accepted value (3) Precision is an indication of how well a set of measurements agree with each other. Precision is indicated by standard deviation. n Std dev = i =1 (x n − x )2 n -1 (4) In the second part of lab a serial dilution was made from a stock sugar solution. The concentration of each solution was calculated using the dilution formula. C1V1 = C2V2 (5) Where C1 and C2 are the stock and diluted concentrations respectively, and V1 and V2 represent the stock and diluted volumes. The densities of each dilution were measured in order to create a standard curve of density vs. sugar concentration. This curve was fitted with a trendline and used to determine the sugar concentration in an unknown solution. 2. Methods This is sometimes listed as the procedure section, and should be written so that someone else could repeat your experiment. It does not need to be written with explicit directions, “fill the graduate about two thirds full with water”. You’re writing this to be read by other scientists, any competent chemist should know what to do from reading the procedure. 2.1 Density of Solids The radius and height of an unknown metal cylinder were measured with a ruler to the nearest 0.01 cm. The cylinders mass was determined using an electronic balance (nearest 0.001 g). These measurements were repeated by three additional experimenters, and data was later exchanged. The volume of the cylinder was also found using the displacement method two times per experimenter, four experimenters total. In the displacement method a 25 mL graduate cylinder (read to the nearest 0.05 mL) was partially filled with water, and then the metal cylinder was carefully submerged into the cylinder. The difference in volumes was the volume of the cylinder. 2.2 Density of Sugar Solutions A stock sugar solution was created by dissolving the assigned amount of sugar into DI water in a 100 mL volumetric flask. From this solution a dilute solution was created by transferring 25 mL of the stock solution to a 50 mL volumetric flask utilizing a volumetric pipette. The flask was then filled to the calibration line with DI water. The dilute solution was then used to make another dilution, which was used to make a third dilution. The density of each solution and that of DI water was determined by measuring the mass of 10 mL samples of each solution. The volumes were measured using a 10 mL volumetric pipette. Mass was determined by transferring the 10 mL of sugar solution into a pre-weighed beaker and then measuring with an electronic balance. 3. Discussion 3.1 Density of Solids Based on the measured density, solid sample A119 was determined to be iron. The average density obtained by using the volume data calculated using the measured dimensions was 8.3 g/cm3 (% error = 5.5 %, Std Dev = 0.29 g/cm3. The average density was determined to be 7.85 g/cm3 (% error = -0.25 %, Std Dev = 0.062 g/cm3) when using the volume obtained from the displacement method. Always use data to reinforce your arguments. The accepted density of iron is 7.87 g/cm3. Both the accuracy and the precision were better using the displacement method of obtaining volume. This can be seen in the lower percent error and standard deviation when using the displacement method. Student Mass (g) Radius (cm) Height (cm) Volume (cm3) Density (g/cm3) Tom 48.477 0.61 5.00 5.8 8.4 % error = 5.5 % Fred Wilma Barney 48.475 48.478 48.480 0.60 0.60 0.62 5.01 5.00 5.05 5.7 5.7 6.1 8.5 8.5 7.9 3 Average Density = 8.3 g/cm Std Dev = 0.29 g/cm3 Table 1 – Density data using measured dimensions to calculate volume. The slight discrepancies in the measured dimensions are due to the difference in the estimated digit when students were interpolating using the ruler. Student Tom Fred Wilma Barney Mass (g) 48.477 48.475 48.478 48.480 3 Volume (cm ) 6.15 6.15 6.20 6.15 6.15 6.25 6.25 6.20 Density (g/cm3) 7.88 7.88 7.87 7.93 7.88 7.76 7.76 7.82 Average Density = 7.85 g/cm3 % error = -0.25 % Std Dev = 0.062 g/cm3 Table 2 – Density data using the displacement method to determine volume. 