pneumatics - educastur.princast

advertisement

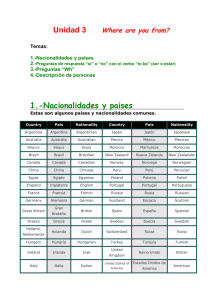

UNIDAD DIDÁCTICA “PNEUMATICS” Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 1 ÍNDICE 1. INTRODUCCIÓN -------------------------------------------------------------------------------------------- 3 2. CONTENIDOS ----------------------------------------------------------------------------------------------- 5 3. OBJETIVOS --------------------------------------------------------------------------------------------------- 5 4. METODOLOGÍA--------------------------------------------------------------------------------------------- 5 5. SECUENCIACIÓN------------------------------------------------------------------------------------------- 5 6. COMPETENCIAS BÁSICAS ------------------------------------------------------------------------------ 7 7. MATERIALES Y ESPACIOS ------------------------------------------------------------------------------ 8 8. EVALUACIÓN ----------------------------------------------------------------------------------------------- 8 9. ANEXO: FICHAS -------------------------------------------------------------------------------------------- 8 a) GLOSARIOS DE TÉRMINOS ------------------------------------------------------------------------------- 9 b) FICHAS DE TEORÍA -------------------------------------------------------------------------------------- 14 c) FICHAS DE PROBLEMAS -------------------------------------------------------------------------------- 26 d) FICHAS DE ACTIVIDADES PARA EL AULA DE INFORMÁTICA--------------------------------- 30 e) FOTOCOPIA DE EXAMEN------------------------------------------------------------------------------- 33 - f) Versión en inglés:------------------------------------------------------------------------------------ 33 Versión en español ---------------------------------------------------------------------------------- 35 IN THE ENGLISH LESSON ------------------------------------------------------------------------------- 37 Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 2 1. INTRODUCCIÓN Unidad didáctica: PNEUMATICS Materia: TECNOLOGÍAS Curso: 4º de ESO Bloque de contenidos: BLOQUE 5 “Neumática e hidráulica” Por ser el primer curso en el que se imparte un bloque relativo a la neumática, no se espera que el alumnado posea conocimientos previos precisos relativos sistemas neumáticos; si acaso ciertos conocimientos sobre presión que hayan podido adquirir en “Física y química”. También cabe esperar que conozcan alguna aplicación sencilla y cotidiana del empleo del aire comprimido (martillos neumáticos, apertura/cierre de puertas en trenes, etc.) así como del empleo de su análogo hidráulico (frenos hidráulicos, etc.). Para el desarrollo de la unidad se plantean 7 sesiones, tal como se muestran en la tabla siguiente. Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 3 Sesión 1 2 Aula Planteamiento Explicación del contenido teórico. Teoría Planteamiento de cuestiones relativas a lo explicado. Resolución de las cuestiones Explicación del contenido teórico. Teoría Circuitos neumáticos sencillos: expresión gráfica. Planteamiento de circuitos básicos. 3 Teoría 5 Informática 4 Otros circuitos neumáticos: expresión gráfica. Planteamiento de circuitos más avanzados. Simulación de los circuitos estudiados. Simulación de nuevos circuitos. Teoría Planteamiento y resolución de problemas. 6 Informática 7 Teoría Simulación de los problemas estudiados. Simulación de circuitos más complejos. Evaluación de los contenidos teóricos y prácticos adquiridos Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 4 2. CONTENIDOS No lingüísticos: (a) Concepto de presión y sus unidades. Realizar cálculos con ella. (b) Identificar los elementos que forman parte de un circuito neumático: cilindros y válvulas. Conocer los distintos tipos y su simbología. (c) Diseñar circuitos neumáticos sencillos empleando la simbología adecuada. (d) Simulaciones informáticas de sistemas neumáticos. Lingüísticos: (a) Conocimiento de los nombres de las magnitudes empleadas en neumática así como de los principales elementos neumáticos (cilindros y válvulas, y sus tipos), a partir del glosario de términos que se facilita (Anexo fichas: (a) Glosarios de términos). (b) Comprensión de la idea general y detalles específicos de textos escritos referidos al funcionamiento y los componentes de sistemas neumáticos. Participación en debates sobre las ventajas y desventajas de los sistemas neumáticos frente a los que funcionan con energía eléctrica: realización de descripciones y comparaciones. Conocimiento de las normas básicas de protección que se exigen en la industria británica. 3. OBJETIVOS 1. Analizar sistemas técnicos para comprender su funcionamiento, conocer sus elementos y las funciones que realizan. 2. Abordar con autonomía y creatividad, individualmente y en grupo, problemas tecnológicos, tanto teóricos y como prácticos. 3. Utilizar la lengua extranjera como vehículo de comunicación en el aula y como instrumento para realizar trabajos de investigación. 4. Mejorar las producciones orales y escritas utilizando la estructura pasiva en contextos adecuados. Reflexionar sobre la importancia de utilizar esta estructura en los textos técnicos. 4. METODOLOGÍA Se desarrolla la unidad siguiendo tres estrategias metodológicas: 1. Clase magistral: exposición teórica. 