high level expression of recombinant erythropoietin in hansenula

advertisement

Egypt. J. Exp. Biol. (Bot.), 10(1): 27 – 35 (2014)

© The Egyptian Society of Experimental Biology

RESEARCH ARTICLE

Sabah Mohamed

Khaled Mahmoud

HIGH

LEVEL

EXPRESSION

HANSENULA POLYMORPHA

OF

ABSTRACT:

The pharmaceutical production of the key

therapeutic protein erythropoietin is largely

dependent on the establishment of a

successful heterologous expression system.

This study reports the successful expression

of the recombinant human erythropoietin in

the

methylotrophic

yeast

Hansenula

polymorpha at a significantly high level (265

mg/l). Although erythropoietin was previously

expressed in a wide variety of mammalian,

bacterial and fungal-based systems, this is

the first time this key hormone is expressed in

the industrially important H. polymorpha. The

significantly high expression level and the

convenience of this organism for the industrial

production of recombinant proteins make the

development of a stable H. polymorpha

erythropoietin transformants an essential

improvement, in the exploitation of this key

protein by the pharmaceutical industry. The

expressed protein was successfully purified

and characterized; confirming its structural

and functional properties, while an industrial

scale development of the system is under

development.

KEY WORDS:

EPO,

Erythropoietin,

H.

polymorpha,

Recombinant proteins, Glycosylated

CORRESPONDENCE:

Khaled Mahmoud

Botany Department, Faculty of Sciences, Ain

Shams University, Cairo, Egypt

Current address:

Leeds Institute of Molecular Medicine, St.

James University Hospital, LS9 7TF, UK

E-mail: bmbkhm@leeds.ac.uk

Sabah Mohamed

Botany Department, Faculty of Sciences, Ain

Shams University, Cairo, Egypt

ARTICLE CODE: 03.02.14

ISSN: 1687-7497

RECOMBIN ANT

ERYTHROPOIETIN

IN

INTRODUCTION:

Erythropoietin (EPO) is an essential

human glycoprotein produced in the renal

fibroblasts, the hepatocytes and the neuronal

cells. It acts as the prime haematopoietic

growth factor; as it plays the principle role in

regulating red blood cells production. An

imbalance in EPO levels can lead either to

anaemia or polycythemia. The recombinant

EPO is used widely for treating cancer and

anaemia patients, especially those with

chronic kidney disease and chemotherapyrelated anemia (Henry and Spivak, 1995; Duh

et al., 2008; Testa, 2010; Chateauvieux et al.,

2011; Bunn, 2013).

Endogenous human EPO is a complex of

165 amino acids which forms a mature 30 kDa

protein with four glycan side chains attached

to it; three located at asparagine 24, 38, and

83, and the fourth is located at Ser-126. In

total, the glycosylation elements comprise

about 40% of the total mass of the protein as

the polypeptide accounts for 18 kDa only

(Jelkmann, 2004). Like other glycoprotein

hormones, EPO exists as a mixture of

isoforms differing mainly in their carbohydrate

structures (Storring and Gaines Das, 1992).

This is because the glycosylation of the

polypeptide moiety is of a post-translational

nature which is influenced by the type of the

cell in which the protein is synthesized and

the physiological factors at the time of the

synthesis.

In

addition,

the

isoforms

composition of an EPO preparation is usually

affected by the purification method which can

also affect its folding (Goto et al., 1988).

Homologously expressed EPO is often

purified in minute quantities from very large

volumes of the urine of the anaemic patients

(Espada and Gutnisky, 1970) or of the plasma

of the anaemic sheep (Goldwasser and Kung,

1971). In 1985, Jacobs et al. isolated the

human EPO cDNA and demonstrated its

heterologous expression in a mammalian host

system. Since then, several patents protected

the production of various EPO isoforms with

similar pharmacological properties (Lin, 1990;

W ellesley et al., 1990; Elliott and Byrne,

2007; Carcagno et al., 2009; Pecker, 2011;

Calo-Fernández and Martínez-Hurtado, 2012).

On Line ISSN: 2090 - 0503

http://www.egyseb.org

28

Egypt. J. Exp. Biol. (Bot.), 10(1): 27 – 35 (2014)

Currently, the recombinant EPO biosimilars (genetically-engineered forms of

erythropoietin) represent the largest market of

a class of biopharmaceuticals; with global

sales of over 13 billion USA dollars per

annum (GBI Research, 2012; Kalorama

Information, 2013). The key patents for the

first generation of EPOs have expired in 2009

and 2010 which opened the market for many

similar analogues to be produced. The

principle step towards any commercial

exploitation of EPO is to establish a reliable

expression system to manufacture the protein

at an industrially viable scale.

W hile most of the recombinant EPO is

produced in mammalian cells-based systems

(Lin et al., 1985), non- glycosylated EPO is

produced in bacteria (Lee-Huang, 1984; Bill et

al., 1995; Nagao et al., 1997). On the other

hand, the baker’s yeast, the methylotrophic

yeast and the soil fungi-based expression

systems

enabled

the

expression

of

recombinant EPO with glycosylation profiles

different from the mammalian cell-produced

forms (Elliott et al., 1989; Celik et al., 2007;

Vats

and

Padh,

2007).

In

addition,

erythropoietin cysteine analogs were recently

expressed in Pichia pastoris (Maleki et al.,

2012).

