Final Report

advertisement

Final Report

IntelliBed Hospital Bed Add-On Kit

For Improved Patient Safety

ECE4884 Senior Design

Section L05, Koblasz

Care Taker Team

Bikram Virk

Sujoy Sanyal

Ryan Eiswerth

Wasif Khawaja

Mushfiq Saleheen

Submitted

May 2, 2008

TABLE OF CONTENTS

Executive Summary ......................................................................................................... iii

1. Introduction ..................................................................................................................1

1.1

1.2

1.3

Objective .............................................................................................................1

Motivation ...........................................................................................................2

Background .........................................................................................................3

2. Project Description and Goals ....................................................................................4

3. Technical Specifications ..............................................................................................6

4. Design Approach and Details

4.1

4.2

4.3

Design Approach ..................................................................................................8

Codes and Standards ...........................................................................................20

Constraints, Alternatives, and Tradeoffs ............................................................21

5. Schedule, Tasks, and Milestones...............................................................................25

6. Project Demonstration...............................................................................................29

7. Marketing and Cost Analysis

7.1

7.2

Marketing Analysis .............................................................................................30

Cost Analysis ......................................................................................................31

8. Summary and Conclusions .......................................................................................34

9. References ...................................................................................................................38

Appendix A – Gantt Chart ........................................................................................... A-1

Appendix B – RFID System Schematic.......................................................................A-2

Care Takers (ECE4884L05)

ii

EXECUTIVE SUMMARY

Hospital attendants continually come in contact with all sorts of harmful germs

while providing treatment to patients. This places the attendants and their patients at a

high risk of being infected. Studies have shown that hospital-acquired infections, also

known as nosocomial infections, alone kill more people a year than automobile accidents

and lung cancer combined [1]. Along with nosocomial infections, hospitals have spent

millions of dollars a year to treat bedsores, which result after patients remain immobile

on their bed for extended periods of time [2].

The IntelliBed project was comprised of two systems that worked in solving

nosocomial infections and bedsores. The first was RFID-based and determined whether

an attendant had washed their hands before they came into contact with a patient lying in

the bed. If the attendant did not dispense soap during a specified period before

approaching the patient, then the system reminded the attendant to wash. This reduced

the chances of carrying harmful parasites from one infected patient to another. The other

system used pressure sensors to prevent bedsores. Whenever this system found that the

patient had not moved for a certain amount of time, it suggested the patient to change

position on the bed. Another important feature of IntelliBed was its compatibility with

any existing hospital beds; the IntelliBed was designed as an add-on to any existing bed

in order to attract more customers.

After initial manufacturing expenses, the total cost for the IntelliBed prototype

was $1,304. Once initial sales increase, production can be increased in order to drive

down the end customer cost. The targeted customers for this product were hospitals,

clinic centers, and nursing homes.

Care Takers (ECE4884L05)

iii

IntelliBed Hospital Bed Add-On Kit

For Improved Patient Safety

1. INTRODUCTION

In hospitals and nursing home, attendants frequently forget to wash their hands

before coming into contact with a patient, which increases the likelihood of nosocomial

infections, also known as hospital-acquired infections. Studies have shown the number

of deaths as a result of nosocomial infections is higher than breast cancer and HIV

combined [3]. Another expensive problem hospitals face is bedsores, which develop on a

patient’s body when they do not change position on their bed for an extended period of

time [4]. Both Nosocomial infections and bedsores can be deadly.

To combat Nosocomial infections and bedsores, the IntelliBed was designed with

several safety components that could be easily attached to most hospital beds. The

objective was to provide hospitals, nursing homes, and other healthcare centers with an

inexpensive alternative to purchasing high-end hospital beds built around similar safety

features. A comparison of this project’s design to comparable beds is more thoroughly

discussed in Section 7.1.

1.1

Objective

By having designed safety features that can be installed onto existing hospital

beds, the goal of the IntelliBed project was to provide hospitals, nursing homes, and other

healthcare centers with an inexpensive alternative to purchasing high-end beds built

around similar features. Some of the features proposed, such as the RFID-linked

database (detailed later), can be connected to systems outside the hospital bed, like a

Care Takers (ECE4884L05)

1

hand-washing system that identifies and reports attendants who did not wash their hands

before they approached a patient.

1.2

Motivation

One of the causes of nosocomial infections results after negligent hospital

attendants come into contact with multiple patients without properly cleansing

themselves between visits [2]. The Centers for Disease Control and Prevention (CDC)

estimated that more than 2 million nosocomial infections occur per year, with around

17,500-70,000 death per year. The annual cost to the healthcare industry to treat

nosocomial infections was estimated between $4.5-5.7 billion [5].

In addition to this problem, bedsores are also a serious concern for hospitals and

patients. Bedsores result after parts of the body are subjected to unrelieved pressure for

extended periods of time, cutting off oxygen and blood flow to the area [4]. Relieving

the pressure can be as simple as adjusting the body’s position periodically. However, for

the elderly and bed-ridden who may not be able to feel when parts of their body are under

pressure, bedsores can become a serious risk. The CDC estimated 1 million bedsorerelated cases per year while 60,000 deaths per year were blamed on bedsore-related

complications. Two thirds of cases occurred in people over 70 years old [4]. Bedsores

and nosocomial infections are serious concerns for patients since both increase the length

of hospital stay, the total charges, and the risk of death.

These concerning statistics exist even though high-end hospital beds are available

that have the potential to dramatically reduce the risk of infections and bedsores.

However, no wide-spread adoption of these beds by healthcare centers has occurred.

This is because these high-end beds are extremely expensive (see section 7.2 for more

Care Takers (ECE4884L05)

2

details). The IntelliBed was designed to be a low-cost alternative to these expensive bed

designs. Healthcare facilities that are looking to provide better safety for their patients

but are not willing to replace the beds they already have for more expensive ones can

purchase the IntelliBed equipment (described in Section 2) and attach these parts to their

current beds.

1.3

Background

RFID tag detection is a new technology and is being applied in many fields,

including healthcare applications. Although hospitals have started to use RFID

technology, such as for positive patient identification or equipment tracking, there is no

RFID system currently established whose purpose it is to prevent the spread of hospitalacquired infection.

