Cornerstone 15-2 Calculating Manufacturing Cycle Efficiency (MCE

advertisement

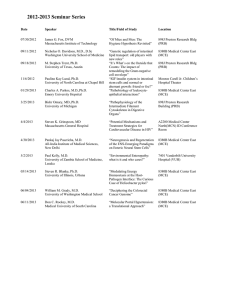

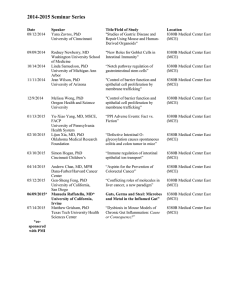

Cornerstone 15-2 Calculating Manufacturing Cycle Efficiency (MCE), page 762 The time that it takes to manufacture a product is influenced by many factors. Some of the factors are meaningful and productive, while others are non-productive and result in wasting valuable time. The Manufacturing Cycle Efficiency (MCE) measures how productive the company is being in its manufacturing process. If a manufacturing operation is experiencing the following activities: Units produced per hour: Move time: Inspection time: Rework time: 100 units (actual velocity) 20 minutes 15 minutes 10 minutes We can calculate the MCE by first determining the actual production time for the output of 100 units. The is calculated by taking the time of each of the activities away from the 60 minutes in each hour. In this case, the actual production time is 15 minutes, calculated as 60 − 20 − 15 − 10 = 15. The production time (15 minutes) divided by the sum of the time it takes to produce the goods (15 + 20 + 15 + 10) or 15/60 is the MCE. In this case it is 0.25. This means that only 25% of the time spent on the manufacturing process is actually productive time, 75% is waste. By changing the activities that are non-productive, we can substantially improve the Manufacturing Cycle Efficiency. This is often the focus of consultants who are hired to re-engineer a company’s internal processes. -1Copyright © 2013 by Nelson Education Ltd.