Mini - Project Idea Note

advertisement

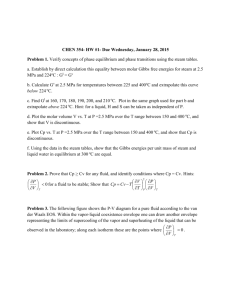

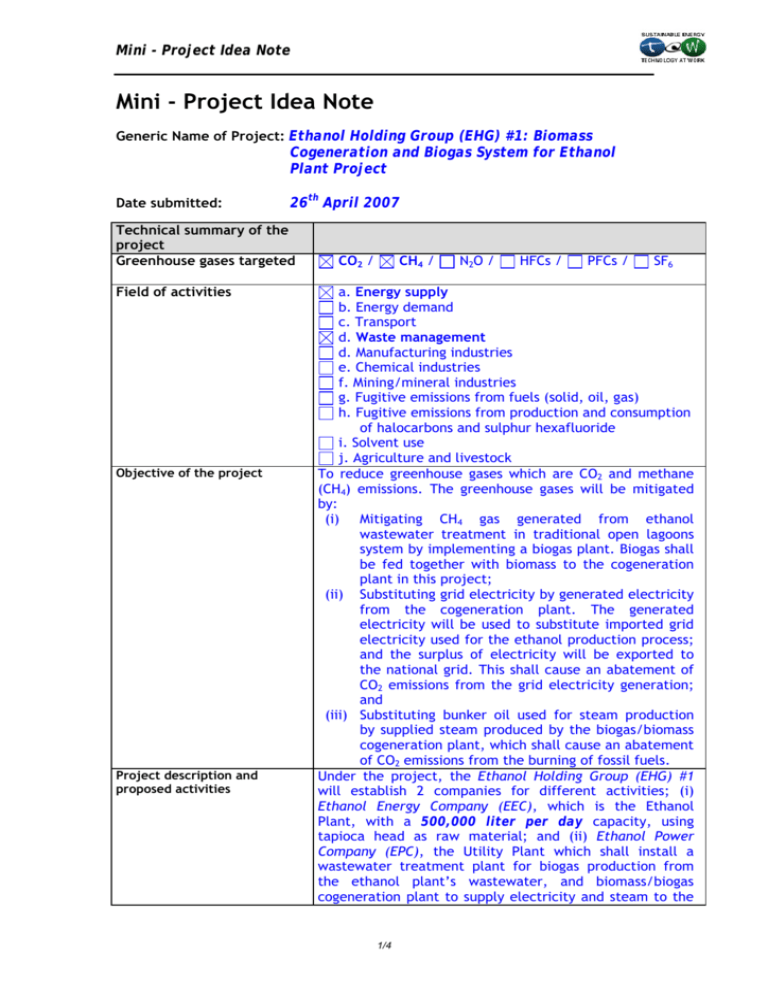

Mini - Project Idea Note Mini - Project Idea Note Generic Name of Project: Ethanol Holding Group (EHG) #1: Biomass Cogeneration and Biogas System for Ethanol Plant Project Date submitted: 26th April 2007 Technical summary of the project Greenhouse gases targeted Field of activities Objective of the project Project description and proposed activities CO2 / CH4 / N2O / HFCs / PFCs / SF6 a. Energy supply b. Energy demand c. Transport d. Waste management d. Manufacturing industries e. Chemical industries f. Mining/mineral industries g. Fugitive emissions from fuels (solid, oil, gas) h. Fugitive emissions from production and consumption of halocarbons and sulphur hexafluoride i. Solvent use j. Agriculture and livestock To reduce greenhouse gases which are CO2 and methane (CH4) emissions. The greenhouse gases will be mitigated by: (i) Mitigating CH4 gas generated from ethanol wastewater treatment in traditional open lagoons system by implementing a biogas plant. Biogas shall be fed together with biomass to the cogeneration plant in this project; (ii) Substituting grid electricity by generated electricity from the cogeneration plant. The generated electricity will be used to substitute imported grid electricity used for the ethanol production process; and the surplus of electricity will be exported to the national grid. This shall cause an abatement of CO2 emissions from the grid electricity generation; and (iii) Substituting bunker oil used for steam production by supplied steam produced by the biogas/biomass cogeneration plant, which shall cause an abatement of CO2 emissions from the burning of fossil fuels. Under the project, the Ethanol Holding Group (EHG) #1 will establish 2 companies for different activities; (i) Ethanol Energy Company (EEC), which is the Ethanol Plant, with a 500,000 liter per day capacity, using tapioca head as raw material; and (ii) Ethanol Power Company (EPC), the Utility Plant which shall install a wastewater treatment plant for biogas production from the ethanol plant’s wastewater, and biomass/biogas cogeneration plant to supply electricity and steam to the 1/4 Mini - Project Idea Note ethanol plant. Details of each company are as follow: • Ethanol Energy Company (EEC): To produce ethanol, V.R.M. green energy expects to buy 1,040,000 ton/year of tapioca head from nearby tapioca fields. The ethanol production process requires 8.6 MW of power demand, approximately 7 ton/hour of saturated steam at 7 bar(a), and approximately 80 ton/hour of saturated steam at 3 bar(a). Expected wastewater generation from the ethanol process is approximately 5,000 m3/day with an average COD of 50,000 mg/liter. • Ethanol Power Company (EPC): The wastewater of the ethanol plant shall be fed to the biogas plant, V.R.M. green power, which aims to produce approximately 78,800 Nm3/day of biogas (@ 65% CH4). Biogas and Biomass fuels, namely, tapioca rhizome, rice husk, decanter cake (from ethanol process), bagasse, and waste wood shall be supplied to the 20 MW-gross capacity cogeneration plant. The cogeneration plant shall supply 8.6 MW power to the ethanol plant, 5.4 MW for loads of the cogeneration plant and biogas plant, and the 6 MW surplus of electricity shall be exported to the national grid under the Very Small Power Producer (VSPP) scheme. Technology to be employed GHG emission reduction shall come from (i) the amount of Thailand’s grid electricity generation substituted, and which consists of the electricity required