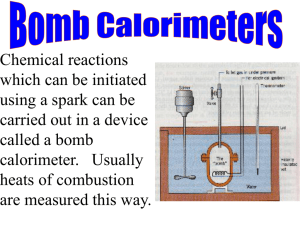

ENERGIES AND HEATS OF COMBUSTION BOMB CALORIMETRY

advertisement

ENERGIES AND HEATS OF COMBUSTION BOMB CALORIMETRY - Bio-diesel Evaluation Theory In this experiment, you will compare the energy released by the combustion of commercial petrodiesel to the energy released by the bio-diesel that you produced earlier in the lab. This will be done by burning them at constant volume in a bomb calorimeter. The molar internal energy (∆Uc,m) of combustion is determined from the heat capacity of the system and the temperature rise. Since the combustion of fuel in a diesel engine occurs under constant volume conditions similar to a calorimeter, the internal energy of combustion is a direct measure of the heat of combustion in an engine. Chemists are most likely to report data back as a molar value (kJ/mole). A more practical measure for energy production (at least practical in the minds of petroleum engineers and engine mechanics) is not the energy per mole, but instead the energy per gram or energy per L released by the diesel fuel. We will compare the energy per gram for the petro-product and the bio-product A bomb calorimeter measures the enthalpy of reaction by carrying out the combustion reaction under constant volume conditions. This exothermic reaction increases the temperature inside the bomb, which then transfers the energy to the external water jacket raising the external temperature. It is this rise in the water-jacket temperature which is monitored and then backcalculated to obtain the energy release by the combustion reaction. Stirrer Thermometer Reaction q Constant Volume Bomb Water Jacket Determination of heat released by reaction, Qrxn. The heat absorbed by the external jacket can be calculated using the heat capacity of the jacket. q jacket (1) C jacket = (6-3) ∆T jacket While in principal one could pre-determine the heat capacity from all the individual metal and water components present in the calorimeter, it is easier to calibrate the system by first measuring the temperature rise from a known standard. Gentry, 2013 If Cjacket has been determined, then the unknown sample can be run. Using C and ∆T gives the amount of heat absorbed by the bomb. The heat that the jacket absorbs, in turn, is equal to the heat that the bomb loses. (2) qbomb = – qjacket= – Cjacket · ∆T There is one more step that must be taken to find qrxn. The heat released by the bomb is due to both the combustion of the sample AND the combustion of the ignition wire. This is easily accounted for by using wire that has a pre-determined energy/length value. (3) qbomb = qrxn + qwire (4) qrxn = qbomb – (cm of wire burned)·(heat/cm) NOTE: Normally if one uses a bomb calorimeter to determine the enthalpy of reaction, there would need to be a series of additional calculations to convert from the constant volume conditions in the bomb to the constant pressure conditions present in an open lab. In the case of a diesel engine, however, the nearly-instantaneous combustion of the gas takes place in a constrained volume (the engine cylinder) rather than in an open beaker. Therefore the calorimeter heat of rxn can be used directly to determine the heat of combustion generated in a diesel engine. (5) qrxn, calorimeter = qcombustion, engine -2 - The Parr Constant Volume (Bomb) Calorimeter The reaction takes place at constant volume in a Parr 1341 stainless steel bomb. The sample is ignited in an oxygen atmosphere by contact with a hot wire. The heat generated by combustion raises the temperature of a known amount of water in the bucket. The bucket and bomb together constitute the reaction chamber. The measurement may be either adiabatic or nonadiabatic. The adiabatic procedure is simply to maintain the temperature of the jacket at the same value as that of the bucket so that there is no heat transfer. In the nonadiabatic procedure, temperature-time measurements are taken before, during, and after the ignition, and the initial and final temperatures are obtained by a suitable extrapolation of the temperature-time graph. You will use the nonadiabatic procedure. PARR 1341 BOMB CALORIMTER Sample Preparation Weigh about 1 gram of benzoic acid or sample and compress the sample into a pellet with the hand press. (Place the die on the end of the base with the shallow indentation. Fill with sample. Press.) Do not use significantly more than 1 gram of sample; too much heat will be evolved and an explosion is likely. Weigh an empty stainless steel cup, place the pellet inside and weigh again. The actual sample mass is obtained by difference. Accurately measure 10 cm of fuse wire. -3 - Place the cup in the holder of the bomb head and attach the wires to the binding posts of the bomb head. If using loose or liquid sample, the wire should be placed close to the top, but not actually imbedded in the sample. If using tableted samples, the wire should press down against the pellet to keep it in place so that it doesn’t slide off to the side. collar ignition wire Filling the Bomb Place about 1 mL of water in the bomb. The bomb head, with attached pellet, is inserted carefully into the bomb and the lid is screwed on finger tight. Close the outlet valve on the bomb. Attach the filler tubing from the oxygen tank to the inlet valve on the bomb. Close the filling valve between the bomb and the gauge (turn clockwise). Open the oxygen tank valve one-quarter turn, open the filling valve slowly, and allow the pressure in the line to rise slowly to the desired value. Then close the filling valve and the tank valve, and open the relief valve under the gauge. The excess pressure in the bomb closes the inlet valve. Remove the hose from the bomb. Remove atmospheric nitrogen before the combustion by putting 10 atm of oxygen into the bomb and then slowly releasing it through the outlet valve. Otherwise, formation of nitrogen oxides will contribute to the temperature change. With the escape valve closed, slowly fill the bomb with O2 to a pressure of 25 atm. Do not overpressurize. Release the residual pressure in the hose by pushing downward on the black relief valve. The pressure gauge should read zero. Detach the hose from the bomb. Preparation of the Calorimeter Two kilograms (2 liters) of water are added to the pail. [Make sure the temperature of the water falls within the range of the calorimeter