submittal copertina.indd

advertisement

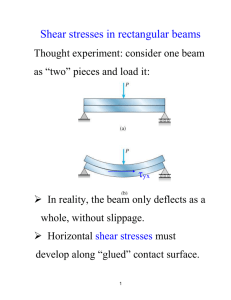

PRODUCT OVERVIEW FM-744 rev01 friulsider Via Trieste 1, 33048 San Giovanni al Natisone, Udine, Italia Tel. +39 0432 747911 - Fax +39 0432 758444 www.friulsider.com - info@friulsider.com Assistenza tec. per Italia: Tel. 0432 747906 - Fax verde 800 301052 SCHEDA TECNICA – TECHNICAL SHEET Rev: 06 Pag. 1/3 FM-744® Ancorante pesante a quattro settori / Heavy duty shield anchor – four segments Occhiolo forgiato Forged eye Gancio forgiato Forged hook Barra filettata Threaded bar Vite TE cl. 8.8 Screw gr. 8.8 *Solo tassello Anchor only DATI TECNICI - TECHNICAL DATA tfix = spessore max fissabile / fixture thickness do = diametro foro / hole diameter h1 = profondità minima foro / minimum hole depth hnom = profondità minima di posa / nominal embedment depth hef = profondità minima di ancoraggio / minimum depth of anchorage df = diametro di passaggio sul pezzo / hole diameter of fixing element hmin = spessore minimo supporto / minimum support thickness Tinst = coppia di serraggio nominale / torque d = diametro vite / screw diameter Lv = lunghezza nominale vite o accessorio / nominal length of screw or accessory L = lunghezza ancorante / anchor length O = Ø interno gancio o occhiolo / internal Ø hook or eye Tipo size dxL tfix mm do mm h1 mm hnom mm hef mm df mm hmin mm M6x40 * 10 55 40 33,5 8 M8x50 * 14 65 50 41 M10x60 * 16 75 60 M12x80 * 20 95 M6x40 12 10 M8x50 15 M10x60 Lv mm O mm Tinst Nm Cod. 100 6 74400b10040 10 100 15 74400b14050 50 12 100 30 74400b16060 80 66,5 14 135 50 74400b20080 55 40 33,5 8 100 50 6 74411b10040 14 65 50 41 10 100 60 15 74411b14050 20 16 75 60 50 12 100 80 30 74411b16060 M12x80 15 20 95 80 66,5 14 135 90 50 74411b20080 M6x40 20 10 55 40 33,5 8 100 65 6 74412b10040■ M8x50 20 14 65 50 41 10 100 75 15 74412b14050■ M10x60 25 16 75 60 50 12 100 95 30 74412b16060■ M12x80 25 20 95 80 66,5 14 135 115 50 74412b20080■ M6x40 10 55 40 33,5 8 100 50 6,5 5 74413b10040■ M8x50 14 65 50 41 10 100 60 11 10 74413b14050■ M10x60 16 75 60 50 12 100 73 14 18 74413b16060■ M12x80 20 95 80 66,5 14 135 90 16 30 74413b20080■ M6x40 10 55 40 33,5 8 100 50 10 5 74414b10040■ M8x50 14 65 50 41 10 100 60 11,5 10 74414b14050■ M10x60 16 75 60 50 12 100 73 14,5 18 74414b16060■ M12x80 20 95 80 66,5 14 135 90 17 30 74414b20080■ * Misure certificate CE con l’utilizzo di viti classe 8.8 (tfix = Lv – hnom) / CE certified when used with screws grade 8.8 (tfix = Lv – hnom) ■ Misure non certificate CE / Not covered by CE certification Friulsider S.p.A si riserva il diritto di apportare modifiche senza preavviso / Friulsider reserves the right to make modifications without prior notice. friulsider SCHEDA TECNICA – TECHNICAL SHEET Via Trieste 1, 33048 San Giovanni al Natisone, Udine, Italia Tel. +39 0432 747911 - Fax +39 0432 758444 www.friulsider.com - info@friulsider.com Assistenza tec. per Italia: Tel. 0432 747906 - Fax verde 800 301052 FM-744® Ancorante pesante a quattro settori / Heavy duty shield anchor – four segments SUPPORTI – BASE MATERIALS idonee / suitable applications calcestruzzo / concrete Rev: 06 Pag. 2/3 parzialmente indicato / partially suitable applications mattone pieno / solid brick pietra compatta / solid stone INSTALLAZIONE – INSTALLATION CARATTERISTICHE ANCORANTE – ANCHOR FEATURES Tipo Type Materiale Material Rivestimento Coating acciaio steel cl. 8.8 ISO 898/1 grade 8.8 ISO 898/1 Ancorante Anchor Vite TE Hex screw Rondella Washer DIN 125/1 Zincatura bianca 5µm ISO 4042 White zinc plated 5µm ISO 4042 cl. 5.8 ISO 898/1 grade 5.8 ISO 898/1 Barra filettata Threaded bar cl.8 DIN 934 grade 8 DIN 934 Dado Hex Nut acciaio forgiato forged steel Gancio / Occhiolo Hook / Eye Tipo ancorante Anchor diameter M6 M8 M10 M12 Sezione resistente Stressed cross-section As [mm ] 20,1 36,6 58,0 84,3 Momento flettente ammissibile cl. 8.8 Recommended Bending moment grade 8.8 Mcons [Nm] 7 17 34 60 Momento flettente ammissibile cl. 5.8 Recommended Bending moment grade 5.8 Mcons [Nm] 4 10 21 37 2 (1) Trazione ammissibile occhiolo forgiato [kN] 1,8 3,0 4,8 7,0 Ncons (1) Recommended Tensile forged eye (1) Trazione ammissibile gancio forgiato [kN] 0,4 0,8 1,2 1,9 Ncons (1) Recommended Tensile forged hook (2) Taglio C 10 hef – barra cl. 5.8 [kN] 2,1 3,8 6,0 8,8 Vcons (2) C 10 hef – bar grade 5.8 Shear 1kN = 100 kgf (1) Questi accessori non sono certificati, i carichi ammissibili derivano dai carichi medi di rottura e sono comprensivi del coefficiente totale =4. These accessories are not included in the certification, the recommended loads derive from the mean ultimate loads and are inclusive of the total safety factor =4. (2) Valori di taglio puro Vcons con distanze dai bordi C 10xhef comprensivi del coefficiente totale =3. Shear pure values Vcons with distance from the edge C 10xhef are inclusive of the total safety factor =3. Friulsider S.p.A si riserva il diritto di apportare modifiche senza preavviso / Friulsider reserves the right to make modifications without prior notice. friulsider SCHEDA TECNICA – TECHNICAL SHEET Via Trieste 1, 33048 San Giovanni al Natisone, Udine, Italia Tel. +39 0432 747911 - Fax +39 0432 758444 www.friulsider.com - info@friulsider.com Assistenza tec. per Italia: Tel. 0432 747906 - Fax verde 800 301052 FM-744® Ancorante pesante a quattro settori / Heavy duty shield anchor – four segments CARICHI di PROGETTO(1) e AMMISSIBILI(2) (consigliati) DESIGN(1) and RECOMMENDED(2) LOADS Rev: 06 Pag. 3/3 ETA-05/0169 Op.7 – Met.A Ancorante singolo senza influenza derivante da distanza dal bordo o interasse in calcestruzzo C20/25 non fessurato. Single anchor with large anchor spacing and edge distances in non-cracked concrete C20/25 Tipo ancorante Anchor diameter Profondità di ancoraggio Depth of anchorage M6 Trazione Tensile Interasse Spacing Distanza dal bordo Edge distance (3) Taglio C 10 hef viti cl. 8.8 (3) Shear C 10 hef - screw grade 8.8 (4) M8 M10 M12 hef [mm] 33,5 41 50 66,5 Nrd [kN] 4,0 8,0 11,9 18,2 Ncons [kN] 2,9 5,7 8,5 13,0 Scr,N [mm] 101 123 150 200 Ccr,N [mm] 50 62 75 100 Vrd [kN] 5,9 11,6 17,2 25,6 Vcons [kN] 4,2 8,3 12,3 18,3 1kN = 100 kgf (1) I carichi di progetto Nrd e Vrd derivano dai carichi caratteristici riportati sulla certificazione ETA-05/0169 e sono comprensivi dei coefficienti parziali di sicurezza ym relativi al singolo diametro (vedi ETA). The design loads Nrd and Vrd derive from the characteristic loads on the ETA-05/0169 certification and are inclusive of the partial safety factors ym proportional to each diameter (see ETA). (2) I carichi ammissibili Ncons e Vcons derivano dai carichi caratteristici riportati sulla certificazione ETA-05/0169 e sono comprensivi dei coefficienti parziali di sicurezza f =1.4 e ym relativi al singolo diametro (vedi ETA). The recommended loads Ncons and Vcons derive from the characteristic loads on the ETA-05/0169 certification and are inclusive of the partial safety factors f=1.4 and ym proportional to each diameter (see ETA). (3) Valori di taglio validi con distanze dai bordi C10xhef. Shear values valid with distance from the edge C 10xhef. (4) Uso limitato ad ancoraggi di componenti strutturali staticamente indeterminati (iperstatici). Use restricted to anchoring of structural components statically indeterminated. Dati di installazione e di posa limite - Minimum installation distances Tipo ancorante Anchor