Rock Testing

advertisement

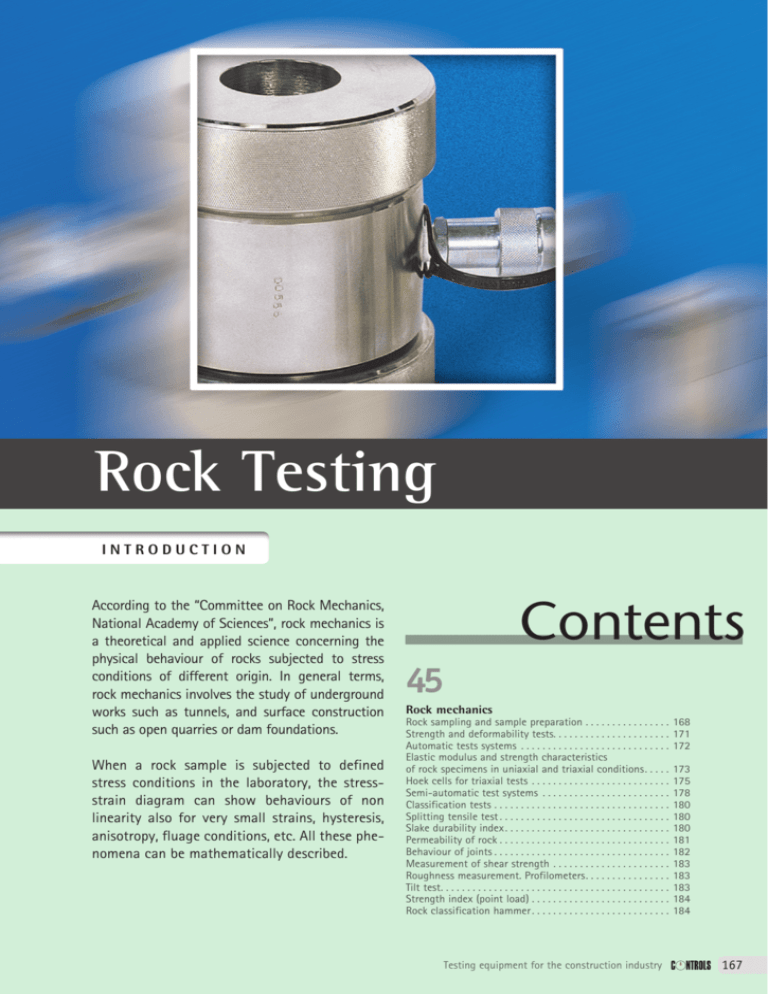

Rock Testing INTRODUCTION According to the “Committee on Rock Mechanics, National Academy of Sciences”, rock mechanics is a theoretical and applied science concerning the physical behaviour of rocks subjected to stress conditions of different origin. In general terms, rock mechanics involves the study of underground works such as tunnels, and surface construction such as open quarries or dam foundations. When a rock sample is subjected to defined stress conditions in the laboratory, the stressstrain diagram can show behaviours of non linearity also for very small strains, hysteresis, anisotropy, fluage conditions, etc. All these phenomena can be mathematically described. Contents 45 Rock mechanics Rock sampling and sample preparation . . . . . . . . . . . . . . . . . Strength and deformability tests . . . . . . . . . . . . . . . . . . . . . . Automatic tests systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Elastic modulus and strength characteristics of rock specimens in uniaxial and triaxial conditions . . . . . Hoek cells for triaxial tests . . . . . . . . . . . . . . . . . . . . . . . . . . . Semi-automatic test systems . . . . . . . . . . . . . . . . . . . . . . . . . Classification tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Splitting tensile test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Slake durability index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Permeability of rock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Behaviour of joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Measurement of shear strength . . . . . . . . . . . . . . . . . . . . . . . Roughness measurement. Profilometers . . . . . . . . . . . . . . . . Tilt test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Strength index (point load) . . . . . . . . . . . . . . . . . . . . . . . . . . . Rock classification hammer . . . . . . . . . . . . . . . . . . . . . . . . . . Testing equipment for the construction industry 168 171 172 173 175 178 180 180 180 181 182 183 183 183 184 184 167 45 ROCK TESTING Rock sampling/ Sample preparation . . . . . . . . . . . . . . . . Rock picks/ Core Trimmer Rock picks Core trimmer and cut-off machine Used for preliminary rock identification. M 45-D0536 Laboratory core trimmer and cut-off machine, complete with water inlet. 230 V, 50 Hz, 1 ph. M 45-D1710 Rock pick pointed tip Fully polished, leather grip. A M 45-D0536/Z Same as above but 110 V, 60 Hz, 1 ph. Weight approx.: 650 g M 45-D1711 Rock pick chisel edge Fully polished, nylon vinyl grip. A M 45-D0536/Y Same as above but 220 V, 60 Hz, 1 ph. q STANDARD ASTM D4543 Weight approx.: 550 g General description and specifications M 45-D0529 Mohs hardness scale set Used to obtain rock samples perfectly machined (cubes, prisms, etc.) from irregular rock or core pieces. It is supplied complete with a proper vice to hold irregular pieces firmly in place up to 70x140 mm approx. Another “V” vice is used to cut cores to a maximum size 75 mm dia. x 140 mm height. Longer cores can be obtained by turning the samples upside down in the vice. It is supplied complete with cooling water inlet. Blade cup wheel and water pump must be ordered separately. 45-D1710, 45-D1711 Power: 1100 W Speed of the blade: 3000 r.p.m. B Dimensions: 730x1050x590 mm A Weight approx.: 100 kg Accessories for 45-D0536 core trimmer and cut-off machine s45-D0536/1 Cooling recirculating pump complete with reservoir. 230 V, 50 Hz, 1 ph. s45-D0536/1Z Same as above but 110 V, 60 Hz, 1 ph. s45-D0536/1Y Same as above but 220 V, 60 Hz, 1 ph. s45-D0536/2 Diamond cutting blade. 230 mm dia. x 2.5 mm thickness. Maximum cutting area 110x70 mm s45-D0536/3 Double-faced diamond cup wheel. 205 mm dia. x 16 mm thickness. Used for finishing sample ends parallel and at right angles to the axis s45-D0536/4 Clamping device for irregular pieces max. dim. 57x104x102 mm (length) and core from 15 to 60 mm dia. 45-D0529 Detail of 45-D0536 with double-faced cup wheel 45-D0536/3 during surface grinding of cylindrical specimens ends - Usable for both trimming and surface grinding - Usable to obtain cube specimens from irregular pieces - Transparent protection cover conforming to CE directive Detail of 45-D0536 with cutting blade 45-D0536/2 during operation 45-D0536 with 45-D0536/4 168 Testing equipment for the construction industry 45-D0536/3, D0536/2 ROCK TESTING . . . . . . . . . . . . . . . . Rock sampling/ Sample preparation 45 Cutting saws/ Coring machines Models of core drill bits Cutting saws Coring machines and bits M 45-C0210/C Rock and masonry saw. 380 V, 50 Hz, 3 ph. M 45-C0330 Laboratory coring machine, 2-speed, complete with water inlet. 230 V, 50-60 Hz, 1 ph. M 45-C0210/CZ Same as above but 220 V, 60 Hz, 3 ph. M 45-C0330/Z Same as above but 110 V, 60 Hz, 1 ph. sCode D.C.D.M.A. Ø specimen mm inches 45-C0343 AX 30.10 1.185 45-C0344 1.5 in. 38.10 1.500 45-C0345 BX 42.04 1.655 45-C0346 NX 54.74 2.155 General description and specifications This rock and masonry saw has been specially developed to cut rock or core samples. The machine is supplied complete with a special clamp to allow irregular specimens to be held firmly in place during the cutting operation. The machine can accept blades up to 450 mm dia. Supplied complete with base frame, water pump and “V” shaped cylinder clamp. The blade must be ordered separately (see accessories). Cutting depth (mm): 115 mm with 350 mm dia. cutting blade and 165 mm dia. with 450 mm dia cutting blade. Power: 2250 W B Dimensions: with base 1200x800x1400 mm A Weight approx.: 125 kg General description and specifications This machine is specifically used in the laboratory for cutting core samples from hard material such as rock and concrete. A clamp is provided to firmly secure the material during the cutting cycle. A special tool is also available (see accessories) to prepare rock samples from core pieces. Drile bits not included. See accessories. Power unit: 1800 W Coring speed: 1485/2720 r.p.m. Coring range: dia. 8 – 60 mm B Dimensions of the base tray assembly: 450x450x300 mm approx. A Weight approx.: 80 kg 45-C0331 Accessories Accessories s45-C0211/4 Diamond blade 350 mm dia. for rock specimens s45-D1717 Clear safety goggles s45-C0331 Clamping device for cores max. dia. 100 mm complete with transparent protection s45-C0343 to 45-C0346 Drill bits and spigot adaptors 45-C0330 with core bit taking sample from a large rock core 45-C0330 with core bit taking sample from a large stone Transparent acrylic protection 45-C0210/C with 45-C0211/4 Testing equipment for the construction industry 169 45 ROCK TESTING Sample preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Speciment grinding/ Dimensional Verification Specimen grinding Specimen dimensional verification q STANDARD q STANDARD EN 12390-2, ASTM D4543 ASTM D4543, ISRM Sugg. Method M 45-D0539 Rock sample verification apparatus M 55-C0201/B Specimen grinding machine. 