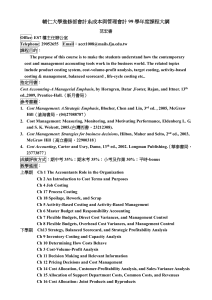

PART 1 Financial Planning, Performance and Control

PART 1

Financial Planning,

Performance and

Control

C. Cost Management (25% - Levels A, B, and C)

Job costing (Cost accumulation method) with Actual costing (Cost measurement method)

Job costing (Cost accumulation method) with Normal Costing (Cost measurement method) & End-of-

Accounting- Year Adjustments

ACTUAL/NORMAL/STANDARD COSTS

TRADITIONAL COSTING SYSTEMS (single& departmental) Vs. ABC

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 1

STUDY UNIT FOUR

COST ACCUMULATION SYSTEMS

INTRODUCTION

Product costing is the process of accumulating, classifying, and assigning direct materials, direct labor, and factory overhead costs to products or services.

Product costing provides useful cost information for both manufacturing and nonmanufacturing firms for

(1) product and service cost determination and inventory measurement,

(2) management planning, cost control, and performance evaluation, and

(3) strategic and operational decision making.

Several different types of product costing systems are available; these include :

(1) Cost accumulation method-job or process costing systems,

(2) Cost measurement method-actual, normal, or standard costing systems, and

(3) Overhead assignment method-traditional or activity-based costing systems.

The choice of a particular system depends on

(1) the nature of the industry and the product or service,

(2) the firm's strategy and management information needs, and

(3) the costs and benefits of acquiring, designing, modifying, and operating a particular system.

Cost accumulation systems represent the manner in which the accounting system develops costs. The system is modified by the cost object involved. Most commonly tested cost accumulation systems are job order costing and process costing,

if the cost object is a custom order, job costing may be used, and

if the cost object is a mass produced homogeneous product (e. g., steel), process costing using average costs would be used.

Further, there are many variations of cost accumulation systems-those that use components of both job order costing and process costing (e. g., operations costing), and

those that account for certain costs at the end of the process (e. g., back flush costing) because there is little need for in- process inventory valuation.

Other systems (e. g., life cycle costing) seek to monitor costs throughout the product's life cycle and expand on the traditional costing systems that focus only on the manufacturing phase of a product's life.

Finally, the assignment of costs to cost objects may occur using a variety of cost drivers (or allocation bases). Activity- based costing is an approach that assists in the assignment of costs, regardless of the cost accumulation system used.

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 2

JOB ORDER COSTING

(COST ACCUMULATION

SYSTEM)

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 3

III. JOB ORDER COSTING (COST ACCUMULATION SYSTEM)

Job-order costing is the method of product costing that identifies the job (or individual units or batches) as the cost objective and is used when there are relatively few units produced and when each unit is unique or easily identifiable.

A. COST OBJECTIVE IS THE JOB (OR UNIT)

Under job order costing, cost is allocated to a specific job as it moves through the manufacturing process.

Record keeping for job-costing emphasizes the job as the cost objective.

Job-cost systems are best suited for customized production environments such as construction, aircraft assembly, printing, etc. A new job-cost record would be started every time a new job (building project, airplane or print job) is started.

B. JOB COST RECORDS

Job-cost records are maintained for each product, service, or batch of products, and they serve as the primary records used to accumulate all costs for the job. Job-cost records are also referred to as job-cost sheets or job orders. Job-cost records accumulate data from the following internal documents:

1. Materials Requisitions

Materials requisitions are documents that show the materials requested for use on the job.

2. Labor Time Tickets (Time Cards)

Labor time tickets (time cards) are documents that show the labor hours and labor rate associated with the time applied to the job.

3. Overview of Job Order Costing

Job-costing systems require a limited number of work-in-process accounts.