2. Método de resolución de cuestiones y/o problemas: resolución de problemas teóricos mediante el diseño de circuitos neumáticos adecuados. 3. Nuevas tecnologías: simulaciones informáticas. 5. SECUENCIACIÓN La siguiente tabla muestra la temporalización, secuenciación y los materiales necesarios para llevar a cabo la unidad didáctica planteada: Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 5 Nº Secuenciación y temporalización 1 Explicación teórica: introducción y compresores y cilindros (35’). Resolución de problemas con cilindros neumáticos (20’). 2 Explicación teórica: válvulas distribuidoras (40’). Circuitos básicos: resolución gráfica de problemas (15’). 3 Explicación teórica: otros tipos de válvulas (30’). Resolución de problemas técnicos mediante circuitos neumáticos (25’) 4 5 6 7 Explicación del manejo del simulador (20’). Resolución de actividades relativas a circuitos neumáticos empleando simuladores informáticos (35’). Repaso de los contenidos teóricos y la simbología (10’). Resolución de problemas técnicos más complejos mediante circuitos neumáticos (45’) Resolución de actividades relativas a circuitos neumáticos empleando simuladores informáticos (55’). Prueba escrita (55’).sobre: - contenidos teóricos, - resolución de problemas. Materiales Libro de texto. Fichas de teoría (Anexo fichas: (b) Fichas de teoría). Fichas de problemas (Anexo fichas: (c) Fichas de problemas). Libro de texto. Fichas de teoría (Anexo fichas: (b) Fichas de teoría). Fichas de problemas (Anexo fichas: (c) Fichas de problemas). Libro de texto. Fichas de teoría (Anexo fichas: (b) Fichas de teoría). Fichas de problemas (Anexo fichas: (c) Fichas de problemas). Fichas con las actividades a realizar (Anexo fichas: (d) Fichas de actividades para el aula de informática). Libro de texto. Fichas de teoría (Anexo fichas: (b) Fichas de teoría). Fichas de problemas (Anexo fichas: (c) Fichas de problemas). Fichas con las actividades a realizar (Anexo fichas: (d) Fichas de actividades para el aula de informática). Fotocopia de la prueba a realizar (Anexo fichas: (e) Fotocopia de examen). Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 6 6. COMPETENCIAS BÁSICAS Competencia en comunicación lingüística: - Adquisición de vocabulario específico. - Lectura e interpretación de textos y gráficos técnicos. - Utilización del inglés como instrumento de aprendizaje e investigación. - Participación en intercambios orales con el profesor y los compañeros realizando comparaciones y descripciones - Realización de Presentaciones orales sobre los sistemas neumáticos y eléctricos utilizando recursos informáticos visuales como apoyo/guía. Competencia matemática: - Uso instrumental de herramientas matemáticas. - Resolución de problemas basados en la aplicación de expresiones matemáticas, referidas a principios físicos, que resuelven problemas prácticos. - Interpretación y obtención de resultados cuantitativos y cualitativos de sistemas de representación gráfica. Competencia en el conocimiento y la interacción con el mundo físico: - Acceso y utilización de información obtenida de Internet, de modo que puedan aplicarla al proceso de resolución de problemas. - Uso de las tecnologías de la información y la comunicación como herramienta de simulación de sistemas técnicos. Competencia social y ciudadana: - A la hora de abordar proyectos en grupo, expresar y discutir adecuadamente ideas y razonamientos, escuchar a los demás, gestionar conflictos y tomar decisiones, adoptando actitudes de respeto y tolerancia hacia los demás. Competencia cultural y artística: - Hacer notar que el diseño de los sistemas técnicos a lo largo de la historia está influenciado por la cultura de la sociedad de pertenencia. Competencia para aprender a aprender: - El método de resolución de problemas proporciona un medio para darnos cuenta de lo que sabemos y de nuestras carencias, permitiéndonos progresar en las posibles soluciones. Autonomía e iniciativa personal: - Planteamiento adecuado de los problemas, que siendo analizados desde distintos puntos de vista, lleven a elegir la solución más adecuada. - Planificación, ejecución y evaluación sistemas técnicos para, por último, ofrecer propuestas de mejora. Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 7 7. MATERIALES Y ESPACIOS En la tabla del apartado 2 se muestran los espacios necesarios para la realización de cada sesión de la unidad didáctica, que pueden resumirse en: - 2 sesiones en el aula de informática, - 5 sesiones en un aula de teoría (pudiendo ser la parte habilitada para tal fin del aula taller). La tabla del apartado 6 muestra los materiales necesarios, con las fichas de la unidad a usar en cada sesión. 8. EVALUACIÓN La siguiente tabla muestra los criterios de evaluación y calificación Teoría Problemas Simulaciones informáticas Criterios de evaluación Criterios de calificación Conocimiento de los sistemas neumáticos, su función y aplicaciones fundamentales. Capacidad 40% para diseñar circuitos neumáticos sencillos. Ponderación Revisión de los materiales de la nota, del alumno/a: libreta, fichas... sobre un Resolución de cuestiones y total de 10 problemas empleando la puntos. simbología adecuada. 