220-380 V, 50 Hz, 3 ph. M 55-C0201/BZ Same as above but 220 V, 60 Hz, 3 ph. General description and specifications Used to grind and polish concrete specimens, natural stones, ceramic materials, rock samples etc. The cube cylinder and core specimens can be easily locked on the table and the grinding head 330 mm dia. can be radially moved either manually or automatically in both directions so the only manual operation requested is the lowering of the grinding head by the top hand wheel. The machine is supplied complete with chip guard, coolant tank, motor pump, one set of abrasive sectors and instruction manual. Diamond grinding sectors are available on request (see accessories). The machine is supplied complete with clamping element for 100, 150 and 200 mm cubes. Clamping devices for cylinders are also available on request (see accessories). The 45-D0534/B Core face preparation jig can be easily fitted by the clamping element supplied with the machine. General specifications Table dimensions: 775x280 mm Grinding wheel dia.: 330 mm Max. vertical daylight: 350 mm Min. vertical daylight: 145 mm Max. specimen size: 200x200 mm cubes; dia. 160x320 mm cylinders Grinding wheel speed: 1400 r.p.m Automatic cross feed in both directions Safety guard with door locking switch Grinding spindle motor power: 1,900 W Feed motor: 110 W Pulp motor: 100 W Total power: 2200 W B Overall dimension: 1200x1020x1640 mm (lxvxh) A Weight approx.: 350 kg A Weight approx. with packing: 415 kg 170 55-C0201/B Accessories and Spare parts s55-C0201/B1 Spare Set of 10 abrasive sectors s55-C0201/B2 Spare Set of 10 diamond impregnated sectors s55-C0201/B3 Accessory to connect an aspirator for dry grinding procedure. Aspiration not included s55-C0201/B4 Clamping device for cylinders from 100 to 160 mm dia. s55-C0201/B5 Clamping device for cylinders from 50 to 100 mm dia. M 45-D0534/B Core face preparation jig General description and specifications For preparation of parallel and flat core faces using horizontal surface grinders (e.g. 55-C0201/B). Consisting of a 4 place locking device capable of clamping core samples from 20 to 55 mm dia. It can be mounted on most grinding machines with or without magnetic chuck. A Weight approx.: 6 kg 45-D0539 with a supplementary 82-D1250 gauge General description and specifications Used to verify the dimensional and shape tolerances of rock core specimens up to 50 mm dia. by 100 mm length. The straightness of the cylindrical surface can be easily verified by the top dial gauge as well as flatness and verticality of end surfaces by the same dial gauge fitted to the lateral magnetic articulated dial gauge holder. The apparatus comprises a base support with column and dial gauge holder that can be adjusted precisely vertically, a precision dial gauge 5x0.001 mm, a “V” block, a magnetic articulated dial gauge holder and small circular magnets to fit the “V” block on the base. Support base dimensions: 135x170x250 mm Column height : 200 mm “V” block dimensions: 45x45x100 mm Dial gauge: 5x0.001 mm A Weight approx.: 8 kg Accessories and spare parts 45-D0534/B Testing equipment for the construction industry s82-D1250 Dial gauge 5x0.001 mm ROCK TESTING . . . . . . . . . . . . . . . . . . . Strength and deformability tests 45 Uniaxial and triaxial test Strength and deformability tests Most of the information obtained from laboratory tests are substantially related to the stress and strain characteristics of the tested materials. The tests generally performed on cylindrical rock samples are the following: - Evaluation of the compressive strength and strain in uniaxial conditions - Evaluation of the compressive strength and strain in triaxial conditions. Triaxial test on rock materials with measurement of axial strains Typical Failure Envelope (diagram τ νs. σ) Uniaxial test Triaxial test q STANDARD q STANDARD ASTM D3148, D2938 ISRM: Suggested methods for determining the uniaxial compressive strength and deformability of rock materials ASTM D2664, D5407 ISRM: Suggested methods for determining the strength of rock materials in triaxial compression The uniaxial test is performed applying an increasing load at a constant rate of stress between 0.5 and 1.0 MPa/s. Axial and radial strain are measured with high sensitivity (about 5x10-6). Subsequent loadunload cycles are also carried out to obtain a correct evaluation of the compressibility properties. The triaxial test is performed on test rock samples, contained in a rubber sealing membrane, placed within a triaxial chamber and subjected to an isotropic pressure (generally between 5 and 60 MPa), kept constant during the test. An axial load is subsequently applied; tests and measurements are carried on in the same way as for uniaxial tests. - From the measurements recorded during the test the following information is obtained: Rate of stress versus axial and radial strain Maximum or failure stress Tangent and secant Young’s modulus measured on the stress-axial strain curve Rate of radial strain versus axial strain to obtain the Poisson’s ratio Maximum stress versus applied cell pressure (in the triaxial tests) to define the failure envelope and the corresponding properties (cohesion and friction). Another important parameter investigated in the triaxial tests concerns the permeability characteristics of rocks and rock behaviour when subjected to high water pressure, especially for the study of dam foundations, and generally for underground tunnels and cavities. Triaxial test on rock materials with