full paper - 2H Offshore Engineering

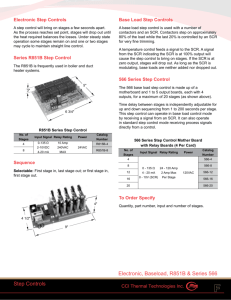

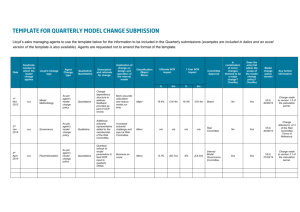

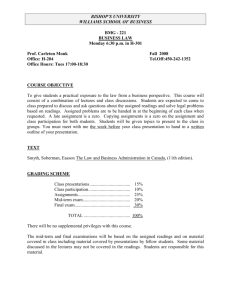

advertisement

Proceedings of the 26th International Conference on Offshore Mechanics and Arctic Engineering OMAE2007 June 10-15, 2007, San Diego, California, USA OMAE2007-29049 WEIGHT OPTIMIZED SCR – ENABLING TECHNOLOGY FOR TURRET MOORED FPSO DEVELOPMENTS Elizabeth Foyt Senior Engineer 2H Offshore Inc Cary Griffin, Senior Engineer 2H Offshore Inc H. Howard Wang ExxonMobil Development Company 1 Mike Campbell, Manager - Engineering Projects, 2H Offshore Inc Wan C. Kan ExxonMobil Development Company Copyright © 2007 by ASME INTRODUCTION Steel catenary risers (SCRs) have been used successfully with floaters such as TLPs, SPARs and Semis. Recently SCR applications have been extended to FPSOs. However, the SCRs have been attached at mid-ship of the FPSOs with milder motion. SCRs in conjunction with a turret moored FPSO in deepwater environments present significant design challenges. The large vertical motions at the FPSO turret induce severe riser response including compression and potential buckling at the TDP area and result in difficulty meeting minimum fatigue life requirements. Special efforts are needed to develop an optimized, feasible SCR configuration to be used in conjunction with a turret moored FPSO for West African environment. The feasibility of a conventional SCR on turret moored FPSO is assessed initially and is confirmed to be difficult to achieve the desired strength and fatigue requirements. Based on previous industry work [1], an optimization study expands on the idea of using varying weight, in the form of different density coatings, along the length of the riser in order to improve SCR strength and fatigue performance. The study demonstrates that the SCR with weighted sections, which improve SCR response at critical area, is a potential alternative solution for the application of SCRs on turret moored FPSO. Further study to understand why the mechanism of the increased weight at the TDP area improves riser performance is carried out, which is key to addressing the issues involved with the feasibility of this type of application. The study also determines the key parameter for SCR peak response, which included static shape, dynamic motions and velocities. This 2 understanding would help provide further insight for future optimization design work. DESIGN DATA AND CRITERIA A production SCR mounted to a turret moored FPSO in a water depth of 1500m off West Africa is evaluated. The key properties are as follow: • 10.75in O.D., 1.0in (25.4mm) wall thickness; • X65 steel; • Insulated with 3.5in thick, 768kg/m³ syntactic foam. Typical West African environmental data is used in the analysis. The concept of the proposed SCR configuration with weighted sections is shown in Figure 1. 1600 1400 Height Above Seabed (m) ABSTRACT Steel catenary risers (SCRs) used in conjunction with a turret moored FPSO in deepwater environments present significant design challenges. The large vertical motions at the FPSO turret induce severe riser response. This results in difficulty meeting strength and fatigue design criteria at the Touch Down Point (TDP) and at the riser hang off location. It is typically considered challenging to achieve feasibility for a conventional SCR application on a turret moored FPSO. Previous industry work for an SCR application used with other floating hosts has demonstrated that SCR strength and fatigue response can be improved using heavy and light coatings strategically placed along the riser [1]. An optimization study is performed, based on previous industry work, which demonstrates that a weight optimized configuration can enable the application of an SCR on a turret moored FPSO. The effect of adding different coatings along the length of the SCR is discussed. The position, length, and density of the coating type are varied to