30% Revisión de los materiales del alumno/a: libreta, fichas... Revisión de los ficheros con las soluciones de los circuitos 30% y los problemas propuestos. Para evaluar la parte teórica se realizará una prueba escrita, calificada sobre 11 puntos: 10 puntos (contenidos de la materia de Tecnologías) más 1 punto extra (contenidos lingüísticos), dándose a elegir al alumnado entre realizar la prueba: - En inglés, de modo que el punto extra involucraría alguna cuestión en español, para asegurar que conoce los nombres y las relaciones de los sistemas neumáticos estudiados. - En español, de modo que el punto extra involucraría alguna cuestión en inglés, que determine si conoce el vocabulario específico y es capaz de emplear construcciones técnicas simples en dicho idioma. 9. ANEXO: FICHAS Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 8 a) GLOSARIOS DE TÉRMINOS PNEUMATICS GLOSSARY I ENGLISH word phonetics 'GktjUeIt& Gt rest p&'zI$&n k&n'tr&Ul &v k&m'prest E& k&m'pres& 'sIlInd& 't$eImb& dI'ten$&n fl&U / E&fl&U 'Inlet 'n%:m&lI closed/'&Up&n 'Ap&reIt/return 'aUtlet paIp 'pl^ndZ& / stem p%:t / weI 'pre$& rAd 'r&Ul& 's&Ul&n%Id spu:l sprI1 str&Uk tG1k t& blAk t& k&'m@:nd t& Iks'tend t& 'Ap&reIt t& rI'trGkt t& slaId 'tredl vGlv SPANISH (main meaning, in brackets) actuador posición de reposo mando aire comprimido compresor cilindro de simple efecto cilindro cilindro de doble efecto cámara enclavamiento flujo/flujo de aire entrada, admisión normalmente cerrada/abierta mando/retorno salida tubería émbolo/vástago de presión vía de escape de utilización presión vástago (barra, vara) rodillo solenoide carrete, bobina muelle de salida carrera de entrada/retorno tanque, depósito cerrar, bloquear controlar (mando) alargar, extender accionar, manejar replegarse, retraerse, meter (retirar) deslizarse pedal válvula Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 9 PNEUMATICS GLOSSARY I ENGLISH word actuator at rest position home position control of/controlling compressed air compressor phonetics 'GktjUeIt& Gt rest p&'zI$&n k&n'tr&Ul &v k&m'prest E& k&m'pres& single-acting cylinder cylinder double-acting cylinder chamber detent flow/airflow inlet normally closed/open operated/return outlet pipe plunger / stem pressure port exhaust port port/way use port pressure rod roller solenoid spool spring expanding stroke stroke retracting/reverse stroke tank to block (up) to command (to be in command of) to extend to operate 'sIlInd& 't$eImb& dI'ten$&n fl&U / E&fl&U 'Inlet 'n%:m&lI closed/'&Up&n 'Ap&reIt/return 'aUtlet paIp 'pl^ndZ& / stem p%:t / weI 'pre$& rAd 'r&Ul& 's&Ul&n%Id spu:l sprI1 str&Uk SPANISH (main meaning, in brackets) actuador posición de reposo mando aire comprimido compresor cilindro de simple efecto cilindro cilindro de doble efecto cámara enclavamiento flujo/flujo de aire entrada, admisión normalmente cerrada/abierta mando/retorno salida tubería émbolo/vástago de presión de escape vía de utilización presión vástago (barra, vara) rodillo solenoide carrete, bobina muelle de salida carrera de entrada/retorno tG1k t& blAk tanque, depósito cerrar, bloquear t& k&'m@:nd controlar (mando) t& Iks'tend t& 'Ap&reIt alargar, extender accionar, manejar replegarse, retraerse, meter (retirar) deslizarse pedal válvula to retract t& rI'trGkt to slide treadle valve t& slaId 'tredl vGlv Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 10 Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 11 Pneumatics Unidad didáctica word 'pre$& vGlv spi:d controller &'dZ^st&bl rIs'trIk$&n fIkst rIs'trIk$&n phonetics dI'rek$&nl k&n'tr&Ul vGlv '$^tl vGlv 'djU&l 'pre$& vGlv válvula antirretorno válvula de simultaneidad válvula reguladora de velocidad unidireccional válvula reguladora unidreccional válvula de control de flujo restricción fija válvula reguladora de velocidad unidreccional válvula de presión válvula selectora SPANISH (main meaning, in brackets) válvula distribuidora Technologies - IES Sánchez Lastra (Mieres) ENGLISH VALVES PNEUMATICS GLOSSARY II 12 speed controller fixed restriction adjustable restriction 'pre$& vGlv spi:d controller &'dZ^st&bl rIs'trIk$&n fIkst rIs'trIk$&n phonetics dI'rek$&nl k&n'tr&Ul vGlv '$^tl vGlv 'djU&l 'pre$& vGlv válvula antirretorno válvula de simultaneidad válvula reguladora de velocidad unidireccional válvula reguladora unidreccional válvula de control de flujo restricción fija válvula reguladora de velocidad unidreccional válvula de presión válvula selectora SPANISH (main meaning, in brackets) válvula distribuidora Technologies - IES Sánchez Lastra (Mieres) one-way flow control valve dual pressure valve Pneumatics Unidad didáctica pressure valve flow control valve non-return valve ENGLISH shuttle valve directional control valve word VALVES PNEUMATICS GLOSSARY II 13 b) FICHAS DE TEORÍA • COMPRESOR ---------------------------------------------------------------------------------------------------- 15 • ACTUATORS: CYLINDERS ------------------------------------------------------------------------------------ 15 • VALVES------------------------------------------------------------------------------------------------------------ 17 DIRECTIONAL CONTROL VALVES -------------------------------------------------------------------- 17 NON-RETURN VALVES ----------------------------------------------------------------------------------- 23 SHUTTLE VALVE-------------------------------------------------------------------------------------- 23 DUAL PRESSURE VALVE --------------------------------------------------------------------------- 