effect of microwave roasting on chemical composition of peanut

advertisement

EFFECT OF MICROWAVE ROASTING ON CHEMICAL

COMPOSITION OF PEANUT SEEDS AND COMPARING IT

WITH THE ORDINARY ROASTING PROCESS

El-Badrawy, E.E.Y.; El-Zainy, A.R.M.; Shalaby, A.O. and El-Sayed, N.Y.

Home Economics Dept., Faculty of Specific Education,

Mansoura University, Egypt.

@ @ñŠì—ä¾bi@òîÇìäÛa@òîiÛa@òîÜ×

@ @ïãbrÛa@ôìäÛa@‹¸û¾a

@ @†bànÇüaë@ñ†ì§a@æbàš@íbÈß

@ @@ïi‹ÈÛa@åìÛaë@‹—·@ïÇìäÛa@áîÜÈnÛa@À

Ýí‹ic@QR@–@QQ@åß@ñÐÛa@óÏ

ﻫـ١٤٢٨ / ﻡ٢٠٠٧

)*+,א

( وو'&$%א!"#א وאلאدאوא

אد

938

א-.وא/0&1א2%א3&

د4وא5د6

نא8)

EFFECT OF MICROWAVE ROASTING ON CHEMICAL COMPOSITION OF PEANUT

SEEDS AND COMPARING IT WITH THE ORDINARY ROASTING PROCESS

El-Badrawy, E.E.Y.; El-Zainy, A.R.M.; Shalaby, A.O. and El-Sayed, N.Y.

Home Economics Dept., Faculty of Specific Education, Mansoura University, Egypt.

ABSTRACT

This work aims to study the ability of using microwave oven in roasting peanut

seeds and comparing it with ordinary one. Chemical composition, minerals content,

individuals amino acids and oligosaccharides were investigated in roasting peanut

seeds as well as raw ones. Also, peanut oil characteristics and its fatty acids

identification were also carried out in raw, microwave roasted and ordinary roasted

peanut oils. The results revealed that roasting of peanut by microwave is better than

ordinary roasting in maintenance of chemical composition and minerals contents. In

addition, it raised Protein efficiency ratio (PER) and biological value (BV) of peanut

protein more than that of ordinary roasting. Microwave roasting did not cause

significant chemical disturbance in peanut oil, while ordinary roasting did in

comparing with raw peanut oil. Microwave roasting did not increase the

malonaldehyde amount while ordinary roasting increased it as compared to raw peanut

oil. Microwave roasting showed high efficiency in keeping the principle characteristics

of raw peanut oil. The unsaturation degree of peanut oil roasted by microwave was

more than that of peanut oil roasted by ordinary method. Trans fatty acids content of

microwave roasted peanut oil was less than that of ordinary roasted one.

Key Words: Microwave cooking – ordinary cooking – roasting - peanut –

oligosaccharides – amino acids – fatty acids.

INTRODUCTION

Social changes and rapid lifestyle make the working women search for a

rapid method for preparing food especially those needed a long time for

cooking or roasting as legumes. In fact, microwave oven achieved their request.

Microwave energy has been used since the early 1960s' for several food

processes such as thawing, drying, baking and cooking (Rosina and Isabel,

1996). Its heating differs from conventional treatment because it is

accomplished by means of electromagnetic waves, which penetrate deeply and

heat rapidly (Schlegel, 1992). These waves have lengths between radio and

infrared waves on the electromagnetic spectrum (Giese, 1992). The heat

production is mainly due to dipole excitation and ion-migration. Friction energy

is produced as a result of the orientation of the dipoles in the altering

electromagnetic field (Rosenberg and Bogle, 1987). Penetration and heating of

food by microwaves energy are instantaneous.

On contrast, conventional heating methods transfer thermal energy from

product-surfaces toward center 10-20 times more slowly as the microwaves

heated product. The greater penetration depth and faster heating rates associated

939

"!א وאلאدאوא

אد#א$%&'*)א

( وو+,

with microwave heating have been recognized as potential factors to improve

the retention thermo labile constituents in foods (Mudgett, 1989). In addition,

76% less energy is required for microwave cooking as compared to

conventional methods (Quenzer and Bruns, 1981). Also, this accelerated

heating provides for higher quality production in terms of taste, texture and

nutritional content, as well as increased production (Giese, 1992). Microwave

can be transmitted through glass, ceramic, plastics and paper. On the other

hand, metal such as aluminum foil and steel, reflect microwaves (Decareau,

1992).

It has been found to be safe; there was no toxicity or adverse effects on

the diets containing meat and legumes cooked by microwave compared with

conventionally cooked ones or diets. In addition, there is no risk from the

radiation used for microwave cooking on health, but care must be taken to

avoid over heating foods (Alhekail, 2001).

Peanut which is known as groundnut (Arachis hypogaea) belongs to the

family leguminosae. It has been grown for oil and as a food commodity (Lucas,

2000 and Abayomi et al., 2002). More than a third of peanut cultivars grown on

a worldwide basis are used as food (Sanders, 2002). It is an important source of

oil, protein, folate, antioxidants and essential fatty acid (Linoleic) (Jui-yueh et

al., 2002). Hence, peanut is having an increasing interest from consumer and

industry field (Chun et al., 2001).

People in Egypt usually consume peanut in its roasted form as a snack.

Traditional roasting process takes about 20 min, which may affect peanut

constituents such as lipids (Abayomi et al., 2002). Roasting by using

microwave oven takes less time, which leads to more maintenance of its

nutrients.

The present investigation aimed to comparing microwave roasting

process with the ordinary one concerning their effect on the chemical

composition, minerals content, amino acids composition and sugars content of

peanut. Also, the effects of microwave and ordinary roasting on oil constants

and fatty acids composition of raw, ordinary roasted and microwave roasted

peanut oils were carried out.

MATERIALS AND METHODS

Seeds of Peanut (Arachis hypogaea) was obtained from the local market

of Mansoura city, Egypt. All seeds were cleaned and strange materials were

removed.

Ordinary roasting:

Peanut seeds were purchased in its roasted form from the local market of

Mansoura city, Egypt. The time of roasting was about 20 min. Seeds were left

940

א-.وא/0&1א2%א3&

د4وא5د6

نא8)

to cool at room temperature, dehulled, kept in plastic bags and stored under

freezing.

