Bibliography - School of Information

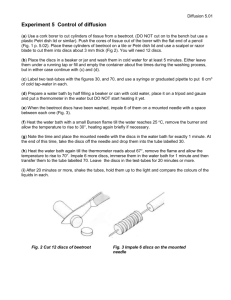

advertisement

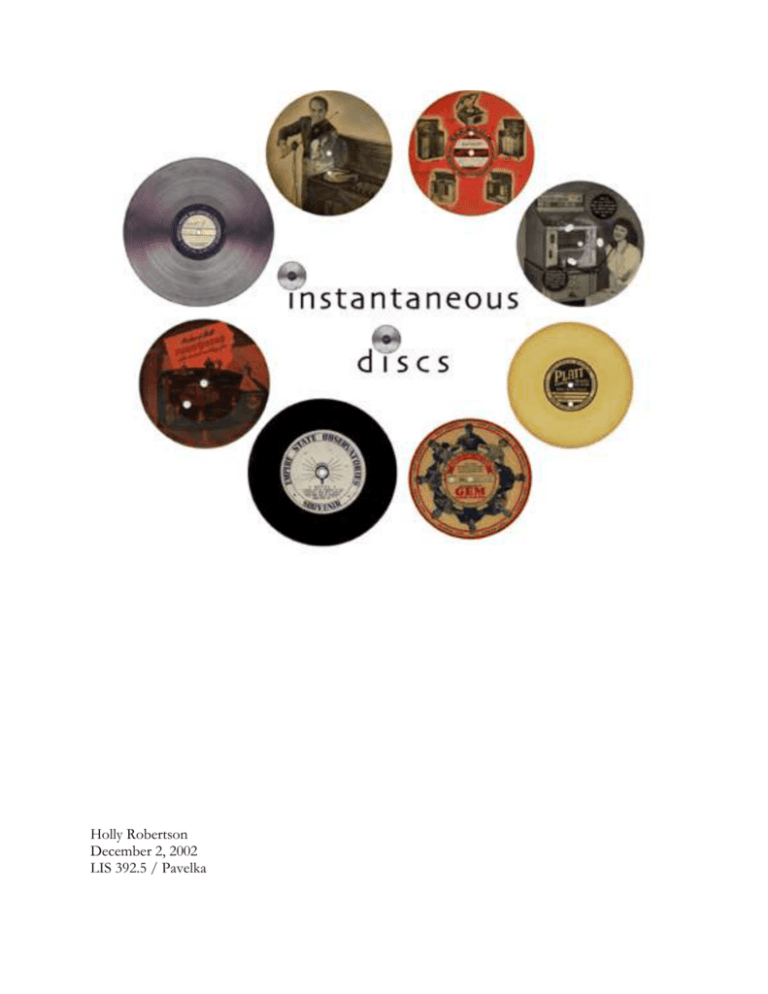

Holly Robertson December 2, 2002 LIS 392.5 / Pavelka History of the Invention, Manufacture, and Use of Instantaneous Discs Between the soaring popularity of recorded sound on the disc of the early twentieth century and the high-fidelity recording capabilities of magnetic tape achieved after World War II lies the brief but enthusiastic niche of the instantaneous disc. Developed in the 1930s and used well into the late 1940s and 1950s as an inexpensive and accessible method of recording, the instantaneous disc was different from commercially distributed records. The instantaneous disc – sometimes called lacquers, acetates (quite erroneously, according to Peter Copeland1), transcription discs, old time radio (OTR) recordings, Insta-discs, dubs, or reference recordings – was a “compromise of ease of engraving and playback life,” composed of softer materials than mass produced phonographs and thus more fragile and susceptible to the hazards of playback. Created using a special turntable either acoustically or magnetically, instantaneous discs created immediately available recordings that were unique, consumer-initiated sonic time capsules of a period in which media innovations were broadening and linking the world in a way quite similar to present day computer technology and the internet. Instantaneous discs appeared at the crossroads of cylinder and disc technology in sound recordings. Cylinders, the earliest form of sound recording and playback, were known as phonographs (only in the United States are flat discs now acceptably called such). Invented in 1877, Thomas Edison’s cylinder recorded sound in a spiral groove around the curved outer space of a hollow cylinder covered in tin foil. Alexander Graham Bell introduced a competitive update on the Edison cylinder in 1885, employing a wax cardboard cylinder instead of tin foil which offered improved sound quality and a more durable recording material. Cylinders were available for commercial sale by 1890, but as they could not be mass produced (each cylinder had to be recorded 1 Copeland defines acetates as “a term applied universally, but incorrectly , to a type of disc record in which the surface comprises cellulose nitrate lacquer, or occasionally gelatine, on a metal or glass base. . . [These discs] became the ideal instantaneous sound recordings medium for the next forty years, after which audio cassettes occupied their niche” (77). individually, with banks of machines recording in sessions), inventors continued searching for a viable medium for mass-producible sound.2 Emile Berliner in 1887 introduced discs on which the recording spiraled in grooves on a flat surface. These discs were created using a lateral cut or the impressing of mono-sound waves into a groove cut by a stylus that vibrates from side to side as dictated by the sound waves of the recording. The stylus follows the same such path upon playback, following the groove and the sideto-side cuts which create the playback sound wave. The earliest discs were lampblack covered surfaces, but Berliner soon employed grease coated zinc discs which, after recording, could be dipped in acid and the etching or sound recording could be transferred to other metal discs, creating a stamping plate to press recordings for mass manufacture. This sort of process mimics the intaglio process used in printing where a plate with incised lines and textures created by cuts, scratching, or etching with acid into the surface that hold ink for transfer to paper. Vulcanite (vulcanized rubber) was employed in the early days of disc manufacture as well, but its tendency to flatten and lose the sound recorded grooves proved it unacceptable.3 Shellac, made from the secretions of the lac insect combined with fillers, pigments, lubricants, binders, and modifiers, was introduced in 18974. Hard wax discs were introduced in 1900, and in the meantime Edison was still developing cylinder technology, introducing his own hard wax cylinders in 1903.5 Discs were winning the popularity contest, however, not only due to their higher sound fidelity but also their ease of use and of recording as well as the fact that disc manufacturers were more adept at promoting their product and popular music was predominantly recorded on disc. Laminated discs, or discs coated with the shellac compound but with a base of heavy paper or cardboard, were introduced by Columbia McWilliams, 4-5. McWilliams, 6. 