Naturally, eukaryotic expression hosts

attach oligosaccharides to the side chain of

the asparagine residues existing in specific

order within the amino acid chain of the

protein. Humanized mammalian host cells

usually glycosylate heterologously expressed

proteins by adding a tri-mannose linked to a

galactose and a sialic acid, whereas yeasts

usually hyperglycosylate the proteins by

adding 100 or more of mannose sugars.

Despite

this,

the

yeast-based

protein

expression systems carry many advantages

over the mammalian-based systems; including

lower overall costs, easier growth conditions

and much higher expression levels. Because

of this, the yeast-based expression systems

are usually preferred for the industrial

production of EPO biosimilars as well as

many other recombinant human proteins

despite the over-glycosylation issue (Goeddel,

1990; Mattanovich et al., 2012).

In order to overcome the glycosylation

differences

between

the

mammalian

expression systems and the yeast-based

systems, metabolically engineered yeast

strains were used, in which the yeast

glycosylation pathway was altered to mimic

the

human

glycosylation

profile.

Erythropoietin was expressed in engineered

strains of the methylotrophic yeast Pichia

pastoris where its heavy glycosylation genes

were knocked out and the genes of the human

glycosylation were introduced to confer a

humanized glycosylation profile on the

expressed proteins (Hamilton et al., 2006).

Alternatively,

in

vitro

post-purification

ISSN: 1687-7497

On Line ISSN: 2090 - 0503

processing methods could be used to tailor

the yeast-expressed recombinant proteins to

the profile of their mammalian counterparts

(Maras et al., 1997).

Hansenula polymorpha is a GRAS

organism (Generally Regarded as Safe) and

belongs to a group of yeasts capable of using

methanol as a sole source of carbon and

energy and so are referred to as the

methylotrophic yeasts (Gellissen, 2000). A

multitude of expression vectors is available

for use in H. polymorpha where the

recombinant protein expression can be

controlled via a carbon source dependent

repression/derepression/induction mechanism

conferred by the inherent properties of the

promoter used (Gellissen et al., 1992; Esser,

2003).

This yeast is relatively simple to

cultivate and scale-up to thousands of litres in

growth tanks. High yields of heterologously

expressed proteins are achieved through high

gene copy integration, fast growth to high cell

density, and an exclusive library of strong

promoters.

Hansenula polymorpha is also able to

secrete the protein products directly in the

culture medium, a fact that renders the whole

process of downstream processing easier and

less costly. The ability of this organism to

survive in a wide pH range, from 2.5 to 6.5,

makes it a versatile protein factory which is

exploited in the production of various

proteins, each of which requires a very

different optimum pH value throughout the

production process (Kunze et al., 2009).

Overall, high yields of recombinant proteins

can be produced in H. polymorpha at a lowcost. In fact, this organism holds the record in

yeast-derived protein production, with a

productivity of more than 13 g/l in phytase

production (Mayer et al., 1999; Sudbery,

2003).

Amongst the methylotrophic yeasts, P.

pastoris and H. polymorpha are particularly

efficient for commercial-scale recombinant

protein production. These two species are

close relatives; in fact the AOX1 promoter of

P. pastoris is the analogue of the H.

polymorpha

MOX

promoter.

However,

although both promoters are responsive to

methanol, in P. pastoris, alcohol oxidase is

rapidly and strongly induced in response to

methanol induction while in H. polymorpha,

methanol oxidase may be induced either by

methanol or by glycerol de-repression. This is

a particularly significant advantage for using

H. polymorpha in applications involving largescale productions, since it circumvents the

potential hazards associated with the use of

methanol (Gellissen et al., 1992; Gellissen,

2000).

P. pastoris expression vectors are

designed for homologous recombination and

integration at the AOX or HIS4 locus, whereas

http://www.egyseb.org

Mohamed & Mohamed, High Level Expression of Recombinant Erythropoietin in Hansenula Polymorpha

those used in H. polymorpha can integrate by

non-homologous recombination at random

loci. Expression vector copies integrated in P.

pastoris are usually limited to <10, whereas

up to 150 copies can integrate in H.

polymorpha.

Since protein expression is

correlated with gene dosage in these

organisms,

it

is

possible

to

achieve

significantly

higher

expression

in

H.

polymorpha despite the fact that the AOX

promoter of P. pastoris is the strongest

promoter. It is also possible to achieve more

control over the level of production by

regulating the copy number.

W hen plasmids are integrated at the

AOX locus, the gene encoding the alcohol

oxidase is disrupted; once the cells are

transferred to methanol their growth is

significantly retarded. The growth rate of H.

polymorpha remains rapid before and after

induction. In addition, H. polymorpha is a

more thermotolerant organism than is P.

pastoris, easily withstanding temperatures up

to 43°C (Sudbery, 2003).

In this study, we have generated stable

H. polymorpha transformants expressing the

recombinant human erythropoietin at levels

significantly higher than those reported from

other expression systems. The protein was

purified and characterized confirming its

biochemical and functional properties. Scaling

up of EPO production in H. polymorpha in a

fermenter-based set up is well underway.

MATERIAL AND METHODS:

Strains:

Hansenula polymorpha strain 201322 was

obtained from the ATCC. Escherichia coli

strain XL10-Gold® was obtained from Agilent.

Constructs:

Erythropoietin open reading frame construct

was obtained in plasmid pReceiver-Y01 from

GeneCopoeia Inc. Vector pGAPZα was

purchased from Invitrogen.