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 4

Pictorial Overview

Job Order Costing

PASS KEY

Application of overhead is accomplished in two steps:

Step #1: Calculate Overhead Rate = Budgeted Overhead Costs ÷ Estimated Cost Driver

Step #2: Apply Overhead = Actual Cost Driver x Overhead Rate (from Step #1)

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 5

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 6

TRADITIONAL COSTING SYSTEMS (single& departmental) Vs. ABC

LIMITATIONS OF TRADITIONAL COSTING SYSTEMS

For example, Dole Company has two factories Alpha and Beta. Alpha is a highly automated factory; Beta is a labor-intensive factory. The company has budgeted the following information for the year:

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 7

To obtain more accurate product-costing information, assume that Dole Company decides to use two cost drivers, i.e., two separate departmental overhead rates for overhead costs, with a machine-hour-based rate for

Alpha and a labor-hour-based rate for Beta. The departmental predetermined overhead cost driver rates are calculated as follows:

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 8

Using departmental overhead rates, the factory overhead cost assigned to the two products follows:

The preceding calculations show that the applied overhead costs with the single plantwide overhead cost driver rate are $13,000 ($45,000 - $32,000) higher for Widget and $13,000 ($15,000 - $28,000) lower for Gidget than had the firm used the two departmental overhead rates. Gidget requires considerably more machine-hours than

Widget, but the overhead cost allocation to products with the single plantwide overhead cost driver rate does not consider these differences. Use of departmental rates causes product cost to more accurately reflect the different amount of labor and the different types of machinery and labor involved in producing the two products.

Departmental rates, however, do not consider the varying overhead costs of different processes or activities; within a department because some factory overhead costs are not volume based. For example, machine setup cost, product design cost, purchase ordering cost, and materials handling cost are not directly related to either direct labor-hours or machine-hours. The traditional volume-based plantwide and departmental cost driver rate overhead allocation methods can lead to inaccurate product costing.

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 9

ACTIVITY-BASED COSTING

(Transaction-based costing)

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 10

ACTIVITY-BASED COSTING (transaction-based costing)

Definition

Activity- base d costing (ABC) is define d as a cost accounting system that is based on activity level as the fundament al cost object. Activity- base d costing is also referred to as transaction-based costing.

The cost driver is typically the number of transactions involve d in a particular activity.

Characteristics of ABC

ABC applies a more focused and detailed approach than using a department or plant as the level for gathering costs.

ABC can be part of a job order system or a process cost system.

ABC can be use d for manufacturing or service businesses.

ABC takes a long-term viewpoint and treats production costs as variable.

The cost driver is often a non-financial variable.

ABC may be used for internal and external purposes (as can job order costing and process costing).

ABC is a refinement of an existing costing system (job-order or process)

Under a traditional (volume-based) costing system, overhead is simply dumped into a single cost pool and spread evenly across all end products.

Under ABC, indirect costs are attached to activities that are then rationally allocated to end products.

ABC may be used by manufacturing, service, or retailing entities.

ABC focuses management on the cost/benefit of activities. Value-added activities increase the product value or service. a. Value Chain (Value-added Activities)

A value chain is a series of activities in which customer usefulness is added to the product. Support activities directly support value- added activities. b. Non -value Added Activities

Non-value added activities do not increase product value or service and are targeted for elimination. These types of activities (e. g. warehousing)should be eliminated.

ABC Vs. Peanut-butter costing.

The inaccurate averaging or spreading of indirect costs over products or service units that use different amounts of resources is called peanut-butter costing.

Peanut-butter costing results in product-cost cross-subsidization, the condition in which the miscosting of one product causes the miscosting of other products.

The peanut-butter effect of using a traditional (i.e., volume-based) costing system can be summarized as follows:

Direct labor and direct materials are traced to products or service units.

A single pool of indirect costs (overhead) is accumulated for a given organizational unit.

Indirect costs from the pool are assigned using an allocative (rather than a tracing) procedure, such as using a single overhead rate for an entire department, e.g., $3 of overhead for every direct labor hour. o

The effect is an

averaging of costs

that may result in significant inaccuracy when products or service units do not use similar amounts of resources.

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 11

A traditional cost system assigns overhead with a single plant-wide overhead application rate or rates for operating departments. These rates are volume-based using an application basis such as direct labor hours or machine hours. All overhead costs, however, do not fluctuate with volume.

Assigning these costs with a volume basis will distort the amount of costs assigned to various product lines. Activity-based costing attempts to correct this by emphasizing long-term product analysis.

Volume-based systems, as illustrated above, involve:

Accumulating costs in general ledger accounts (utilities, taxes, etc.).

Using a single cost pool to combine the costs in all the related accounts.