determine an optimum configuration for both strength and fatigue response. This paper will also discuss observations which may help explain why weighted sections can improve SCR response at the critical area. 1200 Light - Low density coating (3.5in, 670kg/m^3) Normal - As is (3.5in, 768.9kg/m^3) Heavy - High density coating (3.5in, 2800kg/m^3) 1000 800 600 400 200 0 0 200 400 600 800 1000 1200 1400 1600 1800 2000 2200 2400 2600 2800 Horizontal Distance from Vessel Attachment Point (m) Light Normal Riser Heavy Riser Figure 1 – SCR Configuration with Different Density Coatings The strength analysis is performed based on a 12-hour 100 year extreme swell condition. Extreme strength response is considered to be acceptable if, along the entire riser, the maximum von Mises stress does not exceed 80% of the yield stress. It is also desirable to maintain positive effective tension in SCR at all load cases. Three FPSO draft conditions are considered including ballast, intermediate and fully loaded. The target field life is 15 years so that the design fatigue life needs to be 150 years or more with a safety factor of ≥10. Fatigue analysis is conducted for 41 condensed swell bins at 3 dominant swell directions. Fatigue damage is calculated using rainflow counting approach to reduce conservatism. Vessel orientation is 15° from the direction of the swell or local sea (165° vessel heading). FEASIBLITY OF A CONVENTIONAL SCR An initial attempt was needed to see if a conventional SCR, without weight optimization, could be made feasible for the turret moored FPSO application. Preliminary strength analysis results showed compression and unacceptable stresses with a wall thickness of 25.4mm as given in Table 1. It was found that the hang off angle has to be increased to 15 deg and the wall thickness to 31.8mm to Copyright © 2007 by ASME Riser Description Draft Condition Min Effective Tension (kN) Stress Utilization at TDP (%) MINIMUM EFFECTIVE TENSION 100 Yr Swell with Associated Local Sea, Failed Mooring 165deg VH 15deg WH, Near Offset 2000 Minimum Effective Tension (kN) marginally satisfy the strength. But the effective tension condition is still not satisfied for the ballast draft condition. The maximum stress utilization with a 31.8mm wall thickness at the TDP is given in Table 1 and shown in Figure 2 for three different draft conditions. For the ballast draft condition the maximum compression at the TDP is 146kN resulting in a maximum stress utilization of 102%. Wall Thickness = 31.8mm Top Angle = 15 Deg Attachment Heave Range ~ 10m Cd = 1.1 1500 1000 500 0 -500 0 500 1000 1500 2000 2500 Distance from Vessel (m) 25.4 mm WT, 10 deg Top Angle Ballast 31.8 mm WT, 15 deg Top Angle Fully Loaded Intermediate Ballast Ballast 116 Intermediate Fully Loaded -99.5 Figure 3 – Minimum Tension at TDP 85 1.7 94 102 -18.6 -146 First order fatigue analysis is carried out using time domain random sea analysis. The minimum fatigue life along the length of the riser is shown in Figure 4 for three different SN curves and given in Table 2. Table 1 – Strength Results for Conventional SCR at TDP S-N Curve B C D VON MISES STRESS/YIELD STRESS 100 Yr Swell with Associated Local Sea, Failed Mooring Zero Offset, Ballast Draft 0.9 0.7 Wall Thickness = 31.8mm Top Angle = 15 Deg Attachment Heave Range ~ 10m Cd = 1.1 0.6 0.5 Table 2 – Fatigue Life at TDP for Conventional SCR 0.4 0.3 0.2 0.1 0 1500 1600 Base Case - 180deg VH, 15deg WH 165deg VH, 15deg WH 1700 1800 1900 Distance from Vessel (m) 180deg VH, 35deg WH Allowable 2000 2100 180deg VH, -15deg WH Figure 2 – Von Mises Stress at TDP The minimum effective tension is shown in Figure 3 for the different drafts considered. The cause of the high stress for the ballast draft condition is due to large compressive tension in the TDP region of the SCR, as a result of the large heave motion at the hangoff location in the order of about 10m. The fatigue life at the TDP area due to all swell bins is below the target fatigue