Reagents and equipments:

Advantage® HD Polymerase Mix, used for

polymerase

reaction-based

amplifications,

was obtained from Clonetech. In-Fusion 2.0

Dry-Down PCR Cloning Kit used for cloning

amplified PCR products was purchased from

Clonetech. Veriti® 96-W ell Thermal Cycler,

Applied Biosystems, was used for thermal

cycling

of

PCR

and

other

enzymatic

incubations. ReadyAgarose Gels and the

ReadySub-Cell GT cell system and buffer

reagents from Bio-Rad were used for nucleic

acids

electrophoresis.

QIAquick

PCR

Purification Kit, QIAquick Gel Extraction Kit

and Plasmid preparation kits from QIAGEN

were used for PCR reaction purification, DNA

gel extraction and plasmid preparations

respectively. All restriction and modification

enzymes were purchased from New England

Bio-labs. Gene Pulser MXcell Electroporation

I ISSN: 1687-7497

29

System,

Bio-Rad,

was

used

for

electroporations.

Innova

4900

incubator

shaker, New Brunswick, and SANYO MIR

Standard Incubator were used for cultures

incubations. Eppendorf centrifuges 5702 R

and 5810R and Avanti® J-26 XP Centrifuge

were used for routine centrifugation and

culture harvest. Corning® 500 ml Erlenmeyer

flask polycarbonate and, PYREX® FernbachStyle Culture Flask with Baffles and Phenolic

Screw Cap, from CORNING, were used for

liquid cultures. BCA Protein Assay Reagent

purchased from Thermo Scientific, was used

for determination of protein concentration.

Cogent® µScale TFF System, from Millipore,

was

used

to

concentrate

EPO

from

supernatants. Criterion Precast Gel System

and buffer reagents from Bio-Rad were used

for

protein

electrophoresis.

Protein

Deglycosylation Mix, New England Biolabs,

was used for protein deglycosylation. Factor

Xa Cleavage Capture Kit, EMD4Biosciencs,

was used for removing the signal sequence

from the expressed protein. Mouse Anti-Myc

tag Monoclonal Antibody, HRP Conjugated,

from abCam, was used in W estern blot

analysis.

iBlot®

W estern

Detection

Chemiluminescent

kit

(anti-Mouse),

Invitrogen, was used for W estern blot

analysis. Cell culture reagents were all

purchased from Becton, Dickinson and

Company (BD). All other laboratory chemicals

were purchased as molecular biology grade

from Sigma. W ater used in reagents

preparations, as well as cell culture was

ultrapure

grade

obtained

from

Milli-Q

Advantage A10 Ultrapure W ater Purification

System, Millipore.

EPO expression in H. polymorpha:

Competent H. polymorpha cells were

prepared and transformed according to Faber

et al. (1994) using the Gene Pulser MXcell

Electroporation System from Bio-Rad. In brief,

a single cell grown on the non-selective YPD

medium (1% Yeast extract, 1% Bactopeptone, 1% glucose, 2% agar) at 37 o C, was

used to grow a fresh overnight culture in

liquid YPD at 37 o C with 250 rpm orbital

shaking. A 100-fold dilution of the growing

cells was made in 200 ml fresh, pre-warmed

(37 o C) YPD medium. Cells were grown at 37 o

C with 250 rpm orbital shaking until the

optical density of the culture reached 1.3 at

663 nm. Cells were then harvested by

centrifugation at 3000 g for 10 minutes and

cell pellet was resuspended in 50 ml of 50mM

potassium phosphate buffer pH 7.5 containing

25 mM dithiotreitol (DTT). Re-suspended cells

were incubated at 37 o C for 10 minutes before

washing twice in 200 ml of the electroporation

buffer STM (270 mM sucrose, 10 mM TrisHC1 pH 7.5 and 1 mM MgC1 2 ).

Cells

were

harvested

again

by

centrifugation at 3000 g and finally resuspended in 1 ml of the STM buffer. 100 µ l

On Line ISSN: 2090 - 0503

http://www.egyseb.org

30

Egypt. J. Exp. Biol. (Bot.), 10(1): 27 – 35 (2014)

fresh aliquots were used for electroporation

with 5 µ g of the gel purified KpnI-linearized

pGAPURAEPO1 in a pre-chilled electroporation

cuvette. The Gene Pulser MXcell was used to

deliver a 5 mille second pulse using 7.5

kV/cm; 50 µ F and 120 Ohm electric field to

the cells/DNA mixture. Immediately following

the pulse, 1 ml of room temperature YPD

medium was added and the cells suspension

was then incubated for 1 h at 37 o C without

shaking. Cells were harvested (5 min, 3000

g), washed once with 1 ml YND selective

medium (0.67% Bacto yeast nitrogen base

without amino acids, 1% glucose) then spread

on selective YND plates (0.67% Bacto yeast

nitrogen base without amino acids, 1%

glucose+ 100 µ g/ml Zeocin, 2% agar) and

incubated at 37 o C. Surviving transformants

started to grow after three days and were left

to grow further for another 2 days. The

transformation

frequency

was

223

transformants/µ g of DNA and 20 fast growing

colonies were selected and re-streaked three

times (each time 4 days at 37 o C) on selective

YND

plates

until

5

fastest

growing

transformants were finally selected for liquid

culture expression.

A single cell colony from each of the

selected fast growing transformants was used

to inoculate a 10 ml YPD medium in a 500 ml

Erlenmeyer flask for 18 hours at 37 o C with

250 rpm orbital shaking. The 10 ml culture

was then used to inoculate a 300 ml YPD

medium in 2.8 L PYREX® Fernbach-Style

Culture Flask with Baffles and Phenolic Screw

Cap. Cultures were incubated at 37 o C with

300 rpm orbital shaking for 5 days. The EPO

construct was designed so that the α

secretion factor is in frame with the EPO

protein which enables the secretion of the

protein directly in the expression medium.