Selecting a single driver to use for the entire indirect cost pool.

Allocating the indirect cost pool to final cost objects.

Activity-based systems, by contrast, involve(4 main steps):

Identifying organization activities that constitute overhead. o In this step ABC team will define activities , activity cost pools and activity measures (resource cost drivers) o Activity cost pools will group activities according to five categories of activities (unit-level activity, batch-level activity, product-sustaining activity, facility-sustaining activity, customerlevel activity)

Assigning the costs of resources consumed by the activities to activity cost pools using resource cost drivers, In this step first-stage allocation will be applied , o Stage one: resource cost assignment of overhead costs to activity cost pools or groups of activities called

activity centers

using appropriate resource cost drivers (here functionally organized overhead costs derived from a company’s general ledger will be assigned to the activity cost pools.)

Calculate activity rates (by dividing total cost for each activity by its

total

activity (activity cost driver) (ex: the cost of product design cost pool will be divided by no. of designs (activity cost driver).

Assign overhead costs to cost objects , in this step second-stage allocation will be applied, o Stage two: activity cost assignment of activity costs to cost objects (Product or service) using appropriate activity cost drivers.

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 12

ABC TERMS

Activity

An activity is work performed within an organization. It is also an aggregation of actions performed within an organization useful for purposes of activity-based costing.

Activities are composed of actions, movements, or work sequences.

For example, moving inventory is a warehousing activity

Resource

A resource is an economic element applied or used to perform activities.

Salaries and materials, for example, are resources used in performing activities.

Two types of cost drivers

As defined in Chapter 3, a cost driver is any factor that causes a change in the cost of an activity. It is also a measurable factor used to assign costs to activities and from activities to other activities, products, or services.

Note; In respect to ABC, two more terms with which you need to be familiar are resource drivers and activity drivers. These are details in the allocation process and you are not expected to know this for a numerical question, but perhaps for a CMA word question.

The two types of cost drivers are

resource cost drivers and

activity cost drivers.

A resource cost driver is a measure of the amount of resources consumed by an activity. It is the cost driver used to assign a resource cost consumed by an activity to a particular cost pool.

An example of a resource cost driver is the percentage of total square feet required to perform an activity.

An activity cost driver measures how much of an activity a cost object uses. It is used to assign cost pool costs to cost objects.

An example is machine hours required for the activity of running machines to produce product X.

Activity-based costing (ABC) is a costing approach that assigns costs to products, services, or customers based on the consumption of resources caused by activities.

Resources are assigned to activities, and activities are assigned to cost objects based on the activities' use.

ABC recognizes the causal relationships of cost drivers to activities

Categories of Activities

There are five categories of activities, based upon where the activity occurs In relation to the final product and the facility as a whole. These four categories are;

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 13

1. A unit-level activity : These activities are performed for each unit that is produced.

Examples of unit-level (volume-based or unit-based) activities include using direct materials, using direct laborhours, inserting a component, inspecting every item, and running machines.

2. A batch-level activity: These activities occur each time a batch is produced rather than for each unit of production.

Examples of batch-level activities are setting up machines, placing purchase orders, scheduling production, inspecting every batch, and handling materials.

3. A product-sustaining activity is performed to support the production of a specific product.

Examples of product-sustaining activities include designing products, administering parts, issuing engineering change orders, and expediting.

4. A facility-sustaining activity is performed to support the production of products in general. Examples of facility-sustaining activities include providing security, safety, maintenance, and plant management, calculating plant depreciation, and paying property taxes.

5. A customer-level activity includes activities that are performed to support customer needs such as customer service, phone banks, or custom orders.

Note; Fortunately, on the CMA Exam you will generally not need to Identify the cost drivers or cost pools in a large question because they will be provided for you. You will simply need to use the provided Information to determine the amount of overhead that will need to be allocated to any product. In a smaller question It is possible that you will need to determine the appropriate driver, but these are usually fairly direct, and If you simply think about what would cause costs to be Incurred, you will see the correct answer.

Benefits and Limitations of an Activity Based Costing System

Benefits

Activity-based costing helps reduce distortions caused by traditional cost allocations.

It provides a clear view of how the mix of a firm's diverse products, services, and activities contributes to the bottom line in the long run.

