Computer Assisted 3D Analysis Tools for Forensic Applications

advertisement

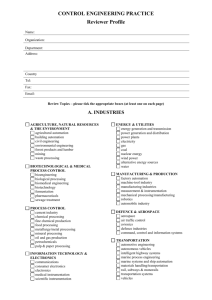

Computer Assisted 3D Analysis Tools for Forensic Applications Table of Contents Introduction __________________________________________________________3 Technical Expertise ___________________________________________________4 Case Study: Validation of Individuality of Tool-marks________________________5 Screwdrivers ________________________________________________________6 Tongue and Groove Pliers ______________________________________________7 Diagonal Cutters _____________________________________________________8 Bolt Cutters _________________________________________________________9 Aviation Snips ______________________________________________________10 Diagonal Wire Cutters ________________________________________________11 Sledgehammers _____________________________________________________12 Case Study: Firearms Evidence _________________________________________13 Cartridge Cases _____________________________________________________13 Bullets ____________________________________________________________14 Case Study: Virtual Comparison Microscope______________________________15 Credit Cards ________________________________________________________16 Nails ______________________________________________________________17 Staples ____________________________________________________________18 Drugs _____________________________________________________________19 About Intelligent Automation, Inc. (IAI) ___________________________________20 Intelligent Automation, Inc. -2- Computer Assisted 3D Analysis Tools for Forensic Applications Introduction Over the past 18 years, Intelligent Automation Inc. (IAI) has grown to become a successful and dynamic R&D company focusing on delivering complex technological solutions to the US Government and various commercial clients across a wide spectrum of scientific disciplines. During this period, a significant portion of IAI's research activities have focused on the forensic science arena. This has resulted in the field of forensics becoming one of IAI's core technology areas. In collaboration with government agencies such as the Department of Justice (DOJ), Federal Bureau of Investigation (FBI), United States Secret Service (USSS), National Institute of Standards and Technology (NIST), National Science Foundation (NSF), and Drug Enforcement Agency (DEA), IAI has developed specialized systems for the automated imaging, acquisition and comparison of firearms, tool-marks and drug-related forensic evidence. These systems exploit the topographical characteristics of the specimens in question. The acquired 3D data can assist forensic examiners in the objective assessment of similarity between specimens. IAI has successfully leveraged its extensive expertise in artificial intelligence, signal and image processing, statistical data analysis, data visualization, sensor system integration, testing and metrology to drive the development of technologies that can assist the forensic science community. Intelligent Automation, Inc. continues to explore and apply innovative technologies across diverse areas of forensic science research. These areas of research range from technological challenges related to fingerprint quality assessment and speaker identification to counterfeit credit card identification among others. Specialized systems built by IAI that effectively use 3D information from a bullet’s surface to improve the matching rate of automated search and retrieval systems Intelligent Automation, Inc. -3- Computer Assisted 3D Analysis Tools for Forensic Applications Technical Expertise Over the years, IAI has developed sophisticated Automated Comparison Systems designed to address real-world forensic problems in an objective and unbiased manner. These systems are typically composed of a number of specialized acquisition and processing components. Our work has resulted in several fundamental patents that have pioneered new approaches to forensic analysis, including for example the capture and use of 3D data. A major focus of our work has been to develop tools and techniques which lead to rigorous means to estimate the likelihood of erroneous identification. The work done by IAI over the past decade requires, among other things, very accurate 2D and 3D measurement of surfaces. As a result, IAI has developed sophisticated metrology tools to capture high resolution data. Over this period, we have also developed several advanced signal processing and pattern classification algorithms for pre-processing, normalization, and signature generation in order to correlate and statistically analyze data as depicted in Figure 1. This has allowed us to estimate the statistical probability of false positive and false negative identifications. IAI personnel have developed expertise in the design and development of Graphical User Interfaces (GUI) suitable to the requirements of forensic examiners. These intuitive and easy-to-use interfaces provide powerful