This

will

facilitate

the

post-expression

concentration and purification of the protein.

Cells were then harvested, (10000 g for 10

minutes) and the supernatant was collected

and kept on ice for processing.

RESULTS AND DISCUSSION:

Design

and

manufacture

of

the

recombinant EPO expression construct:

A range of auxotrophic H. polymorpha host

strains is available which can be transformed by

complementing

their

deficiencies

(positive

control). The ATCC H. polymorpha strain 201322

is a uracil deficient as it lacks the URA3 gene

which

encodes

orotidine-5’phosphate

decarboxylase (ODCase), an enzyme required

for the biosynthesis of uracil. Loss of ODCase

activity leads to a lack of cell growth unless

uracil or uridine is added to the media.

Transforming a URA3 deficient H. polymorpha

with plasmids containing the URA3 gene enables

maintaining these plasmids in an autonomous

multicopy

state

within

the

organism

(Roggenkamp et al., 1986). In addition, the

ISSN: 1687-7497

On Line ISSN: 2090 - 0503

presence of a heterologous URA3 gene in the

transformation

plasmids

favours

multiple

integration within the genome which results in

stable transformants that can carry <100 copies

of

the

transformation

construct

without

maintaining the selection pressure (Gatzke et al.,

1995; Brito et al., 1999; Esser, 2003; Sudbery,

2003).

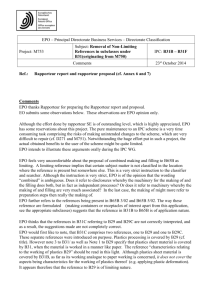

The pGAPZα was selected (Fig. 1a), as the

backbone for constructing an expression vector

to produce the recombinant EPO in the

auxotroph ATCC H. polymorpha strain 201322.

Although this plasmid was originally designed for

expressing recombinant proteins in P. pastoris, it

carries elements which function equally well in H.

polymorpha. The expression promoter was the

glyceraldehyde-3-phosphate

dehydrogenase

promoter (PGAP). This is a high level

constitutive

promoter

which

was

used

successfully for recombinant protein expression

in H. polymorpha. In fact, the expression levels

obtained from PGAP were comparable to those

obtained from the famous methanol oxidase

promoter which is usually used for the

recombinant protein expression in H. polymorpha

(Heo et al., 2003). The alcohol oxidase element

of the pGAPZα vector (AOX TT) also functions

well in H. polymorpha since its transcriptional

machinery correctly recognizes and utilizes the

elements of the alcohol oxidase promoter

(Raschke et al., 1996). In addition, pGAPZα

uses Zeocin as a selection marker for both

bacterial and yeast transformants. Zeocin

selection has also proved to be successful in H.

polymorpha (Salomons et al., 2000; Qian et al.,

2009).

The OmicsLink pReceiver-Y01 construct

(Fig. 1b) was used as a source for the EPO

cDNA (ORF), where the fragment was released

by an EcoRI/NotI double digest. The released

fragment (522 bp) was gel purified using the

QIAquick Gel Extraction Kit according to the

manufacturer recommendations. The Invitrogen

vector pGAPZαA (Fig. 1a) was also EcoRI/NotI

double digested and gel purified before ligated

with the EPO cDNA using T4 DNA ligase.

Ligated vector was transformed into XL10-Gold®

E coli competent cells by heat shock and the

transformants were selected on 100 µg/ml

Zeocin LB agar plates (1% Bacto Tryptone, 0.5%

Bacto Yeast Extract, 1% NaCl, 2% agar) then 10

stable transformants were minipreped and

checked for the presence of the right size EPO

cDNA fragment using EcoRI/NotI restriction

digestion. The sequence and the in frame

alignment of the EPO construct was confirmed

by DNA sequencing and the resulting expression

construct was named pGAPZEPO1 and was

propagated in E. coli on Zeocin selection to

prepare enough DNA using the QIAGEN Midi

plasmid prep kit for subsequent creation of the

final expression construct.

In order to add an extra selection criterion

and encourage the generation of multiple

genome-integrated

constructs,

in

the

H.

http://www.egyseb.org

31

Mohamed & Mohamed, High Level Expression of Recombinant Erythropoietin in Hansenula Polymorpha

polymorpha

expression

transformants,

we

inserted the S. cerevisiae URA3 gene (Bonneaud

et al., 1991) into the pGAPZEPO1 construct at

the BglII restriction site. Gatzke et al. (1995)

showed that the copy number of the integrated

plasmids in the transformed H. polymorpha is

dependent on the plasmid marker used for the

selection of the transformants. Since the URA3

gene of S. cerevisiae is expressed at a low level

in H. polymorpha, the selection of transformants

with the highest growth rate positively

discriminates cells with multiple copies of this

marker. In contrast, plasmids bearing the

homologous H. polymorpha URA3 gene usually

integrate into the genome in a single copy. In

order to do this, we used the OmicsLink

pReceiver-Y01x vector (Fig. 1B) as a template to

amplify the S. cerevisiae URA3 segment using

PCR. Forward and reverse oligonucleotide

primers flanking the URA3 segment were

designed carrying the BglII recognition site. The

forward primer was designed so that an extra

restriction site (KpnI) is located 3’ to the BglII

site with the intention that it can be used for

linearization of the final construct (Fig. 1C).

