Last Minute Risk Analysis (LMRA)

advertisement

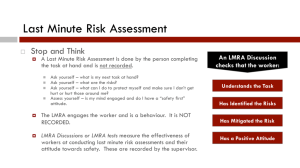

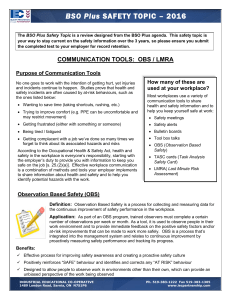

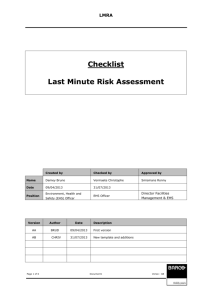

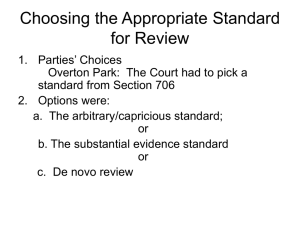

Last Minute Risk Analysis (LMRA) January 2011 During the inspections carried out by DIBEC we regularly come across undesirable situations that could easily have been prevented. We are talking here about activities that are undertaken without thinking carefully about the risks that could have an impact on health and safety. By performing an LMRA it is possible to identify these risks in good time and often also to eliminate them. In this newsletter we would like to provide you with further information on how the LMRA works and how using it can contribute to a good, safe working environment for all employees. The new “VCA */**/petrochemicals” health and safety checklists for contractors include the requirement to perform an LMRA. The LMRA has already been introduced within various Ballast Nedam companies. However, we have noticed that it is not yet being applied by everyone on a daily basis. The LMRA originated in the petrochemical industry. Here it is often necessary to perform an LMRA in advance in order for work to be allowed to begin. In many cases this LMRA is linked to a work permit and therefore has to be carried out in a demonstrable way. This means that a checklist has to be completed every day before work gets under way and, if no risks are identified, activities can commence in a safe manner. Within Ballast Nedam an LMRA was chosen that employees perform in their heads and therefore does not need to be recorded. The aim of the LMRA is to increase safety in the workplace for construction site employees. If employees themselves think, before starting work, about the environment and situations in which various activities need to be performed, for example, risky situations can be avoided. The LMRA is performed before work begins. Employees are required to check whether any risks are present. If risks are found, employees must consider whether the causes can be identified and, if they can, a solution must be thought of and implemented. An important point to note is that if a dangerous situation is identified, this must always be reported to the employee’s manager. In this way the manager can prevent a similar risk from arising again for other employees or when similar activities are being carried out at a later stage. A tool has been devised to assist employees in this task. This is a card stating potential risks and the steps to be taken to ensure that work can be carried out safely and effectively. The card is shown at the bottom of this newsletter and is available in various languages. It can be ordered via Ballast Nedam’s Reprographics department. It is advisable to draw the attention of construction site employees to the way the LMRA is performed on a regular basis. This can be done with the help of a toolbox, for example, or by talking to employees while they are carrying out their work. The LMRA naturally also applies to subcontractors, who must be made aware during their introduction that they are also expected to perform the LMRA. An important point to note in relation to the LMRA is that employees should be given a proper introduction to it. This applies both to the company’s own employees and to subcontractors. DIBEC can assist you with this. If you are interested in organising an introduction to the LMRA or a refresher session, or if you have any questions as a result of this newsletter, please do not hesitate to contact us.