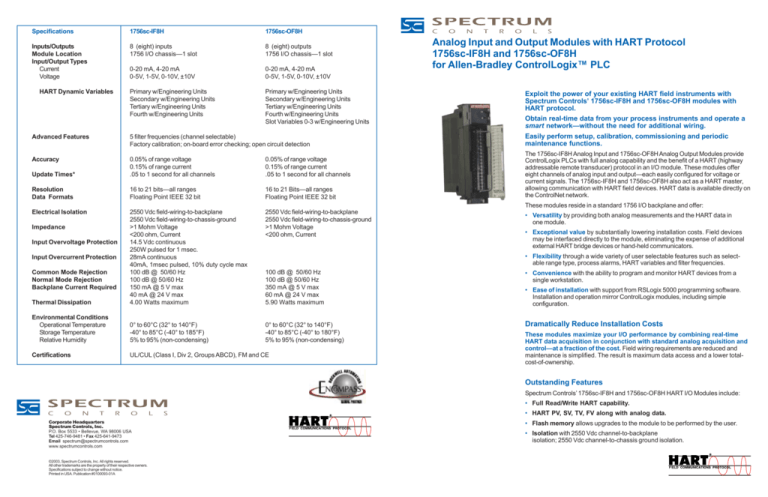

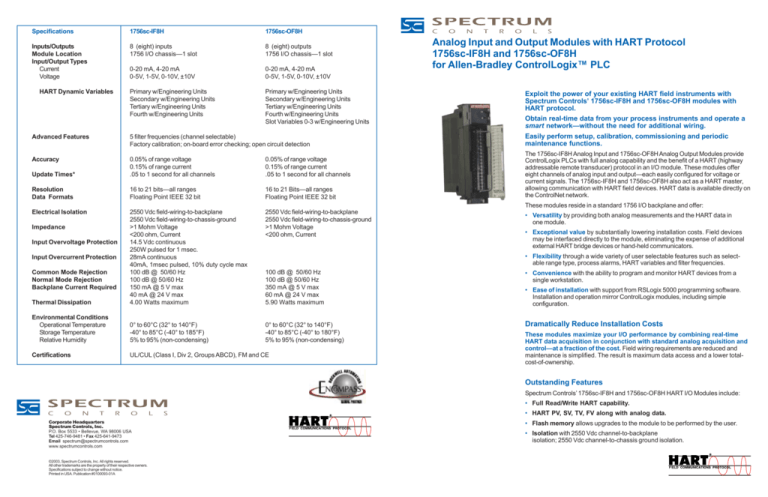

Specifications

1756sc-IF8H

1756sc-OF8H

Inputs/Outputs

Module Location

Input/Output Types

Current

Voltage

8 (eight) inputs

1756 I/O chassis—1 slot

8 (eight) outputs

1756 I/O chassis—1 slot

0-20 mA, 4-20 mA

0-5V, 1-5V, 0-10V, ±10V

0-20 mA, 4-20 mA

0-5V, 1-5V, 0-10V, ±10V

Primary w/Engineering Units

Secondary w/Engineering Units

Tertiary w/Engineering Units

Fourth w/Engineering Units

Primary w/Engineering Units

Secondary w/Engineering Units

Tertiary w/Engineering Units

Fourth w/Engineering Units

Slot Variables 0-3 w/Engineering Units

HART Dynamic Variables

Analog Input and Output Modules with HART Protocol

1756sc-IF8H and 1756sc-OF8H

for Allen-Bradley ControlLogix™ PLC

Exploit the power of your existing HART field instruments with

Spectrum Controls’ 1756sc-IF8H and 1756sc-OF8H modules with

HART protocol.

Obtain real-time data from your process instruments and operate a

smart network—without the need for additional wiring.

Easily perform setup, calibration, commissioning and periodic

maintenance functions.

