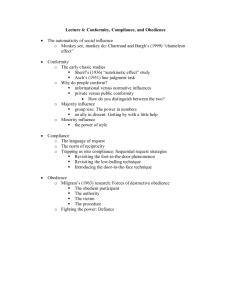

5. Conformity assessment

advertisement