23 FLOW CONTROL VALVES ------------------------------------------------------------------------------- 24 SPEED CONTROLLER or ONE WAY FLOW CONTROL VALVE ------------------------------ 24 ADJUSTABLE RESTRITION VALVE --------------------------------------------------------------- 24 FIXED RESTRICTION VALVE ---------------------------------------------------------------------- 24 VALVES SUMMARY -------------------------------------------------------------------------------------------------- 25 Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 14 PNEUMATICS So far, we have studied circuits fed with electrical energy. However, electricity is not the only source which allows us to produce work: compressed air can perform work as well. Pneumatics studies those systems that work with compressed air. If we compare electrical and pneumatic systems we will notice that both systems have the same main elements. We will need an energy source, an actuator (or a receiver, a device that changes the source’s energy into another type of energy), control devices and a path connecting all the appliances. Some examples are given in the table below. ELEMENTS ELECTRICAL SYSTEMS PNEUMATIC SYSTEMS Power supplies - cells - batteries - alternators - compressors Actuators - motor - resistor - bulb - buzzer - cylinders Control devices - switches - valves Connections - wires - conductors - pipes • COMPRESOR A compressor is a device that supplies an amount of air at a given pressure. It basically consists of a piston inside a cylinder. Through a crankshaft, a motor (electric or combustion motor) makes the piston move. When the cylinder’s chamber is full of air, the piston motion compresses the air. The air inlet and outlet are controlled by valves that open and close when it becomes necessary. Compressors have got a tank to store the compressed air till it is used. When pressure inside the receiver tank reaches its highest level, the compressor’s piston will stop, as a security measure from the machine. • ACTUATORS: CYLINDERS The most common pneumatic actuator is the cylinder. It consists of a piston with a rod inside a cylindrical chamber. Cylinders change the air pressure on its piston, into its rod motion. The distance moved by the rod in its motion is called stroke. So we have an expanding stroke (the rod goes out of the cylinder, the Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 15 cylinder extends) and a retracting/reverse stroke (the rod goes into the cylinder, the cylinder retracts). chambers area of piston cylinder area of rod expanding stroke rod piston port or way stroke retracting stroke reverse stroke double acting pneumatic cylinder We can figure out the force exerted by the cylinder applying Pascal’s law (theoretical force): F = P⋅ A where: F is force in Newtons (N), P is air pressure in Pascals (Pa), A is piston area in square meters; in a round piston with diameter d: A = UNITS Pressure: π ⋅d 4 2 . And thus we can define pressure as: F P= A 1bar = 105 Pa 1atm = 1,013bar Force: 1kg = 9,8 N ≅ 10 N There are many different sorts of cylinders, but we are going to study only two of them (symbols follow the rule DIN 24300). Single-acting cylinder (spring return): The air pressure is applied only to one side of the piston, the one without spring. So compressed air causes the expanding stroke while the spring causes the retracting stroke. Double-acting cylinder (air return): The air pressure is applied to both sides of the piston. In this case, compressed air causes expanding and retracting strokes. Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 16 • VALVES Valves control the airflow in pneumatic systems. We can classify them in different groups according to valve function, but we will just study some of them: Directional control valves: They just block, open or change the flow paths to and from cylinders. Non-return valves: They include valves that block airflow depending on the direction (shuttle valve, dual pressure valve, one-way flow control valve…). Flow control valves: They include valves that restrict and control volume of fluid, not pressure, in a point of the circuit (adjustable restriction, fixed restriction, speed controller…). Pressure valves: They include valves that restrict and control air pressure. DIRECTIONAL CONTROL VALVES Valves can be made in different ways. The easiest way consists in a sliding spool moving inside a cylindrical chamber. The spool motion opens and blocks internal passages allowing the air to flow from one point to another. The following pictures show a directional control valve. By looking at them we can easily understand how this kind of valves works. expanding stroke cylinder directional control valve 3 / 2 valve (3 ways/ports - 2 positions) position 1 port / way pressure air supply Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 17 retracting stroke cylinder spool directional control valve 3 / 2 valve (3 ways/ports - 2 positions) position 2 exhaust port With the valve in: - Position 1 (expanding stroke): Compressed air reaches the cylinder that will extend. The exhaust port is closed. The valve spring is operated. - Position 2 (retracting stroke): Pushing the button, the cylinder chamber is connected to the exhaust port, so the cylinder will retract because of the strength of its spring. The air supply is closed. A directional control valve is named by its number of ports or ways, and its number of positions: - 2/2 valve: 2 ports, 2 positions, 3/2 valve: 3 ports, 2 positions, 4/2 valve: 4 ports, 2 positions, 5/2 valve: 5 ports, 2 positions, 4/3 valve: 4 ports, 3 positions, 5/3 valve: 5 ports, 3 positions. We use schematic symbols to draw valves. The picture above is a 3/2 valve, the following picture shows its symbol: Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 18 You can see that a valve symbol is made up of different parts: 1. Positions: Each square or block shows a position. If the valve has 2 positions, we will draw two squares joined together. 