Real-Time Performance Measurement Improves Operations of Sasol

Real-Time Performance Measurement

Improves Operations of Sasol Plants

Sasol ( originally called the South African Coal, Oil & Gas Corporation or the Suid

Afrikaanse Steenkool, Olie en Gas Korporasie ) is a South African company involved in mining, energy, chemicals and synthetic fuels. The company is best known for producing petroleum and diesel fuel from coal and natural gas using Fischer-Tropsch synthesis. Chemical products produced by the firm include polymers, solvents, olefins, surfactants, waxes, phenolics, and nitrogenous products. The company also produces crude oil off the coast of

Gabon, refines imported crude into liquid fuels and retails liquid fuels and lubricants. Sasol’s Infrachem Utilities and Syngas division produces electricity, demineralized water, and steam used in production processes for both internal and external customers.

The Invensys Business Performance Services consulting team worked with personnel from the Sasol One Site in Sasolburg, South Africa, to develop real-time performance measurements at its Steam Plants 1 and 2. Dynamic performance measures (DPMs) were developed to provide underlying realtime performance measures of each production unit in the steam plants.

Real-time financial metrics were also created to calculate cost and profit for each process unit and area. Management and operator dashboards were created which utilize DPMs and real-time financial data to provide business management with critical business information in real-time to enable better, more informed business decisions.

Early results indicate that the plant is exceeding the projected bottom line benefit results of $400,000 (US) dollars per year in savings from just these two relatively small plants. The team from Sasol, Invensys, and EOH are currently in the process of rolling out the real-time performance measures to five other plants in the same division.

Figure 1 provides an overview of the value stream in this division. The water used in the process is drawn from the Vaal River, treated in the Demin plant, mixed with A&B grade condensate recovered from the plants, and used to produce steam in Steam Station 1, Steam Station 2, and the automatic thermal reformer (ATR) area. This steam is supplied to approximately 20 internal and external customers.

Steam Stations 1 and 2

The initial focus of the real-time measurement project has been Steam

Station 1 and 2. These stations had been operating well below capacity due to a reduction in steam demand from its customer base. In 2004, Sasol began importing significant quantities of natural gas from Mozambique, which replaced coal that had previously been used in synthetic fuel production and in turn reduced the need for steam used in coal reformation. The reduction in steam demand changed the focus of production strategy at these units from maximizing production to minimizing cost.

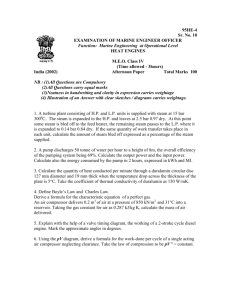

Figure 1: Flow Diagram of Steam Station 1.

Steam Stations 1 and 2 consist of multiple boilers serving a single header.

The demand from Infrachem’s customer base is provided by ATR steam as the base load and swing demand is made up by Steam Stations 1 and 2.

Steam is sold to internal and external customers at a market price which is based on an internal algorithm that approximates a fair market price at current conditions. The steam stations are also contractually obligated to run with a 160 tons per hour amount of spare steam. This is approximately equal to the steam output from one boiler. If the plants cannot meet demand, the electrical generation customers are first reduced because they can buy electricity off the grid instead of generating. However, excessive power usage from the grid can create huge costs.

Steam Station 1 supplies steam at 425-430 o C at 41-42 bar while attempting to maintain a constant steam delivery. Steam Station 2 supplies steam at

450 o C at 40.2-40.2 bar and acts as the swing plant to handle load variances.

The variance is manually controlled. A boiler can be run with either two or three mills feeding coal into it. When two mills are feeding coal, steam capacity is between 80 and 110 tons per hour and when the boiler is fed with three mills the steam capacity is between 110 and 145 tons per hour. The coal feed rates are controlled to maintain the desired steam delivery levels.

Boiler efficiency is defined as the heat transferred to steam divided by the heating value of the fuel. Generally, boiler efficiency is a function of the heat transfer efficiency, which is associated with stack temperature, and the combustion efficiency, which is associated with excess air, as well as other factors. Other variable cost factors include demineralized water and electricity. Since many of the boiler operations are manual, helping operators better understand the overall boiler economics as they relate to operations and strategy has the potential to improve business performance.