measurement of axial strains Typical Peak Strength Envelope (diagram σ νs. σ ) 1 3 Testing equipment for the construction industry 171 45 ROCK TESTING Automatic test systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . Main features of the complete system - Automatic Uniaxial and Triaxial compression tests - P.I.D. closed loop control - Control up to 4 different hydraulic frames - Tests performed under control of: - Load/Stress - Displacement - Strain - Easy access to graphical and numerical monitoring in real time of all the measurements: axial load and displacement, cell pressure, axial and horizontal strain - Automatic control of cell pressure for triaxial tests - Particularly suitable for investigation of the past failure behaviour of rocks (displacement controlled tests) - Real time variation of the settings, including the control method (load, displacement or strain) 50-C5902/FR Frame with Hoek cell, 50-C9842 ADVANTEST 9, 45-C7022/S SERCOMP 7, and 86-D2999 PC cabinet Determination of Elastic Modulus - Hoek triaxial cell to be selected conforming the specimen size (Triaxial tests only) - Strain gauges and accessories - Test software. q STANDARD Operating principle and strength characteristics of rock specimens in uniaxial and triaxial conditions ASTM D2664, D2938, D3148, D5407, ISRM Sugg. Method EN 14580, EN 1926 Introduction Controls rock mechanics automatic test systems are designed to test various materials from soft sandstone to high strength basaltic samples. The complete test system includes: - Servohydraulic control console for load application conforming the relevant standards (see ADVANTEST code 50-C9842) - High stiffness testing frame to be selected conforming to the size of the sample and the expected strength (see load frames from 50-C4600/FR to 50-C6600/FR model page 238) - Servohydraulic control console for lateral pressure control (see SERCOMP 7 code 45-C7022/S). This unit which is derived from the standard SERCOMP 7 code 50-C7022, has been specifically designed for rock testing (Triaxial tests only) 172 According to the reference standards, during the test the compression load on the rock specimen shall be applied continuously without shock, in such a manner to produce a strain rate as constant as possible, so that failure will occur within 5-10 min of loading or alternatively at a constant rate of stress, within the limits of 0.5-1.0 MPa/sec. Moreover, for triaxial tests, the confining pressure has to be maintained constant to within ± 1%. Our new System has been designed to completely fulfil these strict specifications of the test procedures. The ADVANTEST 9 is driven by a sophisticated micro-processed servo-control and both uniaxial and triaxial tests can be carried on at very stable rate of stress, displacement or strain. The SERCOMP 7 provides the automatic control and managing of cell pressure within the limits prescribed by the Standards. Strain measurements are performed by means of strain gauges applied directly to the specimen, both in axial and radial direction, Testing equipment for the construction industry so that Poisson’s ratio and compressibility parameters are easily and properly evaluated during the test. Axial load and cell pressure are also monitored by means of load cells and/or pressure transducers at high levels of sensitivity and accuracy. All the test data are graphically displayed in real time, and stored in ASCII files for further analysis with appropriate software packages. Note. For a complete list of suggested items to perform Triaxial and Uniaxial test see Table on page 177. ROCK TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . Automatic test systems 45 Determination of Elastic Modulus and strength characteristics of rock specimens in uniaxial and triaxial conditions (continued) Trixial test on rock core with measurement of vertical stress, axial and circumferential strain and confining pressure. N O T E General specifications of the SERCOMP 7 and ADVANTEST 9 consoles (For more details and specifications see pages 241 and 247) Sercomp 7 45-C7022/S Advantest 9 50-C9842 Hydraulic port 2* Power W 750 Max. working pressure, bar 600 Test performance with PID closed loop control Resolution up to 1/65000 Current specs. 230 V, 50-60 Hz, 1 ph. or 110 V, 60 Hz, 1 ph. (please specify) 470x410x1000 120 Overall specs. mm (lxdxh) Weight approx. kg 4* 750 700 with PID closed loop control up to 1/262000 230 V, 50-60 Hz, 1 ph. or 110 V, 60 Hz, 1 ph. (please specify) 470x410x1000 + PC 140 (including PC and printer, which are supplied with the unit) *The SERCOMP 7 and ADVANTEST 9 consoles can control respectively from to 2 up to 4 loading frames for compression and/ or flexural tests on cement and concrete (see page 241 and 247) Detail of rock sample fitted with strain gages Advantest 9: An advanced flexible testing system ideal for standard and advanced automatic tests on construction materials • P.I.D. Closed loop control • Control up to 4 different hydraulic frames • Perform tests under control of: - Load/Stress - Displacement - Strain • For connection of pressure transducer, load cells, displacement and strain transducers • Particularly suitable to test Deformability and Ductility (from postpeak test path) of: - Rock samples - Fiber reinforced concrete - Shotcrete - Concrete with polymer fibre lining • High flexibility: can control very low capacity hydraulic frames up to 5000 kN • Advanced Quality-Performance/Price ratio. The system is fully described on page 247 Testing equipment for the construction industry 173 45 ROCK TESTING Automatic test systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . - Load and displacement - Cell pressure (triaxial test only) - Axial or radial strain (single strain gauge or average). - Easy calibration procedure and control - Store of recorded data in ASCII file - Direct access during the test to the list of the data recorded from the beginning - Possibility to pause the test, change setup and continue with the new parameters. Uniaxial and triaxial tests: Test software - Set-up of load/displacement/strain ramp and cycles - Diagrams in real time of: - Stress, displacement, average or single strain vs. time - Stress vs. displacement - Stress vs. strain - Multi-diagrams display. - Display in real time of recorded data: Processing and printout We propose two MS EXCEL data sheets that, by the readings of the ADVANTEST 9, perform: - Uniaxial tests - Stress-strain analysis - Poisson ratio vs. strain plot - Secant and tangent modulus calculation - Triaxial tests - Stress-strain analysis - Poisson ratio vs. strain plot - Failure envelope analysis. Uniaxial test 150 100 50 0 3 1. 