Major benefits of the activity-based costing are the following:

1. ABC provides more accurate and informative product costs, which lead to more accurate product profitability measurements and to better-informed strategic decisions about pricing, product line, customer market, and capital expenditure.

2. ABC provides more accurate measurements of activity-driving costs, which helps managers improve product and process value by making better product design decisions, controlling costs better, and fostering various value-enhancement projects.

3. ABC provides managers easier access to relevant costs for making business decisions, enabling them to take a more competitive position

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 14

Limitations

Although activity-based costing provides better tracing of costs to individual products than traditional systems, managers should be aware of its limitations before using it to calculate product costs:

1. Allocations. Even if activity data are available, some costs probably require allocations to departments and products based on arbitrary volume measures because finding a specific activity that causes the incurrence of the costs might not be practical. Examples are some of the facility-sustaining costs, such as cleaning the factory and managing the production process

2. ABC reports do not conform to GAAP, so restating financial data adds an expense and causes confusion

(unsure whether to rely on the ABC or external data).

3. Expense and time. An ABC system is very expensive to develop a~t and is very time consuming. Like most innovative management or accounting systems,

4. ABC usually requires more than a year for successful development and implementation.

5. ABC generates vast amounts of information. Too much information can mislead managers into concentrating on the wrong data.

Comprehensive Example to compute product costs under a traditional costing system and an activity based costing system.

The following example contrasts steps 2 and 3 of the traditional costing system, using direct labor-hours as the cost driver, with the activity-based costing system, using both volume-based and non-volume-based cost drivers.

Northern High-Tech, Inc., successfully produces and sells two types of quality printers, the deluxe and the regular. Assume that the company has the following financial and cost data for the two products:

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 15

The company's management accountant has identified the following activities, budgeted cost pools, and activity drivers:

These are the actual activity units or transactions for each product:

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 16

Traditional Costing Analysis In the traditional costing approach, the factory overhead (OH) is allocated on the basis of direct labor-hours (DLH) as the cost driver:

Activity-Based Costing Analysis In the activity-based costing approach, the cost driver rate for each activity cost driver-that is, the activity rate-is calculated as follows:

Factory overhead costs are assigned to both products, as shown by these calculations

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 17

EFFECTS OF ABC

An ABC system will apply high amounts of overhead to a product that places high demands on expensive resources. If a product places few demands on expensive resources, the system will assign little of that cost to the product. This will remove much of the cost distortion caused by traditional, volume- based overhead systems.

Exhibit 4-6 presents a product profitability analysis under the activity-based costing system and Exhibit 4-7 compares product costs and profit margins under the two costing systems.

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 18

Remember that one major limitation of the traditional costing system is that it generally undercosts complex low-volume products and overcasts high-volume products.

The activity-based costing system presents a more accurate measurement pattern of overhead consumption.

The preceding comparison shows that the traditional product costing system can significantly undercost the deluxe printer (a low-volume product) and overcast the regular printer (a high-volume product) compared with the actual overhead consumption. Consequently, traditional product costing can cause distorted inventory measurement, incorrect product-line decisions, unrealistic pricing, ineffective resource allocations, misplaced strategic focus, misidentified critical success factors, and lost competitive advantage.

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 19

LIFE-CYCLE COSTING (basis for cost planning and product pricing NOT GAAP)

A life-cycle approach to budgeting estimates a product's revenues and expenses over its entire sales life cycle beginning with research and development, proceeding through the introduction and growth stages into the maturity stage, and finally into the harvest or decline stage.

Accordingly, life-cycle costing fakes a long-term view of the entire cost life cycle, also known as the value chain.

Value Chain for a Manufacturer

Downstream costs Upstream costs

The total costs for a product's life cycle have three phases, thus Costs are determined for all value-chain categories:

1.

Upstream (R&D, design), a.

Upstream costs: costs that are prior to the manufacturing of the product or sale of the service, such as R&D or design (prototypes, tests, and engineering)

2.

Manufacturing, a.

Manufacturing costs: costs involved in producing a product or service, such as purchasing and direct and indirect manufacturing costs and

3.

Downstream (marketing, distribution, and customer service). a.