life of 150 years when considering the use of the best weld “C” fatigue curve. The fatigue performance may be improved due to variations in vessel drafts during operating. This spreading effect may increase fatigue life by a factor of about 2.5 at the TDP area. However, the fatigue performance is still considered to be very marginal even if the best weld fatigue curve is used. UNFACTORED FATIGUE LIFE 41 Condensed Swell Sea States, SCF=1.1 1.0E+06 1.0E+05 Fatigue Life (Yrs) Von Mises Stress/ Yield Stress 0.8 Min Fatigue Life at TDP (Yrs) 227 62 15 1.0E+04 1.0E+03 1.0E+02 1.0E+01 1.0E+00 0 500 1000 1500 2000 2500 Distance from Vessel (m) Swell - B Swell - C2 Swell - D Figure 4 – Fatigue Life of SCR for Different Curves In summary, feasibility of a conventional SCR with turret moored FPSO is questionable. Hence, as a means of improving 3 Copyright © 2007 by ASME OPTIMIZATION OF SCR CONFIGURATIONS Previous studies for SCR applications on other floating hosts indicate that a heavy section in the sag-bend region and light section along the touch-down region improves response [1]. To improve the response of the SCR on a turret moored FPSO in both strength and fatigue performance, an optimization study on SCR configurations with weighted sections is carried out. The general arrangement used as the base case for this study is shown in Figure 5. An initial weight optimized SCR configuration is adopted based on the use of heavy 2800kg/m³ and light 650kg/m³ density coatings along the length to vary the weight of the riser at key locations. PRODUCTION SCR - WEIGHT OPTIMISATION CONFIGURATION DEFINITION 1600 Height Above Seabed (m) 1400 • • Removing the lightweight coating at the TDP; Reducing overall weight of the heavy section whilst still meeting design criteria. While the strength performance is acceptable as the coating density is decreased to 1500kg/m³, effective tension approaches zero at the touch down zone, as shown in Figure 6. A final configuration is chosen which uses an 1850kg/m³ heavy coating along 425m of the sag-bend region and no light weight coating. PRODUCTION RISER - MINIMUM EFFECTIVE TENSION 100 Yr Swell, Ballast Draft Condition 2500 Minimum Effective Tension (kN) the SCR response, an optimized SCR configuration is needed to obtain a feasible solution. 2000 1500 1000 500 1200 Normal Coating 0 1000 0 500 1000 1500 2000 2500 Distance From Vessel (m) 800 Heavy Coating 600 Light Coating 1850kg/m³ Heavy Coating Only (Conf S) 1500kg/m³ Heavy Coating Only (Conf R) 2800kg/m³ Heavy and Light Coatings (Conf I) Normal Coating 400 Figure 6 – Effective Tension along Riser Length 200 0 0 200 400 600 800 1000 1200 1400 1600 Horizontal Distance From Riser Attachment Point (m) Figure 5 – Layout of Weight Optimized Sections To obtain an acceptable configuration, a total of 9 configurations which vary the light and heavy section lengths and thicknesses are evaluated for strength and fatigue response. Of these, a configuration is found which satisfies both fatigue and strength criteria. A comparison between the weight optimized configuration and the conventional SCR is given in Table 3. Case Conventional Riser Weight optimized Max von Mises Stress/Yield Hangoff TDP Mini Fatigue Life DoE C/2 (yrs) Hangoff TDP 0.50 0.82 372 31 0.57 0.48 318 264 Table 3 – Weight Optimized Configuration with Heavy and Light Sections Analysis of the multiple weight optimized configuration indicates that a section of heavy coating closer to the touchdown zone improves the strength and fatigue performance of the SCR. Following the development of a feasible weight optimized configuration, further optimization is conducted by: 4 DESIGN OF SCR WEIGHTED SECTIONS High density coating provides an acceptable solution from a structural standpoint. Other weight options are desirable to allow flexibility in cost and installation conditions. Hence, alternative means of achieving increased weight are evaluated, including: • Increasing the J-lay collar diameter