4 Copeland, 79; McWilliams 5-6. 5 McWilliams, 7. 2 3 Records in 1906.6 Cheaper and yet of higher sound quality than their predecessors, laminate discs were more economical to produce because the paper base meant utilizing less shellac, and better shellac was used since it was not needed in such high quantities. Suddenly, improvements in sound recording materials came to a near halt as interests turned to the new entertainment medium of radio and the improvement of the sound recording process from an acoustic to amplified electromagnetic process. By 1929, Edison had given up on cylinders as a medium for sound recording, and shellac coated discs would remain the format for mass produced records.7 Peter Copeland, Conservation Manager and sound engineer at the British Library Sound Archive, credits the invention of the instantaneous disc to Cecil Watts, who in 1934 discovered that discs with a surface coating of cellulose nitrate (or nitrocellulose) were soft enough to allow grooves to be cut yet sturdy enough to allow a few playbacks on common record players.8 Although it is arguable that instantaneous disc recordings were available throughout the advancing material history of the sound recording disc, it seems that the specific manufacture of instantaneous discs and the devices on which to record these discs for wide-spread use begins in 1934 with the cellulose nitrate laminate disc. Materials in use prior to cellulose nitrate include laminated discs coated with soft wax, ethyl cellulose, and cellulose acetate, as well as discs solely composed of soft metals such as aluminum or zinc. Cellulose nitrate, while certainly not a champion of stability, is however much more durable and has better playback sound quality than its soft wax or ethyl cellulose counterparts, which may be part of the reason that instantaneous discs are widely understood to be composed of only that material. Also, very few aluminum or other soft metal discs are still in existence; Elizabeth McLeod, documentarian of early radio, notes that during the scrap drives of World War II, citizens were urged to turn in as much aluminum as they could for recycling. Thousands of unique 6 McWilliams, 8. McWilliams, 10-11. 8 Copeland, 76. 7 recordings were lost when “patriotic performers could see no reason to hold onto ten years of old broadcasts when there was a war to be won.”9 Instantaneous discs were used for an incalculable variety of recordings. Radio stations were the most fervent users of the discs; by 1936, many stations had the equipment to produce their own instantaneous discs. NBC was among the first station to purchase such a machine and on January 1, 1936 announced its Reference Recording division to engineer recordings.10 CBS acquired equipment in September 1938 and ABC soon thereafter. Bing Crosby, later a catalyst for the invention of sound recordings on magnetic tape, was based at ABC which used the technology of instantaneous discs to edit and mix sound recordings. Radio dramas, soap operas, and newscasts were prerecorded on the discs for later playback (these were also known as “time-shifted” recordings) as were ads and on-air checks. One of the most famous recordings on instantaneous discs was created by reporter Herb Morrison and audio engineer Charlie Nelson for NBC in May of 1937. Invited to record interviews of passengers embarking the luxury hotel airship Hindenburg, Morrison and Nelson instead captured the Hindenburg disaster. According to early radio expert Michael Biel who examined the instantaneous discs recorded at the Lakehurst site: You can see several deep digs in the lacquer before the groove disappears. Then almost immediately there is a faint groove for about two revolutions while Charlie Nelsen gently lowered the cutting head back to the disc [after the explosion]. Fortunately the cutting stylus never cut through the lacquer to the aluminum base. If that had happened the most dramatic part of the recording would not have been made because the stylus would have been ruined. The digs and bouncing off of the cutting head were caused by the shock wave of the explosion which reached the machine just after Morrison said, “It burst into flame . . .”11 McLeod, http://www.midcoast.com/~lizmcl/earlyradio.html. McLeod notes in a post to the Old Time Radio listserve (September 27, 2000) that “during WW2, and again during the Korean War, there were companies that specialized in