capabilities to the forensic examiner to visualize, compare and verify the degree of similarity between any two specimens in question. In the following sections, we briefly present a few case studies undertaken by IAI in the field of forensic science. Various components of a generic Automated Comparison System Intelligent Automation, Inc. -4- Computer Assisted 3D Analysis Tools for Forensic Applications Case Study: Validation of Individuality of Tool-marks The ability to validate that a particular tool was used to create a tool-mark found at a crime scene is of significant importance for the presentation of evidence in court. Such association is based on the fact that the microscopic marks found on the tool's working surface (and transferred to the tool-mark) are sufficiently unique to enable a one-to-one association between the tool and the tool-mark. Intelligent Automation Inc. has undertaken a study to validate the assertion that a one-to-one identification between a tool and the tool-marks created by the tool is possible. During the course of this study, a number of different sets of tool-marks were created on various types of media using a variety of tools. This study has resulted in the development of a highly successful 3Dbased automated tool-mark comparison/analysis system. A variety of tools whose working surfaces are manufactured using different techniques were used for creating sample tool-marks Impressed tool-marks created by same bolt-cutter (rows) and different bolt-cutters (columns) Intelligent Automation, Inc. Matching alignment for 2 impressed tool-marks made by the same bolt cutter -5- Computer Assisted 3D Analysis Tools for Forensic Applications Screwdrivers The working surface of the screwdrivers used in this study was manufactured through stamping. Tool-marks were created on (i) lead sheet and (ii) aluminum sheets. The set of tool-marks created on lead sheets consisted of “push” and “pull” striations by the screwdriver, and an impression of the tip. Tool-marks were created at 3 different angles of attack on the lead sheets. These tool-marks were created to study how the variation of the screwdriver angle of attack affects the creation of striations on the tool-marks. Tool-marks created on aluminum sheets consisted of "push" striations for a single working surface at a defined angle of attack. These tool-marks were used to study how the media on which the tool-mark is created affects the individuality of the tool-mark and the validation of one-to-one association between the tool-mark and the tool. Striations Impressions Creation of screwdriver tool-marks Screwdriver Striations 3D profile of a striated screwdriver tool-mark Intelligent Automation, Inc. Sample screwdriver tool-marks on lead sheet Screwdriver Impression 3D profile of an impressed screwdriver tool-mark -6- Computer Assisted 3D Analysis Tools for Forensic Applications Tongue and Groove Pliers The working surface of the tongue and groove pliers used in this study was manufactured by broaching. Tool-marks were created on (i) lead rope, (ii) brass pipes and (iii) galvanized steel pipes. The tool-marks on lead rope included an impressed tool-mark corresponding to a single tooth of the tongue and groove pliers, and a striated tool-mark corresponding to the rotation of the tool on the lead rope. Tool-marks created on brass and galvanized steel pipes consisted of striations formed as a result of the movement of the jaws of the pliers on the pipe’s surface. The same set of tongue and groove pliers were used to make the tool-marks on both the brass pipes and the galvanized steel pipes. The premise for creating tool-marks on both brass pipes and galvanized steel pipes was to compare striated tool-marks created by the same tool on different materials of interest. Creation of a tongue & groove plier’s tool-mark Tongue & Groove Plier Striations 3D profile of a striated tongue & groove plier tool-mark Intelligent Automation, Inc. Tongue & groove plier tool-marks on steel pipe Tongue & Groove Plier Impression 3D profile of an impressed tongue & groove plier tool-mark -7- Computer Assisted 3D Analysis Tools for Forensic Applications Diagonal Cutters The working surface of the diagonal cutters used in this study was manufactured by filing. Toolmarks were created on (i) lead sheets and (ii) solid core copper wire. Tool-marks on lead sheets corresponded to the angled walls created by the pinching action of the working surfaces as it cut through the lead sheets. Tool-marks on solid copper wire were made by cutting the copper wire. For each diagonal cutter, the set of impressed tool-marks was created by cutting copper wire at the same position on the jaw of the diagonal cutter. The basis for selecting solid core copper wire for creation of tool-marks was to select a media that is commonly associated with the use of the tool. Working surface of the diagonal cutter Creation of a tool-mark using a diagonal cutter Diagonal Cutter Impression Sample diagonal cutter tool-mark on solid core copper wire Intelligent Automation, Inc. 3D