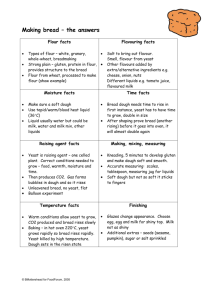

Baking Ingredients Yeast

advertisement

Baking Ingredients You don’t need to keep too many ingredients on hand to bake at any given time. And since today is the right day to bake with Fleischmann’s Yeast, it’s good to have these easy-to-store items around as staples Yeast Yeast is the heart of the bread making process. It’s the essential ingredient that makes the dough rise and gives home-baked bread its wonderful taste and aroma. Other ingredients are added to complete the reactions that result in a perfectly baked loaf of hot, crusty homemade bread. In each yeast envelope, there are thousands of living plant-like microorganisms. When activated by warm liquid, and fed by sugar or starch, the yeast releases tiny bubbles of carbon dioxide gas. This gas is what makes the dough rise and achieve its light texture after baking Fleischmann’s Active Dry Yeast The original dry yeast product was introduced in 1943. This product works best when dissolved in water prior to mixing. Fleischmann’s Rapid Rise™ Yeast This is Fleischmann’s quick and easy instant active dry yeast. You do not need to dissolve it first, but you can combine it with other ingredients when you use the quick, one-rise method. And since only one rise is required, the time it takes for dough to rise is significantly shortened...by as much as 50%. Fleischmann’s Fresh Active Yeast Also known as compressed or cake yeast, this product comes in a cake form. To use, simply crumble into dry ingredients or soften in warm water first. Flour Wheat is the most common type of flour used in bread baking. It includes all-purpose flour, bread flour and whole wheat flour. Wheat is rich in gluten, a protein that gives dough its elasticity and strength. When yeast and flour are mixed with liquid and then kneaded or beaten, the gluten forms and stretches to create a network that traps the carbon dioxide bubbles produced by the yeast. Recipes with whole wheat flour have less gluten and make denser loaves. That’s why these recipes generally require some all-purpose flour which increases the gluten and makes lighter, taller loaves. Liquids Water is the most important liquid because it does 2 critical things: It dissolves and activates the yeast. It blends with the flour to create a sticky and elastic dough. Milk, buttermilk, cream or juice may be added to enhance the flavor or texture. Only warm liquids should be added to dry ingredients in a recipe because: A too-cool liquid will slow or stop yeast action. A too-hot liquid will destroy the yeast and prevent it from rising. Ideal temperature ranges are 100°F-110°F, when yeast is dissolved directly in water; 120°F130°F when un-dissolved yeast is added to dry ingredients. Sweetner Sugar adds flavor and rich brown color to a bread's crust. Brown sugar, honey, molasses, jams and dried fresh fruits may also be used. Salt Salt is an important ingredient in bread baking because it: Slows rising time, allowing the flavor of the dough to develop. Adds structure to the dough by strengthening the gluten, which keeps the carbon dioxide bubbles from expanding too rapidly. Never omit salt when it’s a recipe ingredient. Salt-free recipes are available if you need them. Eggs Eggs add food value, color and flavor to breads. They also help make the crumb fine and the crust tender. Eggs add richness and protein. Some recipes call for eggs to be used as a wash that adds color. Fat Butter, margarine, shortening or oil add flavor and make bread tender and moist. Fat slows moisture loss, helping bread stay fresh longer. Fat is heated with liquid when using RapidRise™ Yeast. Do not substitute oil for margarine/shortening unless the recipe calls for it The Science of Yeast Yeast is a tiny plant-like microorganism that exists all around us - in soil, on plants and even in the air. It has existed for so long, it is referred to as ‘the oldest plant cultivated by man’. The main purpose of yeast is to serve as a catalyst in the process of fermentation, which is essential in the making of bread. While there are many types - or strains - of yeast, at Fleischmann’s, our sole focus is on Saccharomyces cerevisiae. This is the yeast that is most commonly used in making bread. It Started in Egypt Research shows that ancient Egypt was the home of modern bread. Archaeologists digging in Egyptian ruins found grinding stones and baking chambers, as well as drawings of 4,000-yearold bakeries and breweries. During this time, bakers were using different grains to create a variety of flavors in their breads. Wheat, which was the most common grain in Egypt, made excellent loaves. To make their breads tastier, bakers began experimenting with different ingredients. Honey, eggs, dates, seeds and spices were added to provide a welcome and delicious variety of choices. They would also often make their breads in different animal shapes - like birds, fish and cows. While these breads were meant for everyday consumption, some had special significance for rituals and festivals. Of course, that tradition continues, as certain holidays are associated with particular types of bread. Getting a Closer Look While the art of breadmaking was evident from the beginning, the science of breadmaking didn’t develop until 1676, when Anton Leewenhoek developed the first microscope. Now scientists could investigate yeast up close and really understand what it was and what it did. It was Louis Pasteur In 1859 who first discovered how yeast works: Yeast feeds on the starches in flour, producing carbon dioxide The carbon dioxide expands the gluten proteins in the flour The gluten proteins cause the dough (of which flour is a main ingredient) to expand and rise Nine years after Pasteur’s discovery, Fleischmann’s Yeast was founded, and the modern baking era was born. THE PRODUCTION OF YEAST From one tiny yeast cell, tons of yeast can be produced. Here’s how the process works: The first step, using a strong microscope, is selecting one healthy and vigorous yeast cell from the desired strain. Once selected, the cell is planted in a sterile test tube, which contains all the nutrients necessary to make yeast grow. In the tube, the yeast cell reproduces, by budding...or multiplying itself. Once the yeast has multiplied into a small mass of pure cells, it is transferred to glass laboratory flasks. These flasks contain a liquid mixture called wort. Wort is a nutrient-rich growth medium containing molasses or another carbohydrate source, vitamins, minerals and other components. FERMENTATION When the yeast cells have increased many times, the fermentation stage begins. The flasks are emptied into sterilized fermentation tanks. The tanks contain more wort, which causes the yeast to continue to multiply. As the yeast cells continue to grow, they are transferred to increasingly larger tanks. The final tank can be as high as a multi-story building, with a capacity of up to 60,000 gallons. By the time the yeast is ready to be harvested, it will have grown into tons of yeast, multiplying 5-8 times...over 3 generations! SEPARATION Once fermentation is complete, the yeast is repeatedly washed and then separated from the growth nutrients through centrifugation. The result is a creamy suspension of pure, active yeast. From here on in, various manufacturing processes take place, depending on how the yeast is to be used.