diameter M6 M8 M10 M12 Interasse minimo fra ancoranti Minimum distance between anchors Smin [mm] 35 40 50 70 Distanza minima dal bordo Minimum distance form edge Cmin [mm] 35 40 50 70 Esempio di carico di taglio diretto verso il bordo del calcestruzzo C20/25 alla distanza Cmin secondo ETAG001 allegato C Example (according to annex C of the ETAG 001)of shear load across the C20/25 concrete edge at a distance of Cmin Tipo ancorante Anchor diameter Taglio C = Cmin Shear C = Cmin M6 M8 M10 M12 Vrd,cmin [kN] 1,3 1,8 2,6 5,0 Vcons,cmin [kN] 0,9 1,3 1,9 3,6 1kN = 100 kgf I valori di carico riportati hanno valore solo se l'installazione è stata eseguita correttamente. Il progettista è responsabile del dimensionamento e del numero degli ancoraggi. Per la progettazione ed il dimensionamento dell'ancoraggio applicare il metodo di calcolo A, secondo ETAG001 Allegato C. The load values are only valid if the installation has been carried out correctly. The design engineer is responsible for the designing and calculation of the fixing. The designing and calculation of the anchorage should be carried out in accordance with annex C, of the ETAG001, design method A. Friulsider S.p.A si riserva il diritto di apportare modifiche senza preavviso / Friulsider reserves the right to make modifications without prior notice. Member of www.eota.eu Centre Scientifique et Technique du Bâtiment 84 avenue Jean Jaurès CHAMPS-SUR-MARNE F-77447 Marne-la-Vallée Cedex 2 Tél. : (33) 01 64 68 82 82 Fax : (33) 01 60 05 70 37 European Technical Assessment ETA-05/016 9 of 29/01/2015 English translation prepared by CSTB - Original version in French language General Part Nom commercial Trade name FM744 Famille de produit Product family Cheville métallique en acier inoxydable, à expansion par vissage à couple contrôlé, de fixation dans le béton non fissuré : diamètres M8, M10, M12 et M16 Torque-controlled expansion anchor, made of galvanized steel, for use in non-cracked concrete: sizes M6, M8, M10 and M12 Titulaire Manufacturer FRIULSIDER Via Trieste,1 I 33048 San Giovanni al Natisone (UDINE) ITALIE Usine de fabrication Manufacturing plants FRIULSIDER Via Trieste,1 I 33048 San Giovanni al Natisone (UDINE) ITALIE Cette evaluation contient: This Assessment contains 12 pages incluant 9 annexes qui font partie intégrante de cette évaluation 12 pages including 9 annexes which form an integral part of this assessment Base de l‘ETE Basis of ETA ETAG 001, Version April 2013, utilisée en tant que EAD ETAG 001, Edition April 2013 used as EAD Cette evaluation remplace: This Assessment replaces ATE 0 5 / 0 1 6 9 valide du 01/09/2010 au 31/08/2015 ETA-0 5 / 0 1 6 9 with validity from 01/09/2010 to 31/08/2015 Translations of this European Technical Assessment in other languages shall fully correspond to the original issued document and should be identified as such. Communication of this European Technical Assessment, including transmission by electronic means, shall be in full. However, partial reproduction may be made, with the written consent of the issuing Technical Assessment Body. Any partial reproduction has to be identified as such. European Technical Assessment ETA-0 5 / 0 1 6 9 169 English translation prepared by CSTB Page 2 of 12 | 2 9 / 0 1 / 2 0 1 5 Specific Part 1 Technical description of the product The Friulsider FM744 anchor in the range of M6 to M12 is an anchor made of galvanised steel which is placed into a drilled hole and anchored by torque-controlled expansion. The illustration and the description of the product are given in Annexes A. 2 Specification of the intended use The performances given in Section 3 are only valid if the anchor is used in compliance with the specifications and conditions given in Annexes B. The provisions made in this European technical assessment are based on an assumed working life of the anchor of 50 years. The indications given on the working life cannot be interpreted as a guarantee given by the producer, but are to be regarded only as a means for choosing the right products in relation to the expected economically reasonable working life of the works. 