ADT Fire & Security - Professional Planning Forum

ADT Fire & Security

Professional Planning Forum | 29.4.13

Ongoing centralisation programme of all

National support functions

National Footprint

We have

1,600 trained and experienced engineers - the largest network in country

Over

450,000 customers

We install year - that’s

27,000 systems every

100+ every day

With

23 offices, we operate in every part of the UK

3749 employees across the UK and

Ireland

A Tyco Business

Setting the scene…

Until just over 2 years ago, all customer enquiries were dealt with at various branches throughout the country only providing support during hours of 09:00 to 17:00.

TO

To retain our position as market leader, we have undergone a great deal of change to ensure that our centralised CSC is now the front of our business and FPOC for our customers

,offering value-added service.

In February 2011, we re-located our support functions to New York Street in

Manchester city centre spending £1.3million on design and build, providing employees with world class facilities.

A Tyco Business

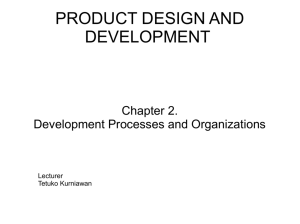

Centralisation - Project Overview

Branch Back Office

Simplify &

Standardize

•

Paperwork

•

Product Range

•

Pricing

•

Planning

•

Logistics

•

Call Flow

Automate

•

Data Entry

•

Decision Making

•

Inspection

•

Docket Pricing

•

Error Proofing

•

Planning

•

Call Handling

•

Self Service

Centralize

•

Back Office Admin

•

Finance

•

Service Planning

•

Install Planning

•

Quoting

•

Shared Services

IMPROVED PLANNING

INCREASE REMOTE FIX

Centres of

Excellence

Field Activity Reporting

CUSTOMER SELF-SERVE

OPTIMISE THROUGH CONTINUOUS

IMPROVEMENT

HEADCOUNT

4000

3500

3000

2500

FY12 FY13 FY14 FY15

A Tyco Business

Operational Efficiency - Customer Contact Strategy

Objective: Enhance customer experience for 300,000 branch calls per year

Stage

Baseline

Current

Goal

Abandon Rates

50%

3%

15%

First Time Fix

25%

72%

60%

Transfers (Average)

2.5

0.6

Max 1

Branch Calls Removed

0%

94%

95%

>500 inbound numbers with different experience every time <10 inbound numbers with 2-3 variations per channel

Since Jan12: 105,000 calls removed - Current Rate: 1,000 per day removed

Branch Receptions removed (12 f/t heads)

A Tyco Business * Based on 17,000 customer calls

Operational Efficiency – Remote Engineers

R emote

E ngineering

S upport

O n

L ine

V irtual

E ngineers

RESOLVE is the only operation of its kind in the UK

It is a 24hr support service for faults and Remote Routine

Inspection (RRI’s) directly without sending out an actual engineer.

They also provide technical support for both ADT customers and engineers and complete over 2000+ RRI’s per month

•

68% of calls passed without engineer visit

•

200,000

Engineer visits per annum Saved

•

Cost savings

for customers and ADT

•

Reduced

Carbon Footprint

A Tyco Business

Centralised Field Planning & Parts Ordering – Efficiencies gained

12-15

Full time employees

8-9

Full time employees

Engineer led activity – ‘I’m too busy’ Load balancing across resource

No smart scheduling/route optimisation

Intruder contract base only

Reactive work scheduling

Variable customer liaison across branches

25% re-work

Complex, lengthy process for Parts Ordering

Development of route optimisation planning

Intruder contract base initially, then remaining disciplines

Planned work scheduling – ‘next job’ feed

Consistent customer liaison

<10% re-work (Target within pilot)

Centralised process – 50% reduction on cycle time

A Tyco Business

Key Achievements

National Parts desk launched focused geographical selection reduced travel between sites for Engineers

Over ½ million truck roles saved (Engineer visits) (inc RRI)