boiling the lacquer off used instantaneous discs so as to reclaim the aluminum platters -- usually paying a few cents per pound for such scrap recordings, and most stations rushed to take advantage of these deals since otherwise the discs would be thrown away, given to curious kids, used as oversized skeet-shooting targets, or just tossed into the basement to rot.” Available online at http://members.aol.com/jeff99500/am11.html 10 Beil (June 17, 1997), http://members.aol.com/jeff570/am2.html 11 Beil (May 6, 1997), http://members.aol.com/jeff1070/hindenburg.html 9 Beyond radio, instantaneous discs were used to record events such as speeches, conference proceedings, and political rallies and debates. Ethnologists used instantaneous disc recording to chronicle oral histories and folk songs which were gaining momentum in popular music. The American Folklife Center and the Special Collections at the Library of Congress houses many collections primarily composed of instantaneous disc holdings created in the 1930s and 1940s, including: “Voices from the Dustbowl: The Charles L. Todd and Robert Sonkin Migrant Worker Collection,”12 “The WPA California Folk Music Project,”13 and “The Frank C. Brown Collection of Field Recordings of North Carolina Folk Music, late 1910s to early 1940s.”14 Consumers used the discs to make personal recordings in the style of today’s do-it-yourself home studios, capturing everything from songs to audio greeting cards in the grooves of cellulose nitrate. Recording studios for instantaneous discs appeared in 1932 while use of aluminum and other soft metal discs dominated the instantaneous market. Charging up to $14 to record a half hour show on eight sides of four 12” uncoated aluminum discs, these studios were not intended for noncommercial use as the average weekly wage at the time was less than $28 per week.15 Speak-OPhone Recording Studio was originally based in Manhattan but soon opened branches in major cities including Chicago, Boston, and Los Angeles. Another large New York based company was Broadcast Producers, Incorporated. Los Angeles was served by 1932 by Bert Gottschalk's ElectroVox Recording Studio in Hollywood --a company finally closed in early 2000, after nearly seven decades in business. 16 Presto Recording Corporation -- originally Presto Products Company established in 1915 as a manufacturer Sonora phonograph and other equipment such as a three American Memory Project, Library of Congress, http://memory.loc.gov/ammem/dli2/techsumm/atoddtech.html American Memory Project, Library of Congress, http://memory.loc.gov/ammem/dli2/techsumm/acowtech.html 14 Special Collection, Library of Congress, http://www.loc.gov/spcoll/036.html 15 McLeod (October 17, 2000), http://members.aol.com/jeff99500/am11.html 16McLeod briefly narrates the early histories of instantaneous disc manufacturers and studios in her online Documenting Early Radio: A Review of Existing Pre-1932 Radio Recordings available online at http://www.midcoast.com/~lizmcl/earlyradio.html. Unfortunately, not much has been written about for manufacturers of instantaneous discs for non-commercial / consumer use. 12 13 pound head for embossing on aluminum blanks -- reorganized in 1933 and one year later announced in the Fall of 1934 the U.S. premiere of the instantaneous disc as it would be popularly known (similar companies announced simultaneous inventions in England and France). The “Presto Disc” was an aluminum plate coated with a cellulose nitrate lacquer. Although the dramatic difference in superior recording quality over the previously used aluminum blanks was immediately obvious, the U.S. Patent office nonetheless denied Presto patent rights as lacquer blanks were nothing new . Recording on pre-grooved blanks, embossing on aluminum blanks, and coating aluminum with various substances were all widespread industry practices, yet the combination of a recordable lacquered disc with pre-grooved blank and an aluminum base was Presto’s contribution. Since their innovation was unpatenable, other companies quickly initiated manufacture of cellulose nitrate blanks soon after the introduction of the Presto disc.17 McLeod, researching the prices of blank instantaneous discs, was able to find figures from the mid 1940s: a company popular after World War II, Audiodisc, produced red label blanks that were $3.40 each for 16” discs, $1.85 each for 12” discs, and $1.10 each for 10” discs; Presto produced less expensive 16” discs “Green Seal type” for $3.25 each – which were actually of better quality “from a preservationist’s perspective.” 