Primers were synthesized and purified before

used in the PCR amplifications. Using the

Advantage® HD Polymerase Mix and the purified

DNA of the vector pReceiver-Y01x, as a

template, a 1.2 kbp URA3 fragment was

amplified and gel purified using the QIAquick Gel

Extraction Kit.

The In-Fusion 2.0 Dry-Down PCR Cloning

Kit was used to clone this 1.2 kbp URA3

fragment into the pGAPZEPO1 construct at the

BglII

site

according

to

manufacturer

recommendations. The generated plasmid was

called pGAPZURAEPO1 and was transformed

into XL10-Gold® E. coli competent cells by heat

shock

according

to

the

manufacturer

recommended procedure.

The bacterial

transformants were selected on 100 µg/ml

Zeocin LB agar plates where 5 stable

transformants were minipreped using the

QIAGEN plasmid miniprep kit, according to the

manufacturer recommendations, and checked for

the presence of the right size URA3 segment by

PCR using the same amplification primers. The

resulting construct (Fig. 1C) was used in

transforming H. polymorpha strain 201322 to

express EPO as described in the following

sections.

Processing and characterization of the

expressed EPO:

The Cogent® µScale TFF system was used

for protein collection and concentration from the

ice-cooled clear supernatant according to

manufacturer

recommendations.

This

concentration process is dependent upon

membrane filtration technology called tangential

flow filtration (TFF). The process uses filtration

membranes with specific cut off threshold to

separate components in a liquid solution based

on their molecular weight and size. A 10 kDa cut

off was used to make sure that the concentration

I ISSN: 1687-7497

process collects all of the recombinant protein

that was expressed in the culture medium. Figure

2 lane C, shows a silver stain of 20 µl of the

concentrated supernatant run on 4-20% precast

gradient Tris-HCl SDS-PAGE. Despite the

presence of some background proteins, the

predominant species is about 36 kDa in size

which is likely to be the glycosylated EPO. The

recombinant EPO construct (Fig. 1C) was

designed to express in frame, at the N-terminus,

with the myc epitobe, as well as a 6 poly-histidin,

tag which will facilitate purification from the

culture supernatant.

Fig.

1.

Constructions

of

the

erythropoietin expression construct.

recombinant

a: Invitrogen pGAPZα vector.

b:

GeneCopoeia

erythropoietin

clone

in

pReceiverYO1x vector.

c:

Recombinant

erythropoietin

expression

construct used to express the protein in H.

polymorpha.

The QIAGEN Ni-NTA Superflow Columns

were then used, according to manufacturer

recommendations, to purify the recombinant

EPO from the concentrated total protein

supernatant, collected from the expression

culture.

The

clear

and

concentrated

supernatant was passed through the buffer

equilibrated columns, under native conditions,

washed twice with the washing buffer before

the protein was eluted with the elution buffer.

The purified EPO was then treated with the

factor Xa protease to remove the N-terminus

α-signal sequence from the native EPO. The

Factor Xa Cleavage Capture Kit was used for

this purpose according to manufacturer

On Line ISSN: 2090 - 0503

http://www.egyseb.org

32

Egypt. J. Exp. Biol. (Bot.), 10(1): 27 – 35 (2014)

recommendations. Purified EPO was mixed

with the Cleavage/Capture Buffer and diluted

factor Xa, incubated at room temperature for

6 hours before factor Xa was removed by

affinity purification of the kit Xarrest Agarose.

The equilibrated agarose was mixed with the

protease reaction with gentle agitation for 15

minutes before the agarose was separated

from

the

clear

buffered

protein

by

centrifugation. Figure 2 lane B is showing the

Ni-column purified EPO run on Coomassiestained 4-20% precast gradiant Tris-HCl SDSPAGE. Despite showing a molecular weight

slightly smaller than the predominant species

in the un-purified culture supernatant (lane

C), the purified EPO is showing a size of 34

kDa. The native mature EPO is known to be

30 kDa in size and the difference is probable

due to over glycosylation, as well as the tags

linked to the protein at it C-terminus (Fig. 1C).

However, the concentration of the purified

protein was estimated by the BCA Protein

Assay Reagent, according to the manufacturer

recommendations.

We

estimated

that

assuming 100% purification efficiency via the

concentration and the Ni-purification, EPO

was produced in H. polymorpha at 265 mg/l of

culture medium. This is about 50 fold the yield

reported before in P pastoris (Celik et al.,

2007) and more than double EPO cysteine

analogs expression under the same AOX

promoter in shake flasks (Maleki et al., 2012).

This significantly high yield may be attributed

to a construct multi-copy integration event

which is known to be associated with the

heterologous recombination of the URA3

marker into the H. polymorpha genome

(Gatzke et al., 1995).

H. polymorpha is

known to be particularly suitable for large

scale

fermenter

recombinant

protein

production (Mayer et al., 1999; Kunze et al.,

2009; Crommelin et al., 2013). This high EPO

expression level potentiates the likelihood of

a successful industrial fermenter scale

production.

After the factor Xa digestion, the purified

EPO

was

deglycosylated

under

nondenaturing conditions by mixing it with the

deglycosylation mix from NEB and incubated

it for 4 hours at 37 o C. The deglycosylated

EPO was then passed through the Ni-columns

to purify it from the deglycosylation mix.