For automated in-bed patient bedsore prevention, products such as MCES’s

calibrated electronic bed and dialysis weighing and motion detection machine, which

effectively uses load cell technology, exist [7]. However, the cost of this machine ranges

from $3000-$4000. Also, special mattresses like the bedsore prevention pad by DuroMed [8] are available on the market. These mattresses are inexpensive but they are not

able to provide a warning when the patient has not moved for a long period of time, and

thus in risk of bedsores. Other comparable hospital beds designed to prevent bedsores

include the Stryker’s Secure II Med/Surg Hospital Bed [9] and the Hill-Rom Total Care

SpO2RT Hospital Bed [10]. However, these beds cost $10,000 and $28,500,

respectively, which is typical for beds that provide their similar features. Also, these

beds do not utilize RFID technology to prevent nosocomial infections.

Care Takers (ECE4884L05)

3

2. PROJECT DESCRIPTION AND GOALS

Figure 1 displays the main components of the IntelliBed. The project’s goal was

to lower hospital-acquired infections by implementing a RFID system to detect

approaching attendants and to reduce the risk of bedsores by using pressure sensors to

detect non-movement. For the RFID system, a 13.56 MHz 1-Watt serial cable RFID

transceiver, which was used to read RFID tags, was placed underneath the bed. The

antennas, which allowed the transceiver to detect tags at a distance, were placed on the

bed within the mattress. The pressure sensors were embedded in the mattress and each of

their outputs was read into the computer for analysis. A more thorough description of the

location of each piece of equipment used in this project is detailed in Section 4.

RFID Antenna

PC Monitor

Passive RFID ID Tag

PC

13.56 MHz RFID Reader

Trossen Robotics

24” Force Sensing Resistor

Figure 1. Main Components of the IntelliBed.

Care Takers (ECE4884L05)

4

The total cost of the IntelliBed equipment was $1,304 with a target selling price

of $2,300 (see section 7.2 for cost and price details). The expected market for IntelliBed

included hospitals, nursing homes, and other healthcare centers involved with patient care

requiring a bed.

A brief description of each component of the IntelliBed project is given:

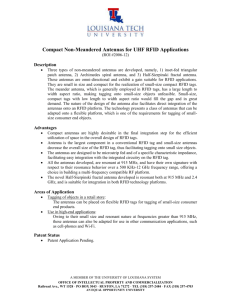

ID ISC.MR101-USB 13.56 MHz Mid Range Reader (1 unit)

Purpose:

Multi-tag Reader for identification of ISO transponders.

It detected the hand-washing status of the approaching attendants.

Placement:

Next to bed at its base.

RFID Antenna (3 units)

Purpose:

Added range to the RFID reader.

Placement:

One antenna at the head, mid-section, and foot of the bed. A two

inch-thick padding was used to separate the antennas from the

metal frame of the mattress. On top of the antennas, another

padding was placed and used to prevent the patient’s weight from

bending the antennas and for the patient’s comfort.

PicKit II Microcontroller Multiplexing Circuit (1 unit)

Purpose:

Controlled switching between the three different antennas. It

allowed a single reader to poll the separate antennas without the

need for each antenna to have its own reader.

Placement:

Underneath the bed.

HP Pavilion Slimline s7700e PC (1 unit)

Purpose:

Stored attendants’ hand-washing database and displayed GUI.

Placement: Next to bed at its base.

Computer Monitor (1 unit)

Purpose:

Displayed GUI warning of patient non-movement, egress, and

the approach of staff with unwashed hands.

Placement:

Mounted on a stand next to the bed

Trossen Robotics 24 Inch Force Sensing Resistor (FSR) and Voltage Divider Kit

(4 units)

Purpose:

These trimmable pressure sensor strips outputted resistance and

voltage readings. Using the change in these values, movement (or

non-movement) was detected. The voltage dividers connected the

FSR’s to the Trossen Robotics Phidget Interface Kit 8/8/8. Voltage

Care Takers (ECE4884L05)

5

Placement:

dividers attached to the leads of the strips allowed the sensitivity of

their readings to be adjusted.

Lengths of strips were laid out parallel to the patient.

Trossen Robotics Phidget Interface Kit 8/8/8 (1 unit)

Purpose:

Used as an analog-to-digital interface between the FSR’s and PC.

Placement: Next to bed at its base.

3. TECHNICAL SPECIFICIATIONS

The proposed and actual specification values for the RFID and pressure systems

are presented in Table 1. The desired detection range for the RFID antennas of 24 inches

was determined by taking into account normal dimensions of hospital rooms. This range

was large enough for the detection of approaching attendants and would have provided

enough time to warn potential germ-carriers appropriately. This desired range was also

small enough to avoid the detection of a tag unnecessarily when an attendant was present

in the room for a purpose other than to attend to the patient.

A transceiver power of 1-Watt ensured that the proposed antenna range of 24

inches was detectable. The frequency of 13.56 MHz was chosen as it was best for the

detection of multiple tags and was large enough to not be obstructed by objects the size of

a human body. In addition, the availability of equipment was commonplace at this

frequency [11].

The Trossen Robotics FSR’s were used for movement detection, which is

described later in Section 4. One of the advantages of using Trossen Robotics Force

Sensing Resistors was that their sensitivity level could be adjusted with the aid of a

voltage divider. The sensitivity specification of the FSR was chosen to be low, where

low sensitivity was set to have a threshold of 20 percent from the sensor strip’s previous

Care Takers (ECE4884L05)

6

Table 1. Technical Design Specifications

Specification

Proposed

Actual

1W ± 2 dB

1W ± 2 dB

13.56 MHz

13.56 MHz

Max. 0.5 A

Max. 0.5 A

RFID Reader

-

Transmitting Power

- Operating Frequency

-

Current Draw

Antenna Dimensions

-

Head Section

17” x 30”

17” x 30”

-

Mid-Section

9” x 30”

9” x 30”

-

Foot-Section

15” x 30”

15” x 30”

Placed On Wooden Table:

Antenna Detection Range

2 ft (24 in.)

1.5-1.75 ft. (18-21 in.)

Placed On Metal Bed Frame:

0-7 in.

Multiplexer

-

Microprocessor

Not Proposed

Pic18 LF2321

-

Power Supply

Not Proposed

3.3 V

-

Current Consumption

Not Proposed

< 5mA

-

Switching Loop-time

Not Proposed

16 ms

Trossen Robotics 24” FSR

-

Force Sensitivity Range

<100 g to > 10 kg

<100 g to > 10 kg

-

Pressure Sensor Range

< 1.5 psi to > 150 psi

< 1.5 psi to > 150 psi

-

Sensitivity to Vibration

Not Significantly Affected

Not Significantly Affected

-

Lifetime

Allowed Patient Rest Time

(No motion)

Pressure Senor Time Monitoring

Care Takers (ECE4884L05)

Not Proposed

>10 Million Actuations

30 Minutes

30 Minutes

Every Minute

Every Second

7

reading. Too high of a sensitivity level would have detected slight movements, such as

the chest of the patient as he or she breathed. However, movements like this would not

be enough to prevent bedsores. Therefore, the sensitivity of the sensors was set to low in

order to disregard the slight movements made by the patient.

