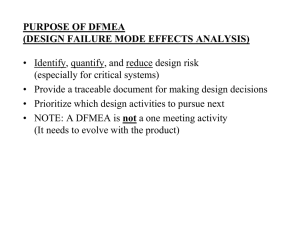

Example of Design Failure Mode and Effect Analysis Design Failure

advertisement

Example of Design Failure Mode and Effect Analysis Design Failure Mode and Effect Analysis Team Approach: The DFMEA is developed and maintained by a multi- disciplinary (or cross-functional) team typically led by the design responsible engineer from the responsible design source (e.g., OEM, Tier 1 supplier or Tier 2 supplier and below). The responsible engineer is expected to directly and actively involve representatives from all affected areas. The areas of expertise and responsibility may include, but are not limited to, assembly, manufacturing, design, analysis/test, reliability, materials, quality, service, and suppliers, as well as the design area responsible for the next higher or lower assembly or system, subsystem, or component. Manufacturing, Assembly, and Serviceability Consideration: The DFMEA should include any potential failure modes and causes that can occur during the manufacturing or assembly process which are the result of the design. Such failure modes may be mitigated by design changes (e.g., a design feature which prevents a part from being assembled in the wrong orientation — i.e., errorproofed). When not mitigated during the DFMEA analysis (as noted in the action plan for that item), their identification, effect, and control should be transferred to and covered by the PFMEA. The DFMEA does not rely on process controls to overcome potential design weaknesses, but it does take the technical and physical limits of a manufacturing and assembly process into consideration, for example: Necessary mold drafts Limited surface finish capability Assembling space (e.g., access for tooling) Limited hardenability of steels Tolerances/process capability/performance The DFMEA can also take into consideration the technical and physical limits of product serviceability and recycling once the product has entered field use, for example: The DFMEA focuses on the design of the product that will be delivered to the final customer (End User). The prerequisite tasks for an effective analysis of the product design include: assembling a team, determining scope, creating block diagrams or P-diagrams depicting product function and requirements. A clear and complete definition of the desired product characteristics better facilitates the identification of potential failure modes. The DFMEA process can be mapped to the customer or organization‟s product development process. A DFMEA should begin with the development of information to understand the system, subsystem, or component being analyzed and define their functional requirements and characteristics. In order to determine the scope of By Pretesh Biswas (APB Consultant) 1 Tool access Diagnostic capability Material classification symbols (for recycling) Materials/chemicals used in the manufacturing processes Page Example of Design Failure Mode and Effect Analysis the DFMEA, the team should consider the following as applicable to component, subsystem or system DFMEAs: What processes, mating components, or systems does the product interface with? Are there functions or features of the product that affect other components or systems? Are there inputs provided by other components or systems that are needed to perform intended functions of the product? Do the product‟s functions include the prevention or detection of a possible failure mode in a linked component or system? These are some of the tools that may be applied, as appropriate, to assist the team in developing the DFMEA. Block (Boundary) Diagram Example. By Pretesh Biswas (APB Consultant) Page The block diagram indicates the interaction of components and subsystems within the scope of the design. This interaction may include: flow of information, energy, force, or fluid. The objective is to understand the requirements or inputs to the system, the activities acting on the inputs or function performed, and the deliverables or output. The diagram may be in the form of boxes connected by lines, with each box corresponding to a major component of the product or a major step of the process. The lines correspond to how the product components are related to, or interface with each other. The organization needs to decide the best 2 The block diagram of the product shows the physical and logical relationships between the components of the product. There are different approaches and formats to the construction of a block diagram. Example of Design Failure Mode and Effect Analysis approach or format for the block diagram. Copies of the diagrams used in DFMEA preparation should accompany the DFMEA. Parameter (P) diagram: Example of Parameter (P) diagram The P-Diagram is a structured tool to help the team understand the physics related to the function(s) of the design. The team analyzes the intended inputs (signals) and outputs (responses or functions) for the design as well as those controlled and uncontrolled factors which can impact performance. The inputs to the product and outputs from the product, i.e., the intended and unintended functions of the product, are useful in identifying error states, noise factors, and control factors. The error states correspond to the Potential Failure Modes in the DFMEA. Other tools and resources that may help the team understand and define the design requirements may include: By Pretesh Biswas (APB Consultant) Page Another step in the DFMEA process is a compilation of the functional and interface requirements of the design. This list may include the following categories such as General (This category considers the purpose of the product and its overall design intent), Safety, Government Regulations, Reliability (Life of the Function), Loading and Duty Cycles such as Customer product usage profile, Quiet Operations such as Noise, vibration and harshness (NVH), Fluid Retention, Ergonomics, Appearance, Packaging &Shipping , Service and Design for assembly & manufacturing. 