5E - 3 1. 0E 5E .5 -0 - 3 3 Axial Strain E- 3 -1 .0 E- 3 -1 .5 E- 3 .0 E- 2 -2 -2 .5 E- 2 E.0 -3 -3 .5 E- 2 Diametral m SStrain 0. Force (kN) 400 350 300 250 200 Strain (mm/mm) Uniaxial test: the test is performed on a cylindrical rock core with strain sensors measuring the vertical and diametral strain Uniaxial test: detail of rock sample fitted with 3 strain gages 82-P0392 Uniaxial test: example of printout ε µε 1 ε µε 3 P kN σ –σ MPa 1 3 ν - Uniaxial test on a cataclasite rock specimen. The vertical cracks are typical of the post peak. Including No.3 Transducer holders 82-D1260, No.3 Transducers 82-P0331/C and Electric mean device 82-P0331/2 174 Testing equipment for the construction industry ROCK TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . Automatic test systems 45 Determination of Elastic Modulus and strength characteristics of rock specimens in uniaxial and triaxial conditions (continued) Triaxial test Hoek cells for triaxial tests The lateral pressure is increased by programming steps and the corresponding axial load is determined. Substantially the failure point is continuously varied by changing the lateral pressure. 3 Hardened steel spherical seat 2 1 Rock specimen Rubber sealing sleeve 7 Hoek cells for triaxial tests Oil inlet General description and specifications Hoek triaxial cells are offered in four models of different size; each one consists of the following: - A cell body 1, complete with two quick release self sealing couplings, for the introduction of the hydraulic oil and cell pressure, and for air outlet and saturation of the chamber respectively. - Two end caps 2, screwed into the cylindrical cell body. - Upper 3 and lower loading caps 4 with spherical coupling - Two female spherical seatings 5 connected to the loading caps 3 and 4 for the correct transmission of the axial load from the loading frame of the compression machine to the specimen. - A rubber sealing sleeve 6 to separate the specimen from the cell fluid. Although each sleeve can be used for several tests, an order of five spare sleeves is recommended (see accessories). Measurements of axial and radial strain are carried out with the use of electric strain gauges 7, both in vertical and horizontal direction, directly glued on the lateral surface of the specimen. The wiring connections are passed within the rubber sleeve through the cell body and loading cap. Each strain gauge must be connected to a proper electric device (see 82-P0070/1) to complete and balance the Wheatstone bridge. The strain gauge measurements can be performed by automatic testing systems described on page 172 or by suitable Datalog described on page 178 The cell pressure and saturation pressure for permeability tests are carried out by the use of appropriate equipment (see page 181). Strain gauges 6 Cell body 4 5 Hoek cells sCode D.C.D.M.A. reference Specimen size d x h (mm) Weight (kg) 45-D0553 45-D0554 45-D0555 45-D0556 AX 1.5 in. BX NX 30.10 x 60 38.10 x 75 42.04 x 85 54.74 x 100 2.50 4.00 6.50 13.00 213 264 263 304 (1) Specimen plus loading caps plus spherical seatings Spare rubber sleeves sCode 45-D0553/1 45-D0554/1 45-D0555/1 45-D0556/1 D.C.D.M.A. Specimen size reference d x h (mm) AX 1.5 in. BX NX 30.10 x 60 38.10 x 75 42.04 x 85 54.74 x 100 Hoek cells for triaxial tests Accessories 45-D0556/A, 45-D0556/B s45-D0556/A (1) (1) Please refer to the right hand sketch to define the number of required parts depending on the Hoek cell size. Pair of load spreader for uniform load distribution Total height(1) mm 45-D0556/H s45-D0556/B (1) Distance pad to reduce the vertical clearance of the compression machine s45-D0556/H Hoek cells holder Schematic view of the Hoek cell with load spread and distance pads within the compression platen of the testing frame Testing equipment for the construction industry 175 45 ROCK TESTING Automatic test systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . Determination of Elastic Modulus and strength characteristics of rock specimens in uniaxial and triaxial conditions/ Accessories Accessories for Hoek cells: Rock sample extruder M 45-D0577/A Specimen extruder Used to extrude the rock sample from its jacket thus avoiding to empty the confining fluid. It consists of a steel frame with a rack and pinion mechanism. Supplied without adapters, which should be ordered separately. See adapters set. A Weight approx.: 11 kg Extruder adapters set Comprising back plate adapter, two support cell body and shaft head. Adapter set code 45-D0577/1 45-D0577/2 45-D0577/3 45-D0577/4 For specimen size AX 1.5 inch. BX NX For use with cell 45-D0553 45-D0554 45-D0555 45-D0556 Weight approx. (kg) 1.7 1.7 1.5 1.5 compression device for uniaxial tests 45-D0577/A LINEAR PATTERN STRAIN GAGES FOR UNIAXIAL AND TRIAXIAL TESTS M 45-C9034 Compression device for rock core specimens 50 to 55 mm dia., 100 to 110 mm high M 45-C9098/D Lower and upper platen compression device for rock core specimens 100 mm dia. q STANDARD ASTM D2938 The apparatus consists of a two-column frame fitted with an upper platen with spherical seat that moves vertically sustained by a spring. The lower platen is fitted to the base. Platen dimensions: 55 mm dia., 28 mm thick Platen minimum hardness: 58 HRC Resistance: 120 + 0.3 % Ohms Warking temperature: -20 to + 80°C M 82-P0390 Linear pattern strain gage, 9.53 mm length This device comprises a lower and upper platen 105 mm dia., 55 mm thick, minimum hardness 58 HRC and a clamping device to fit the upper platen of the EN series compression machines 300 mm dia. The lower platen can be easily centred on the piston or on a suitable distance piece instead of the standard compression platen of the machine. M 82-P0391 Linear pattern strain gage, 20 mm length A Weight approx.: net 5 kg Accessories M 82-P0392 Linear pattern strain gage, 30 mm length M 82-P0393 Linear pattern strain gage, 60 mm length M 82-P0399/A 45-C9034 Strain gage application kit. M 82-P0398 Electric interface for connecting up to 4 strain gages to MCC8, ADVANTEST 9 and DATALOG. M 82-P0390/1 Contacts for strain gages. 