CHAPTER 15: SHORT-TERM SCHEDULING – Suggested Solutions

advertisement

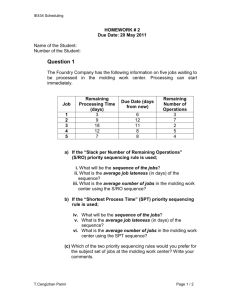

CHAPTER 15: SHORT-TERM SCHEDULING – Suggested Solutions to Selected Questions Summer II, 2009 Question 15.3 Original distance minimization problem: Row subtraction is done next: Site/Customer A B C D Site/Customer A B C D 1 2 3 4 7 5 6 8 3 4 7 6 4 6 9 7 8 5 6 4 1 2 3 4 4 1 0 4 0 0 1 2 1 2 3 3 5 1 0 0 Column subtraction is done next: Cover zeros with lines: Site/Customer A B C D Site/Customer A B C D 1 2 3 4 4 1 0 4 0 0 1 2 0 1 2 2 5 1 0 0 1 2 3 4 4 1 0 4 0 0 1 2 0 1 2 2 5 1 0 0 A minimum of four lines was used – implying existence of an optimal assignment. Optimal assignment: Taxi at post 1 to customer C Taxi at post 2 to customer B Taxi at post 3 to customer A Taxi at post 4 to customer D Total distance traveled = 4 + 4 + 6 + 4 = 18 miles. Question 15.4 Because this is a maximization problem, create an opportunity loss table by subtracting each number in the table from 11 (the highest number in the table): Original problem: Opportunity loss table: Job/Machine A B C D Job/Machine A B C D 1 2 3 4 7 10 11 9 9 9 5 11 8 7 9 5 10 6 6 8 1 2 3 4 4 1 0 2 2 2 6 0 3 4 2 6 1 5 5 3 Row subtraction is done next: Column subtraction is done next: Job/Machine A B C D Job/Machine A B C D 1 2 3 4 3 0 0 2 1 1 6 0 2 3 2 6 0 4 5 3 1 2 3 4 3 0 0 2 1 1 6 0 0 1 0 4 0 4 5 3 Cover zeros with lines: 1 (a) An optimal assignment can be made: Job/Machine A B C D 1 2 3 4 3 0 0 2 1 1 6 0 0 1 0 4 0 4 5 3 Job 1 to Machine D Job 2 to Machine A Job 3 to Machine C Job 4 to Machine B (b) Total production = 10 + 10 + 9 + 11 = 40 BUS P301:01 Question 15.9 Because this is a maximization problem, subtract each number from 95 to create an opportunity loss table. The problem can then be solved using the minimization algorithm. Original problem: Opportunity loss table: Professor/Course Stat Mgmt Fisher Golhar Hug Rustagi 90 70 85 55 65 60 40 80 Fin Econ Professor/Course Stat Mgmt Fin Econ 95 80 80 65 40 75 60 55 Fisher Golhar Hug Rustagi 5 25 10 40 30 35 55 15 0 15 15 30 55 20 35 40 Row subtraction is done next: Professor/Course Stat Mgmt Fisher Golhar Hug Rustagi Column subtraction is done next: Fin Econ Professor/Course Stat Mgmt Fin Econ 0 0 5 15 55 5 25 25 Fisher Golhar Hug Rustagi 5 10 0 25 30 20 45 0 0 0 5 15 50 0 20 20 Mgmt Fin Econ 30 20 45 0 0 0 5 15 50 0 20 20 5 10 0 25 30 20 45 0 Cover zeros with lines: Professor/Course Stat Fisher Golhar Hug Rustagi 5 10 0 25 (a) An optimal assignment can be made: Fisher to Finance Golhar to Economics Hug to Statistics Rustagi to Management Total rating = 95 75 85 80 335 (b) Since Fisher is not teaching statistics, the answer does not change. Total rating remains 335. Question 15.12 This is a job-sequencing problem whose objective here is to minimize total lateness. Comparing the scheduling efficiency of the several algorithms presented in terms of lateness. Original problem: Today is day 205. 2 Job Due date Remaining Processing Time A B C D 212 209 208 210 6 3 3 8 BUS P301:01 (a) First come, first served (FCFS): Job Processing Flow Time Time Start A B C D (b) 6 3 3 8 20 Processing Time B C A D 3 3 6 8 20 Processing Time D A C B 8 6 3 3 20 Flow Time Start End 3 6 12 20 41 205 208 211 217 Flow Time Start 8 14 17 20 59 Processing Time Flow Time 3 3 8 6 20 3 6 14 20 43 C B D A Days Late 0 4 8 14 Total: 26 days Number of jobs in system= 47/20 = 2.35 Average lateness= 26/4 = 6.5 207 210 216 224 Due Date 209 208 212 210 Days Late 0 2 Number of jobs in system= 41/20 = 2.05 4 14 Total: 20 days Average lateness = 20/4 = 5.0 205 213 219 222 End Due Date 212 218 221 224 210 212 208 209 Days Late 2 6 Number of jobs in system= 59/20 = 2.95 13 15 Total: 36 days Average lateness = 36/4 = 9.0 Start 205 208 211 219 Due End Date 207 210 218 224 208 209 210 212 Days Late 0 1 Number of jobs in system= 43/20 = 2.15 8 12 Total: 21 days Average= 21/4 = 5.25 Critical ratio: Job Due Date Remaining Processing Time Critical Ratio A B C D 212 209 208 210 6 3 3 8 (212 – 205)/6 = 1.17 (209 – 205)/3 = 1.33 (208 – 205)/3 = 1.00 (210 – 205)/8 = 0.63 Critical ratio 3 212 209 208 210 Earliest due date (EDD): Job (e) 210 