View Full Text-PDF

advertisement

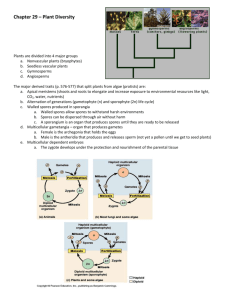

Int.J.Curr.Microbiol.App.Sci (2013) 2(10):506-515 ISSN: 2319-7706 Volume 2 Number 10 (2013) pp. 506-515 http://www.ijcmas.com Original Research Article Wet-heat inactivation of bacterial endospores in packaged fruit juices A.A.Brooks* Department of Microbiology, University of Calabar, Nigeria *Corresponding author ABSTRACT Keywords Bacterial endospores; Inactivation; Fruit juices; Thermal resistance. Thermal resistance of bacterial endospores was evaluated at different temperature regimes using wet-heat inactivation process. This was with the view to determining the thermal inactivation characteristics of bacterial spores recovered from selected packaged fruit juices. The bacterial strains recovered were Bacillus subtilis K16, Bacillus coagulans B74, Bacillus cereus Y28B, Clostridium perfingens T20 and Clostridium sporogenes A63. The success of the inactivation process was determined by the ability of the inactivated spores to germinate and form colonies. The decimal reduction times (D - values) for spores from strains K16, B74, Y28B, T20 and A63 were 2.20, 1.78, 2.32, 2.16 and 2.0 minutes at 650C, 750C, 850C and 950C respectively. The Z values were 7.40C, 8.50C, 6.80C, 7.60C and 8.70C respectively. There were high variations in the heat resistance amongst the five spore crops studied, in the order B74>T20> A63>K16>Y28B. There was a perfect correlation between the process temperature and the D-values with high correlation coefficients. The linear regression analysis of the data for all the strains fitted into the linear model Y=a + b x. More than 75.0% of the spores from Y28B were inactivated within 30 minutes of heat treatment at 650C. Spores from other strains exhibited marked heat resistance at the different temperature regimes tested. Surviving sub population of spores were observed after heat treatment for 30 minutes at all temperatures tested. Therefore, temperature higher than 950C may be required to inactivate bacterial spores in fruit juices. Introduction A wide variety of fruit juices are produced and consumed globally. Fruit juices are rich in vitamins and they supply the human body with essential precursors for effective metabolic processes. They are usually consumed without much regard to their microbiological status and safety because fruit juices are not often considered as high risk products. Although some of the fruit juices available in world 506 markets are terminally pasteurized and are therefore expected to contain no microbial contaminant, quite a number of them are either not subjected to thermal and other conventional treatments or are inadequately treated. Such untreated or inadequately treated products may be microbiologically unfit for drinking as they may contain pathogenic bacteria such as Escherichia coli 0157:H7 and Int.J.Curr.Microbiol.App.Sci (2013) 2(10):506-515 Salmonella species that can cause serious illnesses (Walner et al., 2006). Some of these bacteria can be quite resistant in acidic conditions and survive for a long period in acidic environment provided by the juices. Their germination and outgrowth often cause substantial problems such as spoilage, lower quality and potential risk of food poisoning outbreaks among consumers. Fruit juices have been reported to be contaminated by spore forming bacteria Alicyclobacillus acidoterrestris (Silva et al., 2012) and Bacillius anthracis (Leishman et al., 2010). Bacterial spores are more resistant to heat and other preservation treatments than the vegetative cells. Fruits juice industries still rely largely on the use of preservative and or thermal treatment such as pasteurization and ultra high temperature (UHT) processes to produce safe fruit drinks. According to Mustafa et al. (2010), these processes depend on both temperature of exposure and the time required to accomplish the required destruction rate. In order to preserve the nutritional and organoleptic qualities of the fruit juices, the heat treatment period is usually brief and the time is not enough to kill a good proportion of the bacterial spores. The results of the investigation conducted by Safe Food Rapid Response Network in Colorado State University, USA, revealed that some cases of out breaks of food borne illnesses in USA were linked to the consumption of unpasteurized fruit juices. For example, the 1996 multi state outbreak of E. coli infection in USA due to the consumption of untreated apple juice; an outbreak