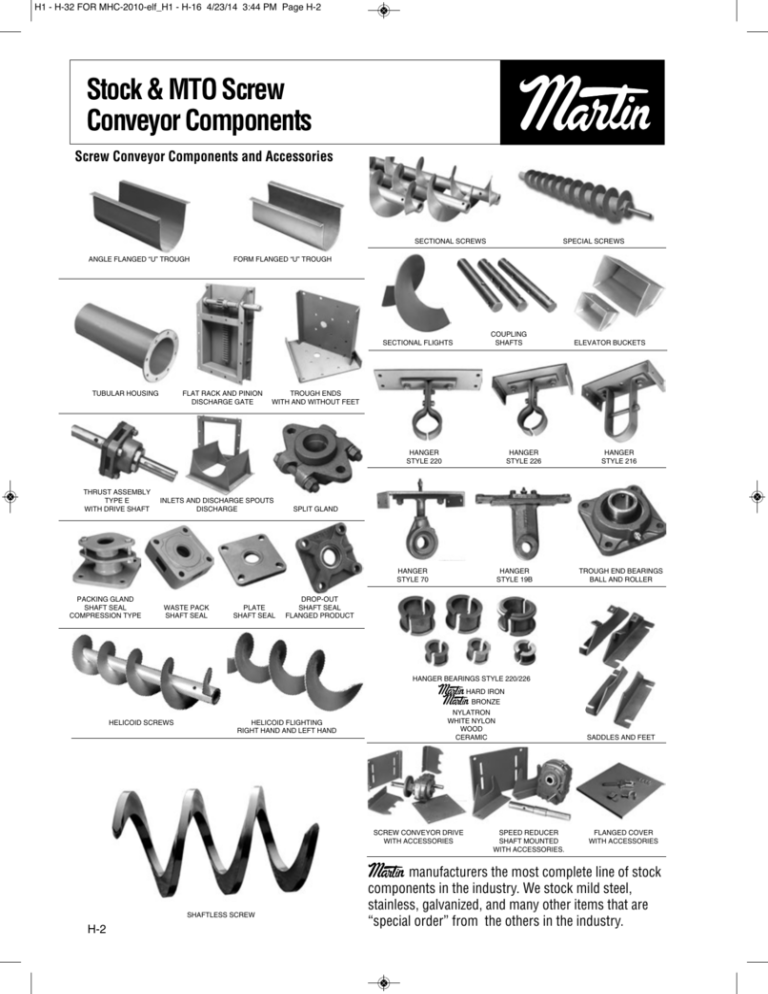

Stock & MTO Screw Conveyor Components

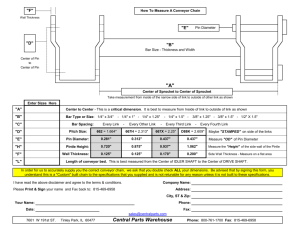

advertisement