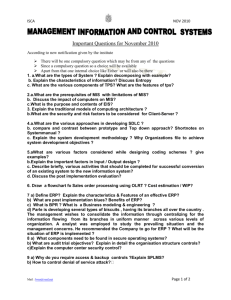

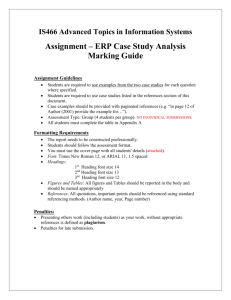

INTRODUCTION to ERP

advertisement