2. Ports or ways: Little straight lines drawn on the block of position at rest. A port could be connected to pressure (pressure port), blocked (port closed), connected to exhaust (exhaust port) or connected to another device (use port). ‘at rest’ position (right square) a. Exhaust port: It is made up with an inverted triangle. b. Pressure port or air supply port: It is made up with two little circles. c. Use port: The one connected to another device. d. Port closed: A ‘T’ indicates that a way is closed; the air can’t flow through it. Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 19 3. Airflow direction: Arrows inside blocks indicate the direction of the airflow. Each block has arrows showing the flow paths, that is, the valve action. Each arrow joins two ports, and its arrowhead is pointing out the port where the air comes out. 4. Left hand actuator (operated) and right hand actuator (return): Actuators are devices that cause the valve to change its position. The symbol of an actuator is drawn next to the block that will be performed when the actuator is operated. spring return pushbutton operated Directional control valve parts are shown in the following picture: square or block (valve positions) direction arrows 'at rest' position home position use port / way (valve passages) left hand actuator: push button operated closed or blocked way pressure port right hand actuator: spring return exhaust port valve actuators 3/2 valve, normally closed, push-button operated and spring return Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 20 With this notation, we can study the main directional valves: Valve name Valve schematic symbol 2/2 valve (2 ports, 2 positions) (normally closed) 3/2 valve (3 ports, 2 positions) (normally closed) 4/2 valve (4 ports, 2 positions) 5/2 valve (5 ports, 2 positions) 4/3 valve (4 ports, 3 positions) (mid-position closed) 5/3 valve (5 ports, 3 position) (mid-position closed) Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 21 The following pictures show the standard symbols for actuators: Actuator type Name Symbol general push button Manual actuators lever pedal or treadle plunger or stem spring Mechanical actuators roller roller (one-way) Mechanical actuating component (joined to another actuator) detent Electrical actuators solenoid Pressure actuators air pilot or pilot pressure Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 22 NON-RETURN VALVES SHUTTLE VALVE This valve has two inlets and one outlet. When air pressure is applied to port X, it will come out of port A; meanwhile port Y is blocked. On the other hand, if air pressure comes in from port Y, it will come out to port A and port Y will be blocked. This valve works as logic OR, we will have pressure in the outlet if we have pressure in any of the inlets or in both inlets. Symbol Frame outlet A Y inlet X inlet Shuttle valve DUAL PRESSURE VALVE This valve has two inlets and one outlet as well. But when air pressure is applied to port X or to port Y the outlet is blocked. Only when both inlets have air pressure, air will come out through outlet port. This valve works as logic AND. Symbol Frame outlet A X inlet Y inlet Dual pressure valve Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 23 FLOW CONTROL VALVES Sometimes we need to control the piston speed. In order to achieve this we control the volume of air using flow control valves. SPEED CONTROLLER or ONE WAY FLOW CONTROL VALVE In this valve the flow is only controlled in one direction, from right-hand side to left-hand side. A screw allows us to change the volume of air and the speed as well. If the air flew from left to right, it would go out through the ball path without flow control. Symbol Frame Speed controller ADJUSTABLE RESTRITION VALVE In this valve the flow is controlled in both directions. The valve frame would be a screw in the air path. Symbol FIXED RESTRICTION VALVE In this valve the flow is lower when the air flows through it, but we can’t adjust the volume of air. Symbol Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 24 VALVE GROUP VALVES SUMMARY SPECIFIC VALVE NAME SYMBOL DIRECTIONAL CONTROL VALVES 2/2 valve 3/2 valve 4/2 valve 5/2 valve 4/3 valve FLOW CONTROL VALVES NON-RETURN VALVES 5/3 valve shuttle valve t dual pressure valve one way flow control valve speed controller adjustable restriction valve fixed restriction valve Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 25 c) FICHAS DE PROBLEMAS EXERCISE 1---------------------------------------------------------------------------------------------------------- 27 EXERCISE 2---------------------------------------------------------------------------------------------------------- 