Figure 2 lane A is showing the deglycosylated

purified EPO after factor Xa treatment. The

SDS PAGE migration is reflecting the removal

of the glycosylation as in lane B the signalless recombinant EPO is migrating at about

35 kDa while after deglycosylation (lane A)

the migration of the protein was shifted to just

above 17 kDa. In order to confirm the identity

of the expressed EPO, anti-myc antibodies

were used to interrogate the protein using

W estern blotting. The recombinant EPO

construct (Fig. 1C) was designed so that a

myc epitobe is fused to the mature protein Cterminus. Figure 3 is showing the X-ray

ISSN: 1687-7497

On Line ISSN: 2090 - 0503

exposure of a chemiluminescence W estern

blot of the α signal-free EPO after and before

deglycosylation. Despite some degradation,

that is likely to result from post-expression

processing and purification, the recombinant

EPO is reacting positively to the anti-myc

antibody detection which confirms the proper

structure of the expressed protein as

designed (Fig. 1C). The W estern blot has also

showed a predominant uniform band migrating

at 18 kDa (lane A) and two closely located

bands (lane B) migrating at 30 and 35 kDa,

respectively.

Fig. 2. SDS-PAGE of the recombinant erythropoietin

expressed in H. polymorpha.

a: purified-deglycosylated EPO after removal of

the signal sequence.

b: purified EPO before deglycosylation.

c: concentrated expression supernatant before

EPO purification.

In order to confirm the identity of these

bands a copy of the Western blot membrane

was used to perform N-terminus protein

sequencing for the three predominant bands

(Fig. 3). The protein bands were electroblotted to the PVDF membrane which was

then stained with Coomassie brilliant blue.

The bands were carefully excised from the

membrane and were sent for N-terminus

protein sequencing service at the Proteome

Factory AG. It was revealed that the 18 kDa

bands on lane A (Fig. 3), as well as the two

closely migrating bands on lane B are sharing

the same N-terminus amino acid sequence of

Met-Gly-Val-His-Glu-Cys-Pro-Ala-Trp-Leu-Trp.

This result confirmed that the factor Xa

digestion to remove the α-signal sequence

from the mature EPO was efficient and the

protein expressed is actually the recombinant

human EPO. It is likely that the two closely

migrating bands, on lane B, are two differently

glycosylated isoforms of the recombinant

EPO, since after the deglycosylation, the

protein migrated as a predominantly single

band on lane A.

http://www.egyseb.org

Mohamed & Mohamed, High Level Expression of Recombinant Erythropoietin in Hansenula Polymorpha

Fig.

33

3. Western blot of the recombinant

erythropoietin expressed in H. polymorpha using

anti-myc antibodies.a: purified-deglycosylated

EPO after removal of the signal sequence. b:

purified EPO before deglycosylation. The Nterminus amino acid sequence is shown next to

each of the major bands.

CONCLUSION:

Hansenula polymorpha proved to be a

suitable expression host for the production of

the recombinant human erythropoietin under

shaking flask conditions. Despite the overglycosylation problem of the synthesized

EPO, the high yield achieved using the URA3

integration construct with the PGAL promoter

carries a great potential for large scale

production due to the significantly high yield.

The generated transformants were maintained

under non-selective conditions which make

them particularly suitable for producing this

pharmaceutically essential protein under

industrial fermentation conditions.

REFERENCES:

Bill RM, Winter PC, McHale CM, Hodges VM, Elder

GE, Caley J, Flitsch SL, Bicknell R, Lappin TR.

1995.

Expression

and

mutagenesis

of

recombinant

human

and

murine

erythropoietins in Escherichia coli. Biochem.

Biophys. Acta, 1261(1): 35–43.

Bonneaud

N, Ozier-Kalogeropoulos O, Li G,

Labouesse M, Minvielle-Sebastia L, Lacroute

F. 1991. A family of low and high copy

replicative,integrative and single-stranded S.

cerevisiae/E. Coli shuttle vectors. Yeast, 7(7):

609–615.

Brito

N, Pe´rez M D, Perdomo G, Gonza´lez C,

Garcı´a-Lugo P, Siverio JM. 1999. A set of

Hansenula polymorpha integrative vectors to

construct lacZ fusions. Appl. Microbiol.

Biotechnol., 53(1): 23–29.

Bunn HF 2013. Erythropoietin. Cold Spring Harb.

Perspect. Med., 3(3): 1-20.

Calo-Fernández B, Martínez-Hurtado JL. 2012.

Biosimilars: Company Strategies to Capture

Value

from

the

Biologics

Market.

Pharmaceuticals (Basel), 5(12): 1393-1408.

Carcagno CM, Criscuolo ME, Melo CA, Vidal MA.

2009. Method for the massive culture of cells

producing recombinant human erythropoietin

US Patent 7638269B1.

Celik E, Calik P, Halloran SM, Oliver SG. 2007.

Production

of

recombinant

human

erythropoietin from Pichia pastoris and its

structural analysis. J. Appl. Microbiol., 103(6):

2084-2094

Chateauvieux S, Grigorakaki C, Morceau F, Dicato

M,

Diederich

M.

2011.

Erythropoietin,

erythropoiesis

and

beyond.

Biochem.

Pharmacol., 82(10): 1291–1303.

Crommelin DJA, Sindelar RD, Meibohm B. 2013.

Pharmaceutical Biotechnology: Fundamentals

and Applications, 4 th Ed., Book, Springer, pp.

544.

Duh MS, Weiner JR, White LN, Lefebvre P,

Greenberg PE. 2008. Management of anaemia:

I ISSN: 1687-7497

a Critical and Systematic Review of the Cost

Effectiveness of Erythropoiesis-Stimulating

Agents. Pharmacoeconomics, 26(2): 99-120.