4. DESIGN APPROACH AND DETAILS

The IntelliBed project was divided into two main parts. The first part was the

RFID detection system, which was used to prevent the spread of nosocomial infections.

The second system was the bedsore prevention system, which detected patient nonmovement after a specified period of time by using Trossen Robotics Force Sensing

Resistors.

4.1

Design Details

RFID system

Figure 2 demonstrates the main components of the RFID system used in this

project. This system had five components: passive RFID tags, three antenna receivers,

multiplexing circuit, a 13.56 MHz transceiver, and a hand-wash history database. A

multiplexer was also included in this system but it is detailed in the next section.

Each tag had a unique ID corresponding to the tag’s owner. Upon receiving the

transmitted signal from an antenna, the inner circuitry in the tag returned the unique

signal that represented the binary ID assigned to each attendant. This response signal was

then detected by one of the three antennas.

Figure 3a shows the three antennas that were designed for the IntelliBed

prototype. Separate antennas were needed since the bed had sections that could be

Care Takers (ECE4884L05)

8

Figure 3a. The Three antennas designed for IntelliBed.

Figure 3b. The antennas location on the bed.

adjusted into different angular positions based on the patient’s preferences. The

placement of the three antennas on the bed is shown in Figure 3b. After testing different

positions, the location of the antennas spread out in this layout was found to provide the

best possible orientation for the detection of a tag worn by an attendant on his or her wrist

no matter what direction he or she approached the bed from.

One important thing noted by the IntelliBed designers concerning the placement

of the antennas was that they must not touch the metal frame of the bed. Touching the

metal frame would have severely distorted their magnetic fields, affected their range, and

subsequent impedance-matching circuitry. A padding of 2 inches was used to separate

the antennas from the bed frame to help isolate them from the metal’s distorting effects.

Care Takers (ECE4884L05)

9

On top of the antennas was placed another padding to prevent the patient’s weight from

bending the antennas.

Even with the bed padding acting as a buffer, testing of the antennas’ range

occurred while the antennas were on the bed as opposed to them being on a table or any

location far from the bed. This was to ensure that any effects the metal bed frame had on

the antennas was taken into account when the antennas’ impedance matching circuits

were designed.

Once a tag was detected by an antenna, the serial number of the tag was compared

in a hand-wash history database on the PC. In this database, information such as whose

tag had been detected and whether they had previously washed their hands was stored. If

a tag was linked in the database with an attendant who had not washed their hands, then

the warning shown in Figure 4 requesting for the attendants to not approach the patient

was displayed on a GUI.

WARNING:

DR. SMITH PLEASE

STAND BACK

Figure 4. GUI display Developed for IntelliBed Project.

Care Takers (ECE4884L05)

10

The upper left-hand corner of Figure 4 is the RFID interface. It was based off of a

modified version from ECE 4007 Floor Mat Group [12]. Pressing the “Connect” button

and then the “Start Monitoring” button activated the RFID reader for detection. The

RFID interface in the IntelliBed GUI was programmed in Visual Basic 6 and can be

found on the IntelliBed team website. The bottom half of the GUI, which dealt with the

pressure sensors and bedsore prevention, will be described later.

RFID Antenna Multiplexer

In order to operate the three IntelliBed antennas with a single transceiver, the

multiplexing circuit configuration shown in Figure 5 was needed. This configuration was

created to poll each antenna to see if any had detected a tag. Each antenna had one of its

Figure 5. Multiplexer circuit configuration of the RFID System.

Care Takers (ECE4884L05)

11

two leads connected directly to the transceiver and the other lead connected to a relay

switch designated to it. Once each antenna’s assigned relay completed its connection to

the transceiver, the transceiver would read only that antenna. Which relay was allowed to

complete its connection to the transceiver was controlled by the MUX.

The centerpiece of the MUX was the 15 user-configurable pin Pic18 LF2321

microcontroller shown in Figure 6a, with its pin layout in Figure 6b. Three of the pins,

RA1, RA2, and RA3, were used to generate a sequential output of Boolean high (3.3 V)

and low (0 V) across Relay 1, Relay 2, and Relay 3, respectively.

Figure 6a. Pic18 LF2321 Microcontroller.

Figure 6b. Pic18 LF2321 Pin Layout.

Figure 7 shows that the loop time between successive settings of a relay was 16

ms, which followed one of the internal timers of the microcontroller. This time was short

enough to ensure no loss of tag detection even if the tag was quickly passed by the

antenna. Figure 7 also shows the delay of 5 ms between each setting of a pin and

subsequent activation of a relay and antenna. This allowance in time ensured the

magnetic field of one antenna would not interfere with that of another since multiple

antenna interference would have unforeseen consequences on tag detection.

Care Takers (ECE4884L05)

12

Figure 7. Oscilloscope Waveform Capture of PIC18 Microcontroller MUX.

Note that the output from the PIC microcontroller for relay 1 and 2 shown in

Figure 7 were actually being turned off every 1/3 of a second because the relay devices

used were active-low. The Pic18 LF2321 microcontroller was programmed in C and its

source code appears on the IntelliBed website.

Movement Monitoring System

The goal of the second system of this project was to prevent bedsores by

implementing pressure sensors to detect patient non-movement. As mentioned before,

bedsore prevention could be as simple as having the patient’s body position adjusted

periodically. By placing pressure sensors underneath the patient, movements were

Care Takers (ECE4884L05)

13

Figure 8. Algorithm used for Bedsore Prevention.

Figure 9. GUI display warning after non-movement was

detected 30 minutes.

Care Takers (ECE4884L05)

14

monitored according to the algorithm shown in Figure 8. A 30 minute timer was reset

after each significant movement was detected by the pressure strips. Significant

movement was specified as a 20 percent change from the pressure sensors last read value.

If no movement was detected for a period of 30 minutes, then the warning in Figure 9

was displayed on the GUI.

Figure 10. Trossen Robotics Force Sensing Resistor.

The specific type of pressure sensor used for monitoring movement was the

Trossen Robotics 24 inch Force Sensing Resistor (FSR), shown in Figure 10. FSRs are

detailed more thoroughly in the next section, but for now note that these sensors

exhibited a decrease in resistance with an increase in the force applied to their surface.

The FSRs were attached to Trossen Robotics Phidget Voltage Dividers like that

shown in Figure 11a. These voltage dividers allowed the sensitivity of the sensors to be

adjusted. The voltage dividers were then interfaced with the PC through the Trossen

Figure 11a. TR Phidget Voltage Divider.

