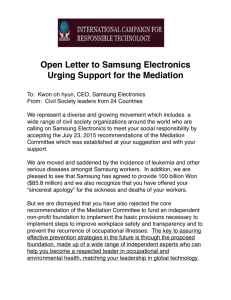

Sustainability Report 2012

advertisement