Dryers - Edinburg Plastics

advertisement

Dryers

In Engineering Resins 85% of all technical service calls are due to

not properly dried resin materials.

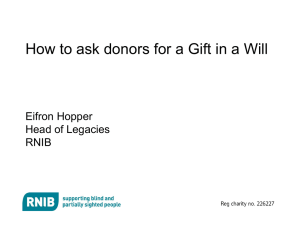

A closed loop, dehumidifying, re-circulating hot air hopper dryer is suggested for drying resins

(see Figure 1). This system utilizes rechargeable desiccant cartridges to provide dry heated air.

A correctly designed hopper and dryer unit will provide a steady flow of dry pellets to the

intake of the molding machine.

( Figure 1 )

There are normally two different sections for sizing this dryer system:

A.) Hopper Capacity is total pounds over the time required to dry (PPH to run

molder “X” required time to dry, per Resin OEM’s recommendations).

B.) Heater/Dryer unit (PPH to run molder) which is a combination of: blower sized by

CFM (Cubic Feet per Minute), Heater sized by amps. (Ampere= unit of electric current),

desiccant beds sized by mass or volume of pellets and controls on the unit. The

Heater/Dryer units are usually sized in PPH meaning maximum material usage per hour.

To avoid cross contamination the dryers and material transfer system must be fully disassembled

before cleaning and air filters should be cleaned regularly.

Hopper Capacity

The dehumidified (dry) heated air, flows through perforated sides within the hopper.

The actual material flowing through the hopper should be a side flow design (side flow =

using a cone located in the center near the bottom of the hopper forcing: first in /first out resin

resin flow through the hopper) which will prevent channel or center flow (center flow= like an

hour glass, material flows from the top first, down and out the center; last in / first out) of the

material. If the center cone is not in place it will effect material residence time through the hopper

(not drying all materials within the hopper) and not give material enough residence time to dry

(new material well feed straight through without drying; last in / first out). One problem is these

center cones are removed for cleaning or maintenance and not replaced.

Plastics Made Simple Training Manual

Copyright 2004-2006 Edinburg Plastics, Inc.

How to calculate the required Hopper Capacity; first you will need:

• Resin OEM’s (Manufactures) recommended material drying conditions; Example:

normal PC (Polycarbonate) the temperature is 250ºF, 2 to “4” hours drying time,

dew point of (-40º F) and moisture below 0.02% by weight.

• Total weight of the part and sprue / runner (for this example 1.4 kg)

• Total cycle time (for this example 64 seconds)

Example A:

• 1.4 kg total part and sprue weight “X” 2.2046 CF (Conversion Factor) = 3.08 lbs.

(if 1400 grams ÷ 454 CF = 3.08 lbs.)

• 60 seconds ÷ 64 seconds cycle time = .9375 CF

• .9375 CF “X” 3.08 lbs. = 2.89 lbs per minute

• 2.893 lbs. per minute “X” 60 minutes per hour = 174 P.P.H. (pounds per hour)

needed for the next section Heater/Dryer unit sizing.

4 hours recommended drying time “X” 174 P.P.H. = 694 lbs. of capacity required in

the hopper. If a manufactures recommended drying time is 2 to 4 hours always calculate

using the higher time (the maximum drying time for PC, that is 2 to 4 hours is used to calculate

an over sized hopper); the 2 hours is if everything is perfect: material came right to you

already dry from the manufacture, humidity that day was low, boxes only opened when

needed and used up fast, in a perfect world, etc… If regrind is added the 4 hours will

need to be 5 hours for less then 15% and 6 hours for over 15% as long as there are no

fines and the grind size is the same or around the same size as prime pellets. Pre-dry

the regrind to or below recommended % moisture by weight before mixing into prime.

• .9375 CF “X” 3.08 lbs. = 2.89 lbs per minute

• 2.893 lbs. per minute “X” 60 minutes per hour = 174 P.P.H. (pounds

per hour) needed for the next section Heater/Dryer unit sizing.