Microwave oven roasting:

Peanut seeds were roasted in glass plate in Microwave oven, microwave

apparatus (Moulinex. Model 34 L). This took 2 min. Seeds were left to cool at

room temperature, dehulled, kept in plastic bags and stored under freezing.

The obtained peanut samples in the present study were divided as follows:

Raw seeds (Raw), Ordinary roasted seeds (O.R.P) and Microwave roasted seeds

(M.R.P).

Analytical methods:

Proximate chemical composition (moisture, crude protein, crude fat, ash

and total carbohydrates) were determined according to the methods

recommended by the A.O.A.C (2000).

The ashed samples were dissolved in 1 % hydrochloric acid as described

by Luten et al. (1996) and subjected to atomic absorption spectrometry (model

2380; Perkin Elmer, Norwalk, CT, USA). The solutions were used for

determination of calcium, potassium, sodium, magnesium, iron, zinc, copper

and manganese at Fac. of science, Mansoura University.

Amino acids content was determined according to Millipore Cooperative

(1987) at National Research Center, Giza, Egypt. The apparatus used is HPLC,

Waters 600E Multisolvent Delivery System, Pico Tag Analysis column, Waters

484 Detector and workstation with Millennium Chromatography Manager

Programme. Chemical score was calculated according to Bhanu et al. (1991)

and the two lowest scores were taken as the first and second limiting amino

acids, Protein efficiency ratio (PER) was calculated using the equation

suggested by Alsmeyer et al. (1974) and Biological value (BV) of protein

samples was calculated using the equation of Oser (1959) as follows:

Chemical score =

mg of essential amino acid in 1g test protein

mg of essential amino acid in 1g reference protein

X 100

PER = - 0.468 + 0.454 (Leucine) - 0.105 (Tyrosine).

BV = 49.09 + 10.530 (PER).

Glucose, Sucrose, Stachyose, and Raffinose sugars were determined by

HPLC (1050 - Hewlett Packard - USA) ac rding to Muzquiz et al. (1992) at

Central Laboratory of Food Tech. Res. Inst., Agric. Res. Center, Giza, Egypt.

The oils of raw, ordinary roasted and microwave roasted peanut were

extracted by the method described by Folch et al. (1957). Acid, Peroxide and

Iodine values were determined according to A.O.A.C (2000). Thiobarbituric

acid (TBA) was colorimetrically measured as mg malonaldehyed / kg as

mentioned by (Sidwell et al., 1954).

941

"!א وאلאدאوא

אد#א$%&'*)א

( وو+,

Methyl esters of fatty acids were determined according to Stahi (1967) at

Central Laboratory of Food Tech. Res. Inst., Agric. Res. Center, Giza, Egypt,

by using a PYE Unicam gas-liquid chromatography (GLC).

Infrared spectroscopy for oil sample was determined according to the

method described by Farag et al., (1977) at Micro Analytical Center, Fac. of

Science, Cairo University.

The values of the means were statistically analyzed by SPSS computer

software. The calculation occurred by analysis of variance ONE WAYANOVA and followed by TUKEY honestly test according to Steel and Torrie

(1980) and Abo Allam (2003).

RESULTS AND DISCUSSION

Effect of processing methods on chemical composition:

Results in Table (1) show that moisture content of raw peanut was

6.35±0.16 g/100g w.w which reached 3.91±0.23 and 2.39±0.03 g /100g w.w

after ordinary and microwave roasting processes, respectively. It can be noticed

that moisture content decreased significantly as a result of both ordinary and

microwave roasting. Also, it's clear that the decrease caused by microwave

roasting is more than that caused by ordinary roasting. These results are in

agreement with those found by Damame et al. (1990), Griffith and Castel

(1998), Abayomi et al. (2002), Sanders et al. (2002) and Adegoke et al. (2004)

who reported that roasting processes decreased moisture content of peanut.

The results revealed that ash content of raw peanut was 2.59±0.03 g/100g

d.w, while it became 2.7±0.06 and 3.0±0.01 g/100g d.w after ordinary and

microwave roasting processes, respectively. It can be noticed that there was a

significant increase in ash content of peanut resulted by microwave roasting,

while ordinary roasting didn't affect it as compared to raw sample. There was a

significant difference between ordinary and microwave roasting of peanut

where the ash content reduced significantly in ordinary roasted sample. Thus,

microwave roasting led to an increase in ash content and this may be due to its

low content of moisture. These results were in agreement with those indicated

by Abayomi et al. (2002) who reported that the ash content of raw peanut

increased as a result of roasting process, while it did not agree with those found

by Adegoke et al. (2004).

From Table (1) it can be observed that protein content of raw peanut was

25.89±0.48 g/100g d.w, which increased to 27.42±0.26 and 28.66±0.33 g/100g

d.w as a result of ordinary and microwave roasting processes, respectively. The

increase was significant by microwave roasting while it was not significant by

ordinary roasting when compared to raw sample. There was no significant

differences between microwave roasted peanut and ordinary roasted one in its

content of protein. These results are similar to those found by Damame et al.

942

א-.وא/0&1א2%א3&

د4وא5د6

نא8)

(1990), Abayomi et al. (2002), Jui-Yueh et al. (2002) and Adegoke et al.

(2004). From the previous results it can be stated that roasting peanut by

microwave is better than ordinary roasting in maintenance of protein.

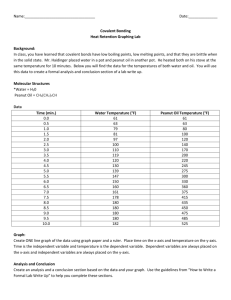

Table (1): Chemical composition of Raw, Ordinary roasted and Microwave

roasted peanut (g/100g )

Chem.Comp

Moisture

Samples

d.w

Raw

w.w

d.w

O.R.P

w.w

d.w

M.R.P

w.w

Ash

2.59 ±0.03

a

6.35 ±0.16 a 2.43 ±0.03

2.70 ±0.06

--a

3.91 ±0.23 b 2.59 ±0.06

3.00 ±0.01

--b

2.39 + 0.03

2.93 ±0.01

c

---

Protein

Fat

Carbohydr

ates

25.89 ±0.48

47.12

24.41 ±0.47

a

a

±0.03a

24.24 ±0.45 44.12 ±0.03 22.86 ±0.46

27.42 ±0.26

47.31

22.58 ±0.20

a,b

±0.09a

b

26.35 ±0.25 45.46 ±0.08 21.70 ±0.41

28.66 ±0.33

48.50

19.85 ±0.22

b

±0.13b

c

27.97 ±0.32 47.34 ±0.13 19.36 ±0.23

Each value is the mean + SE, Mean values in each column having different superscripts (a, b, c, d, ….. ) are

significantly different at P < 0.05, Chem.Comp (Chemical Composition), O.R.P (Ordinary Roasted Peanut) and M.R.P

(Microwave Roasted Peanut).