profile of an impressed diagonal cutter tool-mark -8- Computer Assisted 3D Analysis Tools for Forensic Applications Bolt Cutters The working surface of the bolt cutters used in this study was manufactured through milling. Tool-marks were created on (i) lead sheet and (ii) galvanized steel chain-link fence. Tool-marks created on lead sheet consisted of impressions that corresponded to the bottom of the “valleys” created by the pinching action of the working surfaces. Tool-marks on galvanized steel chain-link fence were created by cutting the media at the same place on the bolt cutter's jaw for each tool. The reason for selecting galvanized steel chain-link fence as the appropriate media for bolt cutters was to use a media that is typically cut using a pair of bolt cutters under real-life circumstances. Working surface of a bolt cutter Creation of a tool-mark using a bolt cutter Bolt Cutter Impression Bolt cutter tool-mark created on galvanized chain link fence Intelligent Automation, Inc. 3D profile of an impressed bolt cutter toolmark -9- Computer Assisted 3D Analysis Tools for Forensic Applications Aviation Snips The working surface of the aviation snips used in this study was manufactured through grinding. Tool-marks were created on (i) standard steel and (ii) cold-rolled steel roofing sheets. The set of tool-marks on standard steel paper clips consisted of impressed tool-marks. The impressions on the side of the tool-mark showed a “tooth like” formation due to the serrations found on the side of the aviation snip blades. In order to make a comparison of these tooth-like features it was necessary to be able to repeatedly acquire a given tooth. For this reason, the toolmarks were created in a way that would isolate surface features created by a single serration. Aviation snips tool-marks were also created on cold-rolled steel roofing sheets. The premise behind selecting cold-rolled steel roofing sheets as the media for creation of tool-marks was that the cold-rolled steel roofing sheets are commonly found on the outer enclosures of buildings frequently, and aviation snips are used to cut through such outer enclosures. Working surface of an aviation snip Creation of a tool-mark using aviation snips Aviation Snip Impression Aviation snip tool-mark created on cold-rolled steel roofing sheets Intelligent Automation, Inc. 3D profile of an impressed aviation snip toolmark - 10 - Computer Assisted 3D Analysis Tools for Forensic Applications Diagonal Wire Cutters The working surface of the diagonal wire cutters used in this study was manufactured through grinding. Impressed tool-marks were created on the electrical contacts of rectifier diodes that had been soldered to printed circuit boards. The electrical contacts are made of steel with a coating of tin and lead. In order for the tool-marks to be created, the rectifier diodes were axially mounted and soldered on the boards. For each diagonal wire cutter, the set of impressed tool-marks were created by cutting the soldered rectifier electrical contacts at the same position on the diagonal wire cutter’s jaw of interest. Working surface of a diagonal wire cutter Creation of a tool-mark using a diagonal wire cutter Diagonal Wire Cutter Impression Diagonal wire cutter tool-mark created on soldered rectifier electrical contacts Intelligent Automation, Inc. 3D profile of an impressed diagonal wire cutter tool-mark - 11 - Computer Assisted 3D Analysis Tools for Forensic Applications Sledgehammers The working surface of the sledgehammers used in this study was manufactured by a lathe. The set of tool-marks for sledgehammers consisted of striated tool-marks on lead sheets. The toolmarks were created by imparting a glancing blow to the lead sheet using the sledgehammer face of interest. Working surface of a sledgehammer Creation of a tool-mark using a sledgehammer Sledgehammer Striations Sledgehammer tool-mark created on lead sheet Intelligent Automation, Inc. 3D profile of a striated sledgehammer tool-mark - 12 - Computer Assisted 3D Analysis Tools for Forensic Applications Case Study: Firearms Evidence Cartridge Cases Intelligent Automation Inc. has undertaken a study to examine the markings imprinted onto cartridge cases as a result of firing a weapon. Often the cartridge case is the most important forensic specimen in the identification of weapons, as bullets are commonly deformed by impact. When a firearm is loaded and fired, mechanisms in the firearm come in contact with the cartridge case. These mechanisms impart impressions and striations on the cartridge case that are unique to the firearm. Some of the most important marks that can be used for identification of cartridge cases are breech face impressions, firing pin impressions, ejector and extractor marks. Firearm examiners exploit the fact that characteristics produced by a firearm are unique and can be used for the firearm identification. A cartridge case holder devised by IAI 3D topography of a breech face impression 3D topography of an ejector mark 3D topography of a firing pin impression