Sakhalin-1 fact sheet-Nov_10, ENG.final doc

advertisement

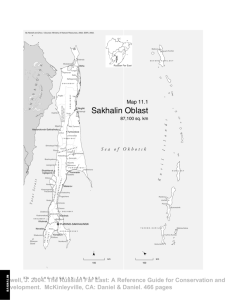

Sakhalin-1 Project Fact Sheet November 2010 Overview The Sakhalin-1 Project is one of the largest single international direct investments in Russia and an excellent example of advanced technological solutions and project management skills being utilized to meet growing worldwide energy demand. Over its years of production operations, the multi-billion dollar project has exhibited exemplary operational, environmental, and safety performance, and has provided multi-faceted benefits to Russia and its citizens. Exxon Neftegas Limited, an affiliate of Exxon Mobil Corporation, is operator of the Sakhalin-1 Project. The project is being implemented by an international consortium comprised of state-owned Russian oil company Rosneft acting via its affiliates RN-Astra (8.5%) and Sakhalinmorneftegas-Shelf (11.5%); the Japanese consortium SODECO (30%); Indian state-owned oil company ONGC Videsh Ltd. (20%); ExxonMobil (30%). Sakhalin-1 includes three oil and gas fields--Chayvo, Odoptu, and Arkutun Dagi--located off the northeast coast of Sakhalin Island in the Russian Far East. Potential recoverable resources are 307 million tons (2.3 billion barrels) of oil and 485 billion cubic meters (17.1 trillion cubic feet) of gas of natural gas. The Sakhalin-1 Project is being executed in phases. The first phase developed the Chayvo field over a five year span. Initial oil and natural gas production from Chayvo started ahead of schedule in October 2005 using interim production facilities. With the startup of the project’s De-Kastri oil export facility in September 2006 and Onshore Production Facility (OPF) in October 2006, the project reached targeted peak oil production rates of 250,000 barrels (33,000 tons) per day in February 2007. Drilling operations at the Odoptu field, which highlight the start of the next phase of the Sakhalin-1 Project, began in May 2009. The field was put into production in September 2010. Production from the field is transported to the Chayvo OPF via an 80 kilometer flowline. Future project phases call for the development of the Arkutun-Dagi field as well as expanded gas production and sales from the Chayvo field. These later project developments are expected to sustain production until 2050. Project Highlights • • • • • • • • Project started oil and gas production on-time and quickly achieved planned production levels. State-of-the-art technologies and management processes have been utilized to maximize production, while maintaining the highest levels of safety, environmental, and operational performance. As of November 2010, over 284 million barrels (approx. 37.4 million tons) of oil produced to date to meet world energy demands; and more than 227 billion cubic feet (6.5 billion cubic meters) of natural gas has been delivered to customers in the Russian Far East. Over US$7.7 billion in contracts awarded to Russian companies or joint ventures (two thirds of the total). More than 550 Russian nationals are currently employed directly by ENL. During the life of the project, over US$70 billion in taxes, royalty payments, and the state’s share of oil and gas is anticipated to be paid to the Russian state. Since the project startup, over US$3.9 billion in royalties, including the state’s share of oil and gas and taxes, has been provided to the Russian Federation which includes more than US$1.35 billion provided to the Sakhalin Oblast. US$150 million of Sakhalin infrastructure improvements which benefit local communities, including hospitals and clinics, roads, bridges, harbors, airports, and power and water facilities. Approx. US$4.5 million in additional charitable contributions to local schools, medical, and civic organizations. Sakhalin-1 Phase 1 Overview Summary: The Chayvo field was initially developed with both onshore (Yastreb) and offshore (Orlan) drilling facilities. In July 2008 dismantling of the Yastreb rig was commenced upon completion of its 1 operations there and the rig was moved to the Odoptu field where it is now in use. Currently, the Orlan is in operation at Chayvo. The produced oil and gas is transported to the OPF where it is processed and stabilized for further shipment. The oil is transported by a 226 kilometer (140 mile) pipeline across Sakhalin Island and under the Tartar Strait to the Khabarovsk Krai on the Russian mainland where it is temporarily stored at the De-Kastri export terminal. From this terminal the oil is transported by an approximately six kilometer undersea pipeline to the world’s largest Single Point Mooring (SPM) tanker loading facility. From the SPM the oil is loaded onto specially designed double-hulled tankers for distribution to the global market. Natural gas is transported a short distance from the OPF where it connects with a network of pipelines owned and operated by other companies for sale to customers in the Russian Far East. Sakhalin-1 Facilities Drilling Facilities: The Yastreb land rig was engineered exclusively for Sakhalin-1 and is the most powerful land rig in the industry. It is designed to drill extended reach wells