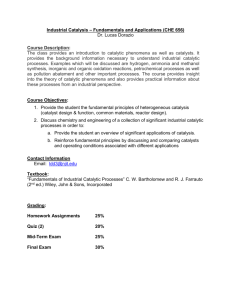

1 Introduction: Green Chemistry and Catalysis - Wiley-VCH

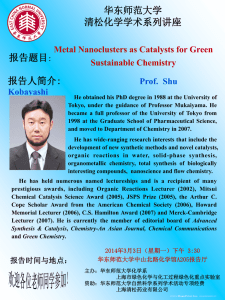

advertisement