Elliott S, Giffin J, Suggs S, Lau EPL, Banks AR.

1989. Secretion of glycosylated human

erythropoietin from yeast directed by the

alpha-factor leader region. Gene, 79(1): 167–

180.

Elliott SG, Byrne TE, 2007. Glycosylation analogs of

erythropoietin. US Patent 7217689B1.

Espada J, Gutnisky A. 1970. Purification of human

urinary erythropoietin. Acta Physiol. Lat. Am.,

20(2): 122-129.

Esser K. 2003. The mycota. In: “A comprehensive

treatise on fungi as experimental systems for

basic and applied research (Kües U, Fischer

R. Ed.)”. 2 nd Ed., Springer, pp. 375.

Faber KN, Haima P, Harder W, Veenhuis M, Ab G.

1994. Highly-efficient electrotransformation of

the yeast Hansenula polymorpha. Curr.

Genet., 25(4): 305–310.

Gatzke R, Weydemann U, Janowicz ZA, Hollenberg

CP. 1995. Stable multicopy integration of

vector sequences in Hansenula polymorpha.

Appl. Microbiol. Biotechnol., 43(5): 844–849.

GBI Research. 2010. The future of blood disorders,

therapeutics, analysis and market forecasts to

2016 - Better and more cost-effective

treatment options create opportunities. Search

Report Linker.

Gellissen G, Janowicza ZA, Weydemanna U, Melbera

K, Strassera AW M, Hollenbergb CP. 1992.

High-level expression of foreign genes in

Hansenula polymorpha. Biotechnol. Adv.,

10(2): 179-189.

Gellissen G. 2000. Heterologous protein production

in methylotrophic yeasts. Appl. Microbiol.

Biotechnol., 54(6):741-750.

Goeddel DV. 1990. Gene expression technology. In:

“Methods Enzymolology (Abelson JN, Simon MI,

David V. Goeddel DV. Eds)”, pp. 681.

On Line ISSN: 2090 - 0503

http://www.egyseb.org

34

Egypt. J. Exp. Biol. (Bot.), 10(1): 27 – 35 (2014)

Goldwasser E, Kung CK. 1971. Purification of

erythropoietin.

Proc.

Natl.

Acad.

Sci.

USA, 68(4): 697-698.

Goto M, Akai K, Murakami A, Hashimoto C, Tsuda E,

Ueda M, Kawanishi G, Takahashi N, Ishimoto

A, Chiba H, Sasaki R. 1988. Production of

Recombinant

Human

Erythropoietin

in

Mammalian Cells: Host–Cell Dependency of

the

Biological

Activity

of

the

Cloned

Glycoprotein. Nat. Biotechnol., 6: 67-71.

Hamilton SR, Davidson RC, Sethuraman N, Nett

JH, Jiang YW, Rios Bobrowicz P, Stadheim

TA, Li H, Choi BK, Hopkins D, Wischnewski

H, Roser

J, Mitchell

T, Strawbridge

RR, Hoopes J, Wildt S, Gerngross TU. 2006.

Humanization of yeast to produce complex

terminally sialylated glycoproteins. Science,

313(5792): 1441-1443.

Henry

DH, Spivak JL. 1995. Clinical use of

erythropoietin. Curr. Opin. Haematol., 2(2):

118–124.

Heo JH, Hong KH, Cho EY, Kim MW, Kim JY, Kim

CH, Rhee SK, Kang HA. 2003. Properties of

the Hansenula polymorpha derived constitutive

GAP promoter, assessed using an HSA

reporter gene. FEMS Yeast Res., 4(2): 175–

184.

Jacobs K, Shoemaker C, Rudersdorf R, Neill SD,

Kaufman RJ, Mufson A, Seehra J, Jones

SS, Hewick

R, Fritsch

EF, et

al.

1985.

Isolation and characterization of genomic and

cDNA clones of human erythropoietin. Nature,

313(6005): 806-810.

Jelkmann

W.

2004.

Molecular

biology

of

erythropoietin. Intern. Med., 43(8): 649-659.

Kalorama Information. 2013. The World Market for

Biosimilars (EPO, G-CSF, HGH, Insulin,

Interferon Alpha, Monoclonal Antibodies,

Other), 4 th Edition.

Kunze G, Kang HA, Gellissen G. 2009. Hansenula

polymorpha (Pichia angusta): Biology and

Applications.

In:

“Yeast

Biotechnology:

Diversity and Applications, (Satyanarayana T,

Kunze G. Eds)”, Book, Springer, pp. 47-64.

Lee-Huang S. 1984. Cloning and expression of

human erythropoietin cDNA in Escherichia

coli. Proc. Natl Acad. Sci., 81(9): 2708–2712.

Lin

F-K, Suggs S, Lin CH, Browne JK, Smalling

R, Egrie

JC, Chen

KK, Fox

GM, Martin

F, Stabinsky Z, et al. 1985. Cloning and

Expression of the human erythropoietin gene.

Proc. Natl Acad. Sci. USA, 82(22): 7580-7584.

Lin F-K. 1990. Production of erythropoietin. US

Patent 5621080A.

Maleki A, Madadkar-Sobhani

A, Roohvand

F,

Najafabadi AR, Shafiee A, Khanahmad H,

Cohan RA, Namvar N, Tajerzadeh H. 2012.

Design,

modeling,

and

expression

of

erythropoietin cysteine analogs in Pichia

pastoris: Improvement of mean residence

times and in vivo activities through cysteinespecific PEGylation. Eur. J. Pharm. Biopharm.,

80(3): 499-507.