Care Takers (ECE4884L05)

Figure 11b. TR Phidget Interface Kit 8/8/8.

15

Robotics Phidget Interface Kit shown in Figure 11b. This interface kit provided a

convenient way to interface up to eight FSRs to the PC using a USB cable. It was also

able to run on a number of operating systems, including WindowsXP, which was used in

this project. It also came with extensive written program examples and in a number of

API’s [13], including VB6, which was used to create the IntelliBed’s GUI.

Figure 12. Layout of the Pressure Sensors on the Bed.

Four FSR strips were connected to the Phidget Interface Kit 8/8/8 and placed

parallel to the length of the bed, as shown in Figure 12. The mid-section of the bed was

chosen for the placement of the sensors because the lower back of the patient is one of

the most common areas of the body prone to bedsores [4]. To prevent excessive bending

of the sensors by the weight of the patient, they were attached on top of hardboard and

placed under 2 inch thick bed padding.

The strategic placement of the FSR strips in the mid-section of the bed also

allowed for the detection of egress of the patient from the bed. The egress algorithm

followed by the code is outlined in Figure 13. If one of the outer strips registered a large

force (defined as a >50% from its previous value) while at the same time the other three

sensors registered a negligible force (defined as < 10% of from its previous value) then it

was assumed that the patient was putting all their weight onto one side of the bed and

Care Takers (ECE4884L05)

16

Figure 13. Egress detection procedure.

about to egress. The GUI was programmed to display the warning shown in Figure 14

when such a situation was detected The scroll bars shown in the bottom half of the GUI

were used as visual indicators of the relative amount of pressure registered by each of the

four FSRs. Quantitative values were displayed next to the scroll bars. These values, like

the scroll bars, were used only to show relative comparisons of force and do not reflect

any unit of measurement such as psi. Notice how one of the outer sensors registered an

applied pressure while the other three registered nothing, which signaled egress.

Sensitivity settings appear to the right of the scroll bar. The three sensitivity levels

available for the pressure sensors and controlled by the voltage dividers were low,

medium, and high.

Care Takers (ECE4884L05)

17

The source code for the GUI, which was written in Visual Basic 6 and based off

of example source code provided by Trossen Robotics, can be found on IntelliBed team

website.

WARNING: EGRESS

DETECTED

Figure 14. GUI displaying Egress Warning.

The Trossen Robotics Force Sensing Resistor

As mentioned before, the type of pressure sensors used in the IntelliBed were the

Trossen Robotics 24 inch Force Sensing Resistors, previously shown in Figure 10. FSRs

are paper-thin, durable, flexible, and trim-able to any size required. FSRs are not load

cells or strain gauges, but they function in a similar manner because, as described later,

Care Takers (ECE4884L05)

18

Figure 15 . Diagram of a typical FSR.

they use electrical properties of resistance to measure the force or pressure applied to its

surface [14].

A typical FSR is made up of two parts, as shown in Figure 15. The first part is a

resistive material (type depends on FSR) applied to a film. The second part is a set of

contacts applied to another film. The resistive material makes an electrical path between

the two sets of conductors on the other film. When a force is applied to the sensor, a

better connection is made between the contacts, and so the conductivity increases as

shown in Figure 16a. The behavior of the FSR’s conductance over a wide range of forces

Figure 16a.

Conductance vs. Force (0-10Kg)

Care Takers (ECE4884L05)

Figure 16b. FSR typical force vs. resistance

response behavior (log/log scale).

19

is approximately a linear function of the force.

Viewing the FSR behavior from a different perspective, Figure 16b shows the

typical force vs. resistance response behavior of a FSR on a log scale. This response

generally follows an inverse power law characteristic of 1/R. In other words, FSRs

exhibit a decrease in resistance with an increase in the force applied to their surface.

4.2

Codes and Standards

The RFID functionality of the IntelliBed was constrained by the fact that

electromagnetic interference in hospital settings must be kept to a minimum, and

transmitted signals from antennas must be held to minimal power levels. In order to drive

a larger antenna, a larger amount of power would have been required. However, since

the RFID system would be in such close proximity to medical electronics in practical use,

no additional power was added to the 1-Watt reader used.

Electromagnetic Compatibility (EMC), which requires “the correct operation, in

the same electromagnetic environment, of different equipment which use electromagnetic

phenomena, and the avoidance of any interference effects [16]” was an important

constraint for this project. However, the 13.56 MHz RFID reader used was known to be

standardized so as not to interfere with electronic medical devices, as described in ISO

35.240.80 [17].

The use of a 13.56 MHz transceiver frequency was also important because this

standardized frequency eliminated the need for hard copper wiring in the tags and

allowed for printed ink tags to be implemented with the system. This frequency also

Care Takers (ECE4884L05)

20

complied with ISO standard 14443, which allowed for standardized and cheaper tags

because of their widely manufactured usage [18].

4.3

Constraints, Alternatives, and Tradeoffs

FSRs are not suitable for precision measurements, as they might exhibit as much

as 15% to 25% variation between each other [15]. However, since precise measurements

were not necessary in the role of movement detection, the IntelliBed prototype was not

affected by the FSR’s shortcoming. However, there were alternatives considered to using

Trossen Robotics FSRs in the role of bedsore prevention. Strain gauges, like the foil-type

shown in Figure 17a, were the most likely alternative to the FSRs. These strain gauges

could have been mounted within the bed mattress, just as the FSRs were placed, and used

to measure the compression and tension of the bed surface as the patient moved.

If strain gauges were used in the IntelliBed project then a Wheatstone Bridge

circuit, similar to that shown in Figure 17b, would have been needed. These circuits

magnify the amplitude of the resistance change of the strain gauges, similar to what the

voltage divider devices did for the Trossen Robotics FSR’s. However, the strain gauge

Figure 17a. Foil-type Strain Gauge.

Care Takers (ECE4884L05)

Figure 17b. Wheatstone Bridge Circuit.

21

and Wheatstone Bridge alternatives that were found did not provide as extensive example

computer source code for interacting with the sensors and the PC as the Trossen Robotics

products did.

Several designs for the IntelliBed RFID antennas were considered. These designs

were based on projects of previous semesters and they include a spiral and two variations

of a concentric loop antenna, as shown in Figure 18a. Though no design had a significant

Spiral-Loop

Concentric-Loop

Variation 1

Concentric-Loop

Variation 2

Figure 18a. Alternative Antenna Designs Considered for IntelliBed System.