for the ethanol plant and the electricity exported to the grid, (ii) the amount of CH4 generated from traditional wastewater treatment in open lagoons with uncontrolled release of CH4 to the atmosphere substituted by a closed tank digester system, and (iii) the amount of substituted bunker oil used for producing steam supply to the ethanol plant. The technologies to be employed in this project is divided into 2 categories: (i) An anaerobic digester that shall be used to remove the organic material in the wastewater, which will reduce the Chemical Oxygen Demand (COD) and subsequently mitigate CH4 emissions from traditional treatment in open lagoons. A biomass/biogas thermal-steam cycle power plant, which comprises of steam boiler, extraction condensing steam turbine, and others. Boiler capacity is 65 bar(a), 490 deg C, 120 ton of steam/hour. Steam shall be supplied to a steam turbine generator to produce 20 MW-gross of electricity, and extracted steam at 7 bar(a) and 3 bar(a) shall be supplied to the ethanol plant. 2/4 Mini - Project Idea Note Location of the project Brief description of the location The project is located in Ratchaburi province, Thailand. of the project (Region and Country were the project will be implemented Expected environmental and social benefits Estimate of Greenhouse Gases abated (in metric tons of CO2equivalent) Socio-economic aspects What social and economic effects can be attributed to the project and which would not have occurred in a comparable situation without that project? The potential GHG-emission reduction is approximately 360,789 tCO2-equivalent/year, or 9,019,721 tCO2equivalent of project duration (estimated 25 years) The project activity will contribute to the sustainable development of Thailand in the following ways: • Enhance Thailand economic sustainability by reducing the country’s dependence on the use of fossil fuels for power generation, which now is dominated by natural gas, lignite and imported fuel oil; • The utilised biogas will reduce methane emission and thus decrease the impact on global warming, and the problem of bad odours caused by wastewater treatment in open lagoons will be mitigated; • Support the government policy in promoting the use of renewable energy; • Enhance Thailand’s economic efficiency through more efficient use of abundant agricultural residues, such as: tapioca rhizome, rice husk, bagasse, waste wood; • Employment opportunities will increase during the construction and operation phases of both ethanol plant and utility plant (biogas and cogeneration plant). Many supply-chain activities will be developed, for example, tapioca farmers, tapioca head supplier, biomass collectors and suppliers, transporters, plant operators, maintenance and service supplier, etc.; and, Improve stability of electricity supply in local areas PIN/PDD DeveloperIntermediary Name of the PIN/PDD Developer Dr. Thierry LEFEVRE, Managing Director Energy Economy Environment Consultants Co. Ltd. SLD Building (7B), 13 Soi Saladaeng 1, Rama IV Road, Silom Sub-district, Bangrak, angkok 10500, Thailand Tel: (662) 235-5817, (662).629.0912 Fax: (66 2) 236-9574 E-mail and web address, if any t.lefevre@eeec.co.th or t.lefevre@ceerd.net Expected schedule Earliest project start date Expected first year of CER delivery Project lifetime By 2007 2009 25 years 3/4 Mini - Project Idea Note Current status or phase of the project Identification and pre-selection phase Opportunity study finished Pre-feasibility study finished Feasibility study finalized Negotiations phase Contracting phase (mention what contracts) etc. 4/4