Toothpick Bridge Design Tips: Build a Strong Truss

advertisement

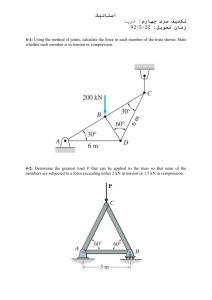

Toothpick Bridge Design Tips Purpose: - To design a truss bridge to a 1:1 scale using toothpicks that is nicely organized and symmetrical in order for it to carry the greatest force load. Content: In order to build a bridge that can carry heavy force loads, it is necessary to understand some of the basic elements about truss design, toothpicks and the materials you are working with. Wood & Toothpicks Since we are building with toothpicks, let’s talk about the material these toothpicks are made of, wood. Wood is a great building material and allows for strong tension and compression forces to be applied to the material. The grain that runs through the wood is what gives the wood most of its strengths. For example, white pine does not have much of a tight grain pattern but oak does. This is why oak lumber has more strength then white pine lumber. Another property that allows wood to have strong strength is its ability to flex. Flexibility is an important aspect that materials must have in order to hold or support great force loads. When something flexes, it allows the material within the object to give with the force rather than crack and split. Steel is also a flexible product making it another common building material. When building with toothpicks, we are using the advantages of wood but we have to look at the things that also works against wood. Wood is able to hold great forces, but does better with tension forces then it does with compression forces. Under tension forces, wood is not able to buckle and twist, the fibers and grain with in the wood keep it from tearing apart. Under compression loads, the wood can easily buckle and twist causing it to fail prematurely. Another aspect that is hard to predict is that each piece of wood has its own grain pattern, kind of like a figure print. The grain pattern is what gives wood its strength, therefore I could have two identical species of wood that have the same dimensions but one piece of wood may be stronger than the other making it difficult to predict which wooden member may break over the others or cause premature failure of the truss. Things to consider about toothpicks in the design process: 1. Toothpicks perform better under tension forces than compression forces. 2. Each toothpick has its own grain pattern, which allows toothpicks to perform differently under the same circumstances. 3. Toothpicks used in class for this project are approximately 2 ½” long. Trusses A truss is a structure that supports a load force and applies it to its outer edges of the truss where it can be transferred to the support bases in which the truss rest on. It is composed of members, load-carrying components of a structure, connected together at nodes, locations where the members are attached together, to form an arrangement of interconnecting triangles used to support bridges, roofs, towers and other structures. Toothpick Bridge Design Tips Mr. Brown’s Physics Class Page 1 of 4 Things to consider about basic truss design: 1. Nodes are the intersection points where the members (toothpicks) connect together. 2. Members are the beams (toothpicks) that support the bridge and the force load applied to the bridge. 3. There must be at least 3 or more members per node, except for the ends of the truss. This provides joints in the toothpick to be properly braced. 4. As long as the nodes are glued or attached properly, failure will always occur within the members of the truss and not the nodes. 5. The members located in the lower half of the truss are typically under tension forces. 6. The members located in the upper half of the truss are typically under compression forces. 7. Members under compression force are prone to critical fail before members under tension forces. 8. Truss designs are symmetrical from the outer edges inward. Bracing The truss is only able to support the force load applied to it as long as it remains in a stable upright position. Compression and tension forces are the two main forces that act on a truss and can cause failure if they become too big, but they are not the only forces that have to be considered. Shear and torsion forces can also cause a bridge to fail. A shear force is a force that acts perpendicular to the substance or object that is under strain. A torsion force is a force that causes an object to twist when uneven forces are applied to it. Bracing on a bridge does not typically carry any load forces, but is important to keep the torsion and shear forces to a minimum. It keeps the truss in its stable upright position and allows the truss to evenly carry its load to the outer edges of the truss. If the bracing is not existent or is insufficient, the bridge may twist and turn causing critical