From the results represented in Table (1), it can be noticed that raw peanut

content of fat was 47.12±0.03 g/100g d.w, while it reached 47.31±0.09 and

48.5±0.13 g/100g d.w as a result of ordinary and microwave roasting processes,

respectively. The results indicated that the fat content of raw peanut increased

significantly by microwave roasting, while it was not influenced by ordinary

roasting. In general, fat content increased by roasting. These results are in

agreement with those found by Damame et al. (1990), Abayomi et al. (2002),

Jui-Yueh et al. (2002) and Adegoke et al. (2004) who reported that there was an

increase in crude oil of peanut after heat treatments. From the showed data it

can be stated that microwave roasting increased fat content of peanut, while

ordinary roasting had no effect on it.

The results also showed that raw peanut content of total carbohydrate was

24.41±0.47 g/100g d.w, while it became 22.58±0.2 and 19.85±0.22g/100g d.w

after ordinary and microwave roasting processes, respectively. It can be noticed

that total carbohydrates content of peanut decreased significantly by both

ordinary and microwave roasting as compared to raw peanut and the most

decrease caused by microwave roasting. There was a significant difference

between ordinary and microwave roasted peanut in their carbohydrate content,

where peanut roasted by microwave had less content than that roasted by the

ordinary method. These results are in agreement with those reported by

Abayomi et al. (2002) and Adegoke et al. (2004).

943

"!א وאلאدאوא

אد#א$%&'*)א

( وو+,

Effect of processing methods on the minerals content:

The results in Table (2), showed that calcium (Ca) content of raw peanut

was 12.24±0.13 mg/100g d.w, while it reached 12.69±0.31 and 11.4±0.05

mg/100g d.w after ordinary and microwave roasting processes, respectively. It

can be observed that Ca content of raw peanut was not influenced significantly

by the two processes ordinary and microwave roasting. There was a significant

difference between ordinary roasted and microwave roasted peanut in their Ca

content, where ordinary roasted peanut content was more than that of

microwave roasted.

The results also showed that magnesium (Mg) content of raw peanut was

4.69±0.05 mg/100 g d.w, while it became 4.32±0.11 and 5.4±0.02 mg/100g d.w

as a result of ordinary and microwave roasting processes, respectively. It is

clear that Mg content of peanut decreased by ordinary roasting, while it

increased by microwave roasting significantly as compared to raw sample.

It can be noticed also that potassium (K) content of raw peanut was

11.45±0.12 mg/100g d.w, while it became 11.88±0.29 and 12.6±0.05 mg/100g

d.w after ordinary and microwave roasting processes, respectively. It can be

observed that K content of peanut increased significantly by microwave

roasting, while it didn't by ordinary roasting when compared to raw sample. No

significant differences in K content between ordinary and microwave roasted

peanut was observed.

From the same table, it can be observed that sodium (Na) content of raw

peanut was 8.59±0.1 mg/100g d.w, while it became 9.72±0.24 and 10.8±0.04

mg/100g d.w after ordinary and microwave roasting processes, respectively. It

can be noticed that Na content of raw peanut increased significantly by both

ordinary and microwave roasting, but the increase was higher in microwave

roasted sample.

Data in Table (2) shows also that iron (Fe) content of raw peanut was

6.51±0.07 mg/100g d.w, which reached 7.02±0.17 and 7.79±0.04 mg/100g d.w

as a result of ordinary and microwave roasting processes, respectively. It can be

observed that Fe content of peanut increased significantly by both ordinary and

microwave roasting and the increase resulted by microwave roasting was more

than that of ordinary roasting as compared to raw peanut.

Also, zinc (Zn) content of raw peanut was 2.6±0.03 mg/100g d.w, while it

became 2.7±0.07 and 2.7±0.01 after ordinary and microwave roasting

processes, respectively. It is clear from the data that there were no significant

differences in Zn content among raw, ordinary roasted and microwave roasted

samples.

Copper (Cu) content of raw peanut was 8.59±0.1 mg/100g d.w, while it

became 10.8±0.26 and 9.6±0.04 mg/100g d.w as a result of ordinary and

microwave roasting processes, respectively. It can be observed that Cu content

944

א-.وא/0&1א2%א3&

د4وא5د6

نא8)

of peanut increased significantly by both ordinary and microwave roasting

processes, but the increase was high in the ordinary roasted sample.

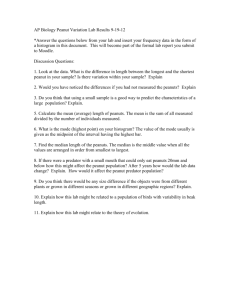

Table (2): Minerals content of Raw, Ordinary roasted and Microwave

roasted peanut (g/100g d.w)

Minerals

Samples

Raw

O.R.P

M.R.P

Ca

Mg

K

Na

Fe

Zn

Cu

Mn

a, b, c

a

a

a

a

a

a

a

12.24

±0.13

4.69

±0.05

11.45

±0.12

8.59

±0.10

6.51

±0.07

2.60

±0.03

8.59

±0.10

5.73

±0.06

b

b

a, b

b

b

a

b

b

12.69

±0.31

4.32

±0.11

11.88

±0.29

9.72

±0.24

7.02

±0.17

2.70

±0.07

10.80

±0.26

8.10

±0.20

c

c

b

c

c

a

c

a

11.40

±0.05

5.40

±0.02

12.60

±0.05

10.80

±0.04

7.79

±0.04

2.70

±0.01

9.60

±0.04

6.00

±0.02

Each value is the mean + SE, Mean values in each column having different superscripts (a, b, c, d, ….. ) are

significantly different at P < 0.05, O.R.P (Ordinary Roasted Peanut) and M.R.P (Microwave Roasted Peanut).

