Harmony Global

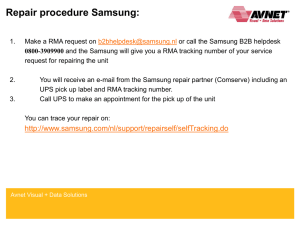

advertisement