of Cryptosporidium infection in 2003 due to the drinking of inadequately treated apple cider and the outbreak of Salmonella infection in 2005 as a result of the consumption of inadequately treated orange juice labeled as fresh squeezed. In Nigeria cases of food borne illnesses arising from the consumption of contaminated fruit juices abound but there is no reliable epidemiological estimate. To date, no precise and consistent data exists, hence it is difficult to assess the impact of fruit juice related illnesses on the Nigerian population. However, the country over the years has been grappled with the problem of food borne illnesses with their attendant social, economic and health implications (Ifenkwe, 2012). Inactivation of bacterial spores required high temperature and long heating time. Although spore dormancy and associated resistance are very stable, these properties are easily lost during inactivation. Therefore, proper spore inactivation is essential for the production of safe and quality fruit juices. Silva et al. (2012) reported on bacterial spore inactivation at 45oc using high pressure processing while Ramirez-lopez (2006) reported on wet heat inactivation of bacterial spores from wheat offals. There is no report (to the knowledge of the author) on wet-heat inactivation of bacterial endospores recovered from fruit juices sold in Nigeria, hence this study. One of the commonest contaminants of fruit juices are the bacterial endospores, which usually have access to the drink from outside the fruits at the manufacturing stage, especially when such drinks are produced under unhygienic conditions. The anoxic environment provided by packaging favours germination and growth of the endospores and liberation of toxins into the juice. Fruit juices are often sealed and terminally pasteurized and are supposed to be 507 Int.J.Curr.Microbiol.App.Sci (2013) 2(10):506-515 microbiologically stable. However, owing to high incidence of fruit juice related illnesses in Nigeria, it is justifiable to ascertain: surfaces of the packages were properly disinfected with methylated spirit. Contents were properly mixed by shaking manually. Thereafter the packages were aseptically opened and 1.0ml of each fruit juice was used to perform serial dilution in ¼ strength of Ringer solution. One milliliter of the diluted cells was inoculated in brain-heart infusion (BHI) broth and incubated at 55oC for 2-5 days. Reinforced clostridial medium was employed for isolation and enumeration of anaerobic spore-forming bacteria using pour plate technique, while aerobic spore formers were enumerated on brain-heart infusion agar. If the pasteurization temperature and exposure time usually employed in fruit juice industries are enough to adequately kill the bacterial endospores in the finished products, and (ii) if the manufacturers of fruit juices have complied with the microbiological standards specified by ICMSF for fruit juices. This study therefore is aimed at evaluating the thermal resistance of bacterial spores in packaged fruit juices by wet-heat inactivation process at different temperature regimes. Identification of spore forming bacteria The spore forming bacteria isolated from the fruit juices were identified using the methods of Oranusi et al. (2012) and Kort et al., (2005), assisted by the identification scheme outlined in Bergey s Manual of Systematic Bacteriology (Holt et al., 1994). Materials and Methods Sample collections Fifty samples of fruit juices, comprising ten each from different packaged Chivita, Five alive, Dansa. Tampico and Frutta were purchased randomly from different super markets across Southern Nigeria. The packages of the fruit juices were visually examined for any defect such as bloating, leakage and physical damage. Other information on the packages recorded included manufacture and expiry dates, batch numbers, National Agency for Food and Drug Administration and Control (NAFDAC) numbers, manufacturers addresses, preservatives used and composition of the fruit juices. The samples were properly labeled and taken to the laboratory for analysis. Preparation of bacterial endospores About 250ml of broth cultures of the different spore forming bacteria were prepared in 500ml-shake flasks at 150 rpm at 37oC. The flasks contained mineral salt medium initially described by Neidheart et al., (1974) with some modifications. The pH of the medium was adjusted to 7.6 with 1N KOH. Spores were harvested after 4 days of incubation at 37oC and purified