to meet weight per-joint weight requirements • A pipe-in-pipe configuration where an external steel sleeve is added to the riser • Increasing the wall thickness of the riser to meet weight requirements • A clump weight solution where a weight is added during installation to each joint in the heavy section The above solutions would all allow for proper insulation of the riser. However, due to the amount of extra weight needed per riser joint, increasing the weight by thickening the wall or adding a pipe sleeve are not feasible; the required wall thickness pipe could not be welded. Increasing the J-lay collar thickness would also not be feasible due the 60in diameter associated with a 2ft long collar. A qualitative comparison of these options is listed in table 4. Copyright © 2007 by ASME Solution Pros Cons High Density Insulation Even distribution of weight Limited proven supplier Increased Wall Thickness Even distribution of weight Required thickness not feasible Steel Pipe Sleeve J-Lay Collar Modification Clump Weight Even distribution of weight, retains insulation properties Collar already integrated, will not slip or fall off Cheap, deployable through the moonpool, can be located to avoid high SCF at welds Sleeve too thick, pipe ovality mismatches High cost, locally high stresses over welds Further development required to prevent sliding, locally high stresses Table 4 – Pros and Cons of Weight Optimization Options The most promising solution appears to be a clump weight design which could be installed on an installation vessel, and away from welds, as shown in Figure 7. It allows for the riser to be fully insulated and potentially reduces procurement and installation costs. Clump weights have been successfully installed on other SCR application in the Gulf of Mexico in order to improve riser response during extreme events [2]. deck with existing equipment and narrow enough to fit through the J-lay tower. Only one clump weight is required per joint over the heavy section. Length (m) OD (m) 1.000 1.261 ID (m) 0.457 Weigh t (lb) 5520 Number Require d 34 Table 5 – Clump Weight Parameters Strength and fatigue analysis is performed on a clump weight solution with a weight distribution equal to the riser with only heavy coatings and equivalent density of 2250kg/m³. Strength response is found to be acceptable. However, the fatigue performance is significantly reduced. The best welds with “C” class fatigue performance are required in the TDP area to satisfy the fatigue design requirements, as shown in Table 4. This change is probably due to the additional drag imparted from the clump weights. The locally higher drag and higher weight caused by the clump weights also decreases fatigue life along the clump weight region, as seen in Figure 8. However, because the relative dynamic motions are significantly lower and the fatigue performance is higher, the decrease in life in this region is acceptable. Unfactored Fatigue Life (yrs) TDP Hang Off (C Class) (C/2 Class) 455 819 190 595 Sensitivity Heavy Coating Clump Weights Table 4 – Effect on Fatigue Life due to Clump Weights CLUMP WEIGHT VS. HEAVY COATING FATIGUE LIFE C Fatigue Curve, TDP Fatigue Spreading 1000000 Fatigue Life (years) 100000 10000 1000 100 10 1 1500 1550 1600 1650 1700 1750 1800 1850 1900 1950 2000 Distance From Vessel (m) Clump Weights Heavy Coating Figure 8 – Fatigue Response of Clump Weight Riser Figure 7 – 2H Design Clump Weight As shown in Table 5, the weight and OD of the clump weight are such that it is light enough to be manipulated on 5 SCR PEAK RESPONSE ASSESSMENT The typical parameter used in design to predict peak response of an SCR is the maximum wave height. However, Copyright © 2007 by ASME other parameters also drive the SCR response. A study was performed to understand the correlation between the peak response and the following parameters: • Maximum and minimum wave height • Maximum upward porch velocity • Maximum downward porch velocity • Maximum upward porch acceleration • Maximum downward porch acceleration • Hang off degree of freedom 1 through 6 Environmental loading conditions consist of 12 one hour random sea analyses. Each random sea analysis uses a 100 year swell conditions and associated current and a different random seed. Extreme motions and SCR response are plotted against each other in order to identify the correlation between peak SCR response and the various vessel motion characteristics. The relationship between maximum downward porch velocity and minimum effective tension at the TDP for the SCR is shown in Figure 9. The correlation between significant wave height and minimum TDP effective tension, which is a commonly used parameter to determine response, is shown in Figure 10. The results show that there is only moderate and considerably scattered correlation between wave height and peak response. STUDY OF THE WEIGHTED SCR CONFIGURATION As discussed above adding distributed weight to the SCR above the sag-bend region improves the SCR strength and fatigue response. It is desirable to understand the reason why the added weight improves the response of the SCR, which may facilitate better SCR design. The mechanism behind the improvements in response is investigated by performing a detailed assessment of the SCR strength response. The SCR response for three SCR configurations is assessed including evaluation of: static shape, tensions and bending moments, dynamic motions, and velocities. The results are evaluated in a number of ways including time traces, envelopes and snapshots. The SCR configurations including normal, heavy coating, and clump weight are shown in Figure 11. MAX DOWNWARD PORCH VELOCITY against MIN EFFECTIVE TENSION 700 TDP Minimum Effective Tension (kN) 600 ExxonMobil - Turret Moored SCR Feasibility Study - Phase IV 500 PRODUCTION RISERS CONFIGURATION DEFINITION Nominal Position - Top Angle = 15deg 400 Compression 1600 1600 1400 1400 1200 1200 300 0 0.0 0.5 1.0 1.5 2.0 2.5 3.0 Max Downward Porch Velocity (m/s) SEED01 SEED02 SEED03 SEED04 SEED05 SEED06 SEED07 SEED08 SEED09 SEED10 SEED11 SEED12 Figure 9 – Maximum Downward Porch Velocity vs. TDP Minimum Effective Tension The results show that maximum downward porch velocity is a reliable indicator to capture the occurrence of minimum effective tension at the TDP. The results show that compression is expected to occur in the SCR for maximum downward porch velocities greater than 2.5m/s. 1000 Normal Riser 800 Heavy Riser 600 Lump Weight Height above Seabed (m) 100 Height above Seabed (m) 200 1000 800 600 400 400 200 200 0 0 0 -200 -400 -600 -800 -1000 -1200 -1400 Horizontal Distance from Hang-Off (m) 0 -200 -400 -600 -800 -1000 -1200 -1400 Horizontal Distance from Hang-Off (m) Figure 11 – SCR Configurations Static Response SCR static response shows that the addition of weight increases tension but reduces TDP bending moments and curvatures. The reduction in static TDP curvature for the heavy coating and clump weight configurations is shown in Figure 12. The SCR static curvature at the TDP is reduced by a factor of 0.8 with the introduction of the additional weight (See Figure 16). As expected, the single lump mass causes a locally high increase in curvature that can be reduced with the use of smaller distributed lump masses. MAX DOWNWARD PORCH VELOCITY against MIN EFFECTIVE TENSION 70 TDP Minimum Effective Tension (kN) 60 50 40 30 20 10 0 0. 0. 1. 1. 2. 2. 3. 3. 4. 4. 