Circular-Loop

Figure 18b. Antenna Design Selected for IntelliBed Project.

advantage over the other, the one that was chosen for the IntelliBed is shown in Figure

18b. This design was recommended by Texas Instruments in their technical report

“Constructing a 1000 x 600 HF Antenna [20]”. TI was able to achieve a detection

range of 24 inches using this antenna design but only after setting their transceiver to a 4-

Care Takers (ECE4884L05)

22

Watt output. However, the transceiver used in the IntelliBed was limited to only 1-Watt.

Nevertheless, when the IntelliBed’s antennas were tested on a wooden table, even with a

1-Watt transceiver they were able to consistently detect at a range of 1.5-1.75 feet.

As an alternative to constructing their own antennas, some previous semester

groups opted for purchasing professionally-made antennas instead. The Floor Mat Group,

whose project also dealt with placing RFID antennas on top of a metal-framed hospital

bed, bought the Medium Gateway Antenna made by Dynasys shown in Figure 19. The

advantage of using this antenna is that it comes with what Dynasys calls their De-Q

feature, which automatically re-tunes the antenna if it is detuned after it is placed near a

material with a high moisture or metal content [21]. This feature allowed the antenna to

have a guaranteed detection range of a couple feet, even when next to large metal objects

like a hospital bed. The Floor Mat group used the Medium 20” x 20” and the Large 20” x

63” Gateway antennas successfully in their project. However, the cost for each antenna

was $400 and $800, respectively [17].

Figure 19. Unenclosed medium 20” x 20” High Frequency

(13.56 MHz) ISO 15693 antenna from Dynasys.

Care Takers (ECE4884L05)

23

If three Medium Gateway antennas were purchased instead of constructing the

three IntelliBed’s antennas, it would have been an expensive $1,200 added to IntelliBed

prototype. If a single Large Gateway antenna, which covers most of the area of the bed,

was purchased instead of buying three separate Medium Gateway antennas, then the

savings would have been $400. However, the Large Gateway’s rigid frame would have

prevented the bed from adjusting into its different positions.

Automatic antenna tuners would have provided the most likely source of success

in achieving maximum range from the IntelliBed antennas. However, the price-tag for

these devices easily ranged in the hundreds of dollars. Figure 20 shows the basic

principle behind automatic antenna tuners. As explained by ARRL, the National

Figure 20. Basic Operation Principle Behind Automatic Antenna Tuners.

Association for Amateur Radio:

“In practical terms, all a tuner does is act as a kind of adjustable impedance transformer

between the antenna system and the radio. It takes whatever impedance the antenna

system presents and attempts to convert it to 50 Ohm--or something reasonably close to

that value--for the transceiver. When the transceiver ‘sees’ a 50 Ohm impedance, it is

able to load its maximum RF output into the system. That power is transferred through

the antenna tuner, to the feed line and, ultimately, to the antenna--minus any losses

incurred along the way [23].”

Care Takers (ECE4884L05)

24

Figure 21. KAT100 High Power Automatic Antenna Tuner.

Figure 21 shows the KAT100-1 High Power Automatic Antenna Tuner, the most

likely device that may have aided the IntelliBed prototype antenna detection range. This

tuner operated from as low as 0.2 Watts to 100 Watts, which meant it would have worked

properly with IntelliBed’s 1 Watt transceiver. However, the cost for this device was $239

[24].

5. SCHEDULE, TASKS, AND MILESTONES

The tasks of the IntelliBed project were divided into the following categories:

1. Listed and Acquired Parts/Components:

The entire group met together and made a detailed list of required parts. The

critical parts included pressure sensors with PC connection, pressure sensor

mounts, PC, RFID reader, RFID antennas, and RFID tags.

Assigned Member(s): All members.

Degree of Difficulty: Easy. With the exception of two FSRs that

inexplicably malfunctioned and required several more to be reordered as

Care Takers (ECE4884L05)

25

replacements, no problem was encountered in the ordering of hardware for

this project.

2. Implemented Weight-Shift Detection

After interfacing the pressure sensors with the PC, Visual Basic 6 code was

developed to detect weight-shift detection.

Assigned Member(s): Sujoy, Ryan, Wasif

Degree of Difficulty: Easy. Trossen Robotics provided clear GUI

examples that allowed the FSRs to essentially be plug-and-play. The

IntelliBed GUI was based off of a modified version of example code

provided by Trossen Robotics.

3. Realized Bed Egress Detection

A program was written to detect patient egress from the reading of the pressure

sensors. Once detected, a warning was displayed on the GUI.

Assigned Member(s): Sujoy, Ryan, Wasif

Degree of Difficulty: Easy. Trossen Robotics provided clear GUI

examples that allowed the FSRs to essentially be plug-and-play. The

IntelliBed GUI was based off of a modified version of example code

provided by Trossen Robotics.

4. Constructed RFID Antenna

Three RFID antennas were constructed. A multiplexing circuit was designed in

order for the one reader to poll each antenna to determine which had detected a

tag.

Assigned Member(s): Bikram, Mushfiq

Degree of Difficulty: Hard. The metal bed frame interfering with the

magnetic fields of the antennas made it difficult to find the impedance

matching circuitry for the antennas. Several weeks were devoted to this

task, but to no avail. Final solution was to use the matching circuitry from

professionally made Gateway antennas (see Section 4.3) bought by a

previous semester’s group.

Care Takers (ECE4884L05)

26

5. Created Interaction with Hand-wash Monitoring System

The RFID reader was connected with the antenna and tuned with the tags to the

correct frequency. A hand-wash monitoring database was created and interfaced

with the RFID system.

Assigned Member(s): Bikram, Mushfiq

Degree of Difficulty: Hard. RFID monitoring system was based off of the

Floor Mat Group’s code from a previous semester. Deciphering the

several files in order to make a single working project file was

challenging. Also, the bedsore prevention GUI was originally written in

Visual Basic 2005. The RFID interface was written in Visual Basic 6 and

so in order to combine the two GUIs into one, the pressure sensor GUI,

which was determined as the easier of the two to translate, had to be rewritten in Visual Basic 6.

6. Implemented the Full System

Once all the components of the project were built, they were interfaced with each

other to realize an integrated system. The final system was tested, debugged and

fine-tuned for final demonstration.

Assigned Member(s): All members

Degree of Difficulty: Hard. One week before project was expected to be

completed, two FSRs inexplicably malfunctioned and the antennas were

not achieving the target range of 24 inches. After using the impedance

matching circuits taken out of the Gateway antennas, antenna range was

improved but still not near target. In addition, after several successful tests

with the MUX, the relays stopped working. The relays were replaced but

whether the fault in the original relays had anything to do with the

Gateway impedance matching circuits remained unexplained.