Downstream costs: costs subsequent to (or coincident with) manufacturing costs, such as marketing, distribution (packaging, shipping and handling, promotions, and advertising), service costs, and warranty costs (defect recalls, returns, and liability).

LIFE CYCLE COSTING VS. TRADITIONAL COSTING

In contrast, traditional approaches focus on cost control (as opposed to cost reduction) during production and treat pre- and postproduction (upstream and downstream) costs as period costs that are largely ignored in determining the profitability of specific products. a. Other costs that traditional methods ignore are the after-purchase costs (operating, .support, repair; and disposal) incurred by customers.

CMA Sample Q (Whole-life cost equals the Life-cycle cost plus after-purchase costs.)

Claremont Company has been asked to evaluate the profitability of a product that it manufactured and sold from

Year 7 through Year 10. The product had a one-year warranty from date of sale. The following information appears in the financial records.

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 20

Research, development, and design cost

Yr 5 & Yr 6

$5,000,000

Manufacturing and distribution costs

Yr 7 - Yr 10

$7,000,000

Warranty costs Warranty cost

Yr 7 - Yr 10

$200,000

Yr 11

$100,000

The life-cycle cost for this product is…………………..

Life-cycle costing takes into account costs incurred at all stages of the value-chain, not just manufacturing. The life-cycle cost for this product is thus $12,300,000 ($5,000,000 + $7,000,000 + $200,000 + $100,000).

Life-cycle and whole-life cost concepts are associated with target costing and target pricing

A firm may determine that market conditions require that a product sell at a given target price. Hence, a target cost can be determined by subtracting the desired unit profit margin from the target price. The cost reduction objectives of life-cycle and whole-life cost

management can

therefore be determined using target costing.

LIFE-CYCLE COSTING (NOT GAAP)

For financial statement purposes, costs during the upstream phase must be expensed in the period incurred. For management accounting purposes, the costs (such as R&D) that result in marketable products represent a life-cycle investment and must therefore be capitalized.

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 21

Backflush costing in just-in-time production systems

A just-in-time (JIT) system produces materials just as they are needed for the next step in production. The trigger for manufacturing at a particular work area is the demand from the next station down the line, thus JIT production systems are a "demand-pull" manufacturing system. Customer demand triggers initial production need, working backward all the way to raw material purchases at the beginning of the cycle. JIT also reduces manufacturing lead time by organizing manufacturing into cells that are closely coordinated. HT ensures timely material deliveries and meets customer demands while simultaneously ensuring high-quality products at the lowest possible cost. Therefore, organizations using HT production have very little inventory, making the choice of inventory valuation methods (e.g., FIFO, weighted-average) and inventory costing methods (e.g., absorption costing, variable costing) irrelevant because the costs flow directly to cost of goods sold during an accounting period.

Backflush costing Vs. Traditional costing systems (sequential tracking)

Backflush costing. Costing system that omits recording some or all of the journal entries relating to the cycle from purchase of direct material to the sale of finished goods.

Traditional costing systems use sequential tracking, which is any process that records purchases and movements of costs between inventories and accounts in the order in which they occur.

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 22

Process cost accounting

Process cost accounting is used to assign costs to inventoriable goods or services. It is applicable to relatively homogeneous products that are mass produced on a continuous basis (e.g., petroleum products, thread, computer monitors, Oil refining, Textiles, Paints, Flour, Canneries, Rubber, Steel, Food processing).

Characteristics of Process Costing

Due to mass production direct labor costs are usually small in comparison to other costing system , thus DL cost combined with Manufacturing overhead to constitutes conversion costs.

Comparing Job-Order and Process Costing

Where job-order costing uses subsidiary ledgers to keep track of specific jobs, process costing typically has a work-in-process account for each department through which the production of output passes.

Process costing is an averaging process that calculates the average cost of all units:

1) Costs are accumulated for a cost object that consists of a large number of similar units of goods or services;

2) Work-in-process is stated in terms of equivalent units;

3) Unit costs are established.

The accumulation of costs under a process costing system is by department rather than by project. This reflects the continuous, homogeneous nature of the manufacturing process.

Because manufacturing overhead is assigned to work-in-process as part of conversion costs, there is rarely an overhead control or overhead applied account under process costing, and the issue of over- or underapplied overhead does not arise. The exception is when a standard costing system is used. Under standard costing, a predetermined overhead rate (as in job-order costing) is used to assign overhead costs.(See flow of cost accumulation in a process costing system in your book).