176 pieces. M 82-P0070/3 Vertical daylight: 112 mm Total height: 250 mm approx. B Overall dimensions: 145 mm dia. x 250 mm A Weight approx.: 10 kg 176 Excel data sheet for stress strain analysis and elastic modulus processing in uniaxial tests. For printout of test data and processing the following diagrams: Stress Strain curves with axial, radial and volume strain; Secant and Tangent moduli vs. axial strain; Poisson’s ratio vs. axial strain; Radial Strain vs. axial strain. 45-C9098/D Testing equipment for the construction industry M 82-P0070/4 Excel data sheet for stress strain analysis and failure envelope for triaxial tests. For printout of test data and processing the same data of the 82-P0070/3 data sheet plus the following: Strength Values vs. confining pressures and strength envelope; Mohr circles and failure envelope. ROCK TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . Automatic test systems 45 Determination of Elastic Modulus and strength characteristics of rock specimens in uniaxial and triaxial conditions/ Configuration of a complete testing system Typical configuration of an automatic system for Uniaxial and Triaxial tests on rock specimens PC Accessory Reference Standards: ISRM Suggested methods; ASTM D2664, D2938, D3148, D5407 sCode Description Q.ty Uniax. Q.ty Triax. AXIAL LOAD UNIT PC cabinet M 86-D2999 PC cabinet for testing systems. 230 V, 50 Hz, 1 ph. ADVANTEST 9 Servohydraulic control console 1 1 for load application 86-D2999 PC cabinet (optional) 1 1 50-C6600/FR 4000 kN cap. EN compression frame (other models available from 2000 to 3000 kN cap. See page 238) 1 1 50-C0050/CAL Special calibration of load digital unit assuring Class 1 from 1% of full scale 1 1 50-C9086 (1) Distance piece dia. 200x100 mm 3 1 50-C9080 (1) Distance piece dia. 200x30 mm 1 1 50-C9082 (1) Distance piece dia. 200x50 mm 2 1 50-C9842 CONFINING PRESSURE UNIT 50-C7022/S SERCOMP 7 Automatic control console for / 1 / / 1 2 HOEK CELLS (different sizes available, see page 175 We propose here NX model) 45-D0556 Hoek cell NX 54.7 mm dia. / 45-D0556/A Pair of load spreaders / 45-D0556/B Distance pad / 45-D0556/1 Spare rubber membrane / 45-D0577/A Rock sample extruder / 45-D0577/4 Extruder adapter set for NX specimens / 1 1 1 5 1 1 45-R0023 82-P0354 constant pressure system in triaxialload testing Three-way connector Pressure transducer 700 bar cap. STRAIN READING AND CONTROL (Select the suitable strain gauges within the models listed below) 82-P0398 Electric device to complete and compensate up 82-P0399/A 82-P0390 82-P0391 82-P0392 82-P0393 82-P0070/3 82-P0070/4 to four Wheatstone bridges with ¼ or ½ bridge set up 1 1 Strain gage application kit 1 1 Strain gage, grid width 4.53x9.53 mm. Pack of 10 1 1 Strain gage, grid width 3x20 mm. Pack of 10 1 1 Strain gage, grid width 2x30 mm. Pack of 10 1 1 Strain gage, grid width 1x60 mm. Pack of 10 1 / Excel data sheet for stress-strain analysis and elastic modulus processing for uniaxial tests 1 / Excel data sheet for stress-strain analysis and failure envelope for triaxial tests / 1 86-D2999 This PC cabinet is a purpose built accessory for use in many laboratory applications, where a PC is required in a testing environment. It is designed to provide PC system protection from airborne contamination such as cement dust. Filtration is achieved by two vented filters in the cabinet. The monitor can be fitted on top of the cabinet and three extractable shelves holds keyboards, printer and mouse. B Overall dimensions: A 500x550x915 mm (lxdxh) Weight approx.: 55 kg N O T E In case of uniaxial test on high strenght specimens featuring explosive failure it is suggested the use of distance pieces complete with threaded centering pin which are identified by the suffix / P. Example 50-C9086/P Detail of rock sample fitted with 3 strain gauges 82-P0392 Testing equipment for the construction industry 177 45 ROCK TESTING Semiautomatic test systems . . . . . . . . . . . . . . . . . . . . . . . Lateral pressure systems/ Stress and strain measurament Semi-automatic test system q STANDARD ASTM D2664, D2938, D3148, D5407 ISRM Sugg. Methods EN 14580, EN 1926 Introduction The Elastic modulus and strength characteristics of rock specimens in uniaxial and triaxial conditions can also be determined in the semiautomatic mode, combining a semiautomatic compression machine with a manual lateral pressure system and with all the other accessories already listed for the automatic system. The basic apparatus should comprise: - Compression testing machine of suf ficient capacity (e.g. our digital model 50-C5632 3000 kN cap.) with additional pressure transducer - Manual or automatic lateral pressure system (e.g. our models 45-D0588 or 45-D7022/S Sercomp 7) - Stress and strain rock measurement device by electric strain gauges (e.g. 82-P0908/B Datalog with accessories, pressure transducer, electric strain gauges, etc.) - Hoek cell with distance pads and load spreaders (e.g. 45-D0553, 45-D0556/A, 45-D0556/B, etc.). The uniaxial test conforming to ASTM D3148 and D2938 is performed without the lateral pressure system. In detail, all requested items, are listed in the Table on page 179 Manual lateral pressure systems 50-C4622 with 82-P0908/B, 45-D0558, Hoek cell and accessories for triaxial test Stress and strain measurement and recording M 82-P0908/B 8 channel automatic data acquisition and conditioning unit. 110-230 V, 50-60 Hz, 1 ph. This system is used to measure stress and strain characteristics of rock samples. In the standard configuration 6 channels are set for strain measurements with electric strain gauges; 2 channels are set for load/pressure measurements with transducers. Supplied complete with RS 232 serial communication cable. M 45-D0558 Low friction manual pressure maintainer for lateral pressure in the Hoek triaxial cells Used for maintaining constant the desired lateral pressure in the Hoek triaxial cells. The unit comprises a hand pump connected to a special oil reservoir, a precision pressure gauge, a pressure