5. Max Wave Height (m) SEED01 SEED02 SEED03 SEED04 SEED05 SEED06 SEED07 SEED08 SEED09 SEED10 SEED11 SEED12 Figure 10 - Maximum Wave Height vs. TDP Minimum Effective Tension 6 Copyright © 2007 by ASME STATIC RESULTANT CURVATURE DYNAMIC RISER SHAPE ENVELOPE No Environmental Loading 45 3.0 40 35 Elevation above Seabed (m) Curvature (1000/m) 2.5 2.0 1.5 1.0 30 25 20 15 10 0.5 5 0 1800 0.0 1700 1750 1800 1850 1900 1950 1850 2000 1900 1950 2000 2050 2100 Distance from Vessel (m) Distance From Vessel (m) Bare SCR Heavy Coating Clump Weight Figure 12 – Static Curvature MOTION RANGE ALONG SCR LENGTH Middle of the Heavy Coating Section Lump Weight Position Vertical Motion Range (m) 12 TDP TDP vterm = Where: • • • • 8 6 4 2 0 2 Bare SCR 3 Location Along SCR4 Length Location Along SCR Lenght Heavy Coating Clump Weight SCR Velocity Response The SCR velocity response is assessed to help understand if it is a factor in the changing motion characteristics. The terminal velocity and actual velocity along the riser length is calculated. Terminal velocity of a free falling body is the speed at which the surrounding fluid drag force matches the pull of gravity, resulting in a constant fall rate. It is defined as follow: 10 1 Bare SCR Figure 14 - Dynamic Riser Shape Envelope in TDP Region Dynamic Motions Riser dynamic motion envelopes and snapshots of the structure are investigated in order to determine how the motion response of the various SCR configurations differs. The vertical motion range extracted from 6 positions along the length of each SCR is shown in Figure 13. 14 Heavy Coating 5 6 • 2W C d Aρ fluid vterm - terminal velocity of the free falling body W - weight of the body Cd - drag coefficient A cross sectional projected area (perpendicular to flow direction) ρfluid - density of the surrounding fluid Clump Weight Figure 13 – Vertical Motion Range Along Riser Length The addition of weight increases the motion response in the region of the weight by a factor of 1.2, and consequently reduces the motion response directly above the TDP by a factor of 0.6. The reduced motion response in the TDP region of the weight optimized SCRs results in lower velocities and consequently the dynamic response is improved as shown in Figure 14. Therefore, reduced loads and stresses occur in the TDP region. 7 Terminal and actual velocity along the length of the SCR for both configurations are shown in Figure 15 and Figure 16. The actual vertical velocity response in the region of the added weight of the SCR configuration with the heavy coating is approximately 20% greater than the bare SCR, as shown in Figure 15. Below the distributed weight, the velocity reduces to 50% of the value for the normal configuration. For the non weight optimized SCR, without the additional weight, the velocity is transferred to the TDP region. Hence, locally high velocities, that exceed the terminal velocity, occur directly above the TDP, where compression occurs. Copyright © 2007 by ASME ACTUAL VERTICAL VELOCITY VERTICAL VELOCITY - ACTUAL AND TERMINAL Heavy Coating Configuration 4.0 4.5 4.0 2.0 3.5 Vertical Velocity (m/s) Vertical Velocity (m/s) 3.0 1.0 0.0 -1.0 Compression -2.0 2.5 2.0 1.5 1.0 -3.0 0.5 -4.0 0 400 800 1200 1600 2000 2400 0.0 Distance from Vessel (m) Bare SCR 1000 1400 1600 1800 2000 2200 2400 Distance from Vessel (m) Terminal Velocity Actual Velocity Figure 17 - Terminal and Actual Velocities Heavy Coating Configuration Effect of Drag Coefficients on SCR Response The effective tension at the TDP is lower for higher drag coefficients and compression occurs when the actual downward vertical velocity exceeds the terminal velocity by a certain amount. For the non-optimized SCR, compression occurs for drag coefficients of 0.8, 1.1 and 1.4, as shown Figure 18. VERTICAL VELOCITY - ACTUAL AND TERMINAL Bare SCR Configuration 4.0 3.5 Compression 3.0 1200 Heavy Coating Figure 15 - Actual Peak Vertical Velocity Envelope along Riser Length Vertical Velocity (m/s) 3.0 2.5 2.0 MINIMUM EFFECTIVE TENSION 1.5 Bare Pipe Drag Coefficient Sensitivity Bare SCR Configuration 1.0 2500 0.0 1000 1200 1400 1600 1800 2000 2200 2400 Distance from Vessel (m) Terminal Velocity Actual Velocity Figure 16 - Terminal and Actual Velocities of Bare SCR Configuration The addition of weight locally increases the terminal velocity, allowing the riser to ‘fall’ faster and hence further during cyclic downward vertical motion. For the heavy coating configuration, the actual maximum downward velocity at the TDP only slightly exceeds its terminal velocity, as shown in Figure 17. Thus, one possible explanation for TDP compression is that if the hang-off forces the TDP region to move downward faster than its terminal velocity, then the upward drag force in this region tends to inflect the riser and the catenary’s shape is locally deformed as a consequence of high compression. 