thermometer, ideally trying to be close to room temperature.] Accurately measure the water by using the 2000 mL volumetric flask; this volume of liqued must be reproducible to within 0.5 ml. Pour all of the water into the pail. Place the pail inside the insulated container. Use the lifting handle (it looks like wire tongs) to insert the bomb into the pail so as not to interfere with the stirrer. Check to see that there are no bubbles escaping from the bomb. If there are bubbles, you must remove the bomb, release the oxygen, and refill and retighten the bomb lid. Under no circumstances should you proceed if there are bubbles escaping! -4 - Connect the ignition wires to the bomb head and be careful not to remove any water from the pail with your fingers. Set the cover on the calorimeter and turn the stirrer by hand to make sure it moves freely. Slip the drive belt onto the pulleys and start the motor. Let the stirrer run for five minutes to reach equilibrium. After this time, read and record the temperature at thirty-second intervals for five minutes. Be sure to read to 0.005oC. At the start of the sixth minute, STAND BACK FROM THE CALORIMETER AND FIRE THE BOMB by pressing the button on the ignition unit. Only press the button momentarily! Stand back for a full 30 seconds after firing. The temperature will start to rise within 20 seconds after ignition. Record the temperature at 30 seconds after ignition and at 30-second intervals thereafter. Continue until the temperature levels off or starts to decrease. Turn off the stirrer, remove the cover, and place it on the stand provided for it. Remove the bomb and slowly release the gas from inside. Open the bomb; place the bomb lid on the stand provided; check for complete combustion; if there is black carbon residue inside then discard the run. Measure the remaining length of fuse wire and subtract from starting length. Do one trial with benzoic acid and one trial with each of the diesel fuels (synthetic and petro). Determining ∆T From Experimental Data The isothermally jacketed calorimeter operates with the jacket at a fixed temperature, which is usually below that of the combustion chamber. Ideally enough time is given for the system to reach thermal equilibrium. If this is the case for your data then ∆T is simply the change in temperature from one plateau to the other. If, however, insufficient time is allowed so that the plateaus are in flux with the ambient surroundings then the results must be adjusted using a procedure developed at the National Bureau of Standards. This procedure is described in greater detail in the Appendix to this document. . For Sloping Beginning and Ending Plateaus For Flat Beginning and Ending Plateaus Tm Te Temp. Temp. Tm ∆T ∆T 60% To To ti Time ti -5 - Time see appendix for details While the heat of combustion at constant pressure is usually what you find reported in the literature, in this experiment you will determine the heat at constant volume, which corresponds to ∆Ucombustion. Calculations The heat contributed by electrically energizing the wire is - 9.624 J/cm. The change in internal energy for the benzoic acid reaction is ∆Urxn = - 26.435 kJ/g. Benzoic Acid Reference: Calculate the change in energy from the wire (∆Uw) and the energy from the benzoic acid (∆Urxn). Using Eq.(3), calculate the expected ∆Ubomb. Graph your data to determine the temperature changes. If you use Excel, be sure to include grid lines. Be sure to graph with enough precision (decimal places) to precisely determine the temperatures to 0.005K. From the temperature rise and the calculated ∆Ubomb, calculate the heat capacity of the calorimeter system (Cjacket) from Eq.(1). Samples: Using the heat capacity of the jacket that was determined from the benzoic acid results and the temperature rise on combustion of the solid being studied, use Eq.(2) to calculate qjacket and hence -qbomb for each of your diesel runs. You should then use Eq.(3) to calculate qrxn =∆Urxn for combustion at the calorimeter temperature. Convert this to ∆qrxn per gram of fuel. Using your previously determined densities, further convert your results to ∆qrxn per gallon of fuel Report: Compare the heats of combustion for your bio-diesel sample and the commercial petro-diesel sample. Report your results as both on a per gram and on a per gallon basis. From the first day of synthesis work, report the amount of free acid present in the original fryer oil. “Clean” vegetable oil has less than 1% free acid. What are the implications for cooking (or eating) of having free acid present in the “dirty” oil. Compare the density of your bio-diesel to that of petro-diesel and to the original cooking oil. Discuss the suitability of switching from petro-diesel to bio-diesel. -6 - APPENDIX National Bureau of Standards Procedure if Calorimeter Not At Equilibrium With Surroundings It can be the case that the calorimeter and the external surroundings are at different temperatures from one another. This means that there can be a flow of thermal energy due to those differences in temperatures in addition to flow of thermal energy due to reaction energies. This ambient thermalization must be accounted for when doing the data analysis. The presence of this problem can be seen when the plateaus at the beginning and end of reaction are not flat, but are sloping as seen on the figure below. Temp. The figure depicts a typical temperature-time graph. Note that since neither the initial slope nor the final Tm slopes are necessarily zero, the data must be Te extrapolated to obtain ∆T, the temperature change at ∆T the time the sample ignited. To obtain ∆T, graph 60% temperature versus time and determine the temperature difference between To (the last temperature before the curve starts to rise) and Tm To (the maximum temperature recorded); multiply this Time ti difference by 0.60 and add the result to the base value To; this new value is Te. Draw a horizontal line at this temperature, Te. At the intersection of this horizontal line (Te) and the experimental curve, draw a vertical line perpendicular to the Te line; this is the ignition time (ti). Use the data prior to To to extrapolate the lower limit for temperature. Similarly use the upper plateau to extrapolate the post-ignition behavior. ∆T is the difference between these two extrapolated lines at the point where Te crosses the curve. -7 -