7. Deliverables Prepared

At least two weeks before each deadline, the entire team prepared for the

deliverables and worked on the project construction. Group members were

assigned different sections of the deliverables.

Assigned Member(s): All members

Care Takers (ECE4884L05)

27

Degree of Difficulty: Hard. Providing clear and detailed documents of the

IntelliBed project proved time-consuming. The IntelliBed designers

suspected more time was involved in documentation of the project than

the actual construction of the project.

No risk was involved in any of these tasks, with the exception of soldering during

the antenna construction. The team was divided into two groups: bedsore prevention,

which included Sujoy and Ryan, and RFID technology, which included Bikram, Mushfiq,

and Wasif. Ryan prepared the weekly project progress reports and attended to the overall

documentation of the IntelliBed project. Aside from regular scheduled class meetings,

the group met several times a week for discussion and project work. Each member was

held accountable to their assigned tasks by the rest of the group.

Figure 22 shows a timeline chart that outlines the key tasks that had to be

accomplished by the project team. A more detailed Gantt chart of the proposed as well as

the actual project schedule appears in Appendix A. The project was finished on its

expected date of completion of May 2, 2008.

Figure 22. Timeline for project.

Care Takers (ECE4884L05)

28

6. PROJECT DEMONSTRATION

Demonstration of the pressure sensor system of the IntelliBed occurred in one of

the senior design rooms. The GUI created for the project was described and displayed.

The pressure sensors were interfaced with the GUI and then spread out parallel to each

other on a hospital bed in a similar layout to their proposed positioning. An egress

warning was shown on the GUI after one of the IntelliBed designers pressed his hand

against one of the outer sensors, leaving the others untouched. The designer then

simulated patient non-movement across the sensors after he pressed down on all the

sensors and maintained this force until the timer countdown finished and a warning

signaled, which the patient to move, was displayed on the GUI. For convenience during

the demonstration, the GUI displayed a warning when patient non-movement was

detected for a period of 10 seconds and not 30 minutes.

The RFID system demonstration also occurred in the senior design room where

the hospital bed was stored. The three antennas were laid out across the bed and

connected to the MUX circuit, which was connected to the RFID transceiver and

interfaced with the GUI. Multiplexing was demonstrated by holding a tag close to each

antenna in turn until the GUI displayed a message that signaled detection.

Two types of tags were issued for the demonstration. One tag was linked in a

premade database to a person who did not wash their hands and the other tag was linked

to someone who did was their hands. When the tag associated with the unwashed

attendant was detected, the GUI displayed a warning for that person to not approach the

bed. When the tag associated with the attendant that had washed their hands was

detected, the GUI was set to display a greeting.

Care Takers (ECE4884L05)

29

Due to concerns of damaging the antennas and the pressure sensors,

demonstration of either occurred without a person lying on top of them, as a patient

would in a finalized product of this project. The IntelliBed design team believed that the

functionality of both the pressure sensors and the antenna detection systems were

demonstrated properly, regardless.

7. MARKETING AND COST ANALYSIS

7.1

Marketing Analysis

Many medical equipment providers have already created hospital beds that

provide the same services as the IntelliBed offers. In some cases, their beds outperform

the IntelliBed. Other comparable hospital bed designs designed to prevent bedsores

include the Stryker’s Secure II Med/Surg Hospital Bed [9] and the Hill-Rom Total Care

SpO2RT Hospital Bed [10] shown in Figure 23. These beds have pressure sensors that

weigh the patient, detect egress/ingress, and can automatically adjust to a chair position

for safer egress. Other main features of these beds include:

Hill-Rom Total Care SpO2RT:

Stryker’s Secure II Med/Surg:

air mattress system

scale

lateral rotation and percussion

an intuitive bed system that helps

increase caregiver productivity,

IntelliDrive mechanism that offers

power assisted transport and

maneuverability of the bed within

and outside of the patient room.

Features of the Stryker’s bed

Care Takers (ECE4884L05)

BackSmart system design that

helps to significantly reduce the

risk of back injuries through

integrated ergonomics,

smart bed monitoring system

called iBed that communicates

local bed status information to

caregivers to help ensure patient

safety and improve overall

efficiency

patented motorized Zoom drive

that significantly reduces effort

needed for patient transport.

30

Figure 23. IntelliBed Competing Products.

However, beds likes these are expensive and so have not experienced wide-spread

adoption by healthcare facilities. The price for the Secure II Med/Surg and the Total

Care SpO2RT bed were $10,000 and $28,500, respectively, which is typical for beds

offering their similar features. Also, these beds do not implement RFID to prevent the

spread of hospital-acquired infections.

The main selling point of IntelliBed was that healthcare centers do not have to

buy expensive beds like Stryker’s or Hill-Rom’s if they wanted to provide a safer

environment for their patients; they can install the IntelliBed components onto their

existing beds, thereby providing similar services as the high-end beds offer, but without

the expensive cost.

7.2

Cost Analysis

Table 2 gives a list of the required parts for the project and their cost. Two types

of equipment were used: movement monitoring related parts and RFID related parts.

Apart from having been used for movement and hand-wash monitoring, the Slimline PC

and computer monitor were able to be used to interface and display other medical

measurements.

Care Takers (ECE4884L05)

31

Table 2. Project Equipment Costs

Product

Quantity

Unit Cost

Total Cost

Trossen Robotics 24” FSR

4

$24

$96

1

$400

$400

Interface Kit 8/8/8

1

$77.60

$78

Cables

1

$10

$10

TI-FEIG RFID Reader

1

$350

$350

Copper Plating

25 ft.

$20

$100

Antenna Board

1 pair

$20

$20

1

$250

$250

System

and Voltage Divider Kit

System

RFID

Pressure Sensor

Group

HP Pavillion Slimline

s7700e PC

PIC Kit II Microprocessor

Total Equipment Cost

$1,304

Table 3 shows a detailed cost list for the project development. The total one-time

development cost for the IntelliBed was $40,950. The main components of this estimate

included the cost for parts of $1,304, a labor cost of $25,200, and an overhead cost of

$14,490. The biggest contributor to the total project cost was labor related expenses,

where an hourly wage of $30 was used to calculate the labor costs. The labor hours

estimated included research and product design, team discussions, parts purchased,

design implementation, test analysis, and debugging. Fringe benefits at 25 percent of

labor costs and overhead cost at 25 percent of materials, labor, and fringe added to give

the total overhead cost. When the IntelliBed goes into production, the labor related costs

was expected to be significantly lower than those estimated for product development.