Advanced Features

5 filter frequencies (channel selectable)

Factory calibration; on-board error checking; open circuit detection

Accuracy

Update Times*

0.05% of range voltage

0.15% of range current

.05 to 1 second for all channels

0.05% of range voltage

0.15% of range current

.05 to 1 second for all channels

Resolution

Data Formats

16 to 21 bits—all ranges

Floating Point IEEE 32 bit

16 to 21 Bits—all ranges

Floating Point IEEE 32 bit

Electrical Isolation

2550 Vdc field-wiring-to-backplane

2550 Vdc field-wiring-to-chassis-ground

>1 Mohm Voltage

<200 ohm, Current

100 dB @ 50/60 Hz

100 dB @ 50/60 Hz

350 mA @ 5 V max

60 mA @ 24 V max

5.90 Watts maximum

• Convenience with the ability to program and monitor HART devices from a

single workstation.

Thermal Dissipation

2550 Vdc field-wiring-to-backplane

2550 Vdc field-wiring-to-chassis-ground

>1 Mohm Voltage

<200 ohm, Current

14.5 Vdc continuous

250W pulsed for 1 msec.

28mA continuous

40mA, 1msec pulsed, 10% duty cycle max

100 dB @ 50/60 Hz

100 dB @ 50/60 Hz

150 mA @ 5 V max

40 mA @ 24 V max

4.00 Watts maximum

Environmental Conditions

Operational Temperature

Storage Temperature

Relative Humidity

0° to 60°C (32° to 140°F)

-40° to 85°C (-40° to 185°F)

5% to 95% (non-condensing)

0° to 60°C (32° to 140°F)

-40° to 85°C (-40° to 180°F)

5% to 95% (non-condensing)

Dramatically Reduce Installation Costs

Certifications

UL/CUL (Class I, Div 2, Groups ABCD), FM and CE

The 1756sc-IF8H Analog Input and 1756sc-OF8H Analog Output Modules provide

ControlLogix PLCs with full analog capability and the benefit of a HART (highway

addressable remote transducer) protocol in an I/O module. These modules offer

eight channels of analog input and output—each easily configured for voltage or

current signals. The 1756sc-IF8H and 1756sc-OF8H also act as a HART master,

allowing communication with HART field devices. HART data is available directly on

the ControlNet network.

These modules reside in a standard 1756 I/O backplane and offer:

Impedance

Input Overvoltage Protection

Input Overcurrent Protection

Common Mode Rejection

Normal Mode Rejection

Backplane Current Required

• Versatility by providing both analog measurements and the HART data in

one module.

• Exceptional value by substantially lowering installation costs. Field devices

may be interfaced directly to the module, eliminating the expense of additional

external HART bridge devices or hand-held communicators.

• Flexibility through a wide variety of user selectable features such as selectable range type, process alarms, HART variables and filter frequencies.

• Ease of installation with support from RSLogix 5000 programming software.

Installation and operation mirror ControlLogix modules, including simple

configuration.

These modules maximize your I/O performance by combining real-time

HART data acquisition in conjunction with standard analog acquisition and

control—at a fraction of the cost. Field wiring requirements are reduced and

maintenance is simplified. The result is maximum data access and a lower totalcost-of-ownership.

Outstanding Features

Spectrum Controls’ 1756sc-IF8H and 1756sc-OF8H HART I/O Modules include:

• Full Read/Write HART capability.

• HART PV, SV, TV, FV along with analog data.

Corporate Headquarters

Spectrum Controls, Inc.

P.O. Box 5533 • Bellevue, WA 98006 USA

Tel 425-746-9481 • Fax 425-641-9473

Email spectrum@spectrumcontrols.com

www.spectrumcontrols.com

©2003, Spectrum Controls, Inc. All rights reserved.

All other trademarks are the property of their respective owners.

Specifications subject to change without notice.

Printed in USA. Publication #0100093-01A

• Flash memory allows upgrades to the module to be performed by the user.

• Isolation with 2550 Vdc channel-to-backplane

isolation; 2550 Vdc channel-to-chassis ground isolation.

