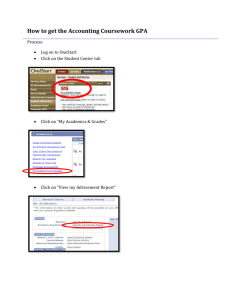

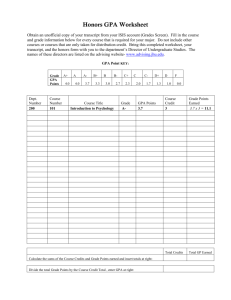

request for proposal procedures - Internal Site of the GPA

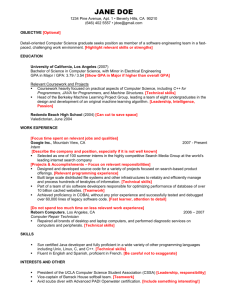

advertisement