Automation and IT Systems

Sasol has made a significant investment in its automation and IT infrastructure. Each of the two steam stations has a dedicated Distributed

Control System (DCS) for control, historization and graphical interface. At the start of the project, neither DCS was heavily loaded. This excess computing capacity in each DCS provided an opportunity to host applications beyond basic process control; in this case, as model implementation and execution host for real-time performance measurements and business intelligence feedback.

The historian server collects critical data for each DCS as well as other production layer systems. Most connections between the DCS and IT layer are through bi-directional communications. Process data moves from the

DCS to the historian server and manipulated data moves back from the historian server to the DCS to be displayed.

Intrachem utilizes SAP R/3 as the main backbone for measuring business performance. The SAP Sales and Distribution (SD), Materials Management

(MM), and Production Planning (PP) modules are used to coordinate sales and distribution, maintenance management and production planning. These

SAP components then provide inputs to the production costing system and monthly management reporting systems. Production volumes are taken from

SAP and used to derive variable costs from the SAP Plant Maintenance

(PM) module. Allocated costs contained in the SAP Controlling (CO) module are also used in the overall costing pictures for each product.

Monthly reporting of financial data provides an overall picture of the steam generation business and the entire Infrachem Syngas, steam and utilities businesses. Reports are generated using Hyperion Financial Management

(HFM) reporting capabilities utilizing key financial data from various spreadsheet sources. Managerial, operations and maintenance reporting utilizes inputs from the ODS system, SAP and other manually entered sources to provide custom reports to meet current requirements. Production supervisors use reports on a daily basis to review the previous day’s production performance.

Real-time Performance Measurement at Sasol

Sasol Intrachem management first became interested in real-time performance measurement after attending a presentation by Business

Performance Services consultants from Invensys. The steam plant was facing cost pressures due to reduced demand in a commodity-based business and was interested in opportunities to reduce costs by introducing new technologies. Sasol’s Information Management Group is charged with investigating and bringing in new technologies that can drive business value for the company.

Invensys has developed a methodology that has yielded measurable economic performance improvements for customers. This methodology is a structured and repeatable process that involves the deployment of a business performance service team to work with the customer’s plant personnel. The key deliverable is a real-time performance measurement system aligned with the manufacturing strategy and accounting system. It provides consistent and accurate real time measurements of plant performance that drive maximum economic business value from plant assets. Steam Plants 1 and 2 were chosen as pilot sites for the project because they faced enormous cost pressures and they provided a manageable and self-contained section to start the process.

Figure 2: DPM Process.

The Invensys Business Performance Services consulting team conducted a plant operation and strategy audit during the week of June 19, 2006. During the visit, Invensys interviewed Sasol management and plant team members from all aspects of plant operations, ranging from plant management to control room operators. Invensys’s structured methodology was used to determine the correct measures of performance and decompose the key plant performance measures into lower-level functional entities that are small enough that they can be managed effectively. The component solutions were then recombined into an overall structure.

This method, called Vollman decomposition (based on the work of business professor, Thomas Vollman), enables the identification of performance measures for each function, process and activity in the organization that are

derived from corporate strategic performance measures. Every function and person can be measured according to their contribution to the business plan.

For performance measures to be effective in process manufacturing operations, they must be generated in the same timeframe as the manufacturing process. If the performance measures are not available until after the decision has been made, it is difficult to have a positive impact on performance.

Development of DPMs

The measurement process helped to reconcile differences in the way that engineering and accounting were measuring raw materials consumption. For example, the production side was basing coal consumption on mechanical devices that measure coal based on the number of revolutions made by a wheel flow meter. The accounting side, on the other hand, based its measurements on weighing devices at the mine and silo measurements. The coal measurement was significantly different between these two measurement systems. Reconciliation was required to arrive at a working solution. The process also helped identify a water source whose cost had previously been incorrectly allocated.

DPMs were modeled in the DCS and developed for each individual boiler, steam station, and for steam generation in general. Three station-level DPMs were developed: steam cost, steam quality and production rate. The objectives of each boiler are to produce the lowest cost steam at the proper pressure and temperature specifications, maintain reliable production, and maintain production rates. For each boiler, the variable steam generating cost including labor consists of four major components: coal, electricity, fuel oil and water. On a per ton of steam basis, the total variable cost can be calculated as follows:

Total Cost/Ton Steam = (Coal Cost + Electricity Cost + Fuel Oil Cost +

Water Cost)/Tons of Steam produced

Steam quality is measured in temperature and pressure. These values are measured from piping to header. Production rate is measured in tons per hour. The plant-level DPMs include aggregate steam cost, contribution margin (customer revenue less variable costs), steam quality, and production rate.