Manganese (Mn) content of raw peanut was 5.73±0.06 mg/100g d.w,

which reached 8.1±0.02 and 6.0±0.02 mg/100g d.w after ordinary and

microwave roasting processes, respectively. From the results it can be stated

that Mn content of peanut increased significantly by ordinary roasting, while it

didn't influence by microwave roasting as compared to the raw sample. On the

other side, Mn content of ordinary roasted peanut was more than that of

microwave roasted. These results are similar to those found by Abayomi et al.

(2002) who reported that total minerals content of raw peanut increased as a

result of roasting process, while it did not agree with those found by Adegoke et

al. (2004). In general all minerals content increased during roasting processes

(ordinary and by the microwave).

However, it could be stated microwave roasting was more effective in

maintenance peanut contents of Mg, Na and Fe, while ordinary roasting was

better in maintenance Ca, Cu and Mg, and they were equal in maintenance of K

and Zn.

Effect of processing methods on amino acids content:

From Table (3), it was obvious that raw peanut seeds contain high levels

of glutamic acid (4.39% d.w), aspartic acid (3.15% d.w), arginine (3.09% d.w)

and moderate amounts of isoleucine (1.67% d.w), phenylalanine (1.34% d.w)

and serine (1.27% d.w). On the other hand, the lowest values were 0.32 and

0.39% d.w for methionine and cysteine, respectively. Regarding the effect of

ordinary and microwave roasting processes on the amino acids content of

peanut, it was noticed an increase in isoleucine, methionine, phenylalanine,

threonine, aspartic acid, glutamic acid and proline contents when compared to

raw peanut. In addition, the data showed that microwave roasting raised the

levels of isoleucine, lysine, arginine, cysteine, glutamic acid, glycine than those

of ordinary roasted peanut.

945

"!א وאلאدאوא

אد#א$%&'*)א

( وو+,

On the other hand, roasting processes decreased the levels of methionine

and tyrosine. These results are in agreement to a less extent with those of Khalil

and Chughtai (1983) and Damame et al. (1990) who reported that methionine

decreased by roasting processes whereas, aspartic acid, glutamic acid, proline,

serine and phenylalanine increased.

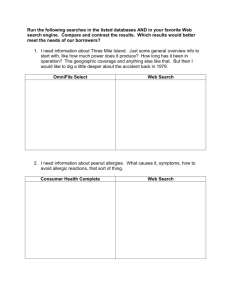

Table (3): Amino acids composition of Raw, Ordinary roasted and

Microwave roasted peanut (g/100g d.w).

Sample

A.A

E.A.A :

Histidine

Leucine2nd

Isoleucine

Lysine

Methionine1st

Phenylalanine

Threonine

Valine

Total

N.E.A.A. :

Alanine

Arginine

Aspartic

Cysteine

Glutamic

Glycine

Proline

Serine

Tyrosine

Total

Total A.A.

E/T

PER

BV

Raw

O.R.P

M.R.P

g/100g

d.w

g/16g

N

g/100g

d.w

g/16g

N

g/100g

d.w

g/16g

N

0.60

0.91

1.67

1.23

0.32

1.34

0.88

1.08

8.03

2.31

3.51

6.45

4.75

1.23

5.17

3.39

4.17

30.98

0.65

0.94

1.69

1.22

0.27

1.41

0.91

1.11

8.20

2.37

3.43

6.16

4.44

0.98

5.14

3.31

4.04

29.87

0.62

1.05

1.71

1.28

0.27

1.42

0.89

1.12

8.36

2.16

3.66

5.96

4.46

0.94

4.95

3.1

3.9

29.13

1.03

3.09

3.15

0.39

4.39

1.05

1.14

1.27

1.19

16.70

24.73

3.97

11.93

12.16

1.50

16.95

4.05

4.40

4.90

4.59

64.45

95.43

1.11

3.04

3.24

0.35

4.43

1.02

1.22

1.33

1.13

16.87

25.07

4.04

11.08

11.81

1.27

16.15

3.71

4.44

4.85

4.12

61.47

91.34

0.96

3.11

3.22

0.41

4.68

1.11

1.14

1.30

1.16

17.09

25.45

3.34

10.85

11.23

1.43

16.32

3.87

3.97

4.53

4.04

59.58

88.71

0.32

0.64

55.83

0.33

0.66

56.04

0.33

0.77

57.20

O.R.P (Ordinary Roasted Peanut), M.R.P (Microwave Roasted Peanut), A.A (amino acids), E.A.A (essential amino

acids), N.E.A.A (non-essential amino acids), E/T (essential to total amino acids ratio) PER (protein efficiency ratio) and

BV (biological value), 1st (first limiting amino acid) and 2nd (second limiting amino acid

Generally ,it was found that total essential amino acids contents increased

by roasting processes and the increase was higher by microwave process where

it was 8.03, 8.2 and 8.36% for raw, ordinary roasted and microwave roasted

peanut, respectively. The total non-essential amino acids contents were 16.7,

16.87 and 17.09%, respectively. Depending upon the previous results, it was

noticed that the essential / total essential amino acids ratio was nearly the same

946

א-.وא/0&1א2%א3&

د4وא5د6

نא8)

in the three samples under study, where it was 0.32, 0.33 and 0.33 for raw

ordinary roasting and microwave roasting peanut, respectively. These findings

did not agree with that obtained by kirba and Eekmen (2003) who reported that

total essential amino acids decreased significantly by roasting for 20 min.

Protein efficiency ratio (PER) of raw, ordinary roasted and microwave

roasted peanut was calculated and the results showed that the two roasting

methods increased it as compared to raw peanut. The increase happened by

microwave roasting was higher than that of ordinary roasting. The increase

percentages were 13.12 and 20.31% for ordinary and microwave roasting

processes, respectively. Also, the same trend was observed in biological value

where an increase was observed by the two roasting processes but it was higher

by microwave process than that occurred by ordinary roasting. However, the

increase in biological value was 0.37 and 2.45% in ordinary roasted and

microwave roasted peanut than that of raw peanut. From these results, it was

clear that roasting of peanut by using microwave oven was better than that of

ordinary roasting process where it raised BV and PER of protein.

The amino acid score results showed that methionine is the first limiting

amino acid, luecine is the second limiting amino acid of peanut, this result does

not agree with that of Khalil and Chughtai (1983) who reported that lysine is

the first limiting amino acid of peanut.