18 Eventually, the recordable instantaneous disc was superseded by magnetic tape technology, first on audio reels and later with audiocassettes. Magnetic tape was cheaper to produce – both in terms of manufacturing and recording costs – and produced a higher sound fidelity than the roughly cut discs. Magnetic tape could be reused, and the recording and playback machines were cheaper to produce, and thus available to most consumers. Information about Presto Recording Corporation was obtained from Alan C. Graves, audio enthusiast and currently in business cutting instantaneous discs at his studio “The Cutting Lathe,” who maintains a webpage chronicling the history of Presto records and featuring several of their brochures at http://www.televar.com/grshome/Presto.htm 18 McLeod (October 17, 2000), http://members.aol.com/jeff99500/am11.html 17 The Material Structure of Instantaneous Discs “Almost without exception, the design of a new material or type of sound recordings has been based on . . . fidelity of reproduction of sound , playback durability . . . and economy of manufacture alone”19 As earlier mentioned, instantaneous discs are made from a variety of materials with the popular consumer version a cellulose nitrate laminated disc with a base material or either metal, glass, or cardboard. This examination of the material structure of instantaneous discs will focus on the cellulose nitrate, also known as nitrocellulose or celluloid, is one of the oldest known plastics. Introduced at the Great Exhibition in London in 1862, it did not become a common material until the mid 1870s.20 The mere mention of cellulose nitrate immediately sounds fire alarms in most archivesas it is the infamous and often disastrous base material of early motion picture film that is prone to burning explosively. As cellulose nitrate decomposes via hydrolytic, thermal and photooxidative means, the molecules undergo chain scission and nitrogen peroxide is produced which is converted to nitrous or nitric acid in liquid water. In the presence of acid, the degradation process becomes an autocatalytic reaction, and explosive. Motion picture films with a cellulose nitrate base are plasticized using camphor whereas the cellulose nitrate coating on instantaneous discs utilizes castor oil as a plasticizer. The camphor in cellulose nitrate motion picture films is not a cause of its instability; although the camphor is “tenaciously retained” by the cellulose nitrate in its solvent plasticizer form, the degradation of the cellulose nitrate itself causes failure while sufficient amounts of camphor remain in the film.21 On the other hand, while the cellulose nitrate of instantaneous discs is much more stable and less dangerous than its motion picture film counterpart due to its use of less nitrated materials extended with inert fillers. The castor oil plasticizer, however, is the main cause of instantaneous disc degradation. 19 Pickett and Lemcoe, 11. Blank, 58. 21 Pickett and Lemcoe, 15. 20 Cellulose nitrate alone is very tough and brittle and inappropriate for use as a coating or engraving surface for instantaneous discs. Castor oil acts as a softener, and is introduced to the cellulose nitrate as external plasticizer that does not chemically combine with the cellulose nitrate (camphor, a solvent, does, and thus is better retained). As castor oil plasticizer is lost from the disc, the cellulose nitrate shrinks. Bonded to the core (the base material of metal, glass, or cardboard), the cellulose nitrate cannot withstand the internal shrinkage stress and instead cracks and peels. According to A. G. Pickett and M. M. Lemcoe, mechanical engineers who in 1959 conducted to this day unparalleled tests on the degradation of instantaneous recordings for the Library of Congress, castor oil can be lost in a number of ways:22 it can degrade to form volatile compounds it can be consumed by fungi it can exude and diffuse from the material without chemical change [resulting in an oily deposit on the surface of discs] it can be extracted by water it can be forced out of the interstices by the action of the attractive forces between nitrocellulose molecules and molecular thermal action which tend to bring the cellulose nitrate molecules closer together [evidenced by the condensing of castor oil molecules into discrete droplets in the plastic which looks like “pores” in the disc surface]. The loss of