Steps in process costing

1.

Account for all units (physical flow of quantities).

2.

3.

Compute the equivalent units of production (EUP).

Compute unit cost per EUP.

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 23

Step 1: Account for All Units : step 1 important to determine any missing information in questions

(normally spoilage), same in both FIFO and Weighted average methods, ignores the % percentage of completion for beginning and ending WIP).

.

Beginning WIP XX

Started Units this period XX

________

Total Units to Account for xxxxxx

Finished or transferredout goods Ending WIP

Step 2: compute Equivalent Units of Production

Spoilage

(lost)

a. One equivalent unit is the amount of direct materials or conversion costs (direct labor and manufacturing overhead) required to produce one unit of finished goods. b. The objective is to allocate direct materials and conversion costs incurred during the period to finished goods, ending work-in-process (EWIP) and spoilage. c. EUP is separately computed for direct materials and conversion (DL & MOH) costs.

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 24

Example: For the current period, Jones started 15,000 units and completed 10,000 units, leaving 5,000 units in process 30 percent complete. How many equivalent units of production did Jones have for the period?

a. 10,000

b. 11,500

c. 13,500

d. 15,000

Answer: 10,000 units + (5,000 units × 0.30)

= 11,500 equivalent units

Two cost-flow assumptions in Process costing: First In First Out (FIFO).Vs. Weighted Average.

First In First Out (FIFO)

Assumptions:

Only costs incurred this period are allocated between finished goods and EWIP. Manufacturing costs in beginning work in process (BWIP) are excluded from the current –period unit cost calculations.

The beginning work in process

(BWIP) inventory is to be completed and transferred first.

The ending work-in-process

(EWIP) inventory results from goods processed this period.

EUP is separately computed for direct materials and conversion

(DL & MOH) costs.

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 25

EUP Computation under FIFO (If materials are added as work in process (continually):

Material Conversion

Total units Completed XX XX

- Beginning WIP (regardless of % of completion) (XX) (XX)

______________________

Units Started and Completed this Period XX XX

+ Amount needed to complete Beginning WIP XX XX

+ Amount Completed on Ending WIP XX XX

_______________________

EUP under FIFO XX XX

_______________________

If materials are added at the beginning of a process :

Total Units Completed XX

+ Amount of materials Needed to Complete BWIP zero

+ Amount of materials Added to Date on EWIP 100%

_____

EUP for Materials XXX

____

If materials are added at the end of a process

Total Units Completed XX

+ Amount of materials Needed to Complete BWIP 100%

+ Amount of materials Added to Date on EWIP zero

_____

EUP for Materials XXX

____

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 26

EUP : Weighted Average

Assumptions

No differentiation is made between goods started in the preceding and the current periods.

The beginning WIP inventory costs are merged with the costs of the units started during the period and new average cost is obtained.

EUP under weighted average differs from EUP under FIFO by the amount of EUP in beginning WIP.

Total EUP completed from beginning WIP is not deducted in determining current EUP.

EUP under weighted average costing may be computed as follows:

Total Units Completed this period XX

+ Work to date on Ending WIP XX

_____

EUP under weighted average XXXX

Comparing Weighted Average to FIFO

The difference between weighted average and FIFO is the handling of beginning WIP.

If there is no beginning WIP inventory, both assumptions will have the same EUP.

EUP :Example 1

The following data relate to the activities of department A during the month of

January : assume that all materials are added at the beginning of the process .

Units

Beginning WIP (66.67% Completed as to Conversion) 1,500

Units started this period 5,000

Units Completed and Transferred to the following process 5,500

EWIP (60% Completed as to conversion) 1,000

Required

Compute EUP using FIFO and Weighted Average.

