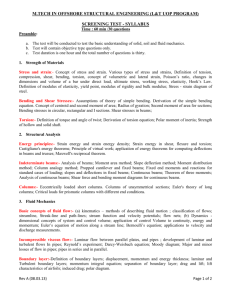

Seismic Design

advertisement