213 216 224 Longest processing time (LPT): Job (d) 205 211 214 217 Due Date Shortest processing time (SPT): Job (c) 6 9 12 20 47 End Need date today s date Days required to complete job Job Sequence Critical Ratio D C A B 0.63 1.00 1.17 1.33 BUS P301:01 Critical ratio: Job D C A B Processing Time Flow Time 8 3 6 3 20 8 11 17 20 56 Due Start End Date 205 213 216 222 212 215 221 224 210 208 212 209 Days Late 2 7 9 15 Total: 33 days Number of jobs in system= 56/20 = 2.80 Average lateness = 33/4 = 8.25 A minimum total lateness of 20 days seems to be about the least we may achieve. Scheduling Rule Average Lateness Average Flow Time Average number of Jobs In System FCFS SPT LPT EDD Critical ratio 6.5 5.0 9.0 5.25 8.25 11.75 10.25 14.75 10.75 14.00 2.35 2.05 2.95 2.15 2.80 SPT is best on all criteria. Question 15.13 This is a job-sequencing problem comparing performance under different dispatching rules. (a) Dispatching Rule EDD SPT LPT FCFS Flow Time Utilization Average Number of Jobs Average Late Job Sequence CX–BR–SY–DE–RG BR–CX–SY–DE–RG RG–DE–SY–CX–BR CX–BR–DE–SY–RG 385 375 495 390 37.6% 38.6% 29.3% 37.2% 2.66 2.59 3.41 2.69 10 12 44 12 Starting day number: 241 (i.e., work can be done on day 241) Method: SPT—Shortest processing time Processing Time Due Date Order Flow Time Completion Time CX-01 25 270 2 40 BR-02 15 300 1 15 DE-06 35 320 4 105 SY-11 30 310 3 70 RG-05 40 360 5 145 Total 145 375 Average 75 Sequence: BR-02,CX-01,SY-11,DE-06,RG-05 Average # in system = 2.586 = 375/145 4 280 255 345 310 385 Late 10 0 25 0 25 60 12 BUS P301:01 Method: LPT—Longest processing time Processing Time Due Date Order Flow Time Completion Time CX-01 25 270 4 130 BR-02 15 300 5 145 DE-06 35 320 2 75 SY-11 30 310 3 105 RG-05 40 360 1 40 Total 145 495 Average 99 Sequence: RG-05,DE-06,SY-11,CX-01,BR-02, Average # in system = 3.414 = 495/145 370 385 315 345 280 Late 100 85 0 35 0 220 44 Method: Earliest due date (EDD); earliest to latest date Processing Time Due Date Slack Order CX-01 25 270 0 1 BR-02 15 300 0 2 DE-06 35 320 0 4 SY-11 30 310 0 3 RG-05 40 360 0 5 Total 145 Average Sequence: CX-01,BR-02,SY-11,DE-06,RG-05 Average # in system = 2.655 = 385/145 Flow Time Completion Time Late 25 40 105 70 145 385 77 265 280 345 310 385 0 0 25 0 25 50 10 Flow Time Completion Time Late 25 40 75 105 145 390 78 265 280 315 345 385 0 0 0 35 25 60 12 Method: First come, first served (FCFS) Processing Time Due Date Slack Order CX-01 25 270 0 1 BR-02 15 300 0 2 DE-06 35 320 0 3 SY-11 30 310 0 4 RG-05 40 360 0 5 Total 145 Average Sequence: CX-01,BR-02,DE-06,SY-11,RG-05, Average # in system = 2.69 = 390/145 (b) The best flow time is SPT (c) The best utilization is SPT (d) The best lateness is EDD (e) Either of these choices could be supported. LPT scores poorly on all three criteria. Question 15.14 This is a job-sequencing problem. Original problem: Today is day 130. 5 Production Days Needed DateOrder Due Job Date Order Received A B C D E 110 120 122 125 130 20 30 10 16 18 180 200 175 230 210 BUS P301:01 (a) (b) (c) FCFS (first come, first served): Job Sequence Date Order Received A B C D E 110 120 122 125 130 EDD (earliest due date): Job Sequence Due Date C A B E D 175 180 200 210 230 SPT (shortest processing time): Job Sequence Processing Time C D E A B 10 16 18 20 30 (d) LPT (longest processing time): Job Sequence Processing Time B A E D C 30 20 18 16 10 Scheduling Rule Average Tardiness Average Flow Time Average Number of Jobs in System FCFS EDD SPT LPT 5.4 0.0 7.2 9.6 60.0 54.4 47.6 65.2 3.2 2.9 2.5 3.5 EDD is best for average Lateness and SPT for the other two measures. 6 BUS P301:01 Question 15.17 This problem calls for the sequencing of seven jobs on two machines. Use Johnson’s rule. (a, c) The jobs should be processed in the sequence: V–Y–U–Z–X–W–T, for a total time of 57. Job Shop Scheduling T U V W X Y Z Time Flow Time Printer Binder Order Printer Binder 15 7 4 7 10 4 7 3 9 10 6 9 5 8 seventh third first sixth fifth second fourth 54 15 4 39 32 8 22 57 28 14 51 45 19 36 57 (b, c) (d) 7 Note: Y could also be placed first, with no change in total times. Binding is idle from 0 to 4 and from 51 to 54 for a total of 7 hours. BUS P301:01