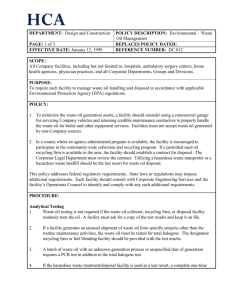

CASE STUDY: Seymour Johnson Air Force Base

advertisement

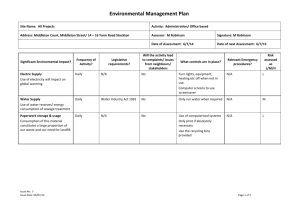

CASE STUDY: Seymour Johnson Air Force Base Location: Industry: Pollution Prevention Application: Annual Savings: Payback Period: Contact: Background Waste Reduction Activities Goldsboro, NC (Wayne County) Federal Military Installation (SIC: 9711) Recycling Programs, Hazardous Material Control, Solvent Substitution $118,000 Immediate to 3.5 years Judith L. Palmer, Environmental Engineer (919) 722-5168 Seymour Johnson Air Force Base (AFB), home of the 4th Fighter Wing, hosts approximately 4,400 military and 1,200 civilian employees who maintain, operate, or support 92 F-15E Strike Eagles and 10 KC-135 Stratotankers. The primary mission of the 4th Fighter Wing is to ensure our country's defense bases. The waste reduction program is a comprehensive effort to address wastes from a diverse set of activities. • Centrifuge Previously, during JP-8 fuel spill cleanup operations, spilled fuel was removed using absorbent pads that ere disposed of as hazardous waste. The base purchased an industrial centrifuge, which effectively and efficiently separates the fuel product from the absorbent, leaving the pads dry enough for reuse or disposal as a solid waste. This reduced the total hazardous waste at the base by one third. All offspecification fuel reclaimed at Seymour Johnson AFB is shipped to Fort Bragg, NC, for use as fuel in the heat plant, at no cost to the government. The cost of the centrifuge has been offset by the elimination of hazardous waste disposal costs associated with the used absorbent pads. • Green Building The new F-15E Squadron Operations facility is being constructed under Green Building specifications. The AFB requires the contractor to divert 75% of construction waste generated at the site from municipal landfills through recycling. The building specifications also require that the contractor use recyclable products in the construction of the building. The building contractor identified cost savings of $98,113 based on an estimated 2695-ton reduction in construction waste. The greatest savings were from abandoned concrete that was re-used for riprap, thus avoiding disposal costs. • Environmental Management Information System (EMIS) EMIS is a centralized computer-based system used to control and track the use of hazardous materials for the entire Air Force Base. EMIS also allows the user to generate real-time data for required environmental reports. • Paint Excess paint and paint-related materials (except "industrial use only" materials) from the AFB are donated to non-profit groups in the community. Waste paint that is not donated is recycled through Safety Kleen. 1997 Case Study SIC 9700 - p. _9_ • Fluorescent Bulb Crushing Fluorescent bulbs, which contain mercury vapors, are considered hazardous waste. In 1997, the AFB crushed 11,312 fluorescent bulbs and separated glass pieces from recovered mercury vapors, thus eliminating the bulbs from the hazardous waste stream. This effort saved approximately $6000 in 1997 hazardous waste disposal costs. • America Recycles Day On the first national "America Recycles Day" in November 1997, the AFB heightened awareness through a highly publicized contest to challenge military families to recycle. Random searches were conducted in the family housing and industrial dumpster areas to determine whether any recyclables were present. If not, the “owner” received a prize package donated by the local community. Another aspect of the celebration involved pledges signed by citizens to commit themselves to recycling and buying recycled goods. The cost for the event was minimal, but its impact was widespread. • Used Oil Used oil is collected throughout the base on an as-needed basis. With the “You Call, We Haul” program, a pre-labeled replaced drum is left where used oil is collected from any of the basewide shops. Yearly training is provided to the approximately 200 accumulation point managers to ensure that they have the knowledge to comply with storage requirements. In 1997, the used oil was donated to Auburn University, which received 24,000 gallons from the AFB for use in their heat plant. • Composting Program In 1997, 500,000 pounds of yard waste and scrap wood were collected from the main base and military family housing areas for use as compost. The finished product is used as a soil additive throughout the base, provided to military family housing residents at no cost, and sold to off-base buyers. • School Partnering Base Environmental Flight personnel participated in “Family Science Night”, and shared recycling ideas with kindergartners through eighth graders and their parents. A fascinating evening, students and parents alike took an interest in practical solutions to environmental resource reuse and recycling. • Bioremediation Site An ongoing initiative to combat the high volume and cost of petroleumcontaminated soil disposal is continuing at the bioremediation site. A windrow and turning process constructed for the natural treatment of petroleumcontaminated soil combines locally acquired turkey manure with the contaminated soils, encouraging the stimulation of microbes that break down the hydrocarbon products. The site is permitted by the State, regularly inspected, and has a flawless record for safety. 1997 Case Study SIC 9700 - p. _10_ Waste Reduced and Cost Savings Table 1 below shows the waste reduced or diverted from traditional disposal methods by programs at the Base, and the associated program costs and annual savings, when known. Table 1: Waste Reduced and Cost Savings by Program Program Material Diverted from Disposal Centrifuge Hazardous waste Green Building Construction debris diverted from landfill Paint and related materials Paint Fluorescent Bulb Crushing Mercury-containing bulbs (hazardous waste) Recycling Household wastes Used Oil Used oil sent to Auburn U. for energy recovery Yard waste and scrap wood diverted from landfill Composting Total Annual Savings Other Activities 1997 Case Study Quantity Material Diverted 20,000 pounds 2695 tons Program Costs Savings $32,500 N/A N/A 11,312 bulbs reduced to 8 drums glass (non-haz. waste) N/A N/A $9300/year Payback: 3.5 years $98,113 in disposal costs for the project $1,844/year in saved disposal costs $6,000/year in saved disposal costs 24,000 gallons N/A $61,000/year in saved tipping fees; $40,000/year in revenue Payback: 1 year N/A 500,000 pounds N/A N/A N/A $100,000 $118,000/year Seymour Johnson Air Force Base was recognized for Outstanding Achievement in the Federal Government Category of the 1997 Governor’s Award for Excellence in Waste Reduction competition. SIC 9700 - p. _11_