castor oil and the deterioration of the cellulose nitrate occur simultaneously and in fact may catalyze one another in a vicious cycle of self perpetuated disc destruction. Again, according to Pickett and Lemcoe, “the oxidation products of the degradation of castor oil may catalyze denitration of cellulose nitrate . . . [while] the loss in strength occasioned by chain scission may hasten failure occasioned by stresses induced by plasticizer loss.”23 This perpetuated cycle may be prompted by environmental conditions such as elevated temperature and correspondent increased air moisture as well as atmospheric contaminants such as excess oxygen and dust. 22 23 Pickett and Lemcoe, 16. Pickett and Lemcoe, 16. Fillers used in cellulose nitrate are very difficult to discuss in terms of their function in the instability of the instantaneous disc because of the diversity of materials utilized. Generally, the role of the filler is above all economical; to extend expensive compounds such as shellac, vinyl, or cellulose nitrate, fillers such as limestone, clay, cellulosic by-product flours, plant fibres, and carbon blank were added to the mixture. Extenders were another additive utilized in the creation of the cellulose nitrate coating to extend the economy of or represent a component that exists to decrease the cost of using the cellulose nitrate. Organic materials, extenders were usually natural waxes or resin by-products from the manufacture of paper from wood or plant fibres.24 Other resins that are often added to cellulose nitrate plastics – not necessarily attributed to use in the creation of instantaneous discs, but exact formulas are difficult to locate – to promote depth, gloss, and adhesion include alkyd resins, shellac, dammar, maleic anhydride resins, and synthetics such as urea, melamine formaldehyde condensates, polyacrylates, epoxy resins, and polyvinyl acetate.25 Much of the material used in the composition of the cellulose nitrate coating went towards creating a soft surface easily engraved by the cutting stylus of instantaneous disc recorders at the expense of repeated playback and material stability. The use of base materials in instantaneous discs is based even more on the cheapest functional materials available. Metal discs, usually aluminum or zinc or other soft, malleable metals, were used as instantaneous discs prior to the development of the cellulose nitrate coating. As a base material or as the main component of the disc, the metal in instantaneous discs will oxidatively degrade, or rust. In cellulose nitrate coated metal discs, the rust will eat through the coating and the oxidative products will promote denitration of the cellulose nitrate. Glass, another base material found in instantaneous disc recordings, is of course inherently fragile. Literature on glass-based instantaneous discs is scarce; the phenomenon of “weeping glass” or moisture leaching out from unstable components may assist in the overall instability of the 24 25 Pickett and Lemcoe, 16. Selwitz, 50-51. cellulose nitrate and other components; this moisture produces an alkaline solution which cracks the glasses and certainly does not assist the chemically stability of the cellulose nitrate and fillers. Cardboard is another material found in the base of instantaneous discs; most cardboard is composed of mechanical groundwood pulp which is highly acidic, which in turn catalyzes the denitration of cellulose nitrate. Preservation Issues: The Care, Storage, and Handling of Instantaneous Discs “[We] did not intend to have an adventure, and at times the staff would have chosen other terms to describe the experience. Nightmare, for example, comes to mind, and the staff members occasionally felt like victims of an archival curse.”26 Alongside cylinder recordings, instantaneous discs are some of the least stable sound recordings found in archives. Although most instantaneous discs were prepared to replicate the look and playback style and speed of commercially pressed records, there are several characteristics which will allow archivists and collectors to easily identify instantaneous discs. Recordings of speeches and conferences as well as discs made by radio stations are usually 16 inches in diameter – the larger sized record allowed for a longer recording / playing time at variable RPMs. These oversized discs are also known as transcription discs and require special turntables with long playing arms for playback. Most instantaneous discs, however, are the