Effect of processing methods on sugars content:

The data concerning sugars content; glucose, sucrose, stachyose and

raffinose of raw and processed peanut are represented in Table (4).

It can be noticed that glucose content of raw peanut was 0.26 g/100g d.w,

while it reached 0.75 and 0.91 g/100g d.w after ordinary and microwave

roasting processes, respectively. Roasting processes increased glucose content

of peanut but it was higher in microwave roasted peanut than that of the

ordinary roasted as compared to raw sample.

Table (4): Sugars content of Raw, Ordinary roasted and Microwave

roasted peanut (g/100g d.w)

Sugars

Samples

Raw

O.R.P

M.R.P

Glucose

Sucrose

S +R

0.26

0.75

0.91

3.80

3.63

0.04

1.50

1.63

1.68

O.R.P (Ordinary Roasted Peanut), M.R.P (Microwave Roasted Peanut), S+R (Stachyose + Raffinose), O-Roasting

(Ordinary Roasted) and M-Roasting (Microwave Roasted).

It can be observed that sucrose content of raw peanut was 3.86 g/100g

d.w, while it became 3.63 and 0.04 g/100g d.w after ordinary and microwave

roasting processes, respectively. It is obvious that ordinary roasted peanut had a

slight decrease in its sucrose content, while microwave roasted peanut had a

great decrease in its sucrose content.

947

"!א وאلאدאوא

אد#א$%&'*)א

( وو+,

Stachyose and raffinose content of raw peanut was 1.5 g/100g d.w, while

it reached 1.63 and 1.86 g/100g d.w after ordinary and microwave roasting

processes, respectively. It can be observed that S+R content increased as a

result of roasting processes and the increase happened in microwave roasted

peanut was more than that of the ordinary roasted.

These results are in accordance with those found by Kirba and Erkmen

(2003) who reported that total sugar content decreased significantly during

roasting process.

Effect of processing methods on oil constants:

The data concerning peanut oil constants; acid value, peroxide value,

Iodine value of extracted oil from raw and processed peanut are illustrated in

Table (5). It can be noticed that the acid value of raw peanut oil was 0.77±0.01,

whil it was 0.89+0.08 and 0.81±0.03 mg KOH/1g oil for both ordinary roasted

and microwave roasted peanut oils, respectively. There were no significant

differences in the acid values of the three oils. It can be stated that ordinary

roasting caused mathematical increase in acid value than that of microwave

roasting but it was not significant. However, the acid values of all samples were

within the normal limits.

The data showed that the peroxide value of raw peanut oil was 5.15±0.34,

while it became 9.8±0.45 and 5.9±0.25 meq/kg oil after ordinary and

microwave roasting processes, respectively. There was a significant increase in

peroxide value as a result of ordinary roasting process, while microwave

roasting didn't affect. From the previous results it could be stated that ordinary

roasting caused great peroxidation of peanut oil, while microwave roasting had

no significant effect. This may be due to the long period of ordinary roasting.

From the presented data, it can be noticed that Iodine value of raw peanut

oil was 95.003±0.97 which reached 92.12±0.2 and 92.52±0.29 g iodine/100g oil

as a result of ordinary and microwave roasting processes, respectively. The

tabulated data revealed that there was no significant difference in iodine value

of microwave roasted peanut oil as compared to raw peanut oil, while it

decreased significantly in ordinary roasted peanut oil.

The previous results are in agreement with those reported by Seda et al.

(2001) and Adegoke et al. (2004) who indicated that ordinary roasting process

raised acid, peroxide and iodine values of peanut oil. On the other hand, the

previous results did not agree with those concluded by Farag (1994) who found

that peroxide values of microwave heated lipids were approximately 2% higher

than those of traditional heated lipids.

From the results it can be stated that microwave roasting didn't affect the

raw peanut oil constants significantly, while ordinary roasting caused a

decrease in the iodine value and increase in peroxide value.

948

א-.وא/0&1א2%א3&

د4وא5د6

نא8)

Table (5): Oil constants and TBA of Raw, Ordinary roasted, Microwave

roasted peanut oil.

Values

Samples

Raw

O.R.P

M.R.P

Acid value

mg KOH/1g oil

0.77±0.01a

0.89±0.08a

0.81±0.03a

Peroxide

value

Iodine value

TBA

meq/kg oil

g iodine/100g oil

mg/kg oil

5.15±0.34a

9.80±0.45b

5.90±0.25a

95.003±0.97a

92.12±0.20b

92.52±0.29a, b

0.69±0.003a

1.48±0.10b

0.51±0.06a

Each value is the mean + SE, Mean values in each column having different superscript (a, b, c, d, …..) are significantly

different at P < 0.05, O.R.P (Ordinary Roasted Peanut) and M.R.P (Microwave Roasted Peanut).

As shown in Table (5), the thiobarbituric acid (TBA) value of raw peanut

oil was 0.69±0.003, while it reached 1.48±0.1 and 0.51±0.06 mg/kg oil after

ordinary roasting and microwave roasting, respectively. It can be noticed that

ordinary roasting increased TBA value significantly, while microwave roasting

did not change it significantly. These results are in agreement with those

reported by Chiou et al. (1991) and Abayomi et al. (2002) who indicated that

there was a slight increase in TBA value of peanut oil after ordinary roasting.

From the previous results it can be stated that microwave roasting had no

significant effect on malonaldehyde amount of raw peanut oil, while ordinary

roasting increased it.

Effect of processing methods on fatty acids content:

The data in Table (6) show the fatty acids content of raw, ordinary roasted

and microwave roasted peanut oils, it can be observed that palmitic acid

(C16:0) in raw peanut oil was the abundant saturated fatty acid 12.20 % which

increased to 16.26% and 14.49% oil after ordinary and microwave roasting

processes, respectively. Also, myristic acid(C14:0) increased after both of

roasting processes while stearic acid (C18:0) decreased after ordinary roasting

and increased by microwave roasting. On the other hand, arachidic acid(C20:0)

increased after ordinary roasting while microwave roasting decreased it when

compared to raw peanut oil.

From the same table, it can be noticed that oleic acid (C18:1) was the

abundant unsturated fatty in peanut oil, also peanut oil contained linoleic

(C18:2) and linolenic (C18:3) unsaturated fatty acids. Their percentages were

41.38, 38.81and 0.58% in raw peanut oil, while they were 34.59, 27.73 and

0.24% after ordinary and 37.09, 32.04 and 0.33 mg/100g oil after microwave

roasting, respectively.