maintainer and a flexible hose 3 m long with 90° quick release coupling. Max. working pressure: 70 MPa A Weight approx.: 15 kg 82-P0908/B 178 Testing equipment for the construction industry ROCK TESTING . . . . . . . . . . . . . . . . . . . . . . . .Semiautomatic test systems 45 Elastic modulus and strength characteristics of rock specimens in uniaxial and triaxial conditions. Configuration of complete testing. General description and specifications Hardware Number of channels: 8 Sensors outputs: - Vex 2V DC (common to all channels) - compatible with Wheatstone full bridges (4/4). For use with 1/4 and 1/2 Wheatstone bridges, see accessory 82-P0398 Sensors inputs: - 0-20000 microV - sensors impedance from 100 Ohm to 10 kOhm Real resolution: 32000 divisions Sampling rate: adjustable up to 3 samples/ sec per channel Data storage User interface: membrane keyboard and 128x64 pixel graphic display Communication ports: RS 232 for data download to PC with Controls DATA soft 82-P0908/ SOF, CONTROLS D-TERMINAL, Microsoft HYPERTERMINAL or equivalent or for serial printer 82-P0172. Power supply: 110-230 V, 50-60 Hz, 1 ph. Dimensions: 320x250x110 mm (lxdxh) Weight: 2.5 kg approx. Typical configuration of a standard semiautomatic system for Uniaxial and Triaxial tests on rock specimens Reference Standards: ASTM D2664, D2938, D3148, D5407 ISRM Suggested method sCode Q.ty Uniax Q.ty Triax Axial load unit and test frame 50-C5632 Semiautomatic compression testing machine, 3000 kN cap. Digimax 3 dual channel data acquisition and processing system 1 1 50-C0050/CAL Special calibration of load digital unit assuring Class 1 from 1% of full scale 1 1 50-C9080 50-C9082 Distance piece dia. 200x30 mm 1 1 Distance piece dia. 200x50 mm 1 1 Confining pressure 45-D0558 Low friction manual pressure maintainer for lateral pressure 45-R0023 Three-way connector 82-P0354 Pressure transducer 700 bar cap. / 1 / 2 / 2 / 1 / 1 Distance pad / 1 Spare rubber membrane / 5 Rock sample extruder / 1 Extruder adapter set for NX specimens. (For other sizes select the sui table adapter. See page 176) / 1 Hoek cells (different sizes available, see page 175 We propose here NX model) 45-D0556 Hoek cell NX 54.7 mm dia. 45-D0556/A Pair of load spreaders 45-D0556/B 45-D0556/1 45-D0577/A 45-D0557/4 On-board firmware - Digital calibration of channels with linear and polynomial mode - Data storing can be activated from remote with external trigger - Independent storing of each channel with dedicated memory configurable as roll-over - Easy recall and management of stored readings - Alarm threshold can be activated on each channel - Date and clock function - Selection of the language. Description Strain reading and control (Select the suitable strain gauges within the models listed below) 82-P0908/B 82-P0398 82-P0399/A 82-P0390 82-P0391 82-P0392 82-P0393 82-P0070/3 82-P0070/4 1 1 Electric device to complete and compensate up to four Wheatstone bridges with ¼ or ½ bridge set up 1 1 Strain gauge application kit 1 1 Strain gauge, grid width 4.53x9.53 mm. Pack of 10 1 1 Strain gauge, grid width 3x20 mm. Pack of 10 1 1 Strain gauge, grid width 2x30 mm. Pack of 10 1 1 Strain gauge, grid width 1x60 mm. Pack of 10 1 / Excel data sheet for stress-strain analysis and elastic modulus processing for uniaxial tests 1 / Excel data sheet for stress-strain analysis and failure envelope for triaxial tests 1 8 channels automatic data acquisition and conditioning unit Accessories s82-P0908/SOF Datasoft software and serial cable for PC connection / Main features: -Displays readings on the PC screen both as numeric values and graphic plots (axes and scales adjustable) -Performs statistical elaboration of groups of readings (min. value, max. value, average value, standard deviation) -Saves measuring sessions generating files -Allows data-files management - MS Windows® 98/2000/ME/XP compatible. PC software sample screen Testing equipment for the construction industry 179 45 ROCK TESTING Classification tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Splitting tensile test/ Slake durability Splitting tensile test of intact core specimens q STANDARD 70-T0108/E equipped with the 50-C9032 device for splitting testing of rock disk ASTM D3967 Introduction This test method has been developed to measure the uniaxial tensile strength of rock specimens by the diametral compression of a disk. The splitting tensile strength is calculated as follows: σ = t 2 P ___ · _________ π L· D where: P maximum compressive force L, D thickness and diameter of rock disk. The test specimens shall be a circular disk with a thickness-to-diameter ratio (L/D) between 0.2 and 0.75. The diameter of the specimen shall be at least 10 times greater than the largest mineral grain constituent. A diameter of 54 mm (NX) will generally satisfy this criterion. We propose, as an accessory to a suitable compression frame, the 50-C9032 Compression device. Considering the average splitting strength value of different types of rock ranging from 3 to 14 MPa, a load frame of 50 kN max. capacity should be suitable. A suitable testing machine is our Universal tester 70-T0108/E, 50 kN cap. that can operate either with load or displacement control. Our Sales Dept. is at your complete disposal for any assistance you may need. M 50-C9032 Compression/splitting device for 54 mm dia. rock specimens This apparatus can be used for splitting tensile strength on rock disk 54 mm dia. Platen dia. is 75 mm. Total height 188 mm. Classification tests: Slake durability index q STANDARD ASTM D4644 M 45-D0546 Slake durability apparatus. 