standard 10 or 12 inch diameter and are recorded at 78 RPM. Disc labels are also a clue; beyond checking for manufacturers such as Speak-O-Phone, Presto, or Phon-O-Cord, instantaneous discs had blanks to write in title and artist information or at times were simply blank white labels with hand-typed or handwritten information. Often, instantaneous discs had more than one hole for spindles in the special recording lathe that were employed to keep the record flat and rotating as the heavy stylus head cut the groove and created the sound recording. Finally, instantaneous discs often feel hollow, indicating an aluminum Paton, commenting on the adventure of pursuing proper care, storage, and transfer recordings for instantaneous discs in the Special Collections Department at Georgia State University (11). 26 or cardboard base material, or contrarily if they are quite heavy, the base material is often glass. Discs that are simply metal are usually instantaneous discs; however, some metal discs were mass pressed for commercial distribution. Two final complications not necessarily unique to instantaneous records but nonetheless often found are discs that have only one side of recorded information (grooves) or recordings that were made from the inside of the record out to the perimeter. These too require special playback machines. Playback can be an activity of destruction for an instantaneous disc. The needle or stylus used for cutting the disc was often steel , and the stylus was weighted down by a heavy head (which applies the “tracking force”) to make a deep groove in the cellulose nitrate. Playing instantaneous records requires an altogether different setup, one that is not found on what remains of consumer level record players. A soft, unabrasive needle with a very light tracking force is required, and these are sometimes made out of wood, paper, or bamboo. Even with the best playback equipment, instantaneous discs will not withstand repeated playback; the soft nature of the plasticized cellulose nitrate will not maintain the groove, and eventually the sound recording will be lost. The estimated number of playbacks depends on the quality of components used in the creation of the disc as well as the care and storage afforded to the sound recording; since each recording is most likely a unique piece of information, no archivist or sound engineer will go on record estimating how many spins it takes to destroy an instantaneous disc groove. Estimates fall between “few”27 and “several.” For this reason if not for the precarious stability of cellulose nitrate discussed in the previous section, instantaneous discs should near the top of the list of preservation priorities for sound recordings, and reformatting should be conducted by a responsible professional with appropriate equipment and knowledge of the media. 27 Copeland, 76. Storage of instantaneous discs is a disputed topic. Like most sound recordings, the standard for storing records is along the vertical plane – storing discs horizontally and piled upon one another would flatten the groove as well as unnecessarily applying weight to fragile plastic which might cause scratches, cracks, and even complete breaks. Storing the soft instantaneous discs vertically, some argue, will cause dents in the perimeter of the disc and possible information loss. Instead, instantaneous discs should be stored horizontally with the non-recorded side down of course and in boxes so that shelf space will be conserved while protection of the disc considered. Chris Ann Paton, Popular Music Collection archivist in the Special Collections Department at Georgia State University, writes of successfully storing instantaneous discs vertically, separated by size to prevent warping, and removing damaged or flaking discs to other storage means (most likely horizontal) to prevent further damage. Another point of contention among those who preserve instantaneous disc collections is the storage sleeve. According to McWilliams, instantaneous discs should never be stored in polyethylene liners because, under certain conditions of temperature and humidity, the plastic will bond with the acetate or nitrate and when the disc is removed from the jacket, the acetate or nitrate, adhering to the liner, will be pulled off its aluminum or glass backing and the recording destroyed.”28 Paper liners, on the other hand, cannot offer the complete air-tight chamber that some conservators recommend for instantaneous discs in order