4,000 Remote Routine Inspections completed per month

Dedicated RRI team launched

Proactive Management of

Routine Inspection Escalations

A Tyco Business

Operational Support – Creation of Resource Planning Team

Pre Feb 2012

•

Contact Centre – Key findings/issues

Insufficient planning team

Two Planning Analysts inexperienced and unsupported

Minimal forecasting capability (only planned 1 week in advance)

No profile analysis

No flexibility to manage peaks and troughs in demand due to fixed shifts

Holiday allowance fixed and not aligned to demand curve

Phones not configured to capture ACW

No capacity or budget plans – FTE requirements based on best guess

SLAs recorded incorrectly (overflow queues, short abandon etc.)

No visibility of lates, adherence etc

New team structure implemented:

Business Planning

& Support

Manager

Senior Planning

Analyst

MI Analysts x 2

Planning &

Reporting Analyst

Scheduling &

Intra-day Analyst

Intraday Analyst x 2

A Tyco Business

Improvements to Date

Implementation of Aspect Ewfm, EQM and

APM

Transition commenced 06/12 and Ewfm went live 08/12

Introduction of standard planning principles

Created detailed Capacity models for all departments to “right-size” the Operation

Shift reviews for all departments to align staffing to demand

Redesigned call flows

Continuous training & development of

Planning Analysts through PPF/Aspect

A Tyco Business

Phones configured to capture ACW and AUX activity

Tangible improvement in management of lates, and adherence & conformance

Empower rolled out to Operations teams holiday bookings

& availability automation

Visibility of shifts, breaks etc

Agent productivity

Consistency of performance and forecast accuracy

Identified opportunities to drive efficiencies going forward

8% reduction in call centre staff who are now utilised in

Resolve Balanced cover of staff throughout each day in each dept. reducing repeat calls due to abandon.

Working towards a minimum 70/30 FT/PT split in CSC

Improved Customer Experience by reducing transfers

Improved knowledge and skills to support achievement of Operational efficiencies

Operational Support - Resource Planning Field Support

Identified issues and concerns

•

Relationships between

CSC and Field

•

Processes impacting performance

•

Holidays, off-line, absence not aligned to demand

Automation of sickness reporting to allow time for dispatch planners to re-schedule (Lean Sigma)

Field Planning expert engaged (via PPF conference)

Detailed capacity plan designed

Road-map created to deliver improvements to the

Customer

Model office developed to validate data and new processes

Engaged with branches during peak periods to minimise performance impact by capping allowances

Seasonal planning trial showed dramatic improvement in service

Capped holidays both in the Field and the CSC

Identified work that could be carried out earlier in December to free up resource in

January

A Tyco Business

People Development | 2010 - Current

Introduced NVQ’s for Customer

Service employees

Core management programme for Team Leaders focusing on developing Soft skills

Robust 3 week induction programme

In house Customer Service workshop designed

Employment Engagement

Steering Group set up and led by People Development team

100% completion of the internal electronic one 2 one process

100 employees so far completed their qualifications

Workshops, job related modules, presentations and the completion of a Team Leader NVQ

Designed and delivered to ensure all new starters have the knowledge in systems, customer service and quality to achieve their targets

On the importance of Service to our customers – delivered to

95 advisors

Focusing on Six Sigma Green Belt processes, and incorporating interactive events throughout the year

Ensuring that all employees are set clear goals and objectives

A Tyco Business

Overall Summary – Efficiencies Achieved to Date

Enquiry to Order

Order to Cash

Service Back Office

Telephone Call Handling

Monitoring Centre

Spans of Control

Central Teams

Admin Simplification

Totals to end Q1FY’13

76FTE

42FTE

13FTE

21FTE

39FTE

73FTE

44FTE

32FTE

340FTE

•

Improved Employee Engagement Score

•

Improved NPS

•

Achievement/Stabilisation of SLA’s

•

Improved Field/Contact Centre Engagement

A Tyco Business