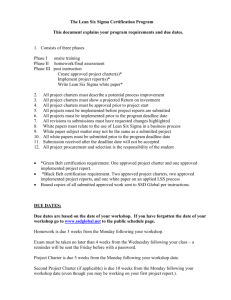

Six Sigma Green Belt Certification

advertisement

Six Sigma Green Belt Certification Self-Paced Internet Course Course Fee: $1295/$1445 (member/non-member) Highlights: This is a self-paced, subject specialist, facilitated course. There are reading materials, assignments, quizzes, and a green belt project. Participants spend an average of 15 hours per week towards reading, understanding, interacting with the facilitator, answering the assignments and quizzes. At the end of the course, the participants will be issued a Proficiency Certificate based on the performance during the course. Overview: 1. CMI’s Six Sigma Green Belt Certification Course gives you the tools and techniques essential to be an effective member of the Six Sigma Green Belt Teams. 2. This course focuses on effective data collection and covers the ‘Define’, ‘Measure’, ‘Analyze’, ‘Improve’ and ‘Control’ (DMAIC) phases of Six Sigma methodology, with special reference to Foundry Processes. 3. Participants to this course will learn how to provide data collection support to Black Belts and also how to fulfill the project leader’s role on small Green Belt foundry projects. 4. Using various exercises, the participants will have an opportunity to learn when, why and how the basic Six Sigma tools are used to identify and minimize the variation in foundry processes After completion of this course, you will be able to: 1. Identify and measure critical customer requirements. 2. Identify and collect relevant data. 3. Lead project teams through the DMAIC process improvement methodology. 4. Use the basic statistical tools and techniques for defect elimination and process simplification. 5. Use Chart Runner statistical software to perform statistical analysis. 6. Turn data into information and information into knowledge to make process improvements. 7. Effectively support Black Belts on Six Sigma Foundry projects. Text Book: CSSGB Primer (Green Belt) Published by Quality Council of Indiana Software: SigmaXL from SigmaXL Company Both the text book and the software will be provided by CMI to the registered candidates for this course. Grading Criteria: Discussion Forum: 30 points 5 Quizzes: 25 points 1 Final Exam: 20 points 5 Assignments: 50 points Six Sigma Green Belt Project Report: 75 points Total: 200 points **You must earn at least 150 of 200 possible points to receive the Green Belt Certification.** Who Should Attend: Supervisors, Managers, Inspectors, Production and Quality Control personnel. There is no certifying body for Six Sigma Certifications. It is up to the individual company to determine what a qualified training program consists of. The American Society for Quality (ASQ) has developed a body of knowledge (BOK) to attempt to standardize green belt training. The Quality Council of Indiana developed a Primer to support the training of this BOK. This course uses that Primer and the ASQ BOK as the curriculum basis for the course. Course Syllabus: Week 1: 1. OVERVIEW 1.1 Introduction to Six Sigma 1.2 Six Sigma Metrics 1.3 Financial benefits of Six Sigma 1.4 Introduction to Statistics Software “SigmaXL” Week 2: 2. DEFINE 2.1 Project Scope 2.2 Project Charter 2.3 Pareto Diagrams 2.4 SIPOC Diagram 2.5 Rolled Throughput Yield 2.6 Voice of Customer 2.7 Critical To Quality 2.8 Metrics Selection 2.9 Green Belt Project Selection Week 3: 3. MEASURE 3.1 Flow charts 3.2 Process Mapping 3.3 Process Inputs and Outputs 3.4 Types of Data 3.5 Measurement Methods 3.6 Gage R&R 3.7 Understanding variation 3.8 Measuring Process Capability 3.9 Green Belt Project Progress Week 4: 4. ANALYZE 4.1 Histograms 4.2 Scatter diagrams 4.3 Box Plots 4.4 Cause and Effect Diagrams 4.5 Affinity Diagrams 4.6 Multi-Vari Analysis 4.7 Modeling Relationships between variables 4.8 Hypothesis Testing 4.9 Analysis of Variance Week 5: 5. CONTROL 5.1 Statistical Process Control – SPC 5.2 Developing a Process Control Plan 5.3 Green Belt Project Progress Week 6: 6. IMPROVE 6.1 Brainstorming 6.2 Multi-Voting 6.3 Design of Experiments (DOE) 6.4 Failure Mode and Effects Analysis (FMEA) 6.5 Green Belt Project Completion Course Instructors: Dr. Hathibelagal Roshan is the president of Intellectual Capital Exchange LLC, a consulting company specializing in Knowledge Management, Quality Management Systems and E-Training. Dr. Roshan is a graduate in Mechanical Engineering, holds a Masters Degree in Foundry Science and Engineering and a Ph.D. degree in Metallurgy. Previous professional experience includes 27 years of teaching and research as a Professor and 10 years of management in industry as Director of Quality and Technology. Dr. Roshan is actively associated with AFS and is the recipient of the Award of Scientific Merit in 2001, the Thomas W. Pangborn Gold Medal in 2007, and the CMI Director’s Award in 2007. Shabana Roshan graduated in Business Administration with a major in Management Information Services from the University of Wisconsin Milwaukee in 1998. She has served as Internet Systems Developer, Senior Application Engineer Consultant, Senior e-Business Solutions Architect and Domino Architect in major consulting and financial institutions in Milwaukee since 1998. She obtained Six Sigma Black Belt Certification from the University of Wisconsin, Milwaukee in 2005. SigmaXL Software – Minimum Requirements (PC) Computer and processor: 500 megahertz (MHz) processor or higher. Memory: 512 megabytes (MB) of RAM or greater. Hard disk: 70 MB of available hard-disk space. Drive: CD-ROM or DVD drive. Display: 1024x768 or higher resolution monitor. Operating system: Microsoft Windows XP with Service Pack (SP) 3¹, or later operating system. Microsoft Excel version: Excel 2003, Excel 2007, Excel 2010², and Excel 2013² with latest service packs installed. th Important: As of April 8 , 2014, Excel 2003 will no longer be supported due to its upcoming Support Lifecycle End Date. AntiVirus: If you are using Symantec Endpoint Protection, you must be using version 11.0.6300 or higher. See the Symantec article here for more information. If you are not on 11.0.6300 or higher, see our help desk article for detailed instructions on upgrading. Note: Users must have administrative rights to install SigmaXL. ¹Microsoft has discontinued support for Windows Vista and XP unless all service packs are installed. ²Office 2010 and 2013 are 64-bit supported, but they require a unique setup file. If you have Office 64-bit, please let us know at the time of purchase. SAMPLE COURSE WEBSITE SAMPLE CASE STUDY DEFINE D M A I C Lead Time to Supply Castings Voice of Customer: You are a supplier that is capable of supplying the castings to meet our quality requirements but you are not able to supply parts when we need them most. Problem Statement: The current lead time to supply new castings is 8 weeks Business Case: Variation in delivery times affects the customers assembly schedule and adversely reflects on customer satisfaction Goal: To reduce the lead time average to six weeks or less Process Map Order is received Mold Date Pour Date Shake out Date Staging Date Shipping Date Time Date of order Six Sigma Green Belt Certification Date of promise Date of delivery Defect Six Sigma Green Belt Certification – Sample Chart