Practice Problems: Supplement 10 (S10), Work Measurement

advertisement

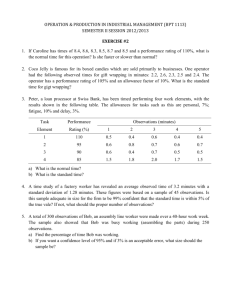

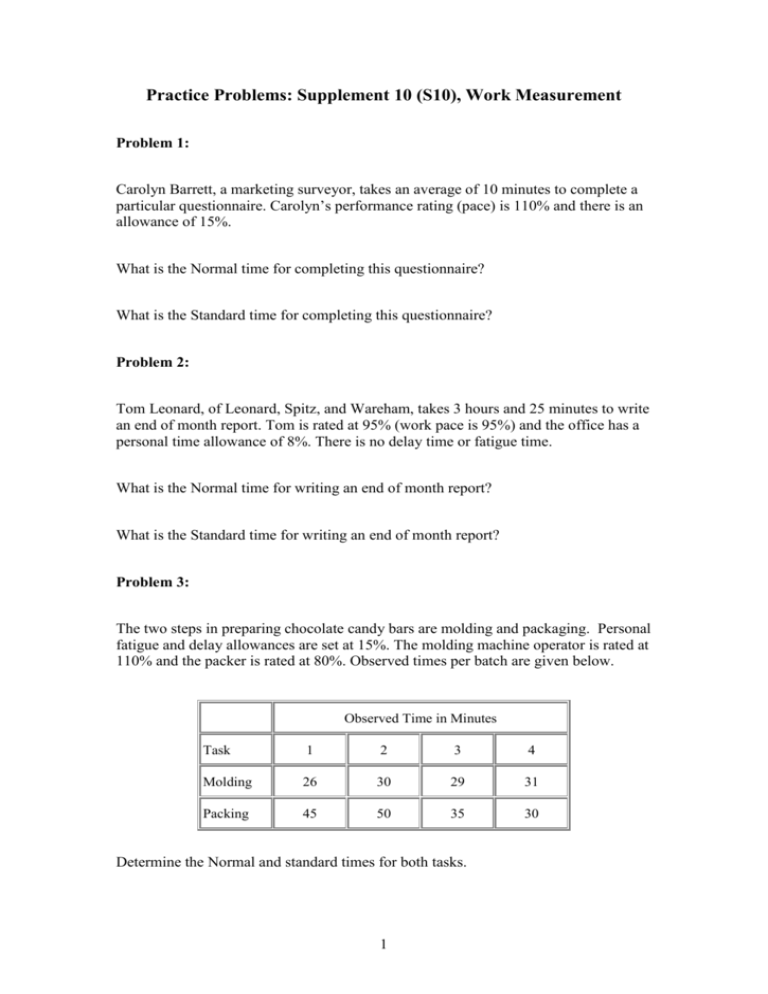

Practice Problems: Supplement 10 (S10), Work Measurement Problem 1: Carolyn Barrett, a marketing surveyor, takes an average of 10 minutes to complete a particular questionnaire. Carolyn’s performance rating (pace) is 110% and there is an allowance of 15%. What is the Normal time for completing this questionnaire? What is the Standard time for completing this questionnaire? Problem 2: Tom Leonard, of Leonard, Spitz, and Wareham, takes 3 hours and 25 minutes to write an end of month report. Tom is rated at 95% (work pace is 95%) and the office has a personal time allowance of 8%. There is no delay time or fatigue time. What is the Normal time for writing an end of month report? What is the Standard time for writing an end of month report? Problem 3: The two steps in preparing chocolate candy bars are molding and packaging. Personal fatigue and delay allowances are set at 15%. The molding machine operator is rated at 110% and the packer is rated at 80%. Observed times per batch are given below. Observed Time in Minutes Task 1 2 3 4 Molding 26 30 29 31 Packing 45 50 35 30 Determine the Normal and standard times for both tasks. 1 Problem 4: A work-study sample of a manufacturing activity conducted over a 40-hour period shows that a worker with an 85% rating produced 12 parts. The worker’s idle time was 10% and the allowance factor was 12% Find the Normal and Standard time for this activity. Problem 5: Jim and Bob recently time-studied a janitorial task. From a sample of 75 observations, they computed an average cycle time of 15 minutes with a standard deviation of 2 minutes. Was their sample large enough that one can be 99% confident that the standard time is within 5% of the true value? Problem 6: Consider the following task broken down into 5 MTM elements: TMUs Code in MTM Books Reach to tool box 14.2 R12D Grasp a tool 3.5 BG1 Separate tool by pressing 10.6 AP2 Turn tool 3.5 T45S Move and focus eyes 13.4 M12B What is the total time for the task? 2 ANSWERS Problem 1: Normal time (total time)(%working on this task)(rating)/(number of units produced) (10)(1.00)(1.10)/1 11 minutes Standard time Total Normal time 11 11 12.9 minutes 1-Allowance factor 1 0.15 .85 Problem 2: Normal time (total time)(%working on this task)(rating)/(number of units produced) (205 minutes)(1.00)(0.95)/1 194.75 minutes Standard time Total Normal time 194.75 194.75 211.68 minutes 1-Allowance factor 1 0.08 .92 Problem 3: Observed Times in Minutes Task 1 2 3 4 Molding 26 30 29 31 Packing 45 50 35 30 For Molding: Average for the actual Molding cycle 29 minutes per batch Normal time (total time)(% working)(rating)/(number of units produced) (29)(1.00)(1.10) /1 31.9 minutes per batch Standard time (Normal time)/(1-Allowance) 31.90 /(1 0.15) 37.5 minutes per batch 3 For Packing: Average actual Packing time = 40 minutes Normal time (total time)(%working)(rating)/(number of units produced) (40)(1.00)(.80) 32 minutes per batch Standard time (Normal time)/(1-Allowance) (32)/(1 0.15) 37.6 minutes Problem 4: Average actual time = 40 hours Normal time (total time)(%working)(rating)/(number of units produced) (40hrs)(0.90)(0.85)/(12) 2.55 hours per part Standard time (Normal time)/(1-Allowance) 2.55 / 0.88 2.90 hours per part Problem 5: To find the number of samples required: z n where h is the accuracy desired and z is the confidence level hx 2 2 2 2.575* 2 5.15 n 47.15 or 48 samples 0.05*15 .75 Therefore, the sample size of 75 is sufficient. 4 Problem 6: TMUs Reach to tool box Code in MTM Books 14.2 R12D 3.5 BG1 10.6 AP2 3.5 T45S Move and focus eyes 13.4 M12B TOTAL 45.2 Grasp a tool Separate tool by pressing Turn tool Remember: 1 TMU = .0006 minutes. Translating to minutes: 45.2 TMUs * .0006 = .027 minutes Translating to seconds: .027 minutes * 60 = 1.627 seconds 5