HART Input and Output Modules

1756sc-IF8H and 1756sc-OF8H

for Allen-Bradley ControlLogix™ PLCs

A ControlLogix PLC can be the HART gateway for a complete plant control system. The power of a ControlNet

network may provide data to any workstation on the system. Asset management, system configuration and

maintenance tasks that required personnel to acquire data from the factory floor may now be easily performed

from a single workstation.

Spectrum Controls’ HART I/O communicates digitally with field devices, increases input/output capacity and provides access

to more information about your process than conventional I/O subsystems. Spectrum Controls’ HART I/O modules perform

both digital and analog data acquisition. These unique modules greatly enhance device diagnostics that affect your control

strategy and alert operators to device malfunctions.

Benefits

Analog Data

and

HART Digital Data

HART

Field Devices

Access multivariable instruments. Dramatically reduce costs using Spectrum Controls’ HART I/O by increasing information

flow four- to eight-fold. For example, a mass flowmeter can measure mass flow, temperature, density and volume flow, but a

HART output channel can read back information such as the actual valve position without the need for additional wiring. Using

standard I/O, you would need to wire each of these signals individually,

Take advantage of smart device capabilities. Spectrum Controls’ HART I/O increases your ability to communicate with

field devices. You can have complete trust in your signal, knowing that Spectrum Controls’ HART I/O is in constant communication with your smart devices. Use the additional HART I/O information from the devices in a control strategy for trending and

alarming—just like signals from standard I/O.

1756sc-IF8H

Spectrum Controls HART

Input Module

1756sc-OF8H

Spectrum Controls HART

Output Module

Flowmeter Inputs

Pressure Inputs

Temperature Inputs

Valve Position Inputs

Valves

Drives

Speed Controls

ControlLogix

or

ProcessLogix

Controller

ControlNet

Network

Plant Control

Workstation

Performance

Diagnostics. Early diagnosis of valve or field instrument problems allows preventative maintenance as required, rather than on

a scheduled basis. Spectrum Controls’ HART I/O allows access critical parameters to determine maintenance cycles.

Modular design. Spectrum Controls’ HART I/O was designed with your investment in mind. All modules are compatible with

existing Allen-Bradley I/O chassis and may be installed under power. These modules offer standard analog input/output

and HART enabled input/output with analog. Each channel is configurable for input range and HART capability. Installation is simple and quick, using existing programming software. Wiring costs decrease substantially as Spectrum Controls’

HART I/O can be installed in the field, close to the actual field devices. Remote mounting the controller with the I/O

further reduces wiring costs by eliminating the need for long cable runs. The integrated design of the Spectrum Controls’ HART I/O saves even more by eliminating the need for marshaling panels.

Workstation

Data Exchange

Producer/consumer technology. Spectrum Controls’ HART I/O was designed to minimize load on your system. Acquire

data via the controller or talk to the module independent of the controller. This minimizes system performance impact and

processor cycles.

RSLinx/OPC/DDE

HART Device

Configuration

Software

Asset

Management

Software

Diagnostic and

Troubleshooting

Software

This combination of Spectrum Controls’ HART

Analog I/O Modules, the ControlLogix PLC and

existing software provide a full feature process

management system with configuration,

troubleshooting and maintenance capability.

Additional Benefits

Application

Software

Increase your process control system’s level of sophistication using Spectrum Controls’ HART I/O. You’re already aware of the

increased input/output capabilities and improved communication with your smart devices. Now go one step further and use an

asset management system (AMS) with your Spectrum Controls’ HART I/O. AMS software allows you to configure, calibrate,

diagnose and troubleshoot your smart field devices from the control room using AMS with Spectrum Controls’ HART I/O.

Increase product quality and minimize unplanned downtime with this dynamic application, while improving the productivity and

profitability of your process.

Minimize programming and setup time. The HART I/Os interface directly to the field instrument using standard terminal block

connections. When HART is enabled, the module automatically detects the device and reports device specific information

back to you. The modules then begin to poll the field device for the HART PV,SV,TV and FV. No programming necessary.

Higher level operations such as ranging and calibration are performed through the use of unconnected messages. You have full

read/write access to your field device allowing common practice, extended and vendor specific HART commands.