Hazard Communication Training - Instructor Guide

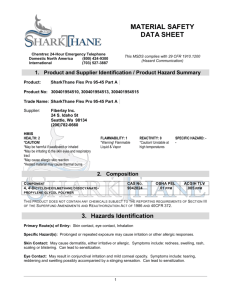

advertisement