Care Takers (ECE4884L05)

32

Table 3. Project Development Costs

Component

Labor

Labor

Equipment

Total

Hours

Cost

Cost

Component

Cost

Movement Measurement

Movement Detection

310

$9,300

Egress Detection

96

$2,880

FEIG RFID

50

$1,500

RFID System

124

$3,720

Class lecture/meetings

260

$7,800

Total Labor

840

$25,200

$250

$12,430

$1,010

$6,230

$0

$7,800

RFID

Interface

Total Equipment Cost

Fringe Benefits, 25% Of

$1,260

$6,300

Labor

Overhead, 25% Of

$8,190

Material, Labor & Fringe

Total Overhead

$14,490

Total Project Cost

$40,950

A detailed product cost and profit analysis is shown in Table 4. In a mass

production facility, each unit was expected to cost $2,065. Based on market evaluations,

it was estimated that 2,000 units would be sold every year for five years. An initial profit

margin of 10.22 percent was used that resulted in each unit expected to be sold for

$2,300. Selling 10,000 units over a five year period was expected to generate

$23,000,000 of revenue with a total profit of $2,350,600.

Care Takers (ECE4884L05)

33

Table 4. Selling Price Estimation

Equipment Cost

$1,226

Assembly Labor

$10

Testing Labor

Subtotal, Labor

Fringe Benefits, 25% of Labor

Subtotal, Labor & Fringe

Overhead, 25% of Material, Labor & Fringe

Subtotal, input Costs

$6

$16

$4

$1,280

$320

$1,600

Sales & Marketing Expense, 15% of Selling Price

$345

Support & Warranty Expense, 5% of Selling price

$115

Amortized Development Costs

Subtotal, All Costs

Profit, 10.22%

Selling Price

Total Revenue, Based on 10,000 Units

Total Profit

$5

$2,065

$235

$2,300

$23,000,000

$2,350,600

8. SUMMARY AND CONCLUSIONS

The prototype of the IntelliBed ended in mixed results. The pressure sensor

system was fully functional within the early design stage of the project. The GUI that

was created properly displayed the pressure sensor data, as well as a warning when nonmovement persisted for any time limit specified by the user.

However, the RFID system did not fully meet expectations. The MUX functioned

properly, switching the connection from the transceiver to each of the three antennas in

turn, and a warning was displayed on the GUI whenever one of the antennas detected a

tag. Unfortunately, the actual antenna detection range was limited (see Table 3).

Care Takers (ECE4884L05)

34

The main factor that was suspected of making it difficult to find the proper

antenna matching network to allow the greatest possible detection range was the

antennas’ proximity to the metal frame of the bed. The proximity to metal is among one

of the top concerns for RFID antenna designers. It is known to greatly alter antenna

design, as explained by Bob Scher, CEO of Dynasys Technologies, Inc.:

“Altered performance of the RFID system can be expected when metals are in close

proximity of the radiation field. Proximity to metals effectively lowers the antenna's

inductance. Lower inductance causes an increase in resonant frequency and also a

reduction in "Q". Designers may consider starting with a higher-than-needed "Q" "in the

lab" to start with, expecting it to be lowered when it is installed in its intended location.

External capacitance may be required to tune the modified antenna system back to

resonance. These types of situations can be experienced around conveyor belt structures

and also embedding antenna loops on concrete driveways where metal re-bar absorbs

some of the radiated energy. [22]”

The proximity of the antennas to the metal bed frame was one of the first

concerns for the IntelliBed design team. The design team proposed during the

Preliminary Design Report to separate the antennas from the metal bed frame using a 2

inch thick bed padding. However, during the testing phase once the detection range for

the antennas were found to be poor, it was quickly determined that a much larger

separation between the antennas and the bed may have been required. Further tests with

the antennas then proceeded with a padding of 7 inch thickness between them and the bed

frame.

The impedance matching networks for all three antennas were first built on a

single Protoboard out of convenience for the designers when fine-tuning the networks.

Wires connecting the matching networks to the antennas were originally around 10” long

and of 2 mm thickness. However, these wires acted as antennas themselves and were

able to detect tags held extremely close to them. Twisting these wires to form something

Care Takers (ECE4884L05)

35

similar to a coaxial cable prevented them from acting as antennas, but did little to have

any noticeable effects on the detection ranges. Wires of larger diameters were also

tested, but ended in inconclusive results.

Nevertheless, based on the already seen side-effect the length of the wires

between the Protoboard and antennas had on generating its own antenna, it was

concluded by the design team that the length and not the width of these wires had a more

significant role on the antennas’ detection ranges. Thus, the lengths of these wires were

continuously reduced and the antenna range continuously tested, with mixed results, until

eventually the matching network was taken off the Protoboard and built directly on the

antenna. However, not only did such a move make it difficult for fine-tuning the

matching network of each of the antennas, but it also ended again with inconclusive

results.

The solution presented itself not in the wires but in the impedance matching

circuitry. After all, in theory a properly tuned matching network would have been able to

take into account any effects the length of the wires would have had on the antenna

range. However, to create a matching network was itself a challenging task, even with

the aid of a VSW meter. For the difficulties to be compounded by the proximity of the

antennas to the bed, the IntelliBed designers could not find stable matching networks for

all the antennas.

The IntelliBed designers then replaced the IntelliBed matching circuitry with the

two matching networks that were in the Dynasys antennas. Recall from Section 4.3 that

the Dynasys networks were able to return themselves in the proximity of metal.

Immediately, results could be seen as a stable detection range of >7 inches was achieved.

Care Takers (ECE4884L05)

36

It is important to note that when the matching network is to be connected to the

antennas, they were not connected directly to the antennas but rather to the opposite end

of the wiring where the MUX was located. This was so the matching network took into

account any loss due to the wiring lengths leading from the transceiver to the separate

antennas spread out across the bed.

Though no further testing on the wires were done, the IntelliBed designers believe

that had 50 ohm coaxial cables been used instead of the standard 2 mm wiring, the

antennas may have achieved more stable results even without the aid of the Dynasys

matching circuitry. 50 ohm coaxial cables are widely used in radio transmitter

applications and may have prevented any loss frequently seen when 2 mm wiring was

used. Also, 50 ohm cables theoretically could have allowed the matching circuitry to be

built directly on the antenna as opposed to nearer the transceiver, since the minimal loss

in the cables would not have to have been taken into account.