3 3.1 3.2 3.3 Performance of the product Mechanical resistance and stability (BWR 1) Essential characteristic Performance Characteristic tension resistance acc. ETAG001, Annex C See Annex C1 Characteristic shear resistance acc. ETAG001, Annex C See Annex C2 Characteristic tension resistance acc. CEN/TS 1992-4 See Annex C3 Characteristic shear resistance acc. CEN/TS 1992-4 See Annex C4 Displacements See Annex C5 Safety in case of fire (BWR 2) Essential characteristic Performance Reaction to fire Anchorages satisfy requirements for Class A1 Hygiene, health and the environment (BWR 3) Regarding dangerous substances contained in this European technical approval, there may be requirements applicable to the products falling within its scope (e.g. transposed European legislation and national laws, regulations and administrative provisions). In order to meet the provisions of the Construction Products Directive, these requirements need also to be complied with, when and where they apply. 3.4 Safety in use (BWR 4) For Basic requirement Safety in use the same criteria are valid as for Basic Requirement Mechanical resistance and stability. 3.5 Protection against noise (BWR 5) Not relevant. 3.6 Energy economy and heat retention (BWR 6) Not relevant. European Technical Assessment ETA-0 5 / 0 1 6 9 169 English translation prepared by CSTB 3.7 Page 3 of 12 | 2 9 / 0 1 / 2 0 1 5 Sustainable use of natural resources ( (BWR 7) For the sustainable use of natural resources no performance was determined for this product. 3.8 General aspects relating to fitness for use Durability and Serviceability are only ensured if the specifications of intended use according to Annex B1 are kept. 4 Assessment and verification of constancy of performance (AVCP) 1 According to the Decision 96/582/EC of the European Commission , as amended, the system of assessment and verification of constancy of performance (see Annex V to Regulation (EU) No 305/2011) given in the following table apply. 5 Product Intended use Metal anchors for use in concrete. For fixing and/or supporting to concrete, structural elements (which contributes to the stability of the works) or heavy units. Level or class ― System 1 Technical details necessary for the implementation of the AVCP system Technical details necessary for the implementation of the Assessment and verification of constancy of performance (AVCP) system are laid down in the control plan deposited at Centre Scientifique et Technique du Bâtiment. The manufacturer shall, on the basis of a contract, involve a notified body approved in the field of anchors for issuing the certificate of conformity CE based on the control plan. The original French version is signed by Charles Baloche Technical Director 1 Official Journal of the European Communities L 254 of 08.10.1996 European Technical Assessment ETA-0 5 / 0 1 6 9 9 English translation prepared by CSTB Page 4 of 12 | 2 9 / 0 1 / 2 0 1 5 5 Schemas of the assembled anchor and of the anchor in use: 1. 2. 3. 