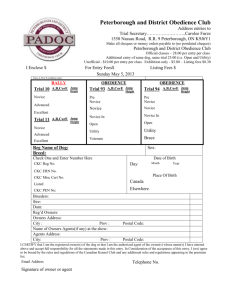

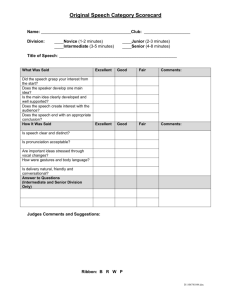

Chapter 11 - Novice Procedures

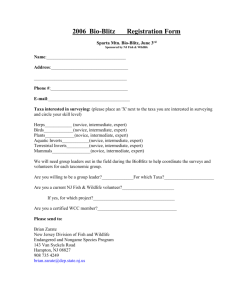

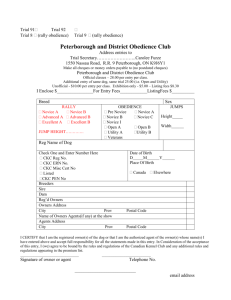

advertisement