Real-time Accounting Metrics

Real-time accounting metrics were also developed to enable management to understand plant business performance in a timely manner. This involves measuring the economics of the operation in real time and making them visible to both operations and financial personnel.

Unit-level operations are based on the individual boilers. Coal, the main cost driver, is consumed along with water, electricity and occasionally fuel oil.

Cost related metrics were developed for each boiler. This data was used for management portal applications and exported to SAP and ValuMax financial applications.

The coal feed rate for each boiler is estimated using the Coal Feed VFD

Speed.

CoalCost

Rands / hour

Rands

TonofCoal

CoalFeed

tons / hour

CoalFeed

tons / hour

17 .

3

CoalFeeder Speed

The cost of electricity is calculated by summing the consumption of the coal mill, ID fan, FD fan, and precipitator (something on what these are) of the three boilers in steam Station 1 and the two boilers in Steam Station 2.

Electricit yCost

IDFan

A , B , C

CoalMill

A , B , C

CoalMill

( Rand

( Rand /

/

IDFans kWh )

PF

FDFan

A , B , C

Precipitat

CoalMill

or

Amps kWh )

PF

1 , 2

(

IDFan

Amps

CoalMill

Voltage

IDFan

Voltage

)

FDFan

A ,

Precipitat or

B

, C

(

( Rand

Rand /

/ kWh ) kWh )

PF

PF

1 , 2

FDFan

Amps

(Pr

FDFan

Voltage

ecipitator

Amps

Pr

ecipitator

Voltage

)

Fuel oil is used as a supplemental energy source in the boiler. The cost is calculated as follows:

FuelOilCos t

Rand / h

Rand

/

m

3

FuelOil

FuelOilFlo w

3 m / h

Water cost is calculated as follows:

WaterCost

Rand / h

Rand

/

m

3

De min W ater

WaterFlow

3 m / h

After the real-time performance measures were established, they were used to provide all layers of the organization with critical business intelligence in a context in which they contribute to improved decisions and provide immediate feedback on how these actions impact strategic and operational metrics.

Figure 3: Typical Dashboard Used by Sasol.

Management dashboards that utilize DPM and real-time financial data provide business management with critical information in real-time to enable better, more informed decisions. Contribution margin is a very important tool used in business management of manufacturing operations, especially when sales price is controlled by the manufacturer and different sales prices are paid by different customers. This metric provides the operational business layer with a business picture of much of its domain of control. The dashboard measures contribution margin for the entire steam operation and on a per-customer basis. (Note: In the end, we did not include this margin).

20

1

CustomerRe venue

VariableCo st

Contributi onMargin

There are two control room process controllers as well as outside SPCs and supervisory personnel. Control room operators typically run one or more boilers at once. The steam stations each have a DCS. However, these DCSs

are not connected together for control room or operational purposes, so the dashboards cannot be readily shared between the two steam stations. But performance data can be shared and compiled through the centralized history server structure provided by the ODS (Operation Data Store) system.

Maintenance and Human Resources Metrics

Steam Stations are contemplating at present the rolling out a maintenance initiative which is designed to improve the availability of key assets by avoiding emergency shutdowns. This was accomplished by improving planning, increasing the predictive-reactive maintenance ratio, setting proper priorities for maintenance activities, and reducing cost. Real-time performance measurements in the maintenance area focus on:

Reactive-predictive maintenance ratio

Availability of each boiler

Reaction time on emergency maintenance which is the time from when the breakdown occurred to when the repair is completed and the equipment is back in operation

Maintenance schedule deviations which are important for improving the maintenance planning process

Implementing the DPMs

DPM algorithms, real-time financial models, and unit levels were implemented in the DCS. Cost factors in the plant floor can now be tracked on a real-time basis through the existing plant-level assets. The execution of algorithms typically takes place in the microprocessors in the DCS where control algorithms are executed. These algorithms are executed at a frequency that is near to the cycle time of the process and the historical collection is performed at a similar frequency. The unit level metrics are then aggregated at the station and plant levels using the historian.