230 V, 50 Hz, 1 ph. M 45-D0546/Z Same as above but 110 V, 60 Hz, 1 ph. M 45-D0546/Y Same as above but 220 V, 60 Hz, 1 ph. This test method has been developed to assess the deterioration of rocks over a period of time when subjected to water immersion. The apparatus consists of a motorised drive unit which is mounted on a baseplate and which can rotate two or four drums at a speed of 20 r.p.m. The tank assemblies are filled with water to a level 20 mm below the drum axis. The test drums are manufactured from 2.00 mm mesh, 140 mm dia. x 100 mm long. A Weight approx.: 15 kg Accessories s45-D0546/1 Pair of mesh drums, complete with coupling and tanks A Weight approx.: 8 kg 45-D0546 180 General description and specifications Testing equipment for the construction industry ROCK TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Permeability of rock 45 Costant pressure apparatus Permeability of rock. Constant head type Introduction This test is performed to measure the water flow through the rock specimen contained in the Hoek cell and subjected to high confining pressure. The hydraulic gradient within the rock sample is supplied by a constant pressure apparatus and the water permeating the sample is collected in a burette. A couple of end caps are also necessary to fit the Hoek cell. 28-WF4312 with Hoek cell, permeability end caps, burette, support base and metal/glass sleeve Typical configuration of a Rock permeability test set Constant pressure apparatus sCode M 28-WF4312 Oil and water constant pressure apparatus for pressure up to 3500 kPa. 230 V, 50 Hz, 1 ph. Rock permeability within Hoek cells 28-WF4312 Oil and water constant pressure apparatus for pressure General description and specifications This apparatus provides an infinitely variable constant pressure and is used in conjunction with the Hoek cell fitted with the permeability end caps, for the investigation of the permeability of rock at high confining pressures in the laboratory. The apparatus comprises: motorised hydraulic pump; honed piston/spring assembly; precision test gauge 0-3500 kPa range; cylindrical oil/water interchange vessel; valves; 2 kg of high viscosity oil. Description Q.ty 1 up to 3500 kPa. 230 V, 50 Hz, 1 ph. 28-T0490 Nylon tubing 6x4 mm dia., 20 m coil 1 45-D0556 (1) Hoek cell NX size 1 45-D0556/3 (1) Permeability end caps for NX Hoek triaxial cell 45-D0556. 1 Set of two 86-D1160 (1) Graduated glass burette 25 ml cap. x 0.1 ml div. 1 86-D1445 Support base 200x130 mm complete with rod 10 mm dia. 1 x 500 mm long 86-D1451 Double sleeve metal/glass 1 45-D0558 (2) Low friction pressure maintainer or 1 45-C7022/S (2) Automatic control console for constant pressure system 1 in the Hoek triaxial cell. 230 V, 50 Hz, 1 ph. (alternative to 45-D0558, suggested for long term tests) (1) Or other sizes (2) Normally required/available for the triaxial test (see pages 178 and 241) Pressure range: 0-3500 kPa B Dimensions: 310x300x390 mm A Weight approx.: 16 kg Accessories s28-WF4191 45-D0558 45-C7022/S Connecting hose to the Hoek cell Permeability end caps Glass burette and accessories s28-WF4302/1 s45-D0553/3 s86-D1160 High viscosity oil. 5 l can Permeability end cap AX size s45-D0554/3 Graduated glass burette 25 ml cap. x 0.1 ml div. Permeability end cap 1.5 in. size s86-D1445 s45-D0555/3 Permeability end cap BX size s86-D1451 s45-D0556/3 Permeability end cap NX size Support base 200x130 mm Double sleeve metal/glass Hoek cells (see page 175) Testing equipment for the construction industry 181 45 ROCK TESTING Behaviour of joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Behaviour of joints Typical roughness profiles Another important section of rock mechanics involves the study of durability and discontinuities within the rock mass, where the compression and shear strength is lower. The behaviour of joints is particularly investigated: they are originated from geological failures, breaking off the rock mass continuity, along which no sliding mechanism is shown. From the rock mechanics point of view the discontinuities are characterised by mechanical strength lower than the original rock matrix and require detailed test investigations. Strength of the joint walls It is conventionally investigated with the Schmidt Hammer (L model). A series of 10 measurements is performed both on the joint walls and on a new failure surface. From the 10 values obtained the 5 lower are rejected and the compression strength is given by the average value of the last 5. This parameter is generally indicated as JCS (Joint Wall Compressive Strength), expressed in MPa. Surface roughness of the joint This parameter is defined on the joint surface with the Barton comb (Profilometer 45-D0556) used to reproduce the roughness profile. The line obtained is compared with a scale of roughness profiles, proposed by Barton, each of them is specified with a classification number JRC, variable from 0 to 20 (JRC = Joint Roughness Coefficient). Tilt test An empirical method for an immediate evaluation of the JRC index is obtained with the tilt test (model 45-B0096). It essentially consists of a horizontal plane, upon which the two parts of the sample are placed, laid one upon the other along the joint surface. Then the plane is gradually tilted until the relative displacement of the upper piece of the sample on the lower one is observed. The equipment is fitted with a lower edge, to stop the lower specimen from sliding, and one goniometer. The tilting angle measured is related to the JRC index with the following: 182 α - ϕR JRC = ______________ Log (JCS/σ) ϕR angle of residual shear friction (obtained from the shear test) σ normal pressure acting on the joint surface, generated by the weight of the upper piece of the sample JCS joint resistance (measured with the Schmidt Hammer) Shear strength of the joint It is obtained from the direct shear test. The peak resistance of a rough joint is calculated from the following relationship (Barton, 1973): τ = σ · tg (ϕ + ieff) with JCS ieff = JRC · log ______ σ Testing equipment for the construction industry Therefore the shear test is performed: - on a smooth joint to directly obtain the shear friction angle ϕ - on a rough joint to calculate ϕ from JCS and JRC. From the above expression it is interesting to observe that, when the normal stress σ equals JCS (compression strength of the joint itself), i becomes 0. The mechanical explanation is that, when the joint walls are fractured for the applied high normal pressure, the shear resistance of the rock only depends from the shear strength angle ϕ and not from the surface roughness of the joint. For the measurement of the residual shear strength of the joint the direct shear test is also used. The mathematical expression representing the behaviour of residual strength is the Coulomb’s linear failure envelope without cohesion: eff τ = σ · tg ϕR ROCK TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Behaviour