3 Functional Requirements: Example of Design Failure Mode and Effect Analysis Schematics, drawings, etc. Bill of Materials (BOM) Interrelationship matrices Interface matrix Quality Function Deployment (QFD) Quality and Reliability History The use of these tools, supported by engineering experience and historical information, can assist in defining a comprehensive set of requirements and functions. The example used with the sample form deals with a Front Door assembly. The product has several functional requirements: Permit ingress to and egress from vehicle Provide occupant protection from Weather (comfort) Noise (comfort) Side impact (safety) Support anchorage for door hardware including Mirror Hinges Latch Window regulator Provide proper surface for appearance items Paint. Soft trim Maintain integrity of inner door panel Page 4 The final DFMEA would include analysis of all these requirements. The example includes part of the analysis of them requirement: “Maintain integrity of inner door panel”. By Pretesh Biswas (APB Consultant) Example of Design Failure Mode and Effect Analysis FMEA Number (A) Enter an alphanumeric string which is used to identify the FMEA document. This is used for document control. System, Subsystem, or Component Name and Number (B). Enter the name and number of the system, subsystem, or component which is being analyzed. Design Responsibility (C) Enter the OEM, organization, and department or group who is design responsible. Also enter the supply organization name, if applicable. Model Year(s)/Program(s) (D) Enter the intended model year(s) and program(s) that will use or be affected by the design being analyzed (if known). Key Date (E). Enter the initial DFMEA due date, which should not exceed the scheduled production design release date. Page Enter the date the original DFMEA was completed and the latest revision date. 5 FMEA Dates (F) By Pretesh Biswas (APB Consultant) Example of Design Failure Mode and Effect Analysis Core Team (G) Enter the team members responsible for developing the DFMEA. Contact information (e.g., name, organization, telephone number, and email) may be included in a referenced supplemental document. Prepared By (H) Enter the name and contact information including the organization (company) of the engineer responsible for preparing the DFMEA. Body of DFMEA Form (Fields a-n) The body of the FMEA contains the analysis of risks related to the potential failures, and improvement action being taken. Item / Function /Requirements (a) Item/Function can be separated into two (or more) columns or combined into a single, bridged column which encompasses these elements. Interfaces (as “items” of analysis) can be either combined or separate. Components may be listed in the item/function column, and an additional column may be added containing the functions or requirements of that item. “Item”, “Function”, and “Requirements” are described below: Item (a 1) Enter the items, interfaces, or parts which have been identified through block diagrams, P-diagrams, schematics and other drawings, and other analysis conducted by the team. The terminology used should be consistent with customer requirements and with those used in other design development documents and analysis to ensure traceability. Function (a1) Enter the function(s) of the item(s) or interface(s) being analyzed which are necessary to meet the design intent based on customer requirements and the team‟s discussion. If the item(s) or interface has more than one function with different potential modes of failure, it is highly recommended that each of these functions and associated failure mode(s) is listed separately. Function becomes a2 if Item and Function are split. Requirements (a2) An additional column, “Requirements”, may be added to further refine the analysis of the failure mode(s). Enter the requirement(s) for each of the functions being analyzed (based on customer requirements and the team‟s discussion). If the function has more than one requirement with different potential modes of failure, it is highly recommended that each of the requirements and functions are listed separately. By Pretesh Biswas (APB Consultant) Page Potential failure mode is defined as the manner in which a component, subsystem, or system could potentially fail to meet or deliver the intended function described in the item column. Identify the potential failure mode(s) associated with the function(s)/requirement(s). Potential