premature failure. Typical bracing on a bridge consist of diagonals that interlock segments of the bridge to keep it from twisting. The bridge has the ability to twist and turn in three dimensions and it is important that the bracing on the bridge exist in all three dimensions as well. It’s important to keep things symmetrical when placing bracing on the bridge. Whatever is applied to one side of the bridge should be replicated to the other. The best thing to keep in mind when building the bridge is that, “The bridge is only as strong as the bracing allows.” Toothpick Bridge Design Tips Mr. Brown’s Physics Class Page 2 of 4 Creating a Blueprint for the Truss As can be seen above in a few of the various truss designs to build, each truss has its own particular design consisting of different size triangles interlocking together to from the back bone of the truss. Since each truss is drawn a little differently, each truss has its own best way in creating a final product. Below are some steps that will go over a few basic components of the design process. 1. Always start the blueprint with the bottom members of the truss. a. Determine the length of the bridge desired. i. I’ll use between 10” & 12” long b. Count the number of members located on the bottom truss. i. For the diagram to the right, there are 6 members. c. Doing a little math, divide minimum and maximum length of the bridge by the number of members. This will give you the minimum and maximum length of each individual length member. i. ii. 10 𝑖𝑛𝑐ℎ𝑒𝑠 6 𝑚𝑒𝑚𝑏𝑒𝑟 12 𝑖𝑛𝑐ℎ𝑒𝑠 6 𝑚𝑒𝑚𝑏𝑒𝑟 = 1.667 𝑖𝑛𝑐ℎ𝑒𝑠 𝑝𝑒𝑟 𝑚𝑒𝑚𝑒𝑏𝑒𝑟 = 2.0 𝑖𝑛𝑐ℎ𝑒𝑠 𝑝𝑒𝑟 𝑚𝑒𝑚𝑏𝑒𝑟 d. Decide on a length that you want the member’s length to be that is between the minimum and maximum values. Also keep in mind that a toothpick’s length is 2 ½” long. i. I’ll choose 1.75 inches per member. (1 ¾”) e. Once establishing the member’s size, multiple it by the number of members located at the bottom of the truss. This will give the total length of the truss that will be built. 𝑖𝑛𝑐ℎ𝑒𝑠 i. 1.75 𝑚𝑒𝑚𝑏𝑒𝑟 𝑥 6 𝑚𝑒𝑚𝑏𝑒𝑟𝑠 = 10.5" 𝑜𝑟 10 1⁄2 " f. On the graph paper using a ruler, make a 10.5 inch line towards the bottom of the paper and make little dash marks every 1.75 inches to mark the locations of the members. Toothpick Bridge Design Tips Mr. Brown’s Physics Class Page 3 of 4 2. Determine the rest of the outer shell along the sides and top. a. Determine the shapes that build your bridge and use them as a guide help establish the angles and lengths of the bridge. i. Keep in mind that the toothpick’s length is only 2 ½” long. b. Sometimes it is useful to make reference lines as a guide to build the bridge. If reference lines are used, make them very faint so that they can be erased once the truss is completed. 3. Fill in the webbing of the truss. a. Keep in mind that a toothpick’s length is only 2 ½” long. b. Make sure that the truss is symmetrical. The lengths of members and angles drawn on one side should be the same as the other side. 4. Once the truss is drawn to a 1:1 scale, which means the blueprint will be the actual size of the truss, you must label the truss as described below: a. Nodes are labeled with a letter i. Node a, Node b, Node c, Node d, …. b. Members are labeled with a number i. Member 1, Member 2, Member 3, Member 4, …. Creating a Blueprint for the Road Deck The road deck is what allows the cars and pedestrians to cross the bridge and get the other side. It ties the two trusses together and provides a flat surface for the cars and pedestrians to travel across. There is no specific design that you must use for the road deck, you must use your own thoughts as to what would work best in order to support the force load and provide stability to the trusses. Below are a few things to consider when designing your. 1. A lot of the steps used to build the truss can be used to build the road deck. 2. Bracing should also be added to the road deck to keep it stable, which it turn will keep the trusses stable. 3. The road deck can be built in 2D or 3D. a. Building the road deck in 2D provides a thin road deck that is the same length as the truss and the desired width that you want to build. b. Building the road deck in 3D provides more support to the truss and acts as a secondary truss to help support the load force applied to the bridge. It has a slight thickness with interlocking triangles that spans the length of the truss and has the desired width that you want to build. 4. Construction paper should be glued to the top of the road deck in order to provide a flat and unobstructed surface for a car (Matchbox) to travel across. Closing: By taking your time and designing a blueprint with high quality, it will speed up the time of construction on the bridge and provide a structure that can handle heavy load forces. Toothpick Bridge Design Tips Mr. Brown’s Physics Class Page 4 of 4