Intelligent Automation, Inc. - 13 - Computer Assisted 3D Analysis Tools for Forensic Applications Bullets Intelligent Automation, Inc. has undertaken a statistical study on the uniqueness of the striations found on bullets fired by the same gun. The purpose of this study is to develop objective standardized procedures to determine whether a given evidence bullet was fired by a suspect gun and to validate these procedures through extensive statistical testing. These procedures are founded on well-established scientific principles and should therefore be verifiable and repeatable. Through extensive research, IAI has obtained valuable results associated with identification criteria for the individuality of guns and for gun-to-bullet comparisons. These criteria have been effectively tested in numerous experiments including sets of consecutively manufactured barrels. Results have demonstrated the effect of barrel wear and the effect of comparisons across different types of ammunition. This statistical study has significant implications not only for the law enforcement community, but also for the justice administration community. A cross-sectional view of a bullet’s surface Intelligent Automation, Inc. 3D profile of a land impression - 14 - Computer Assisted 3D Analysis Tools for Forensic Applications Case Study: Virtual Comparison Microscope Intelligent Automation, Inc. has developed a visualization tool called a “Virtual Comparison Microscope”. The Virtual Comparison Microscope is a Windows-based, user-friendly software tool that allows the firearms/tool-marks examiner to verify the degree of similarity between two specimens in question. The Virtual Comparison Microscope was designed to emulate the operation of the conventional comparison microscope. The Virtual Comparison Microscope is capable of rendering a 2D view of the 3D surfaces in a manner similar to that of the conventional comparison microscope. It enables the user to translate and rotate one specimen with respect to the other, align and overlap them, modify illumination conditions, zoom in and out, adjust the point of view of the user, and to create a split image on the screen to demarcate one image from the other. Furthermore, the Virtual Comparison Microscope provides advanced visualization and signal processing capabilities that are unavailable to real comparison microscopes. The software provides functionality for performing various types of data processing such as outlier identification, interpolation, filtering, histogram equalization, and surface leveling that may assist in the comparison of specimens. Other unique characteristics of the Virtual Comparison Microscope include its ability to simulate any material or “palette” which may be useful to the user as well as adjustment of the angle of incidence of the light and the light intensity that can assist in emphasizing certain features in the 3D images for better visualization. 2 diagonal cutter impressions aligned adjacent to each other using the virtual comparison microscope Intelligent Automation, Inc. 2 bolt cutter impressions automatically aligned for matching comparison by the virtual comparison microscope - 15 - Computer Assisted 3D Analysis Tools for Forensic Applications Credit Cards Intelligent Automation Inc. has undertaken a study to investigate whether a one-to-one correspondence exists between a credit card and the machine that performed embossing on the credit card. Typically, dies stamp information on the credit card such as the credit card number and name of the credit card owner. This result in impressions being imparted on the surface of the credit card that are unique to the die. In some cases of fraud, an embossing machine is used to imprint a legitimate credit card number obtained illegally onto blank credit cards. Frequently, impressions exist within a credit card's raised surfaces that are hard to access through conventional means. Thus, it is extremely difficult to identify unique features in the embossed character which would link the credit card to a specific embossing machine. Intelligent Automation, Inc.’s acquisition and processing technology enables the acquisition, detection and statistical analysis of unique microscopic impressions present on the surface of credit cards as a result of the process of embossing. These microscopic impressions can help assist in identifying the origin of a credit card and in determining if two or more credit cards in question share the same origin. Such an analysis can result in detection of counterfeit credit cards and also the identification of the machine used for embossing. The preliminary results of this study demonstrate that the acquisition of high resolution 3D data can provide a means to identify the origin of a credit card. Acquisition of such 3D data presents an opportunity to validate the degree to which a one-to-one identification exists between a credit card and the die that embossed the alphanumeric characters on it. Similar microscopic characteristics are seen through the Virtual Comparison