failure modes should be described in technical terms, and not necessarily as a symptom noticeable by the customer. Each function may have multiple failure modes. A large number of failure modes identified for a single function may indicate that the requirement is not well defined. The assumption is made that the failure could occur, but may not necessarily occur, consequently the 6 Potential Failure Mode (b) Example of Design Failure Mode and Effect Analysis use of the word “potential”. Potential failure modes: that could occur only under certain operating conditions (i.e., hot, cold. dry, dusty, etc.) and under certain usage conditions (i.e., above-average mileage, rough; terrain, city driving only, etc.) should be considered. After determining all the failure modes, a validation of the completeness of the analysis can be made through a review of past things-gone-wrong, concerns, reports, and group brainstorming. The potential failure mode may also be the cause of a potential failure mode in a higher level subsystem or system, or lead to the effect of one in a lower level component. Potential Failure Modes Potential Effect(s) of Failure (c) Page 7 Potential effects of failure are defined as the effects of the failure mode on the function, as perceived by the customer(s). Describe the effects of the failure in terms of what the customer might notice or experience, remembering that the customer may be an internal customer as well as the ultimate End User. State clearly if the failure mode could impact safety or non-compliance to regulations. The effects should always be stated in terms of the specific system, subsystem, or component being analyzed. Remember that a hierarchical relationship exists between the component, subsystem, and system levels. For example, a part could fracture, which may cause the assembly to vibrate, resulting in an intermittent system operation. The intermittent system operation could cause performance to degrade and ultimately lead to customer dissatisfaction. The intent is to predict the potential failure effects to the team‟s level of knowledge. By Pretesh Biswas (APB Consultant) Example of Design Failure Mode and Effect Analysis Example of Potential Effect Severity (d): Severity is the value associated with the most serious effect for a given failure mode. Severity is a relative ranking within the scope of the individual FMEA. The team should agree on evaluation criteria and a ranking system and apply them consistently, even if modified for individual process analysis. It is not recommended to modify criteria ranking values of 9 and10. Failure modes with a rank of severity 1 should not be analyzed further. Failure to Meet Safety and/or Regulatory Requirements Loss or Degradation of primary function Loss or Degradation of secondaryfunction Annoyance 10 9 8 7 6 5 4 3 2 1 Page No effect Potential failure mode affects safe vehicle operation and/or involves noncompliance with government regulation without warning. Potential failure mode affects safe vehicle operation and/or involves noncompliance with government regulation with warning. Loss of primary function (vehicle inoperable, does not affect safe vehicle operation) Degradation of primary function (vehicle operable, but at reduced level of performance) Loss of secondary function (vehicle operable, but convenience functions inoperable). Degradation of secondary function (vehicle operable, but comfort /convenience functions at reduced level of performance). Appearance or Audible Noise, vehicle operable, item does not conform and noticed by most customers (> 75%) Appearance or Audible Noise, vehicle operable, item does not conform and noticed by many customers (50%). Appearance or Audible Noise, vehicle operable, item does not conform and noticed by discriminating customers (< 25%) No discernible effect. Example of DFMEA Severity Evaluation criteria Rank 8 Criteria Severity of Effect on Product(Customer Effect) Effect By Pretesh Biswas (APB Consultant) Example of Design Failure Mode and Effect Analysis Classification (e) This column may be used to highlight high-priority failure modes and their associated causes. As a result of this analysis, the team may use this information to identify special characteristics. Customer specific requirements may identify special product or process characteristic symbols and their usage. A characteristic designated in the design record as special without an associated design failure mode identified in the DFMEA is an indication of a weakness in the design process. Potential Cause(s)/Mechanism(s) of Failure Mode (f) This information can be separated into multiple columns or combined into a single column. In the development of the FMEA, the identification of all potential causes of the failure mode is key to subsequent analysis. Although varied techniques (such as brainstorming) can be used to determine the potential cause(s) of the failure mode, it is recommended that the team should focus on an understanding of the failure mechanism for each failure mode. Potential Mechanism(s) of Failure Mode (f1) A failure mechanism is the physical, chemical, electrical, thermal, or other process that results in the failure mode. It is important