to offshore targets from land-based locations. State-of-the-art Extended Reach Drilling (ERD) technology reduced the high capital and operating costs of large offshore structures and at the same time minimized the environmental impact in this sensitive near-shore area. In June 2003, ENL initiated the shore-based ERD program to install wells under the seabed at distances exceeding 11 kilometers to tap the northwestern flank of the main Chayvo oil zone. Drilling at Chayvo was completed with a total of 20 ERD wells drilled, setting records in depth, horizontal reach and drilling speed. The Yastreb rig was dismantled, modified and transported to Odoptu field where it has been in operation since the startup of drilling in May 2009. Oil and gas is also produced from the Orlan offshore platform. The 20-well concrete structure is being used to develop the southwestern flank of the main Chayvo zone. Installation of the Orlan platform was completed in July 2005 and drilling operations commenced in December 2005. Offshore processing facilities are minimal, with a full well stream sent to shore for further processing at the Chayvo OPF. Drilling operations on the Orlan platform were completed with a total of 21 ERD wells drilled. Most of the Orlan wells are in the 5.5 kilometer range, with the longest well drilled measuring 7.5 kilometers long. The Odoptu field is located over nine kilometers offshore northeast Sakhalin Island near Piltun Bay and is being developed from the Yastreb drilling rig which was relocated from the Chayvo field. The Odoptu field began production in September 2010. In June 2010, the field’s OP-9 well was completed at a total measured depth of 11.036 meters – at that time making it the longest well drilled at Odoptu and the fifth longest reach well in the world. As of November 2010, a total of seven production wells 2 have been completed at the site. Production from Odoptu is transported via a new 80 kilometer long flowline to the existing Chayvo Onshore Processing Facility. Processing Facilities: Production from the Chayvo and Odoptu fields is transported to the Chayvo OPF, which is designed to produce at the rate of approximately 34,000 metric tons (250,000 barrels) of oil and 22.4 million cubic meters (800 million cubic feet) of gas per day. The OPF produces stabilized crude oil which is shipped to the De-Kastri terminal for export, and natural gas which is either supplied to the Russian Far East or injected back into the Chayvo field to maintain reservoir pressure. Crude Oil Export System—pipeline, terminal, tanker loading facilities The project crude oil export system was commissioned in August 2006. Construction was completed on a 24-inch, 226 kilometer (140 mile) pipeline to transport crude from the OPF across Sakhalin Island and the Tatar Strait to the newly-constructed De-Kastri terminal in the Khabarovsk Krai. Tanker loading operations began at De-Kastri in September 2006. The De-Kastri terminal provides storage and a SPM tanker loading facility that can accommodate year-round crude oil export to world markets. The terminal includes two 100,000 cubic meters (650,000 barrel) capacity storage tanks to hold the Sakhalin-1 crude oil prior to tanker transfer and shipment. Because of its remote location, the terminal is essentially self-sufficient. It has its own electrical power generation, water supply, waste management system and living quarters for the operating staff. The crude is exported via a subsea loading line to the SPM facility, which is located 5.7 kilometers east of the Klykov Peninsula in Chikhacheva Bay. A dedicated fleet of double-hulled Aframax-class tankers carrying up to 100,000 tons (720,000 barrels) of crude is used for year-round export of crude oil from the De-Kastri terminal to world markets which includes Japan, South Korea, USA, Australia, New Zealand and other countries in Southeast Asia. The Sakhalin-1 Consortium members market their share of the crude individually. Future Project Phases Arkutun-Dagi The Arkutun-Dagi oil and gas field is located approximately 25 kilometers off the northeast coast of Sakhalin and to the east of the Chayvo field. The project plans call for the field to be developed from a new drilling and production platform consisting of a gravity-based structure and topsides, which are expected to be the biggest in the industry. Arkutun-Dagi’s gravity-based structure is being constructed in a Russian Far East dry dock in Nakhodka. Oil and gas will be transported via a new flowline to the existing Chayvo Onshore Processing Facility and after that via existing pipelines for sale. The Arkutun-Dagi field is anticipated to begin producing in 2014. The peak production rate at the field is estimated at 4.5 million tons of oil per year. Phase 2 Chayvo Natural Gas Development Future project plans call for the expanded development of Chayvo natural gas resources that are not associated with current oil production. These development plans will require the drilling of additional gas wells and the expansion of existing onshore and offshore facilities. This project would allow for expanded gas sales to domestic and export markets. 3