Microscope when the same embossed character is compared in 2 sample credit cards Intelligent Automation, Inc. - 16 - Computer Assisted 3D Analysis Tools for Forensic Applications Nails Intelligent Automation Inc. has undertaken a study to analyze the feasibility of identifying nails manufactured by the same machine. The matching of nails is possible because machines used in their manufacturing leave unique tool-marks. Examination of the sample nails has revealed the presence of characteristics that are unique to the nails manufactured by the same machine. Therefore, nails that share the same tool-marks allow them to be associated with a particular machine. A pair of nails having similar tool-marks as seen in the Virtual Comparison Microscope Intelligent Automation, Inc. - 17 - Computer Assisted 3D Analysis Tools for Forensic Applications Staples Intelligent Automation Inc. is investigating whether used staple pins bear microscopic characteristics that can enable their association to a specific desk stapler. The stapling process results in features being transferred from the stapler to the staple pin. When these microscopic marks were acquired and analyzed, preliminary results demonstrated that the microscopic marks present on the staple pins could allow for a one-to-one association between the stapler and the tool-marks imparted on the staple pin. A pair of staple pins that were matched based on the microscopic characteristics imparted by the working surfaces of the desk stapler on the staple pins Intelligent Automation, Inc. - 18 - Computer Assisted 3D Analysis Tools for Forensic Applications Drugs Intelligent Automation Inc. has developed a specialized imaging system for the automated imaging and acquisition of such drug related forensic evidence. This system was developed for the Drug Enforcement Administration (DEA) with this need in mind. It has the capability of acquiring high-resolution 2D images of small to medium size objects under a variety of calibrated lighting conditions (side lighting, and ring lighting), and to store these images in a database for future comparison/reference. 3D profile of the letter “Y” imprinted on a Bayer capsule Intelligent Automation, Inc. IAI’s developed system with the insets showing a close up of the sensor and the acquisition station - 19 - Computer Assisted 3D Analysis Tools for Forensic Applications About Intelligent Automation, Inc. (IAI) Intelligent Automation, Inc. (IAI) is a woman owned firm founded in 1987 by Drs. Leonard and Jacqueline Haynes. Since its inception, IAI has expanded to an organization of over 90 technical staff housed in Rockville, Maryland, USA. IAI is led by Chief Executive Officer, Joseph E. Schwartz, President Leonard Haynes, Executive Vice President Jacqueline Haynes, and by an outstanding group of senior scientists, engineers, and managers who direct our technical and administrative efforts. Historically, much of our research has been funded by US Government Small Business Innovation Research (SBIR) contracts and Broad Agency Announcements (BAA). IAI's success in the SBIR program is reflected in its 2000 selection to receive the prestigious Tibbetts Award from the Small Business Administration for excellence in technology research. In recent years the company has evolved to become a developer of productized services and technology and an important R&D provider to major first tier integrators including BAE Systems, Boeing, CSC, Honeywell, Lockheed Martin, Motorola, Northrop Grumman and Raytheon. Intelligent Automation, Inc. is very effective at developing a technology from the concept stage through design, building and testing of a prototype system. Our basic approach to commercializing our technology is to team with partners who have existing products, a strong marketing position and capability, and a reputation as a producer of related products. IAI's technologies in the marketplace today include: 2 and 3 dimensional forensics imaging equipment used for matching bullets; platforms and tools for development of agent-based systems; high precision machine tools using a hexapod-configured device; tools for fault diagnosis and prognosis in complex systems; ad hoc mobile network protocols; and assistive learning devices for children with learning disabilities. Intelligent Automation, Inc. continues to maintain its core focus as an R&D company responding to the complex technological requirements of our Government and commercial clients. We continue to aggressively seek partners to assist in the commercialization of our technology, for current and new market niches. Please do not hesitate to contact us if you need assistance in addressing a technological need, or believe our technology can make an important contribution to your service or product line. For additional information, please contact: Dr. Benjamin Bachrach, Vice President Intelligent Automation, Inc. 15400 Calhoun Drive, Suite 400 Rockville, MD 20855 United States Phone: (301) 294-5237 Fax: (301) 294-5201 Email: bach@i-a-i.com Intelligent Automation, Inc. - 20 -