to make the distinction that a failure mode is an "observed" or "external" effect so as not to confuse failure mode, with failure mechanism, the actual physical phenomenon behind the failure mode or the process of degradation or chain of events leading to and resulting in a particular failure mode. To the extent possible, list every potential mechanism for each failure mode. The mechanism should be listed as concisely and completely as possible. For a system, the failure mechanism is the process of error propagation following a component failure which leads to a system failure. A product or process can have several failure modes which are correlated to each other because of a common failure mechanism behind them. Ensure that process effects are considered as part of the DFMEA process. Page Potential cause of failure is defined as an indication of how the design process could allow the failure to occur, described in terms of something that can be corrected or can be controlled. Potential cause of failure may be an indication of a design weakness, the consequence of which is the failure mode. Causes are the circumstances that induce or activate a failure mechanism. In identifying potential causes of failure, use concise descriptions of the specific causes of failures, e.g., specified bolt plating allows for hydrogen embrittlement. Ambiguous phrases such as, poor design or improper design, should not be used. Investigation of causes needs to focus on the failure mode and not on the effect(s). In determining the Cause(s), the team should assume the existence of the cause under discussion will result in the failure mode (i.e., the failure mode does not require multiple causes to occur). Typically, there may be several causes each of which can result in the failure mode. This results in multiple lines (cause branches) for the failure mode. To the extent possible, list every potential cause for each failure mode/failure mechanism. The cause should be listed as concisely and completely as possible. Separating the causes will result in a focused analysis for each cause and may yield different measurement, controls, and action plans. In preparing the DFMEA, assume that the design will be manufactured and assembled to the design intent. Exceptions can be made at the team‟s discretion where historical data indicate deficiencies in the manufacturing process. 9 Potential Cause(s) of Failure Mode (f2) By Pretesh Biswas (APB Consultant) Example of Design Failure Mode and Effect Analysis Failure Mode Mechanism Cause Mechanical linkage break due to inadequate corrosion protection Master cylinder vacuum lock due to seal design No transfer of Vehicle does not Loss of hydraulic fluid from loose hydraulic line due to incorrect force from pedal to stop connector torque specification. pads Loss of hydraulic fluid due to hydraulic lines crimped/compressed, inappropriate tube material specified. Mechanical linkage joints stiff due to inappropriate lubrication specification, Reduced transfer Vehicle stops in Mechanical linkage joints corroded due to inadequate corrosion of force from excess of yy feet protection. pedal to pads Partial loss of hydraulic fluid due to hydraulic lines crimped, inappropriate tube material specified Stops vehicle Excessive/rapid Cumulative pressure build-up in master cylinder due to seal with more than xx transfer of force design g‟s of force from pedal to pads Activate with no Corrosion or deposit build up on rails or pad ears clue to surface demand; Vehicle finish not promoting adequate self-cleaning and corrosion Pads do not release movement is protection impeded Activate with no Hydraulic pressure demand; Vehicle Master cylinder vacuum lock due to seal design does not release cannot move Examples of Potential Causes Occurrence (g) Occurrence is the likelihood that a specific cause/mechanism will occur resulting in the failure mode within the design life. The likelihood of occurrence ranking number has a relative meaning rather than an absolute value. A consistent occurrence ranking system should be used to ensure continuity. The occurrence number is a relative ranking within the scope of the FMEA and may not reflect the actual likelihood of occurrence. The team should agree on evaluation criteria and a ranking system and apply them consistently, even if modified for individual process analysis. Occurrence should be estimated using a 1 to 10 scale. In determining this estimate, questions such as the following should be considered: Page Is the item a carryover or similar to a previous level item? How significant are changes from a previous level item? Is the item radically different from a previous level item? Is the item completely new? What is the application or what are the environmental changes? . Has an engineering analysis (e.g., reliability) been used to estimate the expected comparable occurrence rate for the application? Have preventive controls been put in place? What is the service history and field experience with similar components, subsystems, or systems? 