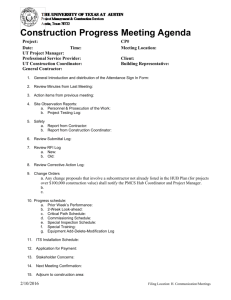

Construction Safety and Health Requirements

advertisement