EUP :Example 1 Solution

Accounting for all units (Physical Quantities)

Units

BWIP

Units Started this period

Total Units to Account for

1500

5000

6500

Units completed and transferred 5500

EWIP 1000

Total Units to Accounted for 6500

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 27

EUP : Examples 1 solution (EUP-FIFO)

Materials Conversion

Units Completed and transferred 5500 5500

Beginning WIP (1500) (1500)

Units Started and Completed this period 4000 4000

Amount needed to complete BWIP

0% materials zero

33.33% Conversion (1500 units X 33.33%) 500

Amount to date on Ending WIP

100% Materials (1000 units x 100%) 1000

60% Conversion (1000 x60%) 600

EUP Under FIFO 5000 5100

EUP :Example 1 solution (EUP-Weighted average )

Materials Conversion

Units Completed and Transferred 5500 5500

Amount to Date on EWIP

100%materials ( 1000 x 100%) 1000

60% Conversion ( 1000 x 60%) 600

EUP Under Weighted Average 6500 6100

EUP : Example 2

The same facts as in example 1 except that all materials are added at the end of the process.

Required

Compute EUP using FIFO and Weighted average

EUP :Example solution (EUP-FIFO )

Materials Conversion

Units Completed and transferred 5500 5500

Beginning WIP (1500) (1500)

Units started and Completed this period 4000 4000

Amount needed to Complete

100% Materials 1500

33.33% Conversion (1500 x33.33%) 500

Amount to Date on Ending WIP

0% materials (1000 x 0%) 0

60% Conversion (1000 x 60%) 600

EUP Under FIFO 5500 5100

EUP :Example solution (EUP-Weighted average )

Materials Conversion

Units Completed and Transferred 5500 5500

Amount to Date on EWIP

0% Materials (1000 x 100%) 0

60%Conversion (1000 x 60%) 600

EUP Under Weighted Average 5500 6100

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 28

Step 3 : Compute Unit Cost

Unit Cost Under FIFO

Current Manufacturing Cost

EUP (FIFO)

Manufacturing Cost Current MC ÷ EUP (FIFO) = Unit Cost

DM $xx ÷ xx = $xx

Conversion (DL&MOH) $xx ÷ xx = xx

Total Unit Cost –FIFO $XXX

Unit cost under Weighted Average (WA)

Cost of BWIP + Current manufacturing Cost

EUP (WA)

Manufacturing Cost BWIP Cost + Current MC ÷ EUP (WA) = Unit Cost

DM $xx + $xx ÷ xx = $xx

Conversion (DL&MOH) $xx + $xx ÷ xx = xx

Total Unit Cost –Weighted Average $XXX

Accounting for spoilage

Southwood Industries uses a process costing system and inspects its goods at the end of manufacturing. The inspection as of June 30 revealed the following information for the month of June.

Good units completed

Normal spoilage (units)

16,000

300

Abnormal spoilage (units) 100

Unit costs were: materials, $3.50; and conversion costs, $6.00.

What is the number of units that Southwood would transfer to its finished goods inventory and the related cost of these units are?

Step 1: calculating the total cost of the completed units = 16,000 X ($3.5+$6) = $ 152,000

Step 2: adding only the cost of normal spoilage as it represents the additional product cost for the completed units totaled 16,000 {Cost of Normal spoilage = 300 X ($3.5+$6) = $2,850}

Thus, for sure the

number of units that Southwood would transfer to its finished goods inventory sould based on the

16,000 “

Good units completed” but with total cost =

$ 152,000 + $2,850= $154,850

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 29

Operation costing

Many companies have costing systems that are neither pure job costing nor pure process costing but have elements of both. so it use a hybrid system called Operation costing, in a hybrid system direct materials costs are charged to specific products (as in job-order systems) but conversion costs are accumulated and a unit conversion cost for each operation is derived (as in process costing).

Example : Fashion Inc. manufactures women’s dresses using cotton and polyester. Since the same style dresses are made out of both fabrics, Fashions uses operation costing.

During June, 1,000 cotton dresses were completely produced.

Also during June, 1,500 polyester dresses were started by adding all materials at the beginning of the process.

Of these 1,500 dresses, 700 were completely finished and the remainder were 25 percent complete by the end of the month. There was no work-in-process inventory at the beginning of June.

Costs incurred during June were as follows.

Cotton

Polyester

$10,000

22,500

Conversion costs 13,300

The cost per unit to manufacture one polyester dress during June was units per unit

M C

$22,500 $13,300.0

1500 1900

$15 $7 $22

Prepared by: Sameh.Y.El-lithy. CMA,CIA. 30