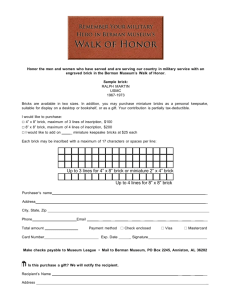

brick lca - Carl S. Sterner

advertisement