to prevent dust, light, air pollutant, and other contaminants from affecting the discs as most manufactured liners have holes for reading discs labels; paper also presents the danger of scratching the discs. The very fragile and easily scratched nature of the discs presents problems in cleaning instantaneous discs. Dirt, which impedes playback, will also abrade if not imbed into the disc with improper cleaning. McWilliams in 1979 suggested the use of Freon TF to remove the greasy dirt 28 McWilliams, 36. found on many instantaneous discs, a method which the Library of Congress employed until recently: Because the residue on [instantaneous discs] is often oil-based, or contaminated with oil, water is ineffective in cleaning them. An organic solvent, that will degrease the records and at the same time have a minimal effect on . . . nitrate coating is necessary. Such a solvent is Freon TF, a non-toxic organohalogen, available from most technical supply houses or from a local Dupont distributor. Instantaneous recordings can be degreased in Freon TF in a manner similar to that used for washing shellacs. Unfortunately, because of the soft surfaces of [instantaneous discs], it is dangerous to rub them directly. Other material can be removed from them by very light wiping with a cotton chamois.29 The greasy layer on the discs was most likely not only accumulated dirt, but components from the cellulose nitrate leaching out from inside the disc. Since the use of Freon TF was found harmful to the environment, sound recording archives such as the Library of Congress have abandoned its use, and are currently searching for other solvents to utilize as cleaners.30 The safest cleaning method is the use of canned air to remove loose surface debris and the very gentle use of a soft cloth to remove any excess dirt. These should be employed prior to playback (one which will hopefully produce an archival record so that the record may forever more rest in peace), and not as a regular maintenance procedure. Another hope exists for instantaneous discs in the recent Japanese invention called the ELP laser turntable. Although not manufactured or widely available in the United States and quite pricy (although prices were recently slashed from the $13,500 to $23,500 range to the $9,000 to $13,000 McWilliams, 39. A September 2002 “News from the Library of Congress” on the Music Library Association website announced, “After Freon solvents became unacceptable for cleaning of audio records because of their environmental impact, this Division undertook a comparison of commercially available cleaning solutions for audio records, and recommended one of them for use. Because of a change in the composition of this product introduced by the manufacturer, it began to grow mold within a few months of storage. The need for a cleaning agent with a generic formula that could be controlled by the Library became evident. A formula for an effective water-based, environmentally friendly cleaning solution that works equally well with acetate, shellac, vinyl records and CD's has been developed and will soon be available on our Website.” Available online at http://www.musiclibraryassoc.org/BCC/BCCHistorical/BCC2002/LC2002.html 29 30 per unit range),31 this turntable employs five laser beams to track the groove in the record instead of a stylus or needle, which are, as mentioned earlier, a source of potential loss of information on instantaneous discs. Although it looks more like a CD player with a tray that opens out of the machine rather than the traditional open-air turntable, this machine can supposedly “compensate for warping, discs of various sizes and speed, certain types of groove damage or variable groove widths” and “even discs that are flaking can be played successfully with this system.”32 Sizes of records are limited, however, from the 7” to 12” range, and the discs must be completely free of dust and dirt to assure quality playback – a feat which is difficult considering the fragile and often sticky nature of the instantaneous discs. Increased awareness about the immediate and special needs of instantaneous discs will bring these formats to the top of preservation priority lists and improvements on ideas such the laser turntable, or the use of image mapping of grooves will allow for more discs to be more easily transferred to newer formats. Discs which are in good condition now should be transferred immediately, lest the unique information contained within be lost as the discs invariably will one day begin to degrade, cracking and shrinking from the base material. As one of the first relics of recorded sound, instantaneous discs are worth preserving even after the recorded sound information has been gleaned from their grooves. Hand written labels, unique and often strange recording methods and patterns, as well as oddities of chemical composition make these discs interesting artifacts of entertainment, scholarship, and history. 