3.2 Density of Sugar Solutions The assigned concentration for the stock sugar solution was 22.00 %, which according to the formula for the true density of a sucrose solution should have a density of 1.0895 g/mL. The measured density of the stock solution was 1.089 g/mL (% error = -0.0459 %). Table 3 shows the data obtained for the serial dilution of the stock sugar solution. If you don’t explicitly state the data you need to indicate where it can be found. Concentration Mass (g) Volume (mL) Density (g/mL) 0.00 % 9.995 10.00 0.9995 2.750 % 10.103 10.00 1.010 Table 3 – Density data for sugar solutions. 5.500 % 10.210 10.00 1.021 11.00 % 10.402 10.00 1.040 22.00 % 10.888 10.00 1.089 Unk F 10.631 10.00 1.063 The data recorded for the solutions with known concentrations was used to create a standard curve of density vs. sugar concentration. In the experiment sugar concentration was the controlled, making it the independent variable, density was the dependant variable. Here is the answer to post lab question a, sometimes the questions can easily be incorporated into the discussion (or introduction). From the graph it is evident that there is a direct linear relationship between density and sugar concentration. The R2 value was 0.9972, indicating that there is a very strong correlation between the measured data and the applied linear regression. Density vs. Sugar Content 1.1 1.08 Density (g/mL) 1.06 1.04 y = 0.0041x + 0.9984 2 R = 0.9972 1.02 1 0.98 0 5 10 15 20 25 Sugar Concentration (%) Figure 2 – Graph of density vs. sugar concentration. The density of unknown F was measured, the equation of the trendline from the standard curve was then used to determine the concentration of sugar in the unknown. Unknown F was determined to have a concentration of 15.76 %. 3.3 Answers to Post Lab Questions Not all of the post lab questions can be easily incorporated into your discussion or introduction. In that case you should answer them in a separate subsection in the discussion section. These math problems could have also been handwritten. c.) 2.00 L = 2000 mL 1.07 g = 2140 g 1 mL 32.5 g = 3.87 g/mL e.) d = 8.39 mL d.) 825 g Pb 1 cm 3 = 72.7 cm 3 Pb 11.35 g f.) % error = (1.36 g/mL - 1.25 g/mL ) × 100 = 8.8 % 2000 mL 1.25 g/mL 4. Conclusion I separated the conclusion from the discussion section, but in CHE 111 it is also acceptable for the conclusion to be a subsection of the discussion. From the data it was apparent that the displacement method is both a more accurate and more precise method of determining the volume of a solid. This is most likely due to the fact that the displacement method can account for any imperfections in the cylinder, which would be impossible to measure with a ruler. This is the answer to post lab question b. Using a ruler to measure the radius of a cylinder is not the ideal tool, if calipers were used a much more accurate radius could be determined. There was also an error associated with the balances used in all measurements in this experiment. The balances were open, thus affected by air currents in the room. This resulted in a constant fluctuation in the last digit. This problem could be solved using balances that have an enclosed weighing tray. You always want to be critical of your experiments, where could things have gone wrong, what could have been improved, etc. References The references listed below (textbooks and the web) are acceptable sources for an introductory level class. As you progress through your studies you should incorporate the use of peer reviewed scientific journals, and rely less on non-reviewed sources (the web). 1. Sandwick, R., Moffett, T., Miller, E., “The Density of Metals and Liquids”, SUNY Plattsburgh 2008. 2. Brady, J.E., Senese, F., “Chemistry Matter and its Changes”, 4th ed., Wiley, Hoboken, NJ, 2004. 3. http://www.elmhurst.edu/~chm/vchembook/120Adensity.html, accessed September 20, 2009. Appendix A – Sample Calculations An example of every type of calculation used should be included. This section may be handwritten, as word processors and math do not go hand in hand. Volume of a cylinder v = π r 2 h = π (0.61 cm ) ⋅ 5.00 cm = 5.8 cm 3 2 Density m 48.477 g d= = = 8.4 g/cm 3 3 v 5.8 cm % - error 8.3 g/cm 3 - 7.87 g/cm 3 × 100 = 5.5 % 7.87 g/cm 3 ( ) Standard Deviation Std dev = (8.4 - 8.3)2 + (8.5 - 8.3)2 + (8.5 - 8.3)2 + (7.9 - 8.3)2 3 = 0.29 g/cm 3 True Density of 22.00 % Sugar Solution 2 True Density = 1.784 X 10 -5 (22.00 ) + 3.729 X 10 -3 (22.00 ) + 0.99886 = 1.0895 g/mL Concentration of sugar in the unknown using the equation of the trendline (1.063 - 0.9985) = 15.76 % 0.0041