Also, the results revealed that raw peanut oil contained16.32 and 83.32%

of saturated and unsaturated fatty acid which became 29.39 and 66.94 and

23.81 and 72.32% after ordinary and microwave roasting processes,

respectively. Hence, the unsaturated to saturated ratio in raw peanut oil was

5.11, which reached 2.28 and 3.04 in ordinary and microwave roasted peanut

oil, respectively. The unsaturation degree of peanut oil roasted by microwave

949

"!א وאلאدאوא

אد#א$%&'*)א

( وو+,

was more than that of peanut oil roasted by ordinary method. This means that

less oxidation happened in the peanut oil roasted by microwave which may be

attributed to the short period of roasting.

Table (6): Fatty acids content of Raw, Ordinary roasted and Microwave

roasted peanut oils (%).

Samples

Fatty Acids

Unknown

Myristic

C14:0

Palmitic

C16:0

Unknown

Stearic

C18:0

Oleic

C18:1

Linoleic

C18:2

Linolenic

C18:3

Unknown

Arachidic

C20:0

Unknown

U.S.F.A

S.F.A

U.S.F.A / S.F.A

Raw

R.R.P

M.R.P

1.75

--12.20

0.38

0.89

41.38

38.81

0.58

--1.10

2.55

83.32

16.32

5.11

4.49

2.50

16.26

5.29

--34.59

27.73

0.24

1.26

0.85

3.09

66.94

29.39

2.28

--2.28

14.49

4.64

1.54

37.09

32.04

0.33

1.05

0.86

1.81

72.32

23.81

3.04

O.R.P (Ordinary Roasted Peanut), M.R.P (Microwave Roasted Peanut), U.S.F.A (Unsaturated fatty acids), S.F.A

(Saturated fatty acids). U.S.F.A= unsaturated fatty acids, S.F.A= saturated fatty acids.

This observation agreed with that of Braddock et al. (1995) who stated

that roasted peanuts are susceptible to lipid oxidation due to the polyunsaturated

fatty acids, and Sanders (2001) who reported that oleic is the most abundant

fatty acid in raw and roasted peanut (26.8%). Ozdemir et al. (2003) concluded

that peanut could be roasted successfully in microwave ovens and Hiromi et al.

(2005) mentioned that unsaturated fatty acids of peanut oil are significantly

protected from oxidation during microwave roasting. So, although roasting

processes caused a decrease in unsaturated fatty acids and an increase in

saturated fatty acids, the oil still has its principle characteristics in the same

trend as reported by Sachiko and Hiromi (1999) who stated that the principle

characteristics of fatty acids still remained after 20 minutes of microwave

heating. On contrary, the previous results didn't agree with those reported by

Seda et al. (2001) who found that myristic and stearic fatty acids decreased and

arachidic increased after roasting process.

It was obvioes that peanut oil is a good source of unsatarated fatty acids

where it contains high amounts of oleic and linoleic acids. These fatty acids are

good for maintaining health where it was reported that diets high in

monounsatnrated fatty acids (MUFA) have a favourable effect on the ratio of

total cholesterol to high density lipoprotein (HDL) choteslerel which is a more

accurate indicator for risk of coronary heart disease (CHD) than total

950

א-.وא/0&1א2%א3&

د4وא5د6

نא8)

cholesterol alone (Kris-Etherton et al., 1999). These observations agreed with

those of Rajaram et al. (2001) and Albert et al. (2002) who indicated that

frequent nut comsumption lowers the risk of (CHD). These results also revealed

that roasting process decreased unsaturated fatty acid and increased saturated

fatty acids. These findings are in agreement with Hassanein et al. (2003). In

addition to the importance of unsaturated fatty acids found in peanut oil for

(CHD) patients, they also have a good role in the therapeutic nutrition of other

patients such as those with colorectal cancer risk and ovarian cancer (Bosetti et

al., 2002).

So it could be concluded that microwave roasting process is better than

the ordinary one in maintenance a high percentage of the unsaturated fatty acids

of raw peanut oil.

Effect of processing methods on trans fatty acids content:

The unsaturated fatty acids are present normally in the cis-isomers. Cisbonds can be isomerizes to the trans-configuration during extraction or

subsequent processing. For example, oxidation or partial hydrogenation can

lead to isomerisation. Several nutritional studies have suggested a direct

relationship between trans fatty acids and increased risk for coronary heart

disease (CHD) (Louheranta et al., 1999 and Sacks and Katan, 2002). It is

commercially important for food labeling purposes to determine this transcontent. It is difficult to separate cis-from trans-isomers by using other

techniques such as gas chromatography; therefore, an infrared method is

commonly used. Cis-isomers absorb between 480 and 700 cm-1 while transisomers absorb between 1000 and 930 cm-1, which the latter band can be used

as the basis for an analytical method (Stuart, 1997).

Both of these geometric isomers absorb strongly at 1163 cm-1 which

represents the C-O stretching frequency from the ester group. The cis-isomer

absorb weakly at 965 cm-1 while the trans-isomers absorb strongly at this

frequency. The results in Figs. (1, 2 and 3) showed that all the processed

samples revealed peaks at 912 and 913 cm-1 which indicated the existence of

trans fatty acids in the oils extracted from raw, ordinary roasted and microwave

roasted peanut. The relative intensity of raw peanut oil was (0.005), both

ordinary and microwave roasting processes raised it to (0.055 and 0.039,

respectively) which indicated the increase in trans fatty acids as compared to

the raw sample. Although microwave raised trans fatty acids of roasted peanut

oil, it was less than that of ordinary roasted one.

951

)*+,א

( وو'&$%א!"#א وאلאدאوא

אد

952

א-.وא/0&1א2%א3&

د4وא5د6

نא8)

These results did not agree with those reported by Sanders (2001) who

stated that there were no detectable levels of trans fatty acids in raw and roasted

peanut oils.

From the previous results it could be stated that microwave roasting

process of peanut is more save than the ordinary process because of occurrence

of trans fatty acids which increase plasma lipids especially low density

lipoprotein cholesterol (LDL) concentration which is often taken as a strong

indication of potential risk for development of atherosclerotic cardiovascular

disease (Willett and Ascherio, 1994).

