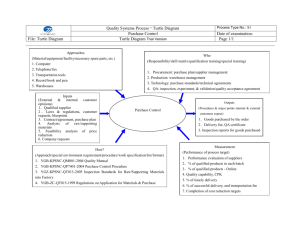

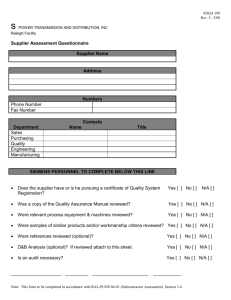

5.4 QA requirements for procurement

advertisement