4. Screw Washer Cone Expansion sleeve Marking hef : effective embedment depth hnom : embedment depth h1 : drilling hole depth tfix : fixture thickness FM744 torque-controlled expansion anchor Product description Assembled and in-use anchor Annex A1 European Technical Assessment ETA-0 5 / 0 1 6 9 9 English translation prepared by CSTB Page 5 of 12 | 2 9 / 0 1 / 2 0 1 5 5 Assembled anchor: bolt and expansion sleeve Table 1: Dimensions Anchor type / marking hnom d D H [mm] [mm] [mm] [mm] FM744 Ø10 M6 40 6 10 FM744 Ø14 M8 50 8 FM744 Ø16 M10 60 FM744 Ø20 M12 80 tw Lscrew 9,5 1,6 50 14 13,5 1,6 60 10 16 14,5 2 80 12 20 18,5 2,5 90 hnom = overall anchor embedment depth in the concrete d = diameter of the threaded part of the screw D = external diameter of the expansion sleeve H = length of the cone tw = thickness of the washer Lscrew = length of the screw The marking is made on the sleeve. Table 2: Materials Part Designation Material 1 Screw Grade 8.8 ISO 898/1 2 Washer DIN 125/1 3 Cone Cold formed Medium carbon steel 4 Expansion sleeve Cold formed Low carbon steel Protection Galvanised ( 5 m) FM744 torque-controlled expansion anchor Product description Parts, materials and marking Annex A2 European Technical Assessment ETA-0 5 / 0 1 6 9 9 English translation prepared by CSTB Page 6 of 12 | 2 9 / 0 1 / 2 0 1 5 5 Specifications of intended use Anchorages subject to: Static and quasi-static loads. Base materials: Non-cracked concrete. Reinforced or unreinforced normal weight concrete of strength classes C20/25 at least to C50/60 at most according to EN 206: 2000-12. Use conditions (Environmental conditions): Structures subject to dry indoor conditions, indoor with temporary condensation. Design: The anchorages are designed in accordance with the ETAG001 Annex C “Design Method for Anchorages” or CEN/TS 1992-4-4 " Design of fastenings for use in concrete” under the responsibility of an engineer experienced in anchorages and concrete work. Verifiable calculation notes and drawings are prepared taking account of the loads to be anchored. The position of the anchor is indicated on the design drawings. Installation: Anchor installation carried out by appropriately qualified personnel and under the supervision of the person responsible for technical matters of the site. Use of the anchor only as supplied by the manufacturer without exchanging the components of an anchor. Anchor installation in accordance with the manufacturer’s specifications and drawings and using the appropriate tools. Effective anchorage depth, edge distances and spacing not less than the specified values without minus tolerances. Hole drilling by hammer drill. Cleaning of the hole of drilling dust. Application of specified torque moment using a calibrated torque wrench. In case of aborted hole, drilling of new hole at a minimum distance of twice the depth of the aborted hole, or smaller distance provided the aborted drill hole is filled with high strength mortar and no shear or oblique tension loads in the direction of aborted hole. FM744 torque-controlled expansion anchor Intended Use Specifications Annex B1 European Technical Assessment ETA-0 5 / 0 1 6 9 9 English translation prepared by CSTB Page 7 of 12 | 2 9 / 0 1 / 2 0 1 5 5 Table 3: Installation data concrete member thickness clearance hole diameter minimum spacing minimum edge distance hef dcut h1 tfix (*) Tinst hmin df smin cmin [mm] [mm] [mm] [mm] [Nm] [mm] [mm] [mm] [mm] M6 setting torque FM744 Ø10 M6 33.5 10 55 12 6 100 8 35 35 M8 fixture thickness FM744 Ø14 M8 41.0 14 65 15 15 100 10 40 40 M10 drill hole depth of diameter drill hole FM744 Ø16 M10 50.0 16 75 20 30 100 12 50 50 M12 Marking of the anchor embedment depth FM744 Ø20 M12 66.5 20 95 15 50 135 14 70 70 (*) : tfix value refers to standard screw 8.8 delivered with the expansion sleeve. The thickness of the fixture can vary by using different lengths of screws from same grade and