8 Minimum Effective Tension (kN) 0.5 2000 1500 1000 500 0 -500 0 400 800 1200 1600 2000 2400 Distance From Vessel (m) Cd=0.5 Cd=0.7 Cd=0.8 Cd=1.1 Cd=1.4 Figure 18 – Minimum Effective Tension for Different Drag Coefficients – Bare SCR Configuration Compression does not occur for the case with a drag coefficient of 0.5 because the actual velocity is only slightly higher than the terminal velocity as shown in Figure 19. For the weight optimized configuration the minimum effective tension is achieved for a drag coefficient of 1.4 and, as shown in Figure 19, compression does not occur even though the actual velocity slightly exceeds the terminal velocity as discussed above. Further work is required to better understand the physics of these observations. Copyright © 2007 by ASME • VERTICAL VELOCITY - ACTUAL AND TERMINAL Bare Pipe Drag Coefficient Sensitivity Bare SCR Configuration 4.0 • Vertical Velocity (m/s) 3.5 3.0 2.5 2.0 1.5 1.0 • 0.5 0.0 0 400 800 1200 1600 2000 2400 Distance from Vessel (m) Terminal - Cd = 0.5 Terminal - Cd = 0.8 Terminal - Cd = 1.1 Terminal - Cd = 1.4 Actual - Cd=0.5 Actual - Cd=0.8 Actual - Cd=1.1 Actual - Cd=1.4 Figure 19 - Terminal and Actual Velocities of Bare SCR Configuration for Different Drag Coefficients MINIMUM EFFECTIVE TENSION Bare Pipe Drag Coefficient Sensitivity Heavy Coating Configuration • The clump weight option, which may provide flexibility from installation and cost perspective, gives acceptable fatigue and strength response. The study shows that there is a strong correlation between maximum downward porch velocity and peak SCR response. The maximum downward porch velocity is a reliable indicator for the occurrence time of the minimum effective tension at the TDP. The addition of a clump weight or heavy coating appears to result in a reduced static curvature and dynamic motion response in the TDP area of the weight optimized SCRs. TDP compression appears to be related to max downward velocity that significantly exceed the terminal velocity. Weight optimized SCRs may enhance performance, in part, by changing the terminal velocity profiles of the rises. Minimum Effective Tension (kN) 2500 REFERENCES 2000 [1]. D. Karunakaran, Subsea 7, & T.S. Meiling, S. Kristoffersen, & K.M. Lund, Statoil – “Weight Optimized SCRs for Deepwater Harsh Environments”, OTC 2005. 1500 1000 500 0 0 500 1000 1500 2000 2500 Distance From Vessel (m) Cd=0.5 Cd=0.7 Cd=0.8 Cd=1.1 Cd=1.4 [2]. M Vanderbossche & J. Brooks BP America, C. Masson % J. Fang INTEC Engineering – “Design and Installation of the Mardi Gras Large Diameter , Deepwater Steel Catenary Risers”, IOPF 2006. Figure 20 - Minimum Effective Tension for Different Drag Coefficients – Heavy Coating SCR Configuration CONCLUSIONS The design challenges of utilizing an SCR on a turret moored FPSO are addressed in this paper. An optimum weighted SCR configuration is presented as an alternative solution to these challenges. This configuration takes installation flexibility and cost into account. In addition, the physics behind the reasons for improvement in response have also been discussed. The following conclusions can be drawn from the study: • With the implementation of optimized weighted sections, SCR strength and fatigue response is improved sufficiently to be within acceptable limits provided high fatigue performance welds be used. • Static response shows that the addition of weight increases tension but reduces TDP bending moments and curvatures. Stress and fatigue performance at the TDP is improved as weight above the TDP increases. 9 Copyright © 2007 by ASME