27 EXERCISE A --------------------------------------------------------------------------------------------------------- 27 EXERCISE B --------------------------------------------------------------------------------------------------------- 27 EXERCISE C --------------------------------------------------------------------------------------------------------- 27 EXERCISE D --------------------------------------------------------------------------------------------------------- 27 EXERCISE E --------------------------------------------------------------------------------------------------------- 27 EXERCISE F --------------------------------------------------------------------------------------------------------- 27 EXERCISE G --------------------------------------------------------------------------------------------------------- 27 EXERCISE H --------------------------------------------------------------------------------------------------------- 27 EXERCISE I ---------------------------------------------------------------------------------------------------------- 27 EXERCISE J ---------------------------------------------------------------------------------------------------------- 27 EXERCISE K --------------------------------------------------------------------------------------------------------- 27 EXERCISE 3---------------------------------------------------------------------------------------------------------- 27 EXERCISE 4---------------------------------------------------------------------------------------------------------- 28 EXERCISE 5---------------------------------------------------------------------------------------------------------- 28 EXERCISE 6---------------------------------------------------------------------------------------------------------- 28 EXERCISE 7---------------------------------------------------------------------------------------------------------- 29 Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 26 PNEUMATICS EXERCISES EXERCISE 1: A single acting cylinder has a 20cm2 area piston. If it is connected to a compressor that supplies a 3bar pressure, work out the force exerted by its rod in Newton and Kg. EXERCISE 2: A double acting cylinder has a 60mm diameter piston and a 10mm diameter rod. If it is connected to a compressor that supplies a 3bar pressure, work out the force exerted by its rod when the expanding and retracting strokes are performed. Now we are going to analyze some circuits designing the basic control pneumatic systems. These exercises will show us how cylinders and valves work together. After that we will solve exercises with the knowledge acquired Design the following pneumatic circuits: EXERCISE A: Controlling a single acting cylinder by pushing a button, or by being in command of any other mechanical actuator (spring return). EXERCISE B: Control of a double acting cylinder by pushing a button, or by operating any other mechanical actuator (spring return). EXERCISE C: Indirect control of a single acting cylinder. EXERCISE D: Conditional control of a single acting cylinder by using directional control valves. That is, controlling a single acting cylinder when two buttons are in command at the same time (spring return). EXERCISE E: Conditional controlling the expanding stroke of a double acting cylinder by using directional control valves (seeing exercise D). EXERCISE F: Controlling a single acting cylinder from two different points. EXERCISE G: Indirect controlling the expanding stroke of a double acting cylinder from two different points by pushing buttons or by operating any others mechanical devices. EXERCISE H: Conditional control of a single acting cylinder by using a dual pressure valve (seeing exercise D). EXERCISE I: Conditional controlling the expanding stroke of a double acting cylinder by using a dual pressure valve (seeing exercise D). EXERCISE J: Speed control of a single acting cylinder. EXERCISE K: Speed control of a double acting cylinder. EXERCISE 3: Design a pneumatic circuit to control a single acting cylinder from three different points. You must use 3/2 valves, normally closed, operated by a push-button and spring return. You will need shuttle valves as well. Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 27 EXERCISE 4: Design the direct controlling of a double acting cylinder using a 4/3 valve, normally closed in middle position and operated by a lever with detent. EXERCISE 5: Complete the following pneumatic circuit. You must manage to make the rod piston go out when both of the buttons are pushed at the same time. If you stop pushing any of the buttons, the rod piston must return automatically. Name all the circuit elements. Design the same circuit using a dual pressure valve. P1 P2 EXERCISE 6: Complete the following pneumatic circuit so that it causes the expanding stroke of the cylinder if you push buttons P1 or P2, but pushing P3 the cylinder will retract. Name all the circuit elements. P1 P2 P3 Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 28 EXERCISE 7: Look at the following pneumatic circuit and answer the questions: a) Name the circuit elements. b) Name the actuators of the valves. c) Explain how the circuit works. d) In a real circuit, where must you place the 1.3 valve? Draw the circuit again, with the valve in that position. 