10 By Pretesh Biswas (APB Consultant) Example of Design Failure Mode and Effect Analysis Likelihood of Failure Criteria: Occurrence of Cause – DFMEA (Design life/reliability of item/vehicle) Very High New technology/new design with no history. High Moderate Low Very Low Criteria: Occurrence of Cause DFMEA (Incidents per Items/vehicles) 100 per thousand 1 in 10 Rank Failure is inevitable with new design, new application, or change in duty cycle/operating conditions. Failure is likely with new design, new application, or change in duty cycle/operating conditions. 50 per thousand 1 in 20 9 20 per thousand 1 in 50 8 Failure is uncertain with new design, new application, or change in duty cycle/ operating conditions. Frequent failures associated with similar designs or in design simulation and testing. Occasional failures associated with similar designs or in design simulation and testing. Isolated failures associated with similar designs or in design simulation and testing. Only isolated failures associated with almost identical design or in design simulation and testing. No observed failures associated with almost identical design or in design simulation and testing. Failure is estimated through Preventive controls. 10 per thousand 1 in 100 7 2 per thousand 1 in 500 6 0.5 per thousand 1 in 2,000 5 0.1 per thousand 1 in 10,000 4 0.O1 per thousand 1 in 1,00,000 3 0.OO1 per thousand 1 in 1,000,000 2 Failure is estimated through Preventive controls. Example of DFMEA Occurrence Evaluation Criteria 10 1 Current Design Controls (h) Current Design Controls are those activities conducted as part of the design process that have been completed or committed to and that will assure the design adequacy for the design functional and reliability requirements under consideration. Eliminate (prevent) the cause of the mechanism of failure or the failure mode from occurring, or reduce its rate of occurrence. By Pretesh Biswas (APB Consultant) Page Prevention: 11 There are two types of design controls to consider: Example of Design Failure Mode and Effect Analysis Detection: Identify (detect) the existence of a cause, the resulting mechanism of failure or the failure mode, either by analytical or physical methods, before the item is released for production. The preferred approach is to first use prevention controls, if possible. The initial occurrence rankings will be affected by the prevention controls provided they are integrated as part of the design intent. Detection control should include identification of those activities which detect the failure mode as well as those that detect the cause. The team should consider analysis, testing, reviews, and other activities that will assure the design adequacy such as: Prevention Controls Benchmarking studies Fail-safe designs Design and Material standards (internal and external) Documentation — records of best practices, lessons learned, etc. from similar designs Simulation studies — analysis of concepts to establish design requirements Error-proofing Detection controls Design reviews Prototype testing Validation testing Simulation studies — validation of design Design of Experiments; including reliability testing Mock-up using similar parts Failure Mode Cause Mechanical linkage break due to inadequate corrosion protection Master cylinder vacuum lock due to seal design Designed per material standard MS-845 Carry-over design with same duty cycle requirements Designed per torque requirements -3993 Detection Control Environmental stress test 03 -9963 Pressure variability testing — system level Loss of hydraulic fluid from loose Vibration step stress test hydraulic line due to incorrect 18-195O connector torque specification Loss of hydraulic fluid due to Designed per Material Design of Experiments hydraulic lines crimped/compressed, standard MS-1178 (DOE) — tube resiliency inappropriate tube material specified Examples of Prevention and Detection Design Controls Page 12 Vehicle does not stop Preventive Control By Pretesh Biswas (APB Consultant) Example of Design Failure Mode and Effect Analysis Detection (i) Detection is the rank associated with the best detection control listed in the Current Design Control Detection column. When more than one control is identified, it is recommended that the detection ranking of each control be included as part of the description of the control. Record the lowest ranking value in the Detection column. A suggested approach to Current Design Control Detection is to assume the failure has occurred and then assess the capabilities of the current design controls to detect this failure mode. Do not automatically presume that the detection ranking is low because the occurrence is low. It is important to assess the capability of the design controls to detect low frequency failure modes or reduce the risk of them going further in the design release process. Detection is a relative ranking within the scope of the individual FMEA. In order to achieve a lower ranking, generally the design control has to be improved. The team should agree on evaluation criteria and a ranking system and apply them consistently, even if modified for individual process analysis. No current design control; Cannot detect or is not analyzed. Rank 10 Design analysis/detection controls have a weak detection Not likely to capability; Virtual Analysis (e.g., CAE, FEA, etc.) is not correlated 9 detect at any