by washing repeatedly in sterile distilled water, each time by centrifugation at x1000g for 30 minutes. The supernatant obtained was heated for 10 minutes at 65oC to eliminate any vegetative cell. The purity of spore sample was confirmed visually and by microscopic examination after spore staining. Sample Analysis Screening the fruit juices for bacterial contaminants Before the samples were screened, the 508 Int.J.Curr.Microbiol.App.Sci (2013) 2(10):506-515 The number of spores in the cell-free spore suspension was determined using Nabeaur hemocytometer followed by serial dilution in sterile peptone salt broth to obtain different spore concentrations ranging from 0.2x106 to 4.0x106 spores per ml. The final spore concentrations were stored in peptone salt broth at 4oC. experimental plates. After incubation visible colonies on the plates were counted and the results compared with the total number of spores counted in the hemocytometer. Inactivation of the spores The D-values (time to inactivate 90% of the spore population) were determined from the straight line portion of the survival-time curves by plotting log of survival counts against their corresponding heating times. The values were obtained from the survival curve equation Determination of Decimal Reduction Time (D-Values) of Spores The bacterial spores were inactivated by wet-heat using the screw-cap tube method described by the Koolman (1973). In this method, 200µl of the different spore concentrations was injected separately with a Hamilton syringe into metal screwcap tube which were preheated at 60oC for 10 minutes for equilibration. The tube contained 9.8ml of trypticase soy broth as inactivation medium Heating was carried out. With the tubes completely immersed in a glycerol broth and heated up to 95oC for 30minutes. There after the spore suspensions were diluted 10 times with sterile distilled water and counted using of Nebeaur hemocytometer. The success of the inactivation process was determined by their ability to germinate on brain heart infusion agar and formed colonies. D= t LogN logN0 Where N is the final spore population, t is the time at LogN and N0 is the initial population of the straight line portion on the destruction curve produced by plotting the log10 numbers of survivors against time at 1000C (Harrigan, 1998). Determination of Viability of the Spores The viability of spores was determined by inoculating the inactivated spores in trypticase soy agar and incubating at 37oC for 4 days. Serial dilution of the inactivated spore suspension was carried out in peptone-saline solution (0.1% peptone, 0.85% Nacl). One milliliter each of the diluted spore suspension was added separately in duplicate to trypticase soy agar by pour plate technique and incubated for 4 days. The number of visible colonies on the plates was counted thereafter. Effect of different temperature regimes on spore inactivation Heat-treated spore suspensions from the different strains containing known population of bacterial spores were incubated in trypticase soy broth at 650C, 750C, 850C and 950C for 30minute respectively. Thereafter the spores were serially diluted in sterile distilled water, plated on brain heart infusion (BHI) agar and incubated at 370C for up to 4 days. Control experiments consisted of BHI agar plates inoculated with similar spore stains without heat treatment and incubated as in Effect of exposure time on spore viability Known population of the five spore crops obtained from the different strains of 509 Int.J.Curr.Microbiol.App.Sci (2013) 2(10):506-515 bacterial contaminants were heated at 650C for ten to seventy minutes. Thereafter 1.0ml of the heated spore suspensions were placed on BHI agar and reinforced clostridial media respectively. The plates were incubated at 370C for 4 days, after which the surviving colonies were determined and log numbers of the surviving colonies were plotted against exposure time at the test temperature. in thermal resistance of the various strains studied in the order B74>T20> A63>K16>Y28B. The results 18.5% of strain B74 was inactivated within 30 minutes of heat treatment. Spores from other strains also exhibited marked resistance at this temperature. A total of 73.3% of spores from strain Y28B germinated at 650C and subsequently became inactivated within 30 minutes at higher temperature. This pronounced inactivation may be due to the fact that low inactivation temperatures usually activate spores allowing increased germination of spores. This