1.0 1.3 1.1 1.2 1.3 Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 29 d) FICHAS DE ACTIVIDADES PARA EL AULA DE INFORMÁTICA ACTIVITY 1 ----------------------------------------------------------------------------------------------------------- 31 ACTIVITY 2 ----------------------------------------------------------------------------------------------------------- 31 ACTIVITY 3 ----------------------------------------------------------------------------------------------------------- 31 ACTIVITY 4 ----------------------------------------------------------------------------------------------------------- 31 ACTIVITY 5 ----------------------------------------------------------------------------------------------------------- 31 ACTIVITY 6 ----------------------------------------------------------------------------------------------------------- 31 ACTIVITY 7 ----------------------------------------------------------------------------------------------------------- 31 ACTIVITY 8 ----------------------------------------------------------------------------------------------------------- 31 ACTIVITY 9 ----------------------------------------------------------------------------------------------------------- 32 ACTIVITY 10---------------------------------------------------------------------------------------------------------- 32 Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 30 ICT ACTIVITIES Draw the following pneumatic system using a simulator. ACTIVITY 1: Direct control of a single acting cylinder by using a 3/2 valve, detent lever operated and spring return. ACTIVITY 2: Direct control of a double acting cylinder by means of a 5/2 valve, detent lever operated. ACTIVITY 3: Direct control of a single acting cylinder from two different points by means of two 3/2 valves (treadle operated and spring return). You must use a shuttle valve. If any of the directional control valves is operated the rod cylinder will extend, otherwise it will retract. ACTIVITY 4: Direct control of a single acting cylinder from two different points by means of three 3/2 valves (push-button operated and spring return). You must use shuttle valves as well. If any of the directional control valves is operated the rod cylinder will extend, otherwise it will retract. ACTIVITY 5: Direct control of a single acting cylinder: the rod cylinder extends when you operate two 3/2 valves (push-button operated and spring return) simultaneously. If one or neither of the valves is operated the rod cylinder will retract. You must do this activity in two different ways: Using a dual pressure valve. Without using a dual pressure valve. ACTIVITY 6: Direct control of a double acting cylinder by using two 3/2 valves (push-button operated and spring return). Each valve controls a stroke (expanding or retracting stroke). ACTIVITY 7: Indirect control of a double acting cylinder by means of a 4/2 valve, pneumatically operated through two 3/2 valves (lever operated and spring return). Each 3/2 valve controls a stroke (expanding or retracting stroke). ACTIVITY 8: Indirect control of a double acting cylinder by using a 4/2 valve, pneumatically operated through: — A 3/2 valve, push-button operated and spring return, for expanding stroke. — A 3/2 valve, roller operated and spring return, for retracting stroke. If you push the button (1st 3/2 valve) a single time, the rod cylinder will extend, due to the fact that the compressed air changes the 4/2 valve position. When the rod ends its expanding stroke it will operate the roller (2nd 3/2 valve). The 4/2 valve will change its position again and the rod cylinder will retract. Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 31 ACTIVITY 9: Indirect control of a double acting cylinder by means of a 5/2 valve, pneumatically operated. You must use four 3/2 valves (push-button operated and spring return). If you pushed two of them at the same time, the rod cylinder would extend. If you pushed the other ones at the same time, the rod would retract. ACTIVITY 10: Given the following picture: Draw the circuit using your computer. Watch its motion. Write the names of all the elements (next to its symbol on this sheet). Explain how it works; that is, try to answer the following questions: What will happen if you operate the 1.3 valve a single time? What will happen if you operate the 1.2 valve or the 1.4 valve? When the rod ends its expanding stroke, which valve will be operated? What will happen at that moment? When the rod reaches the end of its expanding stroke, what would happen if you operate the 1.3 valve? Which stroke is slower? Why? 1.0 1.5 1.1 1.2 1.4 1.3 Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 1.5 32 e) FOTOCOPIA DE EXAMEN - Versión en inglés: PNEUMATICS - EXAM Name: Date: Group: EXERCISE 1: Complete the table with the name or the symbol of each element: English name Symbol Pedal or treadle Shuttle valve Exhaust port Double-acting cylinder (3 marks out of 10) Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 33 EXERCISE 2: Controlling a single acting cylinder by being in command of a mechanical actuator and spring return. (3 marks out of 10) EXERCISE 3: a) Name all the circuit elements. b) Complete the following pneumatic circuit (drawing the arrows). You must manage to make the rod piston go out when both of the buttons are pushed