stage to expected actual operating conditions. Product verification/validation after design freeze& prior to launch with pass/fail testing (Subsystem or system testing with acceptance 8 criteria such as ride and handling, shipping evaluation, etc.) Post Design Product verification/validation after design freeze and prior to Freeze and launch with test to failure testing (Subsystem or system testing until 7 prior to launch failure occurs, testing of system interactions, etc.). Product verification/validation after design freeze and prior to launch with degradation testing (Subsystem or system testing after 6 durability test, e.g., function check). Product validation (reliability testing, development or validation tests) prior to design freeze using pass/fail testing (e.g., acceptance 5 criteria for performance, function checks, etc.) Prior to Design Product validation (reliability testing, development or validation Freeze tests) prior to design freeze using test to failure (e.g., until leaks, 4 yields, cracks, etc.) Product validation (reliability testing, development or validation tests) prior to design freeze using degradation testing (e.g., data 3 trends, before/after values, etc.) Virtual Design analysis/detection controls have a strong detection Analysis capability. Virtual analysis (e.g. CAE, FEA, etc.) is highly 2 Correlated correlated with actual or expected operating conditions prior to design freeze. Detection not Failure cause or failure mode cannot occur because it is fully applicable; prevented through design solutions (e.g., proven design standard, 1 Failure Prevention best practice or common material, etc.) Suggested DFMEA/PFMEA Prevention/Detection Evaluation Criteria By Pretesh Biswas (APB Consultant) Likelihood for Detection Almost Impossible Very Remote Remote Very low low Moderate Moderately high High Very High Almost Certain 13 No detection opportunity Criteria: Likelihood of Detection by Design Control Page Opportunity for Detection Example of Design Failure Mode and Effect Analysis Determining Action Priorities Once the team has completed the initial identification of failure modes and effects, causes and controls, including rankings for severity, occurrence, and detection, they must decide if further efforts are needed to reduce the risk. Due to the inherent limitations on resources, time, technology, and other factors, they must choose how to best prioritize these efforts. The initial focus of the team should be oriented towards failure modes with the highest severity rankings. When the severity is 9 or 10, it is imperative that the team must ensure that the risk is addressed through existing design controls or recommended actions. For failure modes with severities 8 or below the team should consider causes having highest occurrence or detection rankings. It is the team‟s responsibility to look at the information identified, decide upon an approach, and determine how to best prioritize the risk reduction efforts that best serve their organization and customers. Risk Priority Number or RPM (i) One approach to assist in action prioritization has been to use the Risk Priority Number: RPN = Severity (S) x Occurrence (O) x Detection (D) Within the scope of the individual FMEA, this value can range between 1 and 1000. The use of an RPN threshold is NOT a recommended practice for determining the need for actions. Applying thresholds assumes that RPNS are a measure of relative risk (which they often are not) and that continuous improvement is not required (which it is). For example, if the customer applied an arbitrary threshold of 100 to the following, the supplier would be required to take action on the characteristic B with the RPN of 112. By Pretesh Biswas (APB Consultant) Page (e.g., vehicle launch) is desirable, it should be based on an analysis of severity, occurrence and detection and not through the application of RPN thresholds. Use of the RPN index in the discussions of the team can be a useful tool. The limitations of the use of RPN need to be understood. However, the use of RPN „thresholds to determine action priority is not recommended. 14 In this example, the RPN is higher for characteristic B, but the priority should be to work on A with the higher severity of 9, although the RPN is 90 which is lower and below the threshold. Another concern with using the threshold approach is that there is no specific RPN value that requires mandatory action. Unfortunately, establishing such thresholds may promote the wrong behavior causing team members to spend time trying to justify a lower occurrence or detection ranking value to reduce RPN. This type of behavior avoids addressing the real problem that underlies the cause of the failure mode and merely keeps the RPN below the threshold. It is important to recognize that while determining “acceptable” risk at a particular program milestone Example of Design Failure Mode and Effect Analysis Recommended Action (k) In general, prevention actions (i.e., reducing the occurrence) are preferable to detection actions. An example of this is the use of proven design standard or best practice rather than product verification/validation after design freeze. The intent of recommended actions