REFERENCES

A.0.A.C (2000): Association of Official Analytical Chemists, 17th ed. Official Methods

of Analysis, Washington, D.C, U.S.A.

Abayomi, P; Isaac, A and Ayodele, O (2002): Effects of processing conditions and

packaging materials on the quality attributes of dry-roasted peanuts. J. Food Sci.

Agric., 82: 1465-1471.

Abo Allam, R M (2003): Data statistical analysis using SPSS program. 1st ed.,

Publication for Universities, Cairo.

Adegoke, G O; Falade, K O and Babalola, O C (2004): Control of lipid oxidation and

fungal spoilage of roasted peanut (Arachis hypogaea) using the spice A

framomum danielli . Food . Agric . Environment ., 2(1): 128-131.

Albert, C M; Gaziano, J M; Willett, W C and Manson, J E (2002): Nut consumption

and decrease risk of cardia death in the Physicians' Health Study. Arch. Intern.

Med., 162: 1382-1387.

Alhekail, Z O (2001): Electromagnetic radiation from microwave ovens. J. Radiol

Port., 21(3): 251–8.

Alsmeyer, R H; Cuningham, A E and Happich, M L (1974): Equations predict PER

from amino acid analysis. Food Techol. July: 34-40.

Bhanu V, Ranacha G and Monterio P (1991): Evaluation of protein isolate from Cassia

uniflora as a source of plant protein. J. Sci. Food. Agric., 54: 659-662.

Bosetti, C; Negri, E and Franceschi, S (2002): Olive oil, seed oil and other added fats

in relation to ovarian cancer. Cancer Cause and Control, 13: 465-70.

Braddock, J C; Sims, C A and O'keefe, S F (1995): Flavour and oxidative stability of

roasted high oleic acid peanuts. J. Food. Sci., 60(3): 489-493.

Chiou, R Y; Tseng, C Y and Ho, S (1991): Characteristics of peanut kernels roasted

under various atmospheric environments. J. Agric Food Chem., 59: 1852-1856.

Chun, L; Lee, J and Eitenmiller R R (2001): Vitamin E stability in peanuts during

roasting and storage. Food Chem., 30A: 22.

Damame, S V; Chavan, J K and Kadam, S S (1990): Effects of roasting and storage on

proteins and oil in peanut kernels. Plant Foods for Human Nutrition, 40 (2): 143148.

Decareau, R V (1992): Microwave foods: New product development. Food and

Nutrition Press. Trumbll, Conn.

953

"!א وאلאدאوא

אد#א$%&'*)א

( وو+,

Farag, R S (1994): Influence of microwave and conventional heating on the quality of

lipids in model and food systems. Fett-Wissenschft-Technologie, 96: 213.

Farag, R S; Abdel-MaIek, G S and Salib, A G (1977): Safflawer and lettuce oils as

potential sources in the prepration of olive oil. Substitues chem. Microbial

Technol., Lebensom., 5: 113-117.

Folch, J; Lees, M and Sloane-Stanly, G H (1957): A simple method for the isolation

and purification of total lipids from vegetables. J. Food Sci. Nutr., 42: 145-152.

Giese, J (1992): Advances in microwave food processing. Food Technol., 9: 118.

Griffith, L D and Castel-Perez, M E (1998): Effect of roasting and malting on

physicochemical properties of selected cereals and legumes. Cearl Chem., 75

(6): 780-784.

Hassanein, M M; El-Shami, S M and El-Mallah, M H (2003): Changes occurring in

vegetable oils composition due to microwave heating. Grasas - Y- Aceites –

Sevilla, 54 (4): 343–349.

Hiromi, Y; Yuki, H; Yuka, T; Tsugumi, N and Yoshiyuki, M (2005): Fatty acids

distributions of triacylglycerols and phospholipids in peanut seeds (Arachis

hypogaea L.) following microwave treatment. J. Food. Comp. and Anal., 18(1):

3-14.

Jui-Yueh, Yeh; Dixon Phillips, R; Anna, V A and Yen-con Hung (2002):

Physicochemical and sensory characteristic changes in fortified peanut spreads

after 3 months of storage at different temperatures. J. Agric. Food Chem., 50:

2377-2384.

Khalil, K J and Chughtai, M I D (1983): Chemical composition and nutritional quality

of five peanut cultivars grown in Pakistan. Plant Food for Human Nutrition.

33(1): 63-70.

Kirba, F and Erkmen, G (2003): Investigation of the effect of roasting temperature on

the nutritive value of hazelnuts. Plant Food for Human Nutrition, 58(3): 1-10.

Kris-Etherton, P M; Pearson, T A; Wan, Y; Hargrove, R L; Moriarty, K; Fishell, V and

Etherton, T D (1999): High monounsaturated fatty acid diets lower both plasma

cholesterol and triacylglycerols concentrations. AM.J.Clin.Nutr., 70: 1009- 1015.

Louheranta, A M; Turpeinen, A K; Vidgren, H M; Schwab, U S and Uusitupa, M I

(1999): A high trans-fatty acid diet and insulin sensitivity in young healthy

women. Metabolism, 48: 870-875.

Lucas, E W (2000): Oilseeds and oil-bearing materials. In: Handbook of Cereal

Science and Technology. Marcel Dekker, New York.

Luten, J; Crews, H; Flynn, A; Van Deal, P; Kastenmayer, P; Hurrell, R; Deelstra, H;

Shen, L; Fairweather-Tait, S; Hickson, K; Farre, R; Schlemmer, U and Frohlich

W (1996): Interlaboratory trial on the determination of the in vitro iron

dialysability from food. J. Sci Food. Agric., 72: 415-424.

Millipore Cooperative (1987): Liquid Chromatographic Analysis of Amino Acids in

Foods Using a Modification of the PICO- TAG Method. New York, USA.

Mudgett, R E (1989): Microwave food processing. Food Technol., 43: 117.

Muzquiz, M; Rey, C; Cuadrado, C and Fenwick, G R (1992): Effect of germination on

oligosaccharides content of lupin species. J. Chromatogr., 607: 349-352.

954

א-.وא/0&1א2%א3&

د4وא5د6

نא8)

Ozdemir, F; Golukcu, M and Topuz, A (2003): Some chemical, physical properties of

raw peanut (Arachis hypogaea) and microwave roasting: Effect on fatty acid

composition of peanut's oil. Gida, 28(1): 39-45.