at the same time. If you stop pushing any of the buttons, the rod piston must return automatically. P1 P2 (4 marks out of 10) EJERCICIO 4: Completa la siguiente tabla con los nombres en español: Símbolo Nombre en español (se pide el nombre genérico de este elemento) (1 punto extra; 0,25 puntos cada elemento) Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 34 - Versión en español NEUMÁTICA - EXAMEN Nombre: Fecha: Grupo: EJERCICIO 1: Completa la tabla con el nombre o el símbolo de cada elemento: Nombre español Símbolo Pedal Válvula selectora del circuito Escape Cilindro de doble efecto (3 puntos sobre 10) Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 35 EJERCICIO 2: Control de un cilindro de simple efecto con mando a través de un actuador manual genérico y retorno por muelle. (3 puntos sobre 10) EJERCICIO 3: c) Nombra todos los elementos del circuito. d) Completa el siguiente circuito neumático (dibujando las flechas). Debes conseguir que el vástago del cilindro salga cuando ambos botones estén pulsados al mismo tiempo. Si dejas de pulsar cualquiera de los botones, el vástago debe retronar automáticamente. P1 P2 (4 puntos sobre 10) EXERCISE 4: Complete the following table with the English names: Symbol English name (we want generic name of this element) (1 extra-mark; 0,25 mark each word) Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 36 f) IN THE ENGLISH LESSON The main goal of these activities for the English lessons is to provide scaffolding strategies so that students can deal with the Technology unit successfully. The following chart shows the basic functions students will need to achieve this. KEY FUNCTIONS-HOW TO EXPRESS…. Conditions -If/when the air pressure is too high….. -If/when the cylinder chamber is full of air…. -what will happen if…………..? Descriptions -There are five different elements… -This system has got five components…. -This picture/graph shows….. Comparisons -Pneumatics systems are safer and more economical than… -The most common actuator…. -Which one is the easiest to install….? Emphasizing result -Pneumatics systems are used… -This component is plugged into….. -A port can be connected…. Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 37 ACTIVITY ONE: DISCUSS THE FOLLOWING QUESTIONS 1a-Can you name machines you are familiar with, which work by using compressed air? 1b-Can you identify pneumatics systems in any of the following pictures? 2-Can you think about the reasons why pneumatics is frequently regarded as an eco-friendly system? 3-Which sources of work do you consider safer and less polluting? Why? ACTIVITY TWO: READ THE FOLLOWING TEXT AND COMPLETE THE CHART Pneumatics is a safer, cleaner, more economical and easy to use system to make mechanisms work. Using compressed air for system controlling in industries has a lot of advantages. a-Many industries suffer serious accidents that can have terrible effects over the population and the environment. Pneumatics is safer than other methods since there is no need to worry about fires. Transport is safe as well, since pipe lines can be used for transporting compressed air to very long distances. This makes a great difference with other methods used in industry. b-Compressed air does not increase levels of pollution. Air is the only product released into the atmosphere. c-Pneumatics systems are easily installed, handled and maintained. So, if it has got so many advantages, why is compressed air not used universally? Obviously, it has several disadvantages too. The most important one is that in order to install an air controlled system very large spaces are needed, while electrical controls are really small. A second disadvantage is that the release of air into the atmosphere can be very noisy. AS YOU CAN SEE TECHNICAL TEXTS USE MANY PASSIVE STRUCTURES: CLASIFY PAST PARTICIPLES IN THE TEXT ACCORDING TO THEIR PRONUNCIATION /t/ /d/ /id/ Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 38 ACTIVITY THREE: WATCH THE VIDEO AND ANSWER THE FOLLOWING QUESTIONS. http://www.youtube.com/watch?v=rRCWqe9JnN8&feature=related 1-Write down the names of the different system components that are mentioned 2-What’s the ‘controller used for? 3-What’s the limit internal pressure allowed, before the system is automatically turned off? 4-What’s the difference between the two regulators shown? 5-How many ‘inputs’ and ‘outputs’ has the SMC valve got? What are they called? ACTIVITY FOUR: YOU HAVE ALREADY STUDIED ELECTRICAL AND PNEMATICS SYSTEMS. NOW, IT WOULD BE VERY INTERESTING TO COMPARE BOTH OF THEM. 4.1-PREPARE A POWER POINT PRESENTATION SHOWING: a-A brief description of the way each system works. b-The main components of each one c-The advantages and disadvantages of each system d-The one you would personally prefer for your own business. Give reason for your choice. 4.2-YOU WILL HAVE TO MAKE AN ORAL PRESENTATION FOR YOUR CLASSMATES. Use the following tips: a-Make it simple: keep the number of slides to a minimum. b-Make it visual: use graphics; pictures or illustrations. c-Avoid slides with too much text. d-Avoid using language which is too complex. Use vocabulary and structures your mates can understand. e-Remember you are the real protagonist. Power Point is just a tool to help you present the information. Pneumatics Unidad didáctica Technologies - IES Sánchez Lastra (Mieres) 39