Totalization can be performed at various periods including shift, day, and month.

Figure 4: Real-time Financial Information Flows through to SAP.

Real-time financial data plus allocated costs tracked by the ValuMax activity based costing system provide a real-time picture of product costs across the portfolio. The same real-time financial data can also be eventually integrated into SAP’s Financial (FI) and CO models as the fidelity and applicability of these data is better understood. The figure below provides a general overview of the real-time business intelligence/finance system for Steam

Stations 1 and 2. DPMs and real-time finance (RTA) models were developed and process in the existing automation system.

Figure 5: Real-time Business Intelligence/Financial System.

Developing a Baseline

Once the metrics were installed, they were historicized to provide a performance profile of each unit, station, etc. under various operating conditions. These baselines enable economic comparison of boilers under various conditions. Improvement initiatives and projects and operational improvements through improved procedures and training can be financially tracked and validated. Baselining also enables development of data for financial and accounting validation.

One of the key opportunities for improved results lies in training the operators to think and act strategically. Dashboards provide operators clear and simple feedback as to individual impact on Sasol’s business performance. Integrating this way of thinking is helping to improve Sasol’s business and build the knowledge and skill base of its operators. Providing operators with a tool that provides feedback as to which boiler produces the least expensive incremental steam enhances performance of each steam station.

For example, operators can make spare and spinning steam decisions based on economic information. Spinning is the available spare steam capacity when the feed rate on an idle mill is increased. Spare steam is the amount of

potential steam available by starting the third mill of a boiler running on just two mills. Operators increase steam output on an instantaneous or immediate basis based on demand changes.

Future Improvements Planned

The various stakeholders provide such widely varied needs that the current infrastructure needs to be expanded to meet the changing and sometimes irregular nature of these needs. Standards such as the ISA-95 plant-toenterprise standard formalize the concepts and interfaces for integrating business systems with production systems. The DPMs and RTF/BI dashboards can be scaled to cover more aspects of the business and custom business applications can be developed more easily within a standards-based environment. The most notable players in this arena are SAP’s xApp for

Manufacturing Integration and Intelligence (xMIII) and Invensys’ ArchestrA plant-level SOA (services oriented architecture). These systems will in the future enable Sasol to map and model its plant information to intelligent plant and business models that not only integrate well with SAP but can meet the varying demands from different levels in the organization.

Divisional management currently has approved expansion in to other plants in the location. The DPMs, real-time financials, and dashboards have only been in place a short time but they have already had a significant impact.

Feedback from managers, engineers and operators is that substantial improvements have been achieved. Operators can see the impact of their actions almost immediately so they are making decisions that make things run better and smoother. For example, a substantial reduction has already been seen in the air flow variability in the burners. Reducing airflow variability reduces coal consumption since too much airflow remove heat from the boiler out the stack and too little airflow results in incomplete combustion. The dashboards also enable engineers to quickly determine the impact of a new control strategy or equipment change.

Benefits

This project provided numerous benefits for Sasol. As the division looks to continue to improve its business and drive business value for the company, it looks to bring in new product technologies and process technologies that can help them achieve this. Sasol Infrachem management views development of its people as one of the company’s most critical tasks. The importance of skills and knowledge development is underscored by government regulations and key personnel nearing retirement.

The DPM methodology, by the nature of the process, brings together different functional areas such as accounting, engineering, management, operations, and maintenance to discuss the overall business. This type of interaction creates understanding across business functions, enables proper strategic performance measures to be developed across functions, and helps create new and valuable business processes aimed at improving the bottom line.

The benefits of this project are clearly positive for Sasol. First month results indicate a 6% savings on energy feedstocks and 4% savings on electricity costs for making steam in Steam Stations 1 and 2 and progressively improved throughout the second and third months. These savings are due to more consistent operation from a business perspective in regards to fuel oil usage and overall tuning of the boilers to run more cost effectively. This equates to approximately $230k savings in the first month. Annualized direct benefits of this project is expected to be about 2% reduction in variable costs associated with energy feedstocks and electricity costs. Some of the next steps include bringing the new business information together with process data to identify other areas of improvement through advanced multivariate statistical analysis, continuous improvement programs such as Six Sigma, and other business value-adding activities.