31 32 ELP Corporation, accessed online November 28, 2002 at http://www.elpj.com/ Michaels, 16. Bibliography History of the Invention, Manufacture, and Use of Instantaneous Discs Biel, Michael. “Broadcasting History: Various Articles by Michael Biel posted to the Old Time Radio Digest (1997-2002). Accessed online November 1, 2002 at http://members.aol.com/jeff99500/am11.html --. “The Hindenburg Broadcast: Posts by Michael Biel to the Old Time Radio Listserve (19972000). Accessed online November 2, 2002 at http://members.aol.com/jeff1070/hindenburg.html Brady, Erika, 1952- / A Spiral Way : How the Phonograph Changed Ethnography. / Jackson / 1999. (GN 348 B73 1999 PCL - *) Copeland, Peter. Sound Recordings. London: The British Library, 1991. Cumella, M. A. The Internet Museum of Flexi / Cardboard / Oddity Records. Accessed online November 1, 2002 at http://www.wfmu.org/MACrec/ Graves, Alan C. The Presto History Page. Accessed online November 1, 2002 at http://www.televar.com/grshome/Presto.htm McLeod, Elizabeth. “Documenting Early Radio: A Review of Existing Pre-1932 Radio Recordings.” Accessed online November 3, 2002 at http://www.midcoast.com/~lizmcl/earlyradio.html --. “AM Broadcasting: Various Articles by Elizabeth McLeod posted to the Old Time Radio Listserve (2002).” Accessed online November 28, 2002 at http://members.aol.com/jeff99500/am11.html Read, Oliver. “Lateral Disc Recording: The Theory and Practice of the Engraving (Cutting) of Instantaneous Recording Discs with Magnetic and Crystal Cutters.” The Recording and Reproduction of Sound.. Indianapolis, Ind.: H. W. Sams, 1949. Read, Oliver, and Walter L. Welch. 1976. From tin foil to stereo: Evolution of the phonograph. 2d ed. Indianapolis, Ind.: H. W. Sams. Schwartzman, Arnold. Phono-graphics : the visual paraphernalia of the talking machine. San Francisco, CA, 1993 (TS 2301 P3 S39 1993 Fine Arts Library) The Material Structure of Instantaneous Discs Blank, Sharon. 1990. An introduction to plastics and rubbers in collections. Studies in Conservation 35, no. 2:53–63. Cook, Warren. n.d. Paper and plastic. Record Exchanger 3:4; 4:1, 4–5. Pickett, A. G., and M. M. Lemcoe. 1991. Preservation and storage of sound recordings. Washington,D.C.: Library of Congress, 1959. Reprint, Association for Recorded Sound Collections, Associated Audio Archives Committee; Kansas City, Mo.: Lowell. Powell, James R., Jr. 1992. The audiophile's technical guide to 78rpm transcription and microgroove recordings. Portage, Mich.: Gramophone Adventures. Selwitz, Charles. “Cellulose Nitrate in Conservation.” Research in Conservation. Getty Conservation Institute, 1988. Accessed online November 28, 2002 at www.getty.edu/conservation/resources/nitrate.pdf Sutton, Allan. Directory of American Disc Record Brands and Manufacturers, 1891-1943. Greenwood, 1994. (ML 18 S9 1994 Fine Arts Lib Reference) Preservation Issues: The Care, Storage, and Handling of Instantaneous Discs Deutsch, Werner, and Anton Noll. 1986. The restauration of historical sound recordings by means of digital signal processing: Psychoacoustical aspects. Phonographic Bulletin 45:36–9. Gibson, Gerald. 1988. Decay and degradation of disc and cylinder recordings in storage. In Audio preservation: A planning study. Silver Spring, Md.: Association for Recorded Sound Collections,186–99. McWilliams, Jerry. The Preservation and Restoration of Sound Recordings. Nashville: The American Association for State and Local History, 1979. Michaels, Jan. “The Condition Survey of Sound Recordings at the National Lib of Canada: Implications for Conservation.” Saving the twentieth century : the conservation of modern materials : proceedings of a conference Symposium '91: Saving the Twentieth Century. Ottawa: Canadian Conservation Institute, 1993. 13-23. Nicolson, John W. The Chemistry of Polymers. 2nd ed. Cambridge: Royal Society of Chemistry, 1997. Paton, Christopher Ann. 1991. Preservation of acetate disc sound recordings at Georgia State University. Midwestern archivist 16, no. 1: 11–20.1