(note: hopper can be over or under sized; over drying will brittle material)

If cycle times change the hopper capacity will need to change. The lower the

cycle time, the larger the hopper capacity will need to be. Lets say your previous

total cycle time was 64 sec. with a 694 lbs. dryer hopper capacity and you reduced

the total cycle time to 58 sec. ”nice job!”; what is the new required hopper capacity?

(answer 767 lbs.) Here is how to calculate the change:

(previous total cycle time) ÷ (current total cycle time) = correction factor

(correction factor) “X” (previous dyer hopper capacity) = new required dryer hopper

capacity. Example B:

64 sec. ÷ 58 sec. = 1.103 CF

1.103 CF “X” 694 lbs. = 767 lbs. new required dryer Hopper Capacity.

1.103 CF “X” 174 PPH = 192 PPH new Heater/Dryer unit capacity.

Plastics Made Simple Training Manual

Copyright 2004-2006 Edinburg Plastics, Inc.

Heater/Dryer unit

Sizing the heater/dryer unit: the manufacture usually has a PPH (pounds per hour) rating

on the unit. The unit rating is based on PPH of material needed through molder or total

part weight (with sprue) “X” (times) the total cycle time with correction factor used or

shown in the previous (Example A) giving answer 174 PPH (not the hopper size or 694 lbs.).

The actual sizing calculation to get this number will depend upon: how many pounds of

desiccant, blower CFM (Cubic Foot per Minute of air flow), heater amps, pipe size,

distance, how many elbows along with how many and mesh size of inline filters. Rule of

thumb; clean all filters and put an air flow meter at the in-feed hose to the hopper; the CFM

of air flow should be equal to the PPH. If you get 174 CFM of air flow on the in-feed

hose the heater/dryer unit “should” handle 174 PPH. {anemometer is an air flow meter; call

the dryer manufacturers they can just tell you P.P.H. for that model number}.

What are the major problems to look for on the Heater/Dryer units?

• Desiccant Pellets must be checked or changed every year. Do not check tops of

beds; get a center sample from the desiccant bed. The dew point of the air at the

input of the hopper should be -20°F to -40°F (best at -40°F) or lower (-50ºF). If

dew point is above –20ºF or varying (the bed starts at –40ºF and after 1-2 hours

it is at –20ºF) there is a problem with the desiccant pellets drying, the bed is too

small, desiccants are not getting regenerated or are used up (too old). {most

desiccant pellet manufacture will check the samples for free to see if they need

to be replaced}

• Make sure Beds are shifting. Rule of thumb desiccant pellets are dried at 536º F

for 1.5 hours and cooled for 2.5 hours; “4 hours total” before switching. {check

with your Manufacture for their temperatures and times}.

Filters not cleaned which have stopped or slowed down airflow. {Magnehelic® or any

differential pressure gauge to tell you when the filter needs cleaning or replacing. You

could also install sensors “Best advice is to clean the filters regularly; put on an operator

or maintenance PM schedule”.}

Heaters will go bad and lower amp draw will tell you when. Dryer air temperature should

be monitored at the input of the hopper (see Figure 1). If you have a set point of 250ºF

and reading 220ºF just before going into the hopper there is a problem. Too low a

temperature from set point, look at the heaters and/or thermocouples, they may have burnt

out or on the way to. {heater manufactures will give you low or minimum Amp draw

numbers indicating when it’s time to change}.

All through this information I have repeated one thing; if you have a problem call your

manufacturer; they will want to teach you so you will buy more equipment, parts and

keep their competition out. And if you do not trust their information, get rid of them.

There are so many manufactures, all ready just to help you. Of course, if you just

want someone to come in and tell you what’s wrong and setup training, call me.

I will be happy to assist you, for a nominal fee of course.

Thanks

Brian Schrowang

Plastics Made Simple Training Manual

Copyright 2004-2006 Edinburg Plastics, Inc.