is to improve the design. Identifying these actions should consider reducing rankings in the following order: severity, occurrence, and detection. Example approaches to reduce these are explained below: To Reduce Severity Ranking: Only a design revision can bring about a reduction in the severity ranking. High severity rankings can sometimes be reduced by making design revisions that compensate or mitigate the resultant severity of failure. For example: The requirement for a tire is to “retain applied air pressure under use”. The severity of the effect of the failure mode “rapid loss of air pressure” would be lower for a "run flat" tire. A design change, in and of itself, does not imply that the severity; will be reduced. Any design change should be reviewed by the team to determine the effect to the product functionality and process. For maximum effectiveness and efficiency of this approach, changes to the product and process design should be implemented early in the development process. For example, alternate materials may need to be considered early in the development cycle to eliminate corrosion severity. To Reduce Occurrence Ranking: A reduction in the occurrence ranking can be effected by removing or controlling one or more of the causes or mechanisms of the failure mode through a design revision. Actions such as, but not limited to, the following should be considered: Error proof the design to eliminate the failure mode Revised design geometry and tolerances Revised design to lower the stresses or replace weak (high failure probability) components Add redundancy Revised material specification To Reduce Detection (D) Ranking: The preferred method is the use of error/mistake proofing. An increase in design validation/ verification actions should result in a reduction of the detection ranking only. In some cases, a design change to a specific part may be required to increase the likelihood of detection (i.e., reduce, the detection ranking). Additionally, the following should be considered: If the assessment leads to no recommended actions for a specific failure mode/cause/control combination, indicate this by entering “None” in this column. It may be useful to also include a rationale if “None” is entered, especially in case of high severity. For design actions consider using the following: By Pretesh Biswas (APB Consultant) 15 Design of Experiments (particularly when multiple or interactive causes of a failure mode are present) Revised test plan Page Example of Design Failure Mode and Effect Analysis Results of design DOE or reliability testing Design analysis (reliability, structural or physics of failure) that would confirm that the solution is effective and does not introduce new potential failure modes Drawing, schematics, or model to confirm physical change of targeted feature Results from a design review Changes to a given Engineering Standard or Design Guidelines Reliability analysis results Item Failure Mode Cause Mechanical linkage break due to inadequate corrosion protection Master cylinder vacuum lock due to seal design Disk Brake System Vehicle does not stop Loss of hydraulic fluid from loose hydraulic line due to incorrect connector torque specification Prevention Controls Designed per material standard MS845 Carry-over design with same duty cycle requirements Designed per torque requirements3993 Detection Controls Environmental stress test 03-9963 Pressure variability testing system level Recommendatio n Action Change material to stainless steel Use carry-over seal design Vibration step- Modify connector stress from bolt-style to test 18-1950 quick-connect Loss of hydraulic fluid due to Designed per Modify hose hydraulic lines material DOE -tube design from MScrimped/ standard MSresiliency. 1178 to MS-2025 compressed, 1178 to increase inappropriate tube strength material specified Examples of Causes, Controls and Recommended Actions Responsibility & Target Completion Date (I) Enter the name of the individual and organization responsible for completing each recommended action including the target completion date. The design-responsible engineer/team leader is responsible for ensuring that all actions recommended have been implemented or adequately addressed. Action Results (m-n) This section identifies the results of any completed actions and their effect on S, O, D rankings and RPN Page After the action has been implemented, enter a brief description of the action taken and actual completion date. 16 Action(s) Taken and Completion Date (m) By Pretesh Biswas (APB Consultant) Example of Design Failure Mode and Effect Analysis Severity, Occurrence, Detection and RPN (n) Page 17 After the preventive/corrective action has been completed, determine and record the resulting severity, occurrence, and detection rankings. Calculate and record the resulting action (risk) priority indicator (RPN). All revised rankings should be reviewed. Actions alone do not guarantee that the problem was solved (i.e., cause addressed), thus an appropriate analysis or test should be completed as verification. If further action is considered necessary, repeat the analysis. The focus should always be on continuous improvement. By Pretesh Biswas (APB Consultant)