same coating. FM744 torque-controlled expansion anchor Intended Use Installation parameters Annex B2 European Technical Assessment ETA-0 5 / 0 1 6 9 9 English translation prepared by CSTB Page 8 of 12 | 2 9 / 0 1 / 2 0 1 5 5 Table 4: Characteristic values for tension loads in case of static and quasi static loading for design method A acc. ETAG001, Annex C M6 * M8 M10 M12 29,3 46,4 67,4 Steel failure Characteristic resistance NRk,s [kN] Partial safety factor Ms1) [-] Characteristic resistance in non-cracked concrete C20/25 N0Rk,p [kN] Partial safety factor for non-cracked concrete Mp1) [-] 1,52) [-] 1,22 [-] 1,41 [-] 1,55 16,1 1,50 Pullout failure NRk,p = c x N0Rk,p C30/37 Increasing factor for NRK in concrete c C40/50 C50/60 6* 12 -* -* Concrete cone failure and splitting failure Effective embedment depth Partial safety factor for non-cracked concrete [mm] Mc = Msp1) [-] 1,52) [-] 1,22 [-] 1,41 [-] 1,55 C30/37 Increasing factor for NRK in concrete c C40/50 C50/60 Char. spacing Char. edge distance * hef 33,5 41 scr,N [mm] 101 123 150 200 splitting scr,sp [mm] 200 250 300 400 concrete cone ccr,N [mm] 50 62 75 100 splitting ccr,sp [mm] 100 125 150 200 -* pull-out failure is not a decisive failure mode for size M10 and M12. 2) 66,5 concrete cone * Use restricted to anchoring of structural components statically indeterminated 1) 50 In absence of other national regulations The value contains an installation safety factor 2 = 1.0 FM744 torque-controlled expansion anchor Annex C1 Design according to ETAG001, Annex C Characteristic resistance under tension loads European Technical Assessment ETA-0 5 / 0 1 6 9 9 English translation prepared by CSTB Page 9 of 12 | 2 9 / 0 1 / 2 0 1 5 5 Table 5: Characteristic values for shear loads in case of static and quasi static loading for design method A acc. ETAG001, Annex C M6 * M8 M10 M12 14,6 21,5 32,0 60 105 1,0 2,0 50 67 16 20 Steel failure without lever arm Characteristic resistance VRk,s [kN] Partial safety factor Ms1) [-] M0Rk,s [Nm] Ms1) [-] k [-] Mc1) [-] lf [mm] 34 41 Outside diameter of anchor dnom [mm] 10 14 Partial safety factor Mc 7,4 1,25 Steel failure with lever arm Characteristic bending resistance Partial safety factor 12 30 1,25 Concrete pry-out failure Factor in equation (5.6) of ETAG001, Annex C, § 5.2.3.3 Partial safety factor 1,0 1,0 1,52) Concrete edge failure Effective length of anchor under shear loading 1) 2) 1) In absence of other national regulations The value contains an installation safety factor [-] 1,5 2) 2 = 1.0 FM744 torque-controlled expansion anchor Annex C2 Design according to ETAG001, Annex C Characteristic resistance under shear loads European Technical Assessment ETA-0 5 / 0 1 6 9 9 English translation prepared by CSTB Page 10 of 12 | 2 9 / 0 1 / 2 0 1 5 5 Table 6: Characteristic values for tension loads in case of static and quasi static loading for design method A acc. CEN/TS 1992-4 M6 * M8 M10 M12 29,3 46,4 67,4 Steel failure Characteristic resistance NRk,s [kN] Partial safety factor Ms1) [-] Characteristic resistance in non-cracked concrete C20/25 N0Rk,p [kN] Partial safety factor for non-cracked concrete Mp1) [-] 1,52) [-] 1,22 [-] 1,41 [-] 1,55 16,1 1,59 Pullout failure NRk,p = c x N0Rk,p C30/37 Increasing factor for NRK in concrete c C40/50 C50/60 6* 12 -* -* Concrete cone failure and splitting failure * Effective embedment depth hef [mm] Factor for non-cracked concrete kucr [-] 10,1 Mc=Msp1) [-] 1,52) [-] 1,22 [-] 1,41 [-] 1,55 Partial safety factor for non-cracked concrete C30/37 Increasing factor for NRK in concrete c C40/50 C50/60 Char. spacing Char. edge distance 33,5 41 scr,N [mm] 101 123 150 200 splitting scr,sp [mm] 200 250 300 400 concrete cone ccr,N [mm] 50 62 75 100 splitting ccr,sp [mm] 100 125 150 200 -* pull-out failure is not a decisive failure mode for size M10 and M12. 