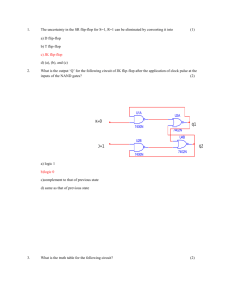

Fundamentals of the Electronic Counters

advertisement