Strategic and Technical Issues in External Systems Integration

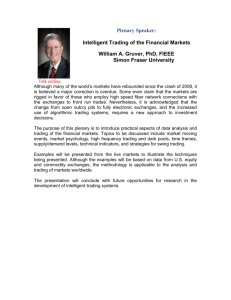

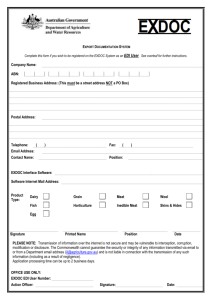

advertisement