2) 66,5 concrete cone * Use restricted to anchoring of structural components statically indeterminated 1) 50 In absence of other national regulations The value contains an installation safety factor 2 = 1.0 FM744 torque-controlled expansion anchor Annex C3 Design according to CEN/TS 1992-4 Characteristic resistance under tension loads European Technical Assessment ETA-0 5 / 0 1 6 9 9 English translation prepared by CSTB Table 7: Page 11 of 12 | 2 9 / 0 1 / 2 0 1 5 5 Characteristic values for shear loads in case of static and quasi static loading for design method A acc. CEN/TS 1992-4 M6 M8 M10 M12 7,4 14,6 21,5 32,0 60 105 1,0 2,0 43 62 16 20 Steel failure without lever arm Characteristic resistance Factor considering ductility Partial safety factor VRk,s [kN] k2 [-] 0,8 Ms1) [-] 1,25 M0Rk,s [Nm] Steel failure with lever arm Characteristic bending resistance Partial safety factor Ms 1) 12 30 [-] 1,25 Concrete pry-out failure Factor in equation (16) of CEN TS 1992-4-4, § 6.2.2.3 k3 [-] Mc1) [-] lf [mm] 40 36 Outside diameter of anchor dnom [mm] 10 14 Partial safety factor Mc Partial safety factor 1,0 1,0 1,52) Concrete edge failure Effective length of anchor under shear loading 1) 2) 1) In absence of other national regulations The value contains an installation safety factor [-] 1,5 2) 2 = 1.0 FM744 torque-controlled expansion anchor Annex C4 Design according to CEN/TS 1992-4 Characteristic resistance under shear loads European Technical Assessment ETA-0 5 / 0 1 6 9 9 English translation prepared by CSTB Page 12 of 12 | 2 9 / 0 1 / 2 0 1 5 5 Table 8: Displacements under tension loading M8 M10 M12 M16 [kN] 2,9 5,7 8,5 13,0 N0 [mm] 0,5 0,6 0,8 1,2 N∞ [mm] 0,6 0,6 0,8 1,2 M8 M10 M12 M16 [kN] 4,4 8,9 13,1 20,2 N0 [mm] 0,7 1,0 1,4 2,1 N∞ [mm] 0,7 1,0 1,4 2,1 M8 M10 M12 M16 [kN] 4,2 8,3 12,3 18,3 V0 [mm] 2,5 3,3 2,9 3,5 V∞ [mm] 3,75 (+0,7) 4,95 (+1,2) 4,35 (+1,2) 5,25 (+1,2) Tension load in non-cracked concrete C20/25 Displacement Tension load in non-cracked concrete C50/60 Displacement Table 9: Displacements under shear loading Shear load in non-cracked concrete C20/25 to C50/60 Displacement * Displacement : the table shows the deformation to be expected from the anchor itself, whilst the bracket value indicates the movement between the anchor body and the hole drilled in the concrete member or the hole in the fixture. Additional displacement due to annular gap between anchor and fixture is to be taken into account. FM744 torque-controlled expansion anchor Annex C5 Design Displacements Friulsider SpA DoP_fm744_rev.01 Declaration of Performance FM 744 via Trieste, 1 San Giovanni al Natisone (UD) Italy - ph. +39 0432 747911 www.friulsider.com - info@friulsider.com Anchor heavy 4 sectors made of zinc plated steel Intended use or uses of the construction product according to ETAG 001 p.1 and 2 Generic type Ba s e material Ma teri al Dura bility Loa ding Fi re Resistance Fi re Reaction Torque controlled expansion a nchor sleeve type Un-cra cked concrete C20/25 to C50/60 a cc. to EN 206-1 Steel zinc coated a cc. to EN ISO 4042 (bolt cl. 8.8 a cc. to EN ISO 898-1) Internal dry conditions Sta ti c a nd quasi-static NPD A1 a ccording to EN 13501-1 ETA-05/0169 i s sued by On the ba sis of Certi fi cate of Conformity 0679-CPD-0112 i ssued by Under Sys tem (AVCP) CSTB a pproval body nr.0679 ETAG001 p.1-2 CSTB noti fy body nr.0679 1 Declared performances according to ETA-05/0169 (ETAG 001 p.1 and 2) Design method ETAG001 Annex C ESSENTIAL CHARACTERISTICS PERFORMANCE Installation parameters