Quenzer, N M and Bruns, E E (1981): Effect of microwave steam and water blanching

on freez-dried spinach. J. Food Sci., 46: 410.

Rajaram, S; Burke, K; Connell, B; Myint, T and Sabate, J (2001): A monounsaturated

fatty acid-rich pecan- enriched diet favourably alters the serum lipid profile of

healthy men and women. J. Nutr., 131: 2275-2279.

Rosenberg, U and Bogle, K W (1987): Microwave thawing, drying and baking in the

food industry. Food Technol., (8): 291.

Rosina, L F and Isabel, M C (1996): Effect of continuous flow microwave treatment on

chemical and microbioiogical characteristics of milk. Z Lebensm Unters Forsch.,

202: 15-18.

Sachiko, T and Hiromi, Y (1999): Microwave heating influences on fatty acid

distributions of triacylglycerols and phospholipids in hypocotyls of soybeans.

Food Chem., 66(3): 345-351.

Sacks, F M and katan, M (2002): Randomized clinical trials on the effects of dietary fat

and carbohydrate on plasma lipoproteins and cardiovascular disease. Am. J.

Med., 13 suppl (9B): 135-245.

Sanders, T H (2001): Non-detectable levels of trans-fattyy acids in peanut butter.

J.Agric. Food Chem., 49: 2349-2351.

Sanders, T H (2002): Groundnut (peanut oil). In: Vegetable Oils in Food Technology

Composition, Properties and Uses, (FD Gunston ed.). Blackwell Publishing,

Oxford.

Sanders, T H; Hendrix, K; Raush, T D and Katz, T A (2002): Effect of microwave

energy on blanchability, shelf life and roast quality of peanuts. Am. Peanuts

Research Edu. Soc. Pro., 34: 112.

Schlegel, W (1992): Commercial pasteurization and sterilization of foods products

using microwave technology. Food Tech., 46: 62-63.

Seda, H A; Moram, G S; Mohamoud, A A and El-Niely, H F G (2001): Chemical and

biological changes of peanut Kernels (Arachis hypogaea) lipids by irradiation or

roasting process. Annals Agric. Sci. Ain Shams Univ., Cairo, 46 (1): 233-251.

Sidwell, C G; Salwin, H; Benca, M and Mitchell, J (1954): The use of Thiobarbituric

acid as a measure of fat oxidation. J. Am. Oil Chem. Soc., 31 (12): 603-606.

Stahi, E (1967): Thin Layer Chromatograpgy a Laboratory Hand Book. Published by

Springer Verloag. Berlin, Heidelberg, New York.

Steel, R G and Torrie, T H (1980): Principles and Procedures of Statistics and

Biometrical Approach. MCGraw Hill Book Comp. INC., New York, USA.

Stuart, B (1997): Biological Applications of Infrared Spectroscopy. Published by John

Wiley Sons. Ltd. Chichester, England PP: 107-109.

Willett, W C and Ascherio, A (1994): Trans fatty acids; Are the effect only marginal?

Am. J. Public Health. 84: 722-724.

955

)*+,א

( وو'&$%א!"#א وאلאدאوא

אد

ﺗﺄﺛﲑ ﺍﻟﺘﺤﻤﻴﺺ ﺑﺎﳌﻴﻜﺮﻭﻭﻳﻒ ﻋﻠﻰ ﺍﻟﱰﻛﻴﺐ ﺍﻟﻜﻴﻤﻴﺎﺋﻲ ﻟﺒﺬﻭﺭ ﺍﻟﻔﻮﻝ ﺍﻟﺴﻮﺩﺍﻧﻲ

ﻭﻣﻘﺎﺭﻧﺘﻪ ﺑﻄﺮﻳﻘﺔ ﺍﻟﺘﺤﻤﻴﺺ ﺍﻟﻌﺎﺩﻱ

אאאو

אאو–א

"# Jن א–("('

א&$%א

ﻗﺴﻡ ﺍﻻﻗﺘﺼﺎﺩ ﺍﻝﻤﻨﺯﻝﻲ – ﻜﻠﻴﺔ ﺍﻝﺘﺭﺒﻴﺔ ﺍﻝﻨﻭﻋﻴﺔ – ﺠﺎﻤﻌﺔ ﺍﻝﻤﻨﺼﻭﺭﺓ – ﻤﺼﺭ

C=99DאA@B99دא?99 @99א?=>99אم;99نא( وو9999

:99%

&3'99وא99ل

א99دאو99ذ99E99א

99אد K9وH=99Iא$99%&C99א!99"#א 99و

E99%א99وو"M=99,E99אK99-9999Lא99J1א(= HE99"K9א$99%&C99

99 Wאعא99 URضא99 1Rو?S 99אRو99 $99 ;99 Qوא 99لא 99دאא99 Pموא99 ?99 OאN

אدW9و (9وو'*=9,H9

"KאX9אX9Yא(/9ل-9א9ووא$9%&C9

WאعאURضא=1Lא( 9?X9Y%9א3Nא5/9א9PمWو=9א

KZ99و=9I

S99 D\WאW[99 1نא

(99 99وو'" 99ن-99 ]^9 9;Wא

99 99אد 399

א$99%&99b;Oא!99"#א 99وa99Mא99J1א(=$99%&]99

&99WA@;998`99ز99د5

=99ل"5N99אc99وZ,و"E99א

99אc99%99dو-99&Z,א

99א99دX99199

"K

אW[1نאوא (9/9

Oوو'9l3)e9")9f,9Dg=9hiאصא9j9 &$9%&X9Y

;%א

אدوذX9Y9(E9א9PمWB9m،نא

(99وو'

$%&]

iزدaM$;15א(=

1=Lא

אد$9;!9,9

زد99,وذ X99 Y99(E99א99Pم99D\W99 "Kא

(9999وو'" $99 ;99,5N99

א$99%&99b;OאeאX99א99;E99"KX9Y%99??Rند=99&99qمאX99Yop99א99لא99دא

وא (9999

Oوو'"-99$99%&WX99אX99Yא9999

Oאد،99و99"^99Wنa99M

א99URضא=99-99991Lع99,א3]99IWjאX99Yא (9999

Oوو'&$99;99D1אX99Yא99

O

אد K

956