Due to the mixed results concerning the RFID antennas, the IntelliBed design

team has concluded its prototype is not ready for mass production. It is recommended

that if any future design group whose project relies heavily on RFID antenna range then

they should purchase professionally-made antennas with automatic impedance matching

networks built in, similar to that made by Dynasys mentioned earlier (see sec. 4.3). If

cost is a concern for the group, then a separate automatic impedance matching network

device that can be attached to antennas could be purchased instead.

Also, the design team suggests to any future project groups whose goal it is to

prevent patient bedside falls for them to utilize the Trossen Robotics 24 inch Force

Sensing Resisters in their design. As described earlier in Section 4, the IntelliBed

Care Takers (ECE4884L05)

37

designers were able to detect patient egress based on registering a large force on either

side of the bed where a sensor was located.

9.

REFERENCES

[1]

WebMD, “Cellultis,” [Online]. Available: www.webmd.com [Accessed: Jan. 29,

2008].

[2]

Dr. Tamer Fouad, M.D., “Study Shows hospital staph infections cause 12,000

deaths, cost $9.5 billion,” www.doctorslounge.com. para. 11, Aug. 2005.

[Online].

Available:http://www.doctorslounge.com/infections/articles/nosocomial/staph_ho

spital. [Accessed Jan 30, 2008].

[3]

MedicineNet, “Staph Infection (Staphylococcus Aureus)” [Online]. Available:

http://www.medicinenet.com/staph_infection/article.htm [Accessed Feb. 20,

2008].

[4]

Health A to Z, “Bedsores,” Health A to Z, 14, [Online].

Available: www.healthatoz.com. [Accessed Jan. 28, 2008].

[5]

Quoc V Nguyen, MD., “Hospital-Acquired Infections,” www.emedicine.com.

Aug. 21, 2007. [Online].

Available: http://www.emedicine.com/PED/topic1619.htm.

[Accessed Jan. 30, 2008].

[6]

CISCO, “CISCO Unveils WiFi RFID Tracking and Multi-Function Box,”

www.cbronline.com. May 4, 2005. [Online]

Available: http://www.cbronline.com/article_news.asp?guid=3B2D6FC7-1041475E-B798-EDC57DA1DC56/ [Accessed Feb 14, 2008].

[7]

Medical Supplies and Equipment Co. {MSEC}, “Calibrated Electronic Bed and

Weighing Machine,” [Online]. Available: www.medical-supplies-equipmentcompany.com. [Accessed Jan. 25, 2008].

[8]

Amazon, “Decubitus Pad Bedsore Prevention”, [Online]. Available:

http://www.amazon.com/Decubitus-Pad-Sore-Prevention-hite/dp/B000PY2EUA.

[Accessed Jan. 31, 2008].

Care Takers (ECE4884L05)

38

[9]

Stryker, “Medical Equipment: Our Products”, Stryker. [Online]. Available:

http://www.stryker.com/enus/products/PatientHandlingEMSandEvacuation

Equipment/Beds/MedSurgBeds/SecureII/index.htm [Accessed March 1, 2008].

[10]

Hill-Rom, “Hill-Rom Products,” Hill-Rom. [Online].

Available: http://www.tradekey.com/selloffer_view/id/1447563.htm [Accessed

March 1, 2008].

[11]

Thomasnet, “RFID Integrated Circuits Operate at 13.56 MHz,” [Online].

Available: http://news.thomasnet.com/fullstory/452444 [Accessed March 2,

2008].

[12]

RFID Floor Mat Group, Available: http://www.ece.gatech.edu/academic/

courses/ece4007/07fall/ece4007l03/group03/

[13]

Trossen Robotics “Phidget 8/8/8 manual” [Online]. Available:

http://www.pdfdownload.org/pdf2html/pdf2html.php?url=http%3A%2F%2Fwww

.phidgets.com%2Fdocumentation%2FPhidgets%2F1018.pdf&images=yes –

[Accessed April 2, 2008].

[14] Trossen Robotics, “24 Inch Force Sensing Resistor Strip”, [Online].

Available: http://www.trossenrobotics.com/store/p/3223-24-Inch-Force-SensingResistor-FSR-Strip.aspx [Accessed March 15, 2008].

[15] William Putnam, R. Benjamin Knapp. “Input/Data Acquisition System Design for

Human Computer Interfacing”. [Online].

Available: http://ccrma.stanford.edu/CCRMA/Courses/252/sensors/node8.html

[Accessed April 28, 2008].

[16] Wikipedia.org, “Electromagnetic Compatibility”. [Online].

Available: http://en.wikipedia.org/wiki/Electromagnetic_compatibility

[Accessed April 1, 2008].

[17]

ISO, “ISO 35.240.80” [Online]. Available: ISO.org.

[Accessed April 16, 2008].

[18]

O. Bashan, “ISO 14443: An Introduction to the Contactless Standard for Smart

Cards and its Relevance to Customers,” On Track Innovations, ltd (OTI). Report.

[19] Wikipedia, “Strain Gauge” [Online]. Available: http://en.wikipedia.org/wiki/

Strain_gauge. [Accessed April 10, 2008].

[20]

Texas Instruments, “Constructing a 1000 x 600 HF Antenna” [Online].

Available: www.ti.com/rfid/docs/manuals/appNotes/HF1000x600AntennaRev2

.pdf

Care Takers (ECE4884L05)

39

[21]

RFIDUSA, “Featuring Dynasys de-Q Tuning” [Online].

Available: http://rfidusa.com/superstore/index.php?cPath=37_30

[Accessed April 20, 2008].

Bob Scher, “Antenna Considerations for Low Frequency RFID Applications,”

Dynasys.[Online]. Available: http://209.85.165.104/search?q=cache:860_

iBxDXPYJ:rfidusa.com /superstore/pdf/Antenna_Considerations_for_LF

.pdf+proximity+to+metals+%2B+rfid&hl=en&ct=clnk&cd=6&gl=us [Accessed

April 20, 2008].

[23] ARRL, the National Association for Amateur Radio, “Antenna Tuner Operation”.

Available: http://www.hamuniverse.com/tuner.html [Accessed May 1, 2008].

[22]

[24]

Elecraft, “KAT100 High Power Automatic Antenna Tuner”, Elecraft. [Online].

Available: http://www.elecraft.com/kat100/kat100_page.htm

[Accessed: May 1, 2008].

Care Takers (ECE4884L05)

40

APPENDIX A

PROJECT GANTT CHART

Care Takers (ECE4884L05)

41

PROPOSED SCHEDULE

ACTUAL SCHEDULE

Care Takers (ECE4884L05)

42

APPENDIX B

MULTIPLEXER SCHEMATIC

Care Takers (ECE4884L05)

43

Care Takers (ECE4884L05)

44