d0 Nominal diameter of drill bit Minimum installation depth hnom Effective anchorage depth hef hmin Minimum thickness of the concrete member Tinst Nominal torque moment smin Minimum spacing cmin Minimum edge distance Tension Steel failure mode Tension Steel characteristic failure (cl. 8.8) NRk,s Partial safety factor for tension steel failure m,sN 1) Pull-out failure mode Tension characteristic load in un-cracked concrete C20/25 NRk,p,ucr Partial safety factor 2 Partial safety factor m,c 1) Critical spacing scr,N ccr,N Critical edge distance Increasing factor for concrete C30/37 c C30/37 Increasing factor for concrete C40/50 c C40/50 Increasing factor for concrete C50/60 c C50/60 Splitting failure mode scr,sp Critical spacing (splitting) ccr,sp Critical edge distance(splitting) Partial safety factor m,c 1) Displacement on Tension Load Service tension load in un-cracked concrete Nucr Short term displacement under tension load N0,ucr Long term displacement under tension load N∞,ucr Shear Steel failure mode VRk,s Shear Steel characteristic failure (cl. 8.8) Bending Moment characteristic failure (cl. 8.8) M0Rk,s Partial safety factor for shear steel failure m,sV 1) Shear Concrete Pry-out and and Edge failure mode k Factor equation (5.6) of ETAG, Annex C, § 5.2.3.3 Effective anchorage length lef Nominal diameter of anchor dnom Partial safety factor ( m,c=m,pr) m 1) Displacement on Shear Load Service shear load in concrete (cl. 8.8) V Short term displacement under shear load V0 Long term displacement under shear load V∞ 1) In absence of other national regulations; According to CPR 305/2011/EU 2) 2) M6 10 40 34 2) 100 6 35 35 M8 14 50 41 100 15 40 40 [kN] [-] 16 29 [kN] [-] [-] [mm] [mm] [-] [-] [-] 6 [mm] [mm] [mm] [mm] [Nm] [mm] [mm] M10 16 60 50 100 30 50 50 M12 20 80 67 135 50 70 70 46 67 1,5 2) 12 17,8 3) 27,3 3) 1,0 1,5 100 50 125 62 1,22 1,41 1,55 150 75 200 100 [mm] [mm] [-] 200 100 250 125 300 150 400 200 [kN] [mm] [mm] 2,9 0,5 0,6 M8 7,4 12 8,5 0,8 0,8 M12 21,5 60 13,0 1,2 1,2 M16 32,0 105 50 16 2,0 67 20 12,3 2,9 5,6 18,3 3,5 6,8 [kN] [Nm] [-] 1,5 [-] [mm] [mm] 34 10 5,7 0,6 0,6 M10 14,6 30 1,25 1,0 41 14 1,5 [-] [kN] [mm] [mm] 4,2 2,5 4,5 8,3 3,3 6,4 Use restricted to anchoring of structural components statically indeterminated; 3) Pull-out failure not decisive. pg.1/2 Friulsider SpA DoP_fm744_rev.01 We i nform you that Friulsider is classified i n the EC 1907/2006 Rea ch Directive as a Downstream -user of s ubstances. The product s upplied does not contain s ubstances classified as SVHC according to the Ca ndidate Li st in a concentration equal or greater than 0.1% (wei ght / weight). Arti cle 31 i s not a pplicable to the present product. The a bove performances a pply for the following a rticle numbers: d 4) M6 M8 M10 M12 L5) [mm] 40 50 60 80 tfix6) [mm] Ma rki ng FM-744 FM-744 FM-744 FM-744 * * * * M6 10 M8 14 M10 16 M12 20 Cod. (only anchor) 74400b10040 74400b14050 74400b16060 74400b20080 * t fix = L screw8.8 – L d 4) M6 M8 M10 M12 4) L5) [mm] 40 50 60 80 tfix6) [mm] 12 15 20 15 Nominal diameter of thread; Ma rki ng FM-744 FM-744 FM-744 FM-744 5) M6 10 M8 14 M10 16 M12 20 Cod. 74411b10040 74411b14050 74411b16060 74411b20080 Length of anchor; 6) Thickness fixture max of screw in use. The performances of the product identified by the above i dentification code a re in conformity with the declared performance. Thi s declaration of performance is i ssued under the sole responsibility of Friulsider SpA. Si gned for a nd behalf of the manufacturer by: Name and functions Place and date of issue Eng.Vittorio Pilla General Director San Giovanni al Natisone, 09-10-2013 According to CPR 305/2011/EU Signature pg.2/2