of joints 45 Measurement of shear strength Roughness measurement. Profilometers / Tilt test Measurement of shear strength q STANDARD ASTM D5607 (1) ISRM: Suggested method for determining shear strength (1974) (1) To perform the test conforming to ASTM standard, four dial gauges for vertical displacement are requested. See accessory 45-D0548/10 M 45-D0548 Rock shear box apparatus. Hand operated General description and specifications This apparatus was originally developed at Imperial College, London, by Professor E. Hoek. It is a simple and practical method of determining the strength and slope stability of rock, both in the field and in the laboratory. The apparatus consists of a shear box designed to accept rock samples not larger than 115x125 mm, or alternatively cores up to 102 mm dia. The shear box consists of two halves, the upper being connected to two rams for reversible shearing action and the lower connected to a ram for normal load application. The loads are recorded by Bourdon tube load gauges. The normal loading system is complete with an adjustable low friction pressure maintainer to absorb volume changes of the specimen during the shearing action and to ensure a constant vertical stress. The apparatus is supplied complete with two 50 kN pumps and manometers and two mould forms used for the correct alignment of the sample before the test with cementation. Gauge range: 50 kN x 1 kN B Dimensions: 460x250x600 mm A Weight approx.: 45 kg Accessories s45-D0548/9 High alumina cement for the cementation of the sample in the shear box. 50 kg bag s82-D1257 Dial gauge 30 mm travel for horizontal displacement x 0.01 mm s45-D0548/10 Set of 4 dial gauges 10x0.002 mm complete with mounting brackets Spare parts s45-D0548/8 Mould former One of the pumps is fitted with a pressure maintainer to assure auniform load during the test 45-D0548 Tilt test M 45-B0096 Apparatus for measurement of the joint roughness coefficient (Tilt Test) Detail of the shear box apparatus fitted with the 45-D0548/10 accessory to perform the test conforming to the ASTM D5607 standard Roughness measurement. Profilometers Used for measurement of the roughness profile of rock samples. 45-B0096 M 45-D0566 Profilometer (Barton comb). 300 mm length General description and specifications A Weight approx.: 1 kg M 45-D0566/A Profilometer (Barton comb). 150 mm length A Weight approx.: 0.5 kg 45-D0566 It is used to calculate the JRC of a rock or of a joint. The equipment consists of an adjustable inclined plane, on which the rock sample (100 mm dia. max.) is placed, separated along the surface where the roughness is to be measured. Then the plane is slowly tilted until sliding of the upper part of the sample on the lower one occurs. From the measured inclination angle it is possible to evaluate the roughness index. Inclination angle: 0-50° B Overall dimensions: 265x170x260 mm A Weight approx.: 4 kg s45-D0548/1 Load gauge, range 0-50 kN x 1 kN Testing equipment for the construction industry 183 45 ROCK TESTING Classification tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Strength index/ Rock classification hammer Strength index - Light and portable unit - Sample size up to 102 mm dia. - Accepts irregular shaped samples - High resolution digital display battery operated - Resistant to failure shocks - Serial port for PC connection included q STANDARD ASTM D5731 - ISRM: Suggested method. M 45-D0550/E Digital rock strength index apparatus (Franklin Press) General description and specifications The apparatus consists of a load frame 60 kN capacity with a hydraulic loading ram actuated by a hand pump. The frame is adjustable to allow for testing sample up to 102 mm dia. A ruler assembled on the frame allows for direct measurement of the distance D between the conical platens before and after the test. The compression load is measured by a pressure transducer with an advanced digital display unit assuring the best accuracy and resistance to the failure shocks. The machine, fitted with the accessory 45-D0550/D5, can also be used for compression tests on small cores or cylindrical specimens. The apparatus is contained in an easyly transportable plastic case. Load range: 0-60 kN Digital display: 2x16 characters Resolution: 32.000 div. Load pacer included Load measured in both kN and MPa Serial port for PC connection Accuracy: ± 1% Case dimensions: 800x500x280 mm Weight: 15 kg approx. Accessories s45-D0550/D5 Set of lower and upper platen 52 mm dia. with spherical seat for compression tests s45-D1717 Clear safety goggles Spare parts s45-D0550/A7 Set of hardened conical platens s45-D0550/A8 Set of gaskets for cylinder and pump 45-D0550/E Compression strength q STANDARD: ASTM D5873 ISRM: Suggested method M 45-D0561 Rock classification hammer (Schmidt hammer – Low impact energy model) General description and specifications Used to measure the rebound index on rock cores and samples. The apparatus is simple, easy to use, and is similar to the one used for testing concrete. The level of impact energy only is different: 0.74 Nm. Rock cores are positioned horizontally and the rebound index is obtained from the average of several measurements performed perpendicularly to the longitudinal axis. The unit is supplied complete with carrying case. B Dimensions of case: 78 mm dia. x 335 mm Accessories M 45-D0562/A ASTM rock cradle Universal model, can hold all standard rock core sample from EX to NX size (21.46 to 54.74 mm dia.) and even more. The apparatus comprises a vertical hammer guide fitted to a steel plate of minimum mass conforming to ASTM D5873, and a magnetic “V” block that can be easily fitted to the steel plate. B Dimensions: 220 mm dia. x 420 mm high approx. A Weight approx.: 27 kg 184 Testing equipment for the construction industry M 58-C0184 Calibration anvil q STANDARD EN 12504-2 ASTM C805, D5873 Used for calibration of concrete test hammer (models 58-C0181/N) and Rock classification hammer (model 45-D0561). Made of special alloy steel and supplied complete with traceable hardness certificate. It is essential for the periodical laboratory verification of the Rock classification hammer. B Dimensions: 150 mm dia. x 230 mm height A Weight approx.: 16 kg 45-D0561 with 45-D0562/A