Maras M, Saelens X, Laroy W, Piens K, Claeyssens

M, Fiers W, Contreras R. 1997. In vitro

conversion of the carbohydrate moiety of

fungal

glycoproteins

to

mammalian-type

oligosaccharides--evidence

for

N-

ISSN: 1687-7497

On Line ISSN: 2090 - 0503

acetylglucosaminyltransferase-I-accepting

glycans from Trichoderma reesei. Eur.

Biochem., 249(3): 701-707.

J.

Mattanovich D, Branduardi P, Dato L, Gasser B,

Sauer M, Porro D. 2012. Recombinant protein

production in yeasts. Methods Mol. Biol., 824:

329-358.

Mayer AF, Hellmuth K, Schlieker H, Lopez-Ulibarri R,

Oertel S, Dahlems U, Strasser AW, van Loon

AP. 1999. An expression system matures: a

highly efficient and cost-effective process for

phytase production by recombinant strains of

Hansenula polymorpha. Biotechnol. Bioeng.,

63(3): 373–381.

Nagao M, Inoue K, Moon SK, Masuda S, Takagi H,

Udaka S, Sasaki R.

1997. Secretory

production

of

erythropoietin

and

the

extracellular domain of the erythropoietin

receptor by Bacillus brevis: affinity purification

and

characterization.

Biosci.

Biotechnol.

Biochem., 61(4): 670–674.

Pecker I. 2011. High level expression of recombinant

human erythropoietin having a modified 5 'UTR. US Patent 07893240.

Qian W, Liu Y, Zhang C, Niu Z, Song H, Qiu B. 2009.

Expression

of

bovine

follicle-stimulating

hormone subunits in a Hansenula polymorpha

expression system increases the secretion and

bioactivity in vivo. Protein Expr. Purif., 68(2):

183–189.

Raschke WC, Neiditsch BR, Hendricks M, Cregg JM.

1996. Inducible expression of a heterologous

protein in Hansenula polymorpha using the

alcohol oxidase I promoter of Pichia pastoris.

Gene, 177(1-2): 163–187.

Roggenkamp RO, Hansen H, Eckart M, Janowicz ZA,

Hollenberg CP. 1986. Transformation of the

methylotrophic yeast Hansenula polymorpha

by autonomous replication and integration

vectors. Mol. Gen. Genet., 202(2): 302-308.

Salomons FA, Kiel JAKW, Faber KN, Veenhuis M,

van der Klei IJ. 2000. Overproduction of Pex5p

stimulates import of alcohol oxidase and

dihydroxyacetone synthase in a Hansenula

polymorpha pex14 null mutant. J. Biol. Chem.,

275(17): 12603–12611.

Storring PL, Gaines Das RE. 1992. The international

standard

for

recombinant

DNA-derived

erythropoietin:

collaborative

study

of

four recombinantDNA-derived erythropoietins

and two highly purified human urinary

erythropoietins. J. Endocrinol., 134(3): 459484.

Sudbery P. 2003. Hansenula polymorpha: Biology

and Applications. Gellissen G. Ed., WileyVCH, Weinham, 2002. Yeast, 20(15): 13071308.

Testa U. 2010. Erythropoietic stimulating agents.

Expert Opin. Emerg. Drugs, 15(1): 119-138.

Vats B, Padh H. 2007. Development of soil amoeba

Dictyostelium discoideum as an expression

system for recombinant human erythropoietin.

World J. Microbiol. Biotechnol., 23(11): 1511–

1518.

Wellesley AKB, Withy RM, Zabrecky JR, Milford

NCM. 1990. Cell Encoding Recombinant

Human Erythropoiete. US patent 4954437.

http://www.egyseb.org

35

Mohamed & Mohamed, High Level Expression of Recombinant Erythropoietin in Hansenula Polymorpha

ا

ج

و

و

ا ر

ل

ا

*' ،

#$ح !

*

ا

** *

ت،

ا

!

*&**

،

م،

ز (' ا & ،"#$%ا

ا " 3

و+

"./

ا

ا ./ج

$

C.م ا .ج " M

ة " 25+

Hرة

ا 1$ $و+ H

ھ-ه ا را 2ا O.ء C.م .ﺢ ./ج ا و+

.ﺢ+ .

/

P "8ة ا * .

ا Oي ا " 3ار 1$و + H

أن

. | & 265 Q H @>+وW H

ل

رH 8

H

و$ !H

$ X

"8 YاC.

ا= .

ا/ر 1$و+ H

و $ (8ا /أن ھ-ه ھ" ا ة اZو " ا " & H * 8 = $ح "8

ر . 8ان

H/

" ,ھ .

.3ج ا

\+ا[ ةا*

ھ-ا ا ! ^ ./ج ا و +ت

ل ا ./ج ا @>+و 2

ھ-ا ا Cم

" (.ق 25+ Y &$ " M

ا * 2وراX

http://www.egyseb.org

ھ

د

ر

! ا

ة

-* "./ا ا و+

" ا

1 23ر ا

(+را *

ا ." 3و ; &. 7ھ-ه ا را 7 + "8 2و 6$ +و5+

= و ري $ (+

ا

و+

وا ظ >

ا >ت ا

" " (.ق وا.@2

'2ا ./ج ا

ا Cم

ا !*

أ.د.

أ.د3 .ء

ن:

ا> ح Hر

(> Kأ Hز$

On Line ISSN: 2090 - 0503

Hر

ا

ت،

ا

ت،

Gان

مط(

I ISSN: 1687-7497