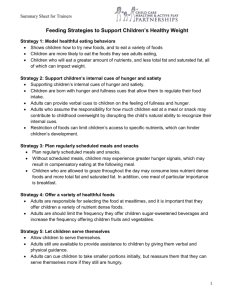

Kraft Foods Responsibility Report

advertisement