assertion agrees with an earlier report by Kort et al. (2005). The percentage of viable spores under the same conditions for strains B74, T20, A63, and K16 were 81.5%, 68.0%,62.5% and 51.7% respectively. The low degrees of germination of spores from these strains at 650C were expected because the spores were isolated from heat resistant strains. Moreso, at pasteurization temperature, the spores may be in deep dormancy and can only be activated at high temperature (Iciek et al., 2005). Statistical analysis The data obtained from this study were analyzed by Analysis of Variance (ANOVA) and correlation analysis, according to Sokal and Rholf (1983), to determine the significant differences amongst the treatments. Results and Discussion All the packaged fruit juices examined yielded moderate growth of spore forming bacteria. A total of five spore crops were isolated from the different bacterial strains recovered from the fruit juices. The bacterial strains were Bacillus subtilis K16, Bacillus coagulans B74, Bacillus cereus Y28B, Clostridium perfringens T20 and Clostridium sporogenes A63. When these spore crops were incubated at 950C for 30 minutes, the percentage spore inactivation for strains B74, T20, A63 , K16 and Y28B increased to 64.4%, 69.0%, 71.3% , 72.7% and 94.1%, respectively. Surviving spores after heat treatment were observed at all temperatures tested. The viable spore subpopulations observed at all temperatures might be due to the fact that fruit juices have high moisture content. Therefore the high moisture content might have offered some protection against thermal inactivation of bacterial endospores. The variation in the percentage inactivation of spores subjected to different degrees of thermal treatment might also be due to differences in the heat Microscopic examination of all the thermally treated spores revealed pronounced morphological malformations such as shrinkage and ridge on the outer spore coat. Similar morphological changes were observed by Mustafa et al., (2010) during their study on morphological changes induced by wet-heat in Bacillus cereus endospores. The inactivation curves of endospores from bacterial strains studied at different temperatures are shown in Figures 1 (a) and (b). The result shows high variations 510 Int.J.Curr.Microbiol.App.Sci (2013) 2(10):506-515 resistant capabilities of the different strains studied. Table.1 Z-values of bacterial endospores recovered from packaged fruit juices. Bacterial Strain Z- values (0C ) Bacillus subtilis K16 7.4 Bacillus coagulans B17 8.5 Bacillus cereus Y28B 6.8 Clostridium perfringens 7.6 T20 Clostridium sporogenes 8.7 A63 In this study, the thermal inactivation of heat resistant bacterial spores did not follow first-order kinetics, because some spores were more heat resistant than others. This is evidenced by the tailing in Figures 1(a) and (b), due to resistant subpopulation. The most resistant strain encountered in this study was Bacillus coagulans B74, with only 64.4% inactivation at 950C after 30 minutes of heat treatment. Figure 3 shows the survivor - time curve for the thermal resistant spores at 850C and 950C respectively. Each of the survivor curve shows a clear tailing deviation, which implies that the wet heat inactivation of the bacterial endospores has a positive correlation with the temperature of exposure. The result also shows that about 35.6 % of strain B74 was still viable after 30 minutes exposure at 950C. Strains Y28B, K16, T20 and A63 exhibited 5.9 %, 27.3%, 31.0% and 28.7% viability at this temperature respectively. Beyond 30 minutes exposure time, the percentage spore viability reduced drastically toward zero. The decimal reduction times (D-values) for spores from the different strains studied at different temperatures are depicted in Figures 2 (a) and (b), while the Z values are shown in Table 1. There was a perfect correlation between the process temperature and the D-values with high correlation coefficients. The linear regression analysis of the data for all the strains fitted into the linear model Y=a + b x. This perfect linearity was expected because when a spore population is heated, the process of spore activation and vegetative cell destruction actually begins with increase in temperature until a high enough temperature is reached when a greater percentage of the population would be inactivated. A similar observation was made by Brown (1994) during his study on spore resistance and ultra heat treatment process. The Z-values for Bacillus strains K16, B74 and Y28B were 7.40C, 8.50C and 6.80C. These values are in agreement with those commonly observed for Bacillus spores which usually vary between 5.50C and 100C (Russell, 2003). In conclusion therefore, temperature higher than 950C may be required to inactivate bacterial spores in fruit juices within 30 minutes. This study has determined moist heat resistant bacteria and their inactivation characteristics in fruit juices. The findings from this investigation will enable fruit juice industry to establish appropriate process controls to ensure that the final product is free from bacteria that can reduce the quality of the product. However, since there are many other factors that affect 511 Int.J.Curr.Microbiol.App.Sci (2013) 2(10):506-515 Figure.1a Inactivation curves of strains Y28B and K16 Lcfu 2.5 2 1.5 Y28B 1 0.5 0 60 70 80 90 Process Temperature (0C) Figure.1b Inactivation curves of strains B74, T20 and A63 Lcfu 2.5 2 B74 T20 1.5 1 0.5 0 60 70 80 Process Temperature (0C) 512 90 A63 K16 Int.J.Curr.Microbiol.App.Sci (2013) 2(10):506-515 Figure.2a Thermal Reduction Times (D values) of bacterial endospores from strains Y28B and K16. Log 10 D 3 2.5 Y= 7. 18 + 0.066X R2 = 0.9820 2 1.5 1 Y28B K16 0.5 0 65 75 85 Temperature (0C) Figure.2b Thermal Reduction Times (D values) of bacterial endospores from strains B74, T20 and A63. Log 10 D 3.5 3 B74 T20 2.5 2 1.5 1 0.5 0 65 75 85 0 Temperature ( C) 513 95 A63 Int.J.Curr.Microbiol.App.Sci (2013) 2(10):506-515 Lcfu Figure.3a Survivor-Time curve for thermal resistant spores Y28B, K16, B74, T20 and A63 at 85°C Time (Minutes) Figure.3b Survivor-Time curve for thermal resistant spores Y28B, K16, B74, T20 and A63 at 95°C Lcfu Time (Minutes) 514 Int.J.Curr.Microbiol.App.Sci (2013) 2(10):506-515 resistance of bacteria, validation of a processing method should be undertaken under realistic conditions using fruit juice as growth medium. Koolman, W. J., 1973.The screw cap tube technique: a new accurate technique for the determination of the wet heat resistance of bacterial spores. In: A. N. Baker, G. W. Gould and J. Wolf (ed.). Spore Research. Academic Press, London, United Kingdom, pp 87- 92. Kort, R., A.C. O Brien, I.H.M. van Stokkum, S.J.M. Oomes, W. Crielaard, K.J. Hellingwerf and Brul, S. 2005. Assessment of heat resistance of bacterial spores from food product isolates by fluorescence monitoring of dipicolinic acid release. Appl. Environ. Microbiol. 71(7) :3556-3564. Leishman, O.N., M.J. Johnson, T.P. Labuza and Diez-Gonzalez, F. 2010. Survival of Bacillus anthracis spores in fruit juices and wine. J. Food Protect. 73(9): 1694-1697. Mustafa, N. E. M., U. Keller, V. Malkus, D. Harmsen, R. Reichelt, A.A. Hussein and El-sanousi, S.M. 2010. Morphological changes induced by wet- heat in Bacillus cereus endospores. Curr.Res.Bacteriol. 3:214226. Neidhart, F. C., P.I. Bloch and Smith, D. F. 1974. Culture medium for enterobacteria. J. Bacteriol. 119:736747 Oranusi, U.S., W. Braide and Osigwe, G. A. 2012. Investigation on the microbial profile of canned foods. J. Biol. Food Sci. Res. 1(1):15-18. Ramirez lopez, L. M., 2006. Heat inactivation of thermo-resistant bacteria isolated from poultry offal. M.SC thesis presented to the Graduate School of Clemson University. References Beaman, T. C., and Gerhardt, P. 1986. Heat resistance of bacterial spores correlated with protoplast dehydration, mineralization and thermal adaptation. Appl. Environ. Microbiol. 52:12421246. Brown, K. L., 1994. Spore resistance and ultra heat treatment process. J.Appl. Bacteriol. Sym. Supple.76:67s-80s. Harrigan, W. F., 1998. Effect of heat on microorganisms: The determination of decimal reduction time (D values) and Z values. Laboratory methods in food microbiology, San Diego, California, Academic Press, pp. 123-135. Holt, J. G., N.P. Krieg, P.H.A. Sneath, J. Satley and Williams, S. T. 1994. Bergey s Manual of Determinative Bacteriology. (9th edn.) Williams and Wilkins Publishers, Baltimore.pp. 787. I. C. M. S. F. ,1974. Sampling for microbiological analysis. International Commission on Microbiological Specification for Food: Principles and specific applications, University of Toronto Press, pp. 1-18. Iciek, J., A. Papiewska and Molska, M. 2005. Inactivation of Bacillus stearothermophilus spores during thermal processing. J. Food Engineer. 171-173 Ifenkwe, G. E., 2012: Food safety regulations; reducing the risk of foodborne diseases in rural communities of Abia State, Nigeria .Agricult. Sci. Res. J. 2(7):384-389. 515