Orthodontic Wires: Materials, Phases & Applications

advertisement

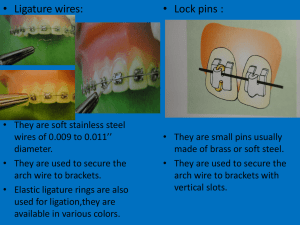

ORTHODONTIC WIRES Arch Wire Materials There are four main types of material compositions for arch wires: 1) Stainless Steel; 2) Nickel-Titanium (Ni-Ti); 3) Beta-Titanium; and 4) Cobalt-Chromium A comprehensive orthodontic treatment is usually divided into three phases: (1) leveling and aligning, (2) space closure and anterior/posterior correction, and (3) detailing and finishing. A variety of alloy wires are used to generate the biomechanical forces associated with tooth movement. Once the wire is activated or bent, it is the unloading or deactivating forces that produce orthodontic tooth movement. With current orthodontic treatment, super elastic nickel-titanium wire is often used for phase 1, with beta titanium and stainless steel (SS) wires most frequently used for phases 2 and 3. As a result, beta titanium and SS wires tend to be reused more often, leaving them exposed to the aqueous oral environment for a longer period of time. Nickel-Titanium (Ni-Ti) wires: Nitinol was invented by William R. Buchler and was introduced to the orthodontic community by Andersan in 1971. They are elastic and can return to their original shape when deformed (shape memory). Therefore, in the beginning stages of orthodontic treatment, Ni-Ti wires are frequently used to put gentle forces on the crooked teeth to align them. A variation of Ni-Ti wires are heat-activated Ni-Ti (Copper Ni-Ti) wires. Heat-activated Ni-Ti wires can hold the deformed configuration at room temperate, but when the wire reaches the temperature of a patient’s mouth, the wire will return to its original shape. Heat-activated Ni-Ti wires are useful in the beginning stages of treatment. If the teeth are extremely crooked, the wire can be cooled so it can be tied into the brackets easier. Then after a few minutes, it will reach the temperature of the patient’s mouth, displaying its Ni-Ti elastic properties. The warm wire will want to assume its original U-shape and carry the teeth to their new, straighter positions. Beta-Titanium wires were introduced by Jon Goldberg and C.J. Burnstone. They were developed after Ni-Ti wires and offer an intermediate range of elasticity and strength, while also being able to be permanently deformed. This wire serves as a good intermediary wire between Ni-Ti and stainless steel. Some orthodontists will use this wire starting in the middle of treatment while other orthodontists do not use this type of wire at all. Composition Tin – 80% Molybdenum – 11.5% Zirconium – 6% Tin – 4.5% Titanium molybdenum alloy (TMA) is also used for archwires and has properties midway between SS and nitinol Stainless steel wires (entered dentistry -1919) have been used for decades due to their high strength. In addition, stainless steel wires do not rust and can be adjusted many different ways by the orthodontist without breaking. However, stainless steel wires are not very elastic, meaning that if you bend these wires too much, they will assume the new position and will not return to their original position. 3 major types are present:-Ferretic SS - Martensitic SS - Austenitic SS Composition Chromium (11-26%)–improves the corrosion resistance Nickel(0-22%) – austenitic stabilizer copper, manganese and nitrogen – similar to the amount of nickel added to the alloy Carbon (0.08-1.2%)– provides strength Silicon – (low concentrations) improves the resistance to oxidation and carburization at high temperatures. Sulfur (0.015%) increases ease of machining Phosphorous – allows sintering at lower temperatures. . Cobalt chromium nickel (Elgiloy) has the advantage that it can be hardened by heat treatment after being formed. Various tempers Red – hard & resilient green – semi-resilient Yellow – slightly less formable but ductile Blue – soft & formable Composition Chromium – 15-22% Nickel – for strength and ductility Iron, molybdenum, tungsten and titanium to form stable carbides and enhance hardness. Cobalt – 40-45% Optiflex arch wires It is a new type of arch wire developed by M.F. Talass in 1992.these arch wires are made of clear optical fiber and are therefore highly aesthetic. In addition, they exhibit high resilience. The drawback of this wire is that it cannot accept a sharp bend. Shape 1) Round – .014 up to .020 2) Rectangular – .021 x .025 3) Square – .016 x .016 4) Multi-stranded wires- 2 or more wires of smaller diameter are twisted together/coiled around a core wire. -- 0.016 or 0.017 * Dimension is in inches Round wires have higher ductility than square or rectangular wires. If both, 1st & 2nd order corrections are required to the same extent, then square or round wires? The square wires have advantage. They simultaneously control torque and result in better orientation into a rectangular slot. (do not turn and no unwanted forces are created). In US - thousandths of an inch 0.016 “ =16 mils In Europe and many other areas – millimeters CONVERSION Divide the dimensions in mils by 4 and place a decimal point behind it. eg – 16 mils = 0.4mm Applications Adams clasp is made in stainless steel in either 0.7 mm (for permanent molars) or 0.6 mm (for premolars and primary molars) wire. Labial bow is constructed using 0.7mm hard round stainless steel wire. Robert`s retractor is a labial bow made in stainless steel wire in 0.5mm. High labial bow with apron springs- It consists of a heavy wire bow of 0.9mm thickness and apron spring made of 0.4mm is attached to the high labial bow. Palatal finger springs are fabricated in 0.5 mm or 0.6 mm hard round stainless steel wire. Z spring is made of 0.5mm wire. T spring is made of 0.5 mm wire. Coffin spring is made of 1.2mm wire. U loop canine